Ensuring Contributions to Materials Science from Small-, Intermediate-, and Large-Scale Science

Introduction

HERBERT H.JOHNSON

Materials is not to be thought of as a single discipline, but rather as a broad and vital field of knowledge and techniques that constitute an essential foundation stone of modern technological societies. In that respect, materials resembles other sprawling fields such as energy, communications, and medical science, each of which encompasses several disciplines and is characterized by intellectual ferment and enormous impact on society.

The several cultures of materials research are a distinguishing feature of the field, a primary source of its intellectual richness and organizational diversity. In contrast to many disciplines the materials field in its present form is relatively new. The materials community has evolved rapidly from separate disciplinary bases in the past quarter century. This process of integration has brought a welcome, but still partial, coherence to the field. It is unlikely, however, that the materials community will ever coalesce into a single discipline. The intellectual and factual breadth of the field is simply too great to be confined within the boundaries of a single disciplinary structure.

It is inevitable, then, that the materials field will on occasion appear disorganized, even turbulent, when compared with more tightly focused and hierarchical fields such as high-energy physics.

Materials also differs from high-energy physics and astronomy, again to use them as examples, in the scale of instrumentation required for experi-

mental research. Advances in fundamental problems in high-energy physics and astronomy require complicated and expensive instruments such as accelerators, storage rings, and telescopes (optical, radio, and orbiting). It is intrinsic to these fields that many experiments require large teams of researchers and a scale of coordinated effort that is absent in most other areas, including materials.

Frontier materials research is, in fact, at present carried out in several modes. Small group research is prominent throughout the materials spectrum in universities as well as in industrial and government laboratories, and small group research continues as a vital source of forefront discoveries. In recent years interdisciplinary research directed toward specific goals, as pioneered by the Materials Research Laboratories (MRL) program, has become increasingly important, as complex materials problems have required the coordinated talents of several investigators. The MRL program has demonstrated the impressive results that can ensue when interdisciplinary groups work toward specific goals with the support of well-developed central laboratory facilities. Finally, a small but growing number of materials investigators are working at large machines, especially synchrotron radiation facilities, obtaining invaluable results that could not be obtained in any other way. This is small group research carried out in a big-science facility and context.

These multiple research modes have arisen because of the increasing complexity of many frontier research problems in materials. Progress often requires the use of several techniques and the associated instrumentation. Interdisciplinary groups become an effective organizational strategy for tackling multifaceted problems. The development of centralized laboratory facilities is essential to minimize equipment costs and to maximize the use of expensive equipment, which should not and cannot be duplicated in every investigator’s laboratory. Each research mode makes a distinctive contribution to the overall strength of the materials field.

Instrumentation will remain a major problem for the universities, not only for research, but for graduate education. The proper training of graduate students requires instrumentation that does not lag in quality and sophistication too far behind the equipment used in industrial and government laboratories. This is essential if new graduates are not to founder in their early professional careers. The cost of the necessary equipment continues to rise rapidly, placing a growing burden on university research groups. Unless present trends can be reversed, the number of universities with comprehensive and high-quality materials research programs will surely decrease in the years ahead.

The conditions for funding of materials research have become increasingly tight and complicated in recent years. There has been a clear trend toward larger grants on more sharply focused topics, at the perceived cost of support to small university groups built around a single professor and his or her

graduate students. Agency program managers appear to be under increasing pressure to turn over their programs in shorter time periods. They sometimes assume an active role in local program decisions, apparently again under pressure to produce specified results over a predetermined period.

This perceived micromanagement of research has put the university system of small group research under additional strain. The time scale in which funding agencies expect significant research results is now equal to or less than the time required for a student to carry out a graduate thesis. This situation has made it much more difficult for faculty members to fund and manage their individual research groups. As a consequence, the university small research group appears to many to be an endangered species!

Problems Facing Small-Science Research in Materials

WILLIAM D.NIX

The quality of materials research depends directly on the quality of the people doing it, whether it is done on a small, intermediate, or large scale. Thus, it is most important, and clearly in the national interest, to attract the brightest and the best to the field. The small-science research group is the basic unit around which graduate education programs are built, and from that perspective it is essential to the entire materials research and development area.

Small-scale research groups typically have close contact with students who are not yet involved in research, so these groups carry the primary responsibility for recruiting for the field. The best candidates sometimes look for ways to be unique and to stand out. They are often idealistic and yet want to do something outstanding that will bear their name. Graduate education through the small-science research group route gives them the opportunity not only to develop their research capability, but also, and of equal importance, to develop intellectually and to prepare themselves for leadership in the field. For this reason alone, small group research is of central importance to the entire field.

A major problem facing small research groups is the escalating need for instrumentation and associated support. The need for modern research instrumentation has been much discussed, is now widely recognized, and is being addressed through various instrumentation programs. Nevertheless, formidable problems remain, especially in the smaller universities. Some universities with substantial past accomplishments can no longer compete in top-rank materials research because of inadequate facilities.

An equally formidable, even more expensive, problem is the need for vastly improved laboratory space and facilities to house future materials research programs. This problem is endemic across the science and engineering fields. Many universities are forced to put modern research programs into space that was constructed many years ago, usually for undergraduate instruction.

The need for greatly expanded and improved facilities and the inability to generate the necessary funds through conventional sources have led some universities to approach the Congress directly for specific appropriations. The concomitant end run around the peer review system has generated a storm of controversy, which shows no sign of abating. It has also surely damaged the financial health of the programs approved through the peer review system.

The universities are not well structured to handle the new instrumentation that is essential for advanced research in all fields of engineering and the physical sciences. Funds are generally not available for new or upgraded laboratory space, for service contracts, or for permanent staff to maintain and operate the increasingly complex new equipment. As a consequence, equipment is often operated at neither optimum specifications nor maximum efficiency. Of course, it is the formal responsibility of the universities to provide funds for these purposes, but they have been slow to realize that modern graduate research programs require new administrative and support structures and sources of funds. The problem is not handled well, even at major institutions.

The Materials Research Laboratories program and the Materials Research Group (MRG) program, both administered by the National Science Foundation, have been a great help in this connection at the universities where these programs exist, but they provide only a small fraction of the help that is needed. It is sometimes suggested that principal investigators at universities should voluntarily include support personnel in their individual research budgets or apportion their research funds to take care of these needs. However, the system contains strong forces that make this suggestion impractical. Research funds for individual principal investigators are limited. Department heads and deans often expect faculty members to generate as much of their salary as possible from contract funds and also to support as many graduate students as possible. The keen competition for funds causes principal investigators to reserve their research funds for only those things that contribute directly to the scientific output of a given project. It is almost invariably counterproductive to individual programs to allocate funds to general support services.

A generally acceptable solution to this problem is not yet evident. It may eventually be necessary to require major research universities to allocate a

reasonable fraction of their funds to research support as a condition for receiving external support.

Strong forces are operating to move university researchers away from the small-science mode and toward a team concept of research. These forces include (1) the need for instrumentation, (2) the necessity for sharing instrumentation, and (3) the increasing complexity of many advanced materials research problems. In addition, the funding agencies appear to be under steady pressure to justify their programs in terms of short answers to application-oriented problems.

This trend has positive features, but it surely has a negative effect on the intellectual development of graduate students. The team concept does prepare students for some forms of industrial research, and it allows them to be associated with high-visibility projects. However, team research also very much restricts the opportunity for intellectual growth during thesis research, as the opportunities for exploratory and original research are usually limited. The planning and goal setting associated with team projects can on occasion reduce a graduate student’s role to that of a cog in a large machine.

Prospective employers invariably ask about the originality shown by graduate students in their thesis research. They rarely ask about students’ ability to fit into a team, except in the context of their ability to get along with people. Originality is best developed and displayed in an unstructured environment. Students must have the opportunity to explore their own ideas and, on occasion, to fail. All evidence suggests that employers of graduate students are interested in people who have been encouraged to think independently and creatively and who are prepared for independent work.

The MRLs and MRGs provide in their interdisciplinary thrust programs a satisfactory compromise between small-scale and team research. Often it is possible to develop a major thrust in a chosen area by clustering groups that operate in a small-science mode. The success of such groups depends on the personalities and interactive chemistries of the people involved. It is a satisfactory experience when it works well but a disaster when done poorly. The most successful collaborations are those that arise spontaneously.

Continuity of support is becoming an increasingly serious problem for university researchers who work in the small-science mode. The research is conducted primarily by graduate students who take between 4 and 5 years to complete their studies, including the thesis. The time scale for this process has not changed significantly in 40 years and is not likely to change in the foreseeable future. Yet, the availability of grants or contracts that extend beyond 1 or 2 years is rare in today’s fast-paced world. It is not uncommon to see graduate students shifted from one project to another several times in the course of their studies. This is inefficient at best, and in some cases even destructive to the student involved. Small-scale research thrives on stable

support that extends over the thesis lifetimes of several students. Most university researchers believe strongly that they have been most productive (as judged by significant papers published or doctoral degrees granted per dollar) in research programs for which support was provided over an extended period of time.

It is often suggested in informal discussions that the development of a new idea in materials science takes a minimum of two graduate-student lifetimes. The first student explores the idea or effect, and the second brings it to fruition and develops the application. However, because the second part of the process depends on the success of the first, some projects would be expected to extend over several student lifetimes.

In spite of the need for stable support, many funding agencies are not able to provide support over an extended period. This may be because of limited total funds, or perhaps because of a perceived need for rapid turnover in the subject matter in an agency program. In any event, their attention span is all too often much shorter than the characteristic time constant for small-science research. In some cases this means that the most pressing problems of the agencies are not addressed by the most gifted and productive university research groups.

Academic materials research is supported almost wholly by the federal government; industry has not been a stable source of long-term funding. This may change as a result of rapidly growing interest in university-industry interactions. However, current university research is directed primarily to basic problems that are of interest to the federal government. This may occasionally lead to neglect of areas that are important to national economic strength. For example, the materials community has played a relatively minor role in the area of microelectronic materials. Magnetic materials is another area that has been neglected by the academic community. The increasing industrial interest in academic materials research may in time lead to a more balanced national materials program.

To the university practitioners of small-scale science, it appears that support for small-scale science is being continually eroded in favor of big science. The reasons for this are both political and sociological. First, it must be acknowledged that many exciting problems in science require large facilities for their solution. However, it is also true that major projects and big science come naturally to the attention of policymakers in the top ranks of government, especially when they are presented by a persuasive and prestigious group of scientists. Furthermore, the big-science communities are considerably more cohesive, essentially because their research progress depends critically upon the development and operation of large facilities. Hence, there is a strong internal driving force that leads big-science communities to develop a tightly focused set of priorities and to present a united front in the never-ending quest for funds.

In contrast, small-science communities such as materials are inherently more decentralized, for the availability of large facilities is not the primary determinant of research success. In materials there are many areas where exciting research progress is possible; some require extensive instrumentation and some do not. Consequently, materials programs appear throughout the budgets of the agencies, but only rarely at a level that attracts the attention of top policymakers. Furthermore, there is no single widely acknowledged organization that can speak for the materials field and convey an authoritative sense of its prospects, accomplishments, and needs. Indeed, researchers in small-science communities are more commonly critical of their colleagues than supportive. This is a problem that the materials community must address.

Basic Research Supported by Mission Agencies

MILDRED S.DRESSELHAUS

A problem that affects all of the scientific communities, including materials, is the question of how to maximize the effectiveness of the basic research programs supported by the mission-oriented agencies. Independent and persuasive studies indicate that the cost of research has been increasing consistently by about 65 percent more than the Consumer Price Index, independent of what the Consumer Price Index is doing at any instant in time. When that fact is considered in relation to the budgeting trends in federal agencies, the only conclusion that can be reached is that there will shortly be a decline in the number of people who will have the privilege of pushing the frontiers of materials science forward.

The materials research community for the first 25 years of the Materials Research Laboratory program has operated on the premise that the federal establishment would continue to provide support on a more-or-less one-way basis. There is of course a different approach, one in which the research community takes the initiative and provides a much more comprehensive rationale for supporting basic research. The following suggestion has less to do with small science, intermediate science, or big science, individually, than it does with the entire research community and the way in which it should relate to the larger technological enterprise.

The suggestion is to place funding of basic science more on a basis of mutual benefit. The core idea of the proposal comes from an experience that most researchers have had at one time or another—consulting for private industry if they are university faculty members or interacting with university

faculty members if they work in industry. Similar relationships hold for staff members of the federal research laboratories.

The proposal is to encourage senior investigators, selected from among the basic research grantees, to visit appropriate groups in the mission agency laboratories for a few days each year to share the experience and expertise gained from years of research in the field. The senior investigators participating in the proposed program would normally be university professors. Many would have significant experience as consultants to private industry; their interaction with the R&D groups in the mission agency would be similar to that of consultants. Participation in this program would of course be voluntary, although in the aggregate it might be expected that about 40 percent of the qualified investigators would participate after receiving research funds from the mission agency for an extended time, perhaps 5 years. Young investigators with less than 10 years of professional experience would normally not be expected to participate. The program might be especially attractive to “elder statesmen” of science, or people who have gone far enough in their careers that they can afford to spend a week or more per year in this kind of activity.

The proposed program has essentially three objectives. The first is to enhance the cost-effectiveness of all programs—the university programs and the programs at the government laboratories, whether they be DOD, DOE, or other federally funded laboratories. There would be a clear gain if this program would enhance the cost-effectiveness of the R&D activities of the laboratories where most of the expenditures of the mission agencies are directed. In this way the basic research programs would gain leverage, and there would be a stronger justification for the expenditures necessary to maintain an effective basic research program in each agency. An expanded justification is desirable, as the cost of research continues to increase, while rapid scientific and technological breakthroughs continue to expand the opportunities for exciting basic research.

The second objective is to develop much stronger bridges of communication between the basic research community and the mission agencies. The benefits of the proposed program would flow in both directions. The results of basic research would be brought in a timely and effective way to the development efforts. At the same time, contact with applied programs often leads to a recognition of new and exciting areas of basic research that are ripe for exploitation. An important additional benefit is that research scientists would be much more aware of the activities in the mission laboratories. This knowledge is important and useful in providing advice to students about the scientific challenges and opportunities that careers in the mission agencies can provide.

The third objective is to broaden understanding and appreciation of the role of basic research, and in this way to accomplish two things: the first is

simply to increase the total amount of resources going into basic research by making it more cost-effective; the second is to buttress the role of basic research so that it can provide even more effective contributions to the technological strength of the nation.

To implement this proposal a pilot program with a small number of participants should be established to evaluate the concept and to learn from early experience. If that evaluation shows that the program would be viable on a national scale and of mutual benefit to enough members of the research and development community, then the program should be enlarged and extended to all who wish to participate.

The Two Domains of Materials Science

ALBERT M.CLOGSTON

Materials science is a highly interdisciplinary field consisting of diverse specialties, including physical metallurgy, solid-state physics, solid-state chemistry, ceramic science, polymer science, materials preparation, and materials analysis. Other individuals would no doubt construct somewhat different lists, depending on their perspective, but that is an indicator of the richness and diversity of the field.

However, these specialties tend to divide into two separate domains, the microscopic and the macroscopic. The microscopic view is concerned mainly with atoms and molecules and the electromagnetic forces that bind them. There is a strong emphasis on such topics as electronic structure, lattice vibrations, and the many interactions of radiation and particles with condensed matter. The macroscopic point of view focuses on the properties of matter in bulk, with typical topics such as microstructure, phase transitions, continuum behavior, and mechanical properties.

These two ways of thinking about materials tend to be vertically integrated with respect to measurements performed, instrumentation used, phenomena studied, and the technologies to which they lead. It is also true that few researchers cross the boundary between these two domains, although those who do often make strong contributions.

In the microscopic domain, which includes solid-state physics, the materials and phenomena studied, and the kinds of instrumentation and measurements required, tend to be associated with what are often described as high-technology industries and materials. With some exceptions these materials are used for their electronic, magnetic, or optical properties. In contrast, research at the microstructure or continuum level leads to technologies

that use high-performance materials, developed primarily for their mechanical properties, often under a wide variety of rigorous operating conditions.

There are tremendous opportunities to advance the science of materials by horizontally integrating studies of the phenomena that are of interest in the microscopic and macroscopic domains. The integration that has occurred over the past quarter century is impressive, but the full potential of the field has not yet been realized. For example, physical metallurgy and solid-state physics have much to say to each other about such topics as interactions at surfaces, fracture, dislocation physics, and electronic materials. Many other examples could be cited. Both physical metallurgy and solid-state physics would derive vast benefits from closer interaction with solid-state chemistry.

As the previous discussion indicates, there is a close connection between materials science and basic materials technology. This tight coupling is one of the striking characteristics of materials science, and certainly one of its greatest strengths. It is the reason why materials science has been the source of major contributions to other sciences and, perhaps even more importantly, to industrial innovation, and why it has such potential for future contributions.

The strong coupling of materials science and technology leads to a second major point, which is the critical role played by basic technology as a link between research and development. This somewhat unconventional view of the research and development process is nevertheless the view of research and development held, at least implicitly, by most of the major industrial laboratories, and also in a formal way by the Department of Defense and the Department of Energy. Basic research as defined by those agencies, for example, can be read to include not only the increase of basic knowledge, but also the increase and enlargement of the technology base for exploratory and advanced development. Basic technology should be recognized as an important research activity, and as the critical link between research and development.

This leads to the proper place for materials research in the overall research and development process. Basic materials science and basic materials technology should both be regarded as research activities in the research and development process. They couple to basic science and basic technologies coming from other sources to make possible the exploratory and advanced development of systems of all kinds, including systems for communications, energy, national security, and transportation.

It is important that basic technology be recognized as a legitimate research activity. It is carried out by the same kinds of people who do basic research for new knowledge. They use the same kinds of instrumentation and the same research methodologies. They are the people who, in industry, do basic research one day and basic technology the next.

New Demands on Materials Science

PRAVEEN CHAUDHARI

Materials science, drawn from studies at the scale of atoms to macroscopic bodies, encompasses much of what we know about the physical world. To cite two examples: the laws of thermodynamics have proved useful not only in designing engines but also in understanding chemical reactions, and quantum mechanics is essential to understanding many scientific phenomena as well as the operation of the silicon transistor.

Materials science is characterized further by the role of empiricism in the practical use of knowledge. It is sometimes believed that if perfect understanding were available, then and only then could a perfect device, or mechanism, or structure be built. However, as those who are knowledgeable about industry know, technology is often at the same level of advancement as science, and occasionally is ahead of it. Thus, scientific understanding and the building of new devices may go hand in hand, with a substantial assist from empiricism.

The interdisciplinary nature of materials science gives rise to the broad scope of its activities and to its importance. This is also true of other interdisciplinary fields such as medical science and computer science. There are also differences between these fields that must be recognized.

In medical science the issues of purpose are well recognized by society. For instance, no one would dispute that to find a cure for cancer is a worthy goal. There is broad and intense interest in knowing how the brain or the human body functions. There is also a sense of immediacy in the medical sciences: a cure for cancer or AIDS is an urgent need.

Computer science differs from medical and materials sciences. It stands in relation to its future much as materials science did before the laws of thermodynamics were discovered. The laws for computer science are still being discovered. It is a nascent, exciting science that will evolve with all of the complexity that is found in materials science.

Materials science is sufficiently complex that to one unfamiliar with the field it appears diffuse and aimless. There are no specific goals and no sense of urgency. Materials researchers need to articulate their role in society. We at the Research Division in IBM have attempted to do this. In so doing we have found it useful to divide scientific work into two categories, called area science and general science.

In area science, scientists and technologists jointly study a particular technology and extract the key technical issues for today and for the future. Those key technical issues are then examined to extract what is called essential, or generic, science—the knowledge that is needed to develop or evolve tech-

nology. Thus, there are two key elements in the process: first, to identify the technical issues and, second, to identify the generic science.

Using this approach, we have found that continuing progress in electronic devices—from data storage to the central processing unit of a computer— depends crucially upon materials and processing sciences. By processing of materials we mean, for example, adding or removing atoms where and when desired. There are many ways to add atoms, including crystal growth, chemical vapor deposition, vacuum deposition, molecular beam epitaxy, sputtering, and electroplating.

There are also many processes by which atoms can be removed. Let us use an etching process as an example of how generic science issues are developed in a given area of science. In the electronics industry, reactive ion etching, an emerging process that is attracting much attention, illustrates the complex demands placed on materials science by advanced technology. Reactive ion etching consists of applying a voltage across charged species in a plasma to accelerate ions, which hit the surface of a substrate. By shielding various areas of the substrate with a “resist,” the substrate can be etched in a directional fashion. Structures can then be constructed by selective deposition of materials into the cavities formed by the original etching treatment.

The density of the plasma used in reactive ion etching lies between the density of matter in intergalactic space and that in nuclear fusion. The chemical and physical properties of the plasma of interest in reactive ion etching are not well known. Moreover, the radicals that exist in these plasmas are not well identified. Until recently, techniques for identifying the chemical species both spatially and temporally were not available.

After the radicals have been identified, the next problem is to investigate the mechanism by which they interact with the substrate. Why is a particular material etched more efficiently than another? Why do polymers behave differently from metals? Why does p-type silicon behave differently from n-type silicon?

The etching reaction occurs not only on the surface of the substrate but also beneath the surface. In fact, the atoms penetrate below the surface. They can be found tens to hundreds of angstroms deep, depending on how the process is carried out. It is important to understand this process in detail, for not only is it desirable to have very clean substrates on which to deposit a substance in a controlled way, but it is also important to be able to produce damage-free regions near the surface of a semiconductor material.

One can ask the following question: If an atom or molecule hits a surface, how does it lose its energy? This question leads to many more detailed questions. What are the modes of energy transfer that apply here? Is there chemisorption or physisorption? How do atoms diffuse near a surface when

a charge is present? Such questions transform a mundane, practical process into a series of questions of fundamental scientific interest.

To go a step further, there are many processes other than reactive ion etching that require understanding a great deal about surfaces and about particle interactions with them. Such understanding is important not only to the computer and electronics industries but also to processes ranging from electroplating, to catalysis, to the evolution of hydrogen in the universe from the atomic to the molecular state.

The study of complex phenomena and processes in industrial technology suggests two important points. The first is that within a given area of science there must be a spectrum of activities that proceed from science to technology. These activities should be evaluated on the basis of their value to society, not on the basis of some arbitrary criterion by which “basic science” is deemed more acceptable than “applied science.” Moreover, distinctions between big science and small science are irrelevant when studying a problem as complex and important as reactive ion etching. Both kinds of science are frequently needed in modern industrial research. In the case of reactive ion etching, many of the modern techniques of materials research are necessary. These include Rutherford backscattering, ion scattering, synchrotron radiation, various surface spectroscopies, nuclear resonance, and transmission electron microscopy.

An important point that cannot be taken for granted or emphasized enough is that the research enterprise of the nation requires an infrastructure that nurtures general science, or science that cannot be identified at present with any particular area of application. This provides the freedom to move freely in a spectrum of specific activity according to the merit of the question being pursued. In materials science three recent developments illustrate the importance of such freedom. The first is the scanning tunneling microscope, which evolved from a desire to improve understanding of the uniformity of dielectrics. When it was shown, however, that atomic resolution could be achieved, the research was redirected into much broader areas of atomic and electronic structure of surfaces. The second example is the quantum Hall effect, which is leading to a better understanding of the behavior of electrons in matter, especially in lower-dimensional systems with various degrees of disorder. The third is the discovery of quasicrystals, which may or may not represent a new structural state of matter but must surely be studied and understood.

Perspectives on Facilities and Instrumentation for Materials Research

Introduction

DEAN E.EASTMAN

In the past few decades, materials research in the United States has emerged as a large national effort vital to our technological and economic welfare. Materials research is interdisciplinary and is carried out through important programs in the university, government, and industrial sectors. Facilities and instrumentation, an essential element of these research programs, are becoming more sophisticated and costly. This chapter presents several perspectives on that element of materials research programs.

Large-Scale Facilities for Materials Research

MARTIN BLUME

Many of the large facilities and the large-scale aspects of materials research originated at Department of Energy (DOE) national laboratories many years ago. The quintessential large facilities are, of course, the high-energy physics facilities. In materials research and in other areas with a strong tradition of small science, these large-scale laboratories evolved gradually; in fact, the first were not built as materials research facilities. They were supported with funds designated for neutron scattering research, for example, from reactor programs.

As a result, there was no problem with funding arrangements until a decade ago, when such facilities started to turn up in materials research budgets. The national laboratories, of course, had their own problems and research programs connected with atomic energy in the days of the Atomic Energy Commission. Thus, DOE not only had these internal programs, but became an agency that also provided large research facilities to universities and, more recently, to the industrial community as well.

The synchrotron light source at the Brookhaven National Laboratory is an example of the large facilities available for materials research. The research carried out at these facilities, as opposed to the high-energy physics facilities, remains basically in the small-science mode and in effect provides research opportunities similar to those in the small laboratories.

For neutron scattering, a fair number of research facilities are available: the intense pulsed neutron source at Argonne, the pulsed source at Los Alamos, and the reactors at Brookhaven and Oak Ridge. In synchrotron radiation the DOE-supported facilities are at Stanford and Brookhaven, with National Science Foundation (NSF)-supported facilities at the University of Wisconsin, Cornell University, and elsewhere. In addition, an electron microscope facility is available at the Lawrence Berkeley Laboratory, a high-magnetic-field facility is available at the Massachusetts Institute of Technology, and there are others.

All of these large research facilities are open to users, and pressures for their use have grown in the last decade. These pressures have had to be responded to by the agencies that fund research in materials science, as opposed to other areas. In the past, materials scientists were accustomed to working parasitically on either a high-energy physics facility or a reactor facility.

The pressures for increased use of synchrotron radiation sources arise from the relatively simple fact that for many generations, x-ray tubes provided more or less the same intensity. With the advent of synchrotron radiation sources, however, came an exponential increase in the intensity of electromagnetic radiation available for research.

Brookhaven has two synchrotron radiation storage rings—an ultraviolet ring that runs at 750 million electron volts (MeV) and provides radiation up to the soft x-ray part of the spectrum, and a high-brightness x-ray ring that runs at 2.5 billion electron volts (GeV) and provides the harder part of the radiation. There are 16 ports for radiation on the ultraviolet ring, each of which is capable of providing up to four experimental beam lines. Similarly, there are 28 ports with perhaps three experimental beam lines possible on each of those ports.

Thus, it is possible to carry out many experiments simultaneously. This provides important advantages, social as well as scientific, but at the same time produces tremendous problems.

The operation of a facility like this differs considerably from that of a high-energy physics facility (where there is only one primary user of the beam) in

that two or three experiments may be going on at one time. How is such a facility organized? How are all of those beam lines built? One way is for the laboratory itself to provide all of the experimental beam lines and then take proposals from each of the users. A difficulty with this approach is that it engenders a large bureaucracy and is counter to the way in which materials science researchers as well as biologists, chemists, and others who use the facility are accustomed to working. The bureaucracy also tends to eliminate spontaneity in the conduct of research. (This is one of the major advantages of having an x-ray source in your basement laboratory. You can go down there without having to ask a committee to use it at a particular time; you can make mistakes and try new things.)

The management of concurrent research at Brookhaven is of interest because it involves a different organizational method—having users build and operate the beam lines. The compromise adopted at Brookhaven is to ask for the organization of participating research teams. These are groups that propose to place instruments at the facility. If a team’s proposal is accepted, the instruments are installed and the Department of Energy provides the photons for research. In return for those photons, the research team makes this instrumentation available one quarter of the time to small users who just want to come in and do a single experiment.

This mode of operation has worked very well. The participating research teams are left to themselves to organize and to carry out their own experiments. A further advantage is that industry is investing in this instrumentation—something that is strongly encouraged. Thus, a system that amounts to time-sharing has succeeded in attracting a fair amount of money and instrumentation expertise.

Many institutions, including governmental laboratories, corporations, and universities, have taken part in this system through the participating research teams. All of them are involved in beam lines at various places. Many of these are beam lines that have been installed by Materials Research Laboratories (MRLs) and are used as parts of the MRLs. Many of the MRLs located near to one another, including those at the University of Pennsylvania, Cornell University, Massachusetts Institute of Technology, and Harvard University, have been actively involved in this way.

Some corporations participating in the Brookhaven system are not known for basic research. Indeed, assistance had to be provided to researchers at some of these corporate research laboratories to enable them to make even a relatively small investment in this equipment outside their own institutions. Thus, some of the corporate research centers have been opened up to basic research. There has also been a good deal of “marriage brokering” to bring together joint university and corporation programs.

Despite the large number of participants in research at Brookhaven, the facility still functions like a small-science facility. It is as if all of the experiments that

required electric power had to be done right at the power plant. Thus, from a research activity viewpoint, facilities like Brookhaven should be viewed not as extremely large single units, but as impressive concatenations of many different facilities and many different types of science. At Brookhaven, for instance, chemists and biologists sit together as members of participating research teams at that early stage. It is important, however, not to overlook the large core cost associated with such a large facility.

Despite the size and complexity of the facility, the operating cost for individual experiments is relatively low. The cost of a shift on one of the beam lines is $80 an hour just for the photons. Although overall operating costs of $14 million per year are not particularly low, the number of beam lines in use is relatively high.

In addition to the participating research teams, many small groups use the facility. For instance, it is not uncommon to see a single professor and a graduate student using one of the beam lines. These small groups can come in at a relatively low initial cost and do this kind of research. Brookhaven has the possibility of providing for travel grants, although this presents one important difficulty—such grants are very useful for small groups, but they can distort the research agenda. They create the possibility that a small group with a good idea but unable to get a research grant will push its efforts in directions dictated by the availability of these facilities.

This important question needs careful attention. This is one reason why it is important to avoid what might be described as “giving away lollipops” with each of the experiments that is funded. It is important not to make research at large facilities (such as Brookhaven) so desirable that people will distort their research in this direction. Balance must be maintained overall in the research program.

It is unfortunate that the funds that are necessary to operate these large facilities often are not fully realized. Consequently, there often is strong pressure to cut back on internal small-science programs at the host laboratory and to use that money for the operation of the large facility. As a consequence of this, at Brookhaven virtually all of the internal research is now based on large facilities.

National Commitment to Facilities and Instrumentation for Materials Research

C.PETER FLYNN

Most university and national laboratory materials research is supported by the National Science Foundation (NSF) through its Division of Materials Research (DMR) and by the Department of Energy (DOE) through the Di-

vision of Materials Sciences (DMS) in Basic Energy Sciences. These two agencies have “grown up” as the field of materials science has come into being over the past two decades. Together they are responsible for about $300 million of yearly materials science funding. This approaches half the annual total in materials research funding for the nation, including that provided from the Department of Defense, industry, the National Bureau of Standards, and so on.

The relevant point for present purposes is that both DMR and DMS commit roughly 25 to 30 percent of their yearly resources to the support of various types of facilities. The details differ in the two cases. Most DOE facility support passes into major Centers for Collaborative Research in such areas as neutron scattering, synchrotron radiation, and electron microscopy, which are established at institutions (both university and governmental) in the DOE Laboratories Program. NSF also supports major centers for synchrotron radiation, microscopy, and so on. Through its Materials Research Laboratories (MRLs), Materials Research Groups (MRGs), and Instrumentation programs, it also funds smaller-scale facilities on a number of university campuses. While the details differ, a massive commitment to the support of facilities is evident in both agencies. Still further facilities for materials research are operated by other organizations, including the National Bureau of Standards and the weapons laboratories at Livermore, Los Alamos, and Sandia.

It is a contemporary phenomenon that such a large portion of research funds is directed to facilities. At the time the MRLs were founded in the early 1960s, there were far fewer facilities, of which neutron sources operated by the Atomic Energy Commission constituted the major part. Without question, the current prominence of facilities funding is in direct recognition of the important role that research facilities play in modern materials science and of the unique research avenues that they open to the enterprising researcher.

Such growth in difficult times has naturally caused tension in funding decisions at both NSF and DOE. A further growth of facilities expenditures by a factor of two to 50 to 60 percent of the total appears unlikely, at least without major new resources, because facilities only contribute to a portion of the entire materials field. To help judge whether the present balance is appropriate, one must be familiar with the level of marginal declinations of research proposals in non-facility-related areas and with the level of marginal research supported by facilities-related programs. The decisions are complex and involve many considerations. These include the fact that facilities are justified in part by the finest work to which they give rise, the long time scales required to establish facilities, the cumulative distortion of the research field and the funding patterns they produce downstream, and many others. These are complex issues on which opinions differ.

Despite the current large investment in materials research, the United States lacks desirable research facilities in a number of areas. At the same time, the marginal rejections of research proposals at both NSF and DOE are alarmingly high in the materials sciences, and the ability to fund new proposals from the brightest young scientists entering the field is dangerously low. The competition between these factors presents a critical dilemma in the disposition of available resources.

In the following brief commentary on the roles that research facilities play, the different types of facilities are referred to as infrastructure, research facilities, and collaborative research centers.

The term infrastructure refers to durable, shareable equipment established in a given research environment for use by several or many researchers to whose work the equipment is, to some degree, beneficial. Examples of such environments might be a campus or department. Equipment typically costs between $100,000 and $300,000. It might consist of a VAX computer, mechanical testing equipment, fairly simple x-ray systems, or a robust scanning electron microscope. Such equipment can be kept up and used to mutual benefit by a number of scientists whose main research directions differ, provided that means for maintenance and occasional expert consultation are available.

To be well used, infrastructure equipment must nevertheless exist inside an organizational framework. If there is an MRL or similar organization on campus, these matters are easily handled. The MRGs—surely a much-needed funding initiative—can bring a leadership structure to many other campuses. Organization is required for maintenance and replacement of infrastructure equipment. A maintenance contract on a computer costs perhaps 10 percent of its purchase price per year, and on an electron microscope perhaps 3 percent. These and other operating costs must generally be defrayed by a system of usage charges. In general, few research universities lack instrumentation of this type, although what exists may not be optimal.

The term research facilities refers to instrumentation that is more specialized, more fragile, and much more expensive than infrastructure equipment. Often these are commercial systems that perform the primary research itself. Examples are high-resolution transmission electron microscopes, surface science systems, machines for advanced materials synthesis, as in molecular beam epitaxy or microfabrication, and complexes of laser equipment. One machine may cost a million dollars. The facility may consist of a single instrument or several. It may be operated by an organization, such as an MRL, or it may be separately funded. Examples of larger complexes are the electron microscopy facilities operated by DOE at Argonne, the University of California at Berkeley, the University of Illinois, and Oak Ridge, and by NSF at Arizona State University, and the NSF surface science facility at Montana State University. These are generally identified with user programs that draw investigators from an extended geographical region.

Research facilities face a number of organizational difficulties. Local expertise at an advanced research level is generally needed to justify the expense. Costs for maintenance, operating, and technical assistance may be considerable. Again, the need to have experts maintain fragile equipment for nonexpert users raises obvious problems. Yet, these questions must be faced. In electron microscopy, for example, the United States still is not self-sustaining in the training of research talent, despite the major role these instruments have played in revealing the structure of solids on the scales of 1 micron to a few angstroms.

Social factors enter into the operation of a research facility and can influence its effectiveness. Because an expert’s involvement is essential, the instruments tend to become captive rather than appropriately accessible. To maintain such equipment at the state of the art can become a funding burden that inhibits other new initiatives. The peer review system has not easily adapted to decisions about organizations with the complexity of MRLs or surface science facilities. The task of handling research facility funding in the best interest of the nation is both delicate and vital.

The third category of facilities is collaborative research centers. These facilities include neutron sources for spectroscopy and synchrotron radiation sources (one or two electron microscope centers with uniquely engineered instruments could possibly be included). Research centers involve large-scale, complex engineering and have price tags of at least $50 million for synchrotron radiation and an order of magnitude more for neutrons. When instrumented, the facilities accommodate 10 to 100 independent projects simultaneously, often operating around the clock.

Collaborative research centers provide the nation with research opportunities that would otherwise be inaccessible. Neutron scattering, for example, has revealed much that is known about phonons in crystals and about magnetic structure. Synchrotron radiation is heir to both x-ray and ultraviolet spectroscopies and has played a key role in the contemporary development of surface science. Existing U.S. neutron reactors at Brookhaven, the National Bureau of Standards, and Oak Ridge are powerful and well used but aging; new facilities are needed. Institut Laue-Langevin in Europe has become a center of activity. The past decade has seen new synchrotron radiation centers built at Brookhaven, Stanford, and Madison to join existing sources. None is yet fully developed. At least two more are planned for special production of hard x rays and high-intensity ultraviolet. Although recent U.S. investment in these areas is more evident than in neutron reactors, these developments only keep us abreast of comparable advances abroad.

Materials science has emerged as a field only over the past two and a half decades—the same period over which the MRLs have existed. A significant part of this self-identification in the United States has occurred in concert with the Division of Materials Research at NSF and the Division of Materials Sciences at DOE. These agencies and the field now face a critical problem:

How can we channel more funds into new research facilities when the funding criteria in other areas of the field are already unrealistically high? Either choice will damage existing programs and cause major research opportunities to be lost.

There are two points to be made. First, the field of materials science is not yet organized so that decisions of this type can be made in the context of the overall national program. Second, the field is not well organized to present its needs appropriately in the national arena.

One major deficiency of the field is the lack of a forum for national consensus. This is not a surprising problem for a field that has drawn itself together from the diverse disciplines of metallurgy, ceramics and polymers, solid-state physics, and chemistry. The National Academy of Engineering and National Academy of Sciences have sponsored symposia on materials science topics and organized bodies such as the Solid State Sciences Committee of the National Research Council. These efforts contribute to the broad exchange of information at a level at least comparable with that of the professional societies in the several areas of materials science. It seems clear, however, that a further ingredient is needed to ensure that representational factors in this diverse field are correctly balanced in the consensus. The funding agencies have charted these difficult waters for a decade or more and have operated representative committees. Their experience is now needed in pulling together an appropriate forum in which national issues in materials science can be discussed and collective decisions can be made in the best interests of the field as a whole.

A representative body of this type would not, of course, eliminate the difficulties mentioned above. The debate over major facility developments would still have charismatic leaders urging decisions that are to their own benefit, and laboratories would still seek to have their own machine concepts funded. Small science would still feel threatened by the encroachment of large machines onto the funding base. The advantage lies in having the debate focused in an arena of continuing, rational discussion. Recommendations could be fitted into a logical pattern in which commitments and priorities evolve hand in hand. It would be possible to consider the way infrastructure, research facility, and collaborative research center funds balance with each other and with science issues unrelated to facilities; whether facilities are in fact paid for substantially with “extra” funds that would not otherwise be available to the field; and whether DOD, industry, and others should contribute more to facility costs to ease the burden on the NSF and DOE materials sciences programs. The best interests of the field are not served by having different bodies recommending solutions to each problem separately.

Materials science could reap a final major benefit from organizing a representational body. By doing so it would identify its own voice in the public debate over funding priorities. Authoritative statements could be made about

the needs of materials science and about the consequences of their neglect. After all, materials science plays as critical a role in national defense and in improving the quality of life as it does in the nation’s industrial well-being and its intellectual progress. The problems of the field are not so much in the division of funds between science and facilities as in the fact that $600 million annually is much too small a national investment in this ubiquitous and still youthful branch of science. Materials scientists need to organize so that this viewpoint becomes recognized and accepted in the national debate.

Instrumentation for Materials Research

J.DAVID LITSTER

Questions of instrumentation for materials research are addressed in the recent report Financing and Managing University Research Equipment, a study carried out under the supervision of the Association of American Universities, the National Association of State Universities and Land-Grant Colleges, and the Council on Governmental Relations. With support from six government funding agencies and the Research Corporation, a three-member field research team, of which I was a member, visited 23 universities, government laboratories, and industrial research laboratories and spoke with approximately 500 people. Recognizing that the existence of a problem in research instrumentation in universities had been well documented by previous studies, we asked the following questions: What changes in federal and state regulations and policies would help solve the problem? What changes should universities make? What changes in tax and other laws might help? What can be accomplished by alternative or creative methods of financing?

Changes can be made in all of these areas to improve the efficiency of university acquisition and management of research equipment. The problem is so large, however, that its solution requires substantial and sustained investment from all available sources.

Let me begin by reviewing the nature of the problem, drawing heavily upon work carried out by the National Science Foundation in its survey of academic research instrumentation in 1982 and 1983.

More than 70 percent of the departments surveyed reported that lack of equipment prevented crucial experiments. About 20 percent of the equipment in their inventory was obsolete. Of the equipment in use, about 22 percent was more than 10 years old; only about 50 percent of the equipment in use is in excellent condition. The report stresses that maintenance and operation of equipment is as serious a problem as getting the money for its initial

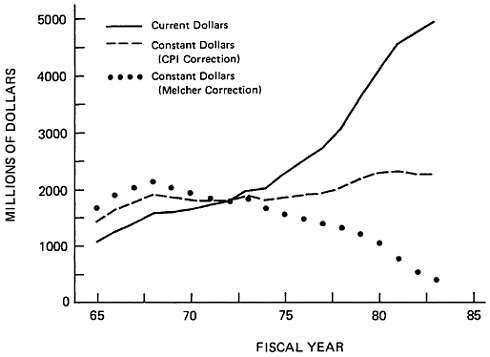

Federal expenditures for R&D in universities and colleges from 1965 to 1983. The solid line shows expenditures in current dollars, and the dashed line is corrected to current dollars using the Consumer Price Index relative to 1972. The dotted line shows expenditures in current dollars corrected for inflation in the cost of scientific equipment.

purchase. With respect to infrastructure, about 50 percent of the departments reported inadequate or nonexistent support facilities.

A further, important ingredient in the problem is the high start-up cost for new projects and for new faculty members. There has been a 78 percent decline in bricks-and-mortar expenditures in real dollars since 1968. This decline also affects instrumentation, since new facilities generally come equipped with instrumentation. Finally, there is the increased sophistication and cost of research equipment in all fields, not just in materials science.

Data in the figure (see above) from the report give a quantitative picture of the research equipment problem. The figure shows the total federal R&D spending in colleges and universities from 1965 to 1983 in current dollars and corrected to constant dollars using the Consumer Price Index. The best data I could find on the proper rate of inflation for costs of research equipment come from an unpublished study by Robert Melcher, a scientist and manager at IBM’s Thomas J.Watson Research Center, Yorktown Heights, New York. Melcher examined the costs of the type of research equipment purchased by

IBM between 1976 and 1981 and found a rate of inflation 1.7 times that of the Consumer Price Index. I have applied Melcher’s correction for inflation and show the results as the dotted line in the figure. This gives an overly pessimistic view of the overall support of research, since most research costs probably increase at a rate closer to the Consumer Price Index. However, it underestimates the seriousness of the problem for research instrumentation, because over most of the period represented in the figure the federal agencies and the universities were reducing the fraction of research dollars that were spent on equipment.

What can be done about this problem? It is important to keep in mind where the resources come from—well over 50 percent of funding for research equipment in materials science is provided by federal agencies; industrial support, which has never been large, accounts for 3 to 5 percent; the universities themselves have been the second major funder of research equipment and have paid for approximately 30 percent of the cost of equipment in use.

What can these various parties do to ease the problem? Federal agencies, for instance, could interpret their regulations, rules, and policies in a consistent way. The present situation tends to make universities unnecessarily conservative in their management practices. It is sometimes difficult to spread the costs of major equipment across Fiscal Year boundaries and certainly across grant boundaries, but frequently this would help. Numerous administrative barriers increase the viscosity of the systems: for example, excessive inventory requirements and the Defense Industry Plant Equipment Center screening for DOD contracts.

In many cases, realistic depreciation allowances for equipment would help, providing that the funds so generated were put toward the purchase of new equipment. This is not a cure-all, of course, because universities can depreciate only the share of equipment that they paid for themselves.

The policies of state agencies raise similar problems because state regulations are frequently more troublesome than those of the federal government. State agencies can help by improving or removing burdensome regulations. In addition, they can help with tax-exempt financing, although it is not clear whether this will be possible if the current proposed federal legislation goes through. In fact, many universities are now seeking to float tax-exempt bonds just to put money in the bank so they will have it in a year or two. Finally, the states could set up agencies to promote science and industry, as North Carolina has already done.

What can the universities do? First, they should recognize that university research differs from that in industry or government laboratories. University research tends to be much more decentralized than it is in industry or government, and significant funding originates from individual principal investigators within the university. However, it is important that, if universities use creative forms of debt financing to acquire equipment, they must not go

into debt in a decentralized fashion. Therefore, it seems likely that resource allocation and planning will become more centralized in universities. Of course, this has its undesirable side effects, and universities will have to make some hard decisions.

Universities will have to cut back on some programs to provide the increased support necessary to maintain the health of others. Each university must investigate its individual potential for university-supported maintenance and repair facilities and perhaps limited inventories of research equipment that could be shared. Iowa State University, for example, has an excellent equipment-sharing program called REAP, elements of which could perhaps be adopted by other universities. In our survey, the field research team investigated carefully the issue of sharing research equipment: Is there enough sharing going on? Should there be more? Are instruments sitting unused? A considerable amount of sharing is already going on in universities, much of which is made possible by the Materials Research Laboratories.

We did find, however, that not in all cases did the universities properly prepare for the realistic costs of operation and maintenance when they were buying research equipment. The universities should try harder to recover realistic depreciation costs. These will, of course, either increase the indirect cost base or increase the direct costs of doing research. Nevertheless, these are real costs that must be met in some way.

We found a further need to work with funding agencies to find an incentive for investigators to transfer equipment to other investigators who might make good use of it, perhaps in other universities. There is little incentive to do that now.

Our overall conclusion was that in the last 10 or 15 years, universities have supported research by supporting people, not instrumentation. Funding by the National Institutes of Health for permanent equipment declined from about 12 percent in 1966 to about 3 percent in 1985, which is clearly too low. Similarly, NSF support for equipment went through a minimum in the period between 1969 and 1976 and has since come back up as the agency recognized the problem.

In summary, an effective and balanced national research program requires that a larger percentage—probably greater than 20 percent—of our resources be devoted to instrumentation, and this must be done on a sustained basis. It will probably be necessary also to increase the size of grants in order to provide this support and to meet the increased costs of operating and maintaining this more sophisticated equipment. If there is no increase in total funding, it may be necessary to reduce the number of grants and the number of investigators supported.

Materials Research and the Corporate Sector

Introduction

ARDEN L.BEMENT, JR.

Many of us have been witness to the increasingly vital force of materials science in the enhancement of U.S. industrial technological potential over the past 25 years. The emergence of new technologies over this period has created demands for advanced materials. Likewise, the development of new materials systems has accelerated advances in new technologies.

This synergistic process has occurred throughout history but never with the intensity apparent today. The major reason for this intensity is our growing ability to devise entirely new materials systems of engineering significance. Examples include the synthesis of diamond and other ultrahard compounds, semiconductor lasers, ultrapure optical wave guides, high-energy-density magnetic materials, high figure-of-merit piezoelectrics, high-modulus fibers, high-purity ultrafine ceramic powders, semiconductor superconductor superlattice and supermatrix devices, polymer blends, and so on.

The establishment of the Materials Research Laboratories (MRLs) was an inspired achievement. The problems faced by the Coordinating Committee for Materials Research and Development 25 years ago are the same problems facing universities today, namely, how to acquire modern research facilities and how to foster cross-disciplinary research efforts to address the more complex problems in materials science. However, the MRLs have achieved much more over the years than the solution to these problems. These labo-

ratories have demonstrated that peer interactions among graduate students brought together from different disciplines to share facilities can intensify the environment for creativity and greatly broaden the learning experience.

Unfortunately, industry’s exposure to the work of the MRLs has been, by and large, indirect, partly because the focus of the MRLs has been considerably upstream conceptually from that of industry. With the exception of a handful of outstanding industrial research laboratories, most companies do not seek out common interfaces with the MRLs. Moreover, interaction with industry was not designed into the MRL model at the outset, certainly not to the extent that it has been included in more recent NSF programs such as the Engineering Research Centers and the Presidential Young Investigators programs.

However, the existing NSF models for industry-university interaction are still far more concerned with leveraging the funding inputs than with leveraging the technology transfer outputs. Since technology transfer is best achieved through personal interactions, the potential for improving the effectiveness of these interactions through collaborative research, scientist exchanges, internships, and the like is far greater than has been realized to date.

Finally, although the United States enjoys a comparative advantage over the rest of the world because of its strong materials science base, this is not enough in the face of growing worldwide competition. We must also be comparatively effective in strengthening our science base and in exploiting it to add greater value to our industrial products. We all share a vital interest in the success of this enterprise because future investment in the national science and technology base will depend directly upon a strong and growing economy. We must find ways to increase the dividends from such investment if we are to build the university research infrastructure that we believe is needed.

While the key to global industrial competitiveness is not science and technology alone, nations that have a strong science and technology base will have a decided advantage in providing new products and services at the highest quality and lowest cost.

This chapter addresses these and other issues centering on the role of materials research in relation to current and future needs, opportunities, and threats in selected industries.

An Automotive Industry Viewpoint of Materials Research

JULIUS J.HARWOOD

The Materials Research Laboratories and the many associated events that have taken place in the materials field since 1960 are in large part responsible for our recognition today that advanced materials are key to many future

industrial innovations and growth in advanced propulsion systems, microelectronics, energy conversion, and a broad range of engineered and manufactured products. Accordingly, advanced materials technology has emerged as one of the major thrusts of national policy planning and programs throughout the industrial world, and particularly in the United States and Japan. Materials technology shares the spotlight with next-generation computers, biotechnology, very-large-scale integrated circuits, robotics, automation, and artificial intelligence.

In the past several years, there has been a shift not only in technological thrust in the United States, but also in the debate and philosophical discussion related to national materials policy. Our concerns have changed from vulnerability of strategic materials and mineral resources to issues related to industrial innovations in advanced materials and research and development priorities associated with these issues.

The debate between high-technology and smokestack industries is over. New technology and knowledge-based industrial activities have emerged as the keys for the future—new technology serving both the core of new entrepreneurial high-technology industries and rejuvenating established industrial sectors. There is a growing awareness that the United States’ materials competitiveness and industrial innovation potential in transportation, communication and information systems, and manufacturing rest more upon the development and application of advanced materials and less critically upon the problems besetting the traditional minerals and commodity industries.

All of this has led to a remarkable intensity of research and development activity and technological developments in advanced materials (worldwide) and the emergence of new materials industries. Also, it is becoming clear that traditional patterns and segmentation of industrial production are not so readily compatible with accelerated and aggressive industrial exploitation of these new materials technologies. New, innovative industrial coalitions, fresh organizational structures, intercompany cooperation, and information sharing in R&D are becoming more and more evident in this country, as are new modes of industry financing and investment, e.g., R&D limited partnerships. These changes hold profound implications for the development of future industrial infrastructures.

This may be particularly true in the commodity materials industries, in which traditional strength in a single or limited range of materials product classes is giving way to a diversified materials character. This transition is markedly evident in the changing industrial scope and activity of several of our large, formerly single-commodity-oriented companies. One sees a growing integration trend in these companies in becoming, as well, producers and suppliers of fabricated end-item components and consumer products for the higher value-added of engineered products in the marketplace.

In like manner, far-reaching changes are taking place in the automotive industry in its all-out attempt to survive the onslaught of foreign competition. New technology has been pinpointed as one of the industry’s keys to survival, and materials technology has been assigned a paramount role in this enterprise. The automotive industry is a voracious consumer of materials and increasingly, unlike in the past, the industry is becoming a key arena in which new high-technology materials and manufacturing methods are being translated into large-scale industrial practice.

In the near term, say by 1990, the automobile may outwardly resemble what is on our roads today, but how that car is manufactured and assembled, the materials from which it is manufactured, and how its functions are controlled are undergoing remarkable changes.

The basic technologies that used to be indigenous to the automotive industry also are changing. Not too many years ago, Ford research was aggressively pushing the development of onboard computers for feedback loop control systems to control engine operations and emissions. In retrospect, it is interesting to recall the debates with the conventional engineering community who preferred to opt for electromechanical hardware, rather than electronic devices, for reliable control systems. Yet, probably the most aggressive in-house training program under way today in the automotive industry is the conversion of mechanical engineers into electronic and electrical engineers to meet the new challenges to the industry. Obviously, as is the case almost throughout the U.S. industrial system, computer scientists and engineers, software analysts, information systems specialists, electronic engineers, and computer personnel of all types are the most sought-after technologists to support design, engineering, development, and manufacturing operations across the board.

Following are a few examples of the newer materials technologies that will exert important influences on the automobile and on the industry.

ELECTRONIC AND INFORMATION MATERIALS

The automobile in a true sense is becoming a communication center on wheels. The impact of electronics and information control systems on driving, engine, braking, suspension and ride quality, transmission, accident avoidance, and driver information operations is only in its infancy. While the automotive industry may not take a leadership role in developing advanced electronic materials, microelectronics, fiber optics, and electro-optical and memory devices, we certainly can expect to see their fast translation and exploitation for automotive vehicle use. In a real sense, the automotive industry will be right on the heels of the electronics and information materials industries, eager to adapt the benefits of photonics, fiber optics, better semiconductor chips, smart sensors, and the like. Semiconductor materials, sensor

materials, and information (electro-optical) materials will become as basic to the automotive industry as were conventional structural materials.

STRUCTURES PLASTICS AND FIBER-REINFORCED PLASTIC COMPONENTS

Over the next 10 years there will be a remarkable change in the use of basic materials in motor vehicles. As is already evident from some of the recent announcements, plastics will play a more and more important role. While the current emphasis still is focused on their use for non-load-bearing exterior panel applications, aggressive application programs are under way to prove out their potential as structural materials candidates. There are experimental vehicles “on the road” that are predominantly plastic cars, with rather exciting performance characteristics.