CHAPTER SEVEN

Bioinspired and Bioderived Materials

CHAPTER SUMMARY

The Panel on Bioinspired and Bioderived Materials focused on how the integration of biology and the physical sciences could result in greatly improved, lightweight, multifunctional materials for DoD. Materials derived from biology, for example, biological molecules as the active element in sensors, and materials inspired by biology—for example, layered, hierarchical, abalone shell-like composites as lightweight, tough armor—were considered. The potential impact of applying biological paradigms to the development of materials to meet DoD requirements was reviewed in depth.

Biological systems have clearly shown that large numbers of molecules, structures, and systems in living organisms possess attractive materials properties that are beyond the reach of current nonbiological synthetic approaches. Many of these molecules, structures, systems, and natural fabrication processes could serve as the basis for synthetic materials with enhanced properties. The challenge of using living organisms as a model for materials for future defense needs lies in identifying defense applications and then understanding and manipulating the biological systems to solve them. However, the integration of biology and materials science is hampered by discipline-driven education and the historical separation of biology and materials science in academic, industrial, and military laboratories.

This chapter details specific DoD opportunities in the areas of structural materials, functional materials, materials for chemical and biological warfare, wound healing, and human perfor-

mance enhancement. Each section contains a discussion of how an identified materials challenge might be met. The panel concluded that

-

Biological toughening mechanisms offer a route to the next generation of lightweight, tough materials.

-

Preservation of the biological function of biological molecules is a key driver for the next generation of biologically enabled devices.

-

In vivo detection strategies to identify toxins and pathogens, including masked agents, may make it possible to detect a single agent molecule.

The panel identified the following priorities for DoD R&D investments:

-

Improve fundamental understanding of the relationships between biological structure, properties, and evolution and materials design and synthesis.

-

Increase communication of DoD material needs to biological and physical scientists.

-

Pursue basic research into biological molecules, structures, systems, and processes to lay the groundwork for their use, or their use as models, in meeting DoD materials needs.

-

Identify and produce biocompatible materials to enable in vivo implantable devices.

-

Develop packaging technologies to preserve the biological function of biologically enabled devices.

In conclusion, biology can suggest directions for addressing many DoD needs in the next several decades. In some areas (e.g., improved battlefield medicine and identification or interdiction of biological warfare agents), solutions may be found in specific biological molecules, cells, or systems; in other cases (e.g., smart materials or lightweight structural materials), biology may point the way to improved strategies for material design and synthesis. Where biological molecules or cells are the active component of a device, the challenge to the materials community is not only incorporation of the sensing entity but, also, and perhaps more important, the preservation of biological function in a nonbiological environment. The common theme for all these technologies, research areas, and applications is to use biological paradigms for the solution of problems of materials design, materials synthesis, and systems assembly.

INTRODUCTION

Biological systems represent a successful strategy for the design of materials, the fabrication of parts and components, and the integration of parts into systems that meet complex performance criteria in a variety of environments. These evolutionarily engineered realities have emerged slowly. The possibility of incorporating the principles of evolutionary “strategy” into modern engineering and scientific practice is emerging in materials science and engineering.

This chapter is concerned with

-

Identification of biologically derived materials for improved warfighting effectiveness,

-

How applying biological paradigms will affect the development of materials meeting DoD needs, and

-

Identification of biologically inspired materials for improved warfighting.

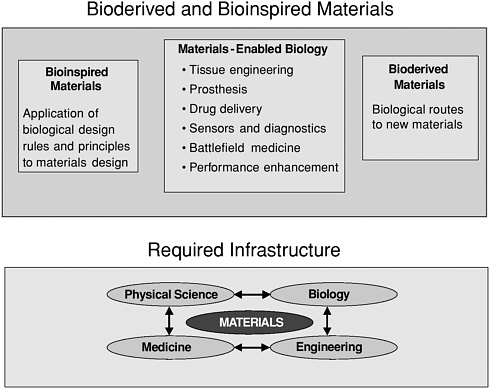

The current materials science paradigm is that a material’s performance is uniquely related to its structure, and the structure of a material reflects the totality of its processing history. This insight allows processes and products to be developed based on scientific principle rather than purely empirical methodologies. Once the process-structure-property-performance database is established, a single material may be processed to satisfy a variety of applications. An example of this is the production of molecularly identical, morphologically distinct poly (ethylene terephthalate) fibers for applications as diverse as pliant textile yarns and stiff reinforcing cords for tires. Materials application in medicine has historically been highly empirical; seldom are materials primarily designed for biological or in vivo applications. The application of the methods of materials science to the understanding of biological materials should prove productive in finding new materials for DoD. An overview of the subject matter and disciplines treated in this chapter is shown in Figure 7-1.

The integration of biology and materials science is hampered by the fact that education is discipline-driven and by the historical separation of biology and material science in academic, industrial, and even military laboratories. This has created problems, among them incompatible usage of terminology, incompatible approaches to problem solving, and divergent cultural viewpoints, that can render interaction difficult.

FIGURE 7-1

Schematic overview of subject matter and disciplines covered in this chapter.

The value of successfully integrating materials science and engineering with biology is difficult to estimate accurately but it represents at the least an opportunity to cross-fertilize and broaden each community’s paradigms. Many of the examples cited below represent either the reality or the promise of this integration.

DOD NEEDS FOR BIOINSPIRED AND BIODERIVED MATERIALS

Mankind has been using biological materials for defense purposes for millennia: wooden staffs for spears or ax handles, vines for ropes, snake venom or plant extracts for biological weapons, shaped bone for tools and weapons. More applications are sure to come. As discussed below,

multilayered abalone shell could point the way toward a new tough, lightweight vehicle armor, and spider silk fibers could become the basis for enhanced protection of personnel. Organic and biological electronics could lead to extremely light laptop computers and other devices. Insects may be seen as analogs of autonomous vehicles, equipped with composite smart armor featuring a variety of sensors and receptors. Conversely, a variety of biocompatible materials could be implanted (e.g., as hearing aids, lenses, artificial blood) to enhance soldier performance.

Billions of years of evolution have given mankind a wide variety of biological solutions to materials problems. The challenge lies in identifying relevant defense applications and understanding and manipulating the biological systems to solve them. It must be borne in mind, however, that the actual use of biological materials or materials that mimic biological systems lags far behind our enthusiasm for them. With a few notable exceptions, these biomolecular materials remain the materials of the future: despite an extraordinary rate of progress in the field, they are likely to be materials of the future for a number of years.

This does not mean that the field should be ignored by those focused on defense applications, awaiting a future when opportunities for applications might appear. Recent research has vastly increased our knowledge and understanding of biological materials and how their unique properties arise from their structure. New tools allow us to modify biological materials for our needs or to synthesize, de novo, materials that are based on biological principles. Nevertheless, there is a need for basic research to improve this understanding. More important, applications arise not from a linear progression of basic to applied research but from the vigilant and creative observation of basic research with an eye toward the unexpected, the unplanned, serendipitous breakthrough. Thus it is fair to say that basic research in all areas of biology must be pursued because there is no way to predict which discoveries in which fields will have important impact.

The greatest problem lies in linking those who discover intellectually interesting things to those who know of and are charged with meeting specific needs. It is not easy to find people who are both aware of current science and know the needs of the military. There is no doubt that there is much already in the basic science literature that could have defense applications but that has not yet been “discovered” by potential users. This will continue to be true as the pace of scientific discovery accelerates. To bridge this gap, basic researchers must be made aware of defense needs, so that they will notice potential applications when the underlying discovery

is made; chance favors the prepared mind. At the same time, defense materials researchers must be closely linked to the basic research establishment so that they can extract potential applications from the flow of apparently nonuseful fundamental discoveries.

But the future lies in the biology. This chapter describes a wide variety of molecules, structures, processes, and concepts in biology that can reasonably be thought to have, at some point, a defense application. In some cases, research toward applications has made good progress. In many other cases, however, at this time we cannot even begin to develop those materials. In fact, in many cases we can list more barriers than routes to materials development. However, the great discoveries are those that even the most visionary cannot envision. Any concept that does not violate a law of thermodynamics should be regarded as possible. The shelves of military warehouses and consumer stores are stocked with valuable useful products whose function was regarded as impossible not many years ago.

“Computers in the future may weigh no more than 1.5 tons.”

—Popular Mechanics, 1949

What, then, do living organisms do that might be exploited for defense applications? What do we know now about these molecules or processes and what do we need to understand to bridge the gap to application?

First and foremost, there is a clear need for better understanding of structure-property-function relationships in these materials. Second, it must be kept in mind that biological activities occur on the molecular level. Even the most complex of behaviors can (or will, once we understand them) be explained in terms of the presence or absence of specific molecules and the interactions among them. Further, it must be kept in mind that nature does not optimize biological materials and processes. Nature makes them just good enough—first, because perfection is not necessary for survival; second, because optimization of one process or structure might be detrimental to another; and third, because biological systems have evolved in the presence of a limited number of the 92 naturally occurring elements, within a narrow range of pH, temperatures, and pressures, and with the requirement that neither the product nor the intermediate molecules along the “production” path be toxic. Thus it is reasonable to argue that if we were to loosen the constraints, as we can when operating outside the organism, we might do better.

The greatest limitation to the mimicking of biological systems in materials and processes for defense applications lies in our insufficient understanding of these systems. One can argue that a more complete understanding should lead to many useful applications. On the other hand, it is equally clear that there are severe limitations on the use of biological molecules, structures, and processes. Biology does not in general thrive under extreme conditions. Biology limits itself by not making use of the vast majority of naturally occurring elements. Biological structures and systems are extremely complex, far more so than their synthetic analogues, and are therefore extremely difficult to manipulate—consider bone compared to titanium or even sophisticated alloys. These barriers could yield to our increased understanding but might also be avoided if the systems to be used were simplified, for example, in synthetic “cells” with artificial membranes enclosing volumes into which only a few well-defined molecules and processes have been incorporated to perform limited specific functions.

SPECIFIC AREAS OF OPPORTUNITY

Structural Materials

Bioinspired processing employs lessons from biology in creating synthetic analog composites. This approach is ideal for designing and fabricating nanostructured organic and organic/inorganic composites by mimicking the processes, structures, and properties of biological materials. Materials like bone, teeth, and shells are simultaneously hard, strong, and tough, with unique hierarchical structural motifs originating at the nanometer scale (Wainwright et al., 1982).

The structures of biological composites are hierarchically organized in discrete levels or scales. Virtually all biocomposite systems have at least one distinct structural feature at the molecular, nanoscopic, microscopic, and macroscopic scales. In the case of biological hard materials, nature grows hierarchically structured organic/inorganic composites in which soft materials (e.g., proteins, membranes, and fibers) organized at lengths of 1 to 100 nm are used as frameworks for the growth of specifically oriented and shaped inorganics (e.g., CaCO3, SiO2, Fe3O4, hydroxyapatite) with small unit cells (~1 nm). The high-modulus inorganic phase provides stiffness and the organic phase enhances toughness. Although the principle

of hierarchical design has already been applied to synthetic composites (Lakes, 1993), techniques to reduce the smallest level of hierarchy to the submicron scale are not complete. Hierarchy at the nanometer scale leads to materials properties fundamentally different from those expected from simple rules for mixing the bulk properties of the constituents (Siegel, 1993).

Levels of structural organization are held together by specific interactions between components. For example, the structure of an abalone shell consists of layered plates of CaCO3 (~200 nm) held together by a much thinner (<10 nm) “mortar” of organic template (Figure 7-2). Whatever the nature of the bonding between levels, adequate adhesion is required for the structural integrity of the system. Structurally organized organic surfaces induce growth of specifically oriented, dissimilar constituents catalytically or epitaxially. Highly interacting levels are organized into a hierarchical composite system designed to meet a complex spectrum of functional requirements. As composite systems increase in complexity, they perform better; the so-called intelligent materials and adaptive composite systems result from complex architectural arrangements. A hierarchical biocomposite is more than just a material from which larger objects can be built. It is a complete structural system where nested levels of structural hierarchy appear to yield improved dielectric and mechanical properties for particular functions.

The use of molecular biology and genetic engineering to produce materials has focused mainly on health care, resulting in, e.g., a large number of recombinant proteins for human therapeutics. Many of these products have been on the market for years, including insulin, human growth hormone, factor VIII, erythropoietin, and tissue plasminogen activator. Recombinant proteins for human health care have one common feature—high cost.

On the other hand, the biological synthesis of functional or structural materials using recombinant DNA technology has not progressed as rapidly as materials for human therapy. One of the main reasons is the lower value added for bioderived materials not targeted to the health care market. It is our belief that there is great potential for using biotechnology to produce biomaterials that could be well suited to DoD needs in 2020. Some of these biomaterials have already been demonstrated to be technically feasible. On the other hand, there are many challenges and barriers to be faced before such biomaterials become realities. In this section, the

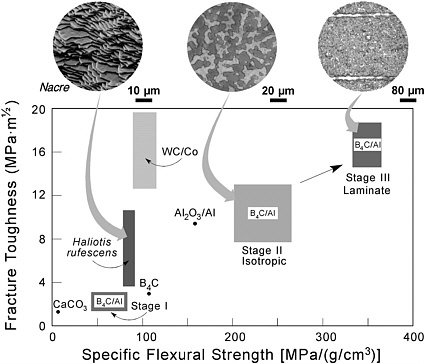

FIGURE 7-2

Mechanical properties of natural and synthetic materials. B4C/Al composites—produced to mimic the interpenetrating and laminated structure of nacre—show significant improvement in properties over single-phase B4C.

panel attempts to illustrate with examples as well as state some of the challenges that lie ahead.

Armor

An area that should be considered is how bioinspired structure might be explored for battlefield armor. For instance, the abalone shell has armor protection capabilities equal to or greater than those of existing materials on a strength-to-weight basis. When laminated hierarchical structures of biological systems (e.g., the nacre of abalone shell) are mimicked in microlaminated ceramic-metal, ceramic-organic, or organic-organic composites, significant improvements in composite mechanical properties are observed (Figure 7-2). Applying a simplified version of this layering to B4C/Al (as well as SiC/Al or B4C/polypropylene) composites significantly increases the mechanical properties. B4C/Al composites are strengthened

as a result of residual stresses with nanoscale modulations in the interpenetrating network of the ceramic and the metal phases.

Greenleaf Corporation at Saegertown, Pennsylvania, has manufactured B4C/Al tiles for use in armor panels aboard C-130 and C-141 gunships. Processing of these ceramic/metal and ceramic/organic microlaminates is based on the concept of infiltrating a laminated scaffolding (e.g., ceramic) with a liquid (e.g., metal or organic polymer). The laminated composites produced by this approach are similar to nacre. However, although these accomplishments attest to the value of transferring lessons from biology and mimicking biological structures to create synthetic analogs, the smallest length scale in a complete system is still in the micron range due to the intrinsic limitation of the tape-casting method employed. On the other hand, the biosynthesis of inorganic biomaterials has not received the same magnitude of research funding as the human health care area. The panel believes that research is necessary to demonstrate the technical and economical feasibilities of such activities.

High Performance Fibers—Silk

It is well known that the natural product silk is one of the strongest and toughest fibers on a per unit weight basis. Of special importance is that silk performs the same whether it is subject to tensile or compressive forces, a property that differentiates silk from synthetic high-performance fibers. The amino acid sequences of many types of silk are now known. The production of recombinant silks based on parts of these sequences has been demonstrated in bacteria. Many companies and U.S. Army laboratories have conducted R&D on silk, among them Protein Polymer Technologies, Inc., DuPont, and the U.S. Army Natick Laboratories.

One of the major hurdles to the commercial development of recombinant silk is its cost. It is difficult today to compete on a cost basis for silk derived from the silk worm versus recombinant protein produced using a bacterial host. Recently, however, Lazaris et al. (2002) have been able to splice the genes for spider silk into cells from a variety of other organisms that, when grown in tissue culture, produce material that can be spun into silk threads. The groups plan to transfer the genes to goats that have been bred to produce the silk in their milk. However, only one of the two proteins of silk has yet been synthesized, and even that one is produced in a form that is shorter and weaker than the natural product. The barrier, as in most other examples discussed here, is biological. We do not yet fully understand the structure of the silk proteins, the mechanism by which the

spider processes the proteins into fibers, and the techniques required to manipulate the extremely long pieces of DNA that code for the large silk proteins.

On the other hand, the integration of recombinant technology with materials science and engineering appears to be a natural partnership to improve the functionalities of recombinant biopolymers like silk over the silk produced naturally (Kaplan, 2002). For example, David Tirrell of the Department of Chemical Engineering at California Institute of Technology has proposed to replace the natural amino acids in native protein polymers using both chemistry and biotechnology to generate such materials with unique added functionalities. New types of polymers with well-defined selectable sequences and uniform composition are possible using these biological production methods. For example, one might see a modified silk with a significant higher strength-to-weight ratio that might be useful as material for the Armed Forces. The generation of highly complex biologically derived structures with new artificial properties and composition is possible.

Functional Materials

Soft Electronics

Recent advances have brought the electron mobilities for organic semiconductors within range of those for amorphous silicon (Heringdorf et al., 2001). This makes organic transistors practicable. Organic LEDs are also on the verge of full commercialization. The core device aspects of these advances are discussed in Chapter 6, but many processing and packaging questions still need to be resolved. DoD applications tend to be more demanding than consumer needs, with greater concern for vibration resistance, redundancy, damage tolerance, and environmental and corrosion resistance.

After the battery, much of the weight of portable electronics arises from the need for a rigid shell. Since silicon is inherently brittle and water-sensitive, for instance, there are high costs associated with the rigid packaging it needs for protection from moisture. The material must also be protected from the stresses associated with thermal expansion, acceleration, and vibration. Organic and/or biological electronics, deposited on flexible substrates, promise very considerable savings in weight. By integrating flexible photovoltaic cells, processors, memory, and display

onto a substrate, it should be possible to make a laptop computer with the weight of a few sheets of paper.

A second advantage that would come from organic electronics, especially for the DoD, is that low-temperature printing processes would bring versatility. Small numbers of specialized circuits could be readily produced by combinations of inkjet and contact printing. Also, circuits could be printed onto external surfaces of equipment or onto clothing.

Molecular or polymeric devices are also more likely to provide a stable interface between electronic equipment and the human nervous system for performance enhancement, prosthetics, and health monitoring.

Biology offers insight into how self-assembled molecular-level electronic devices may be printed onto flexible substrates at low processing temperatures. To build devices that exploit the toughness of polymers and the simplicity of printing, we need to learn how to emulate biological processes and work with controlled disorder. We need a better understanding of the mechanisms of intermolecular electron or energy transfer, especially in disordered organic conductors. Much can be learned from their electron-transfer protein counterparts, such as the cytochromes. One approach to better understanding these transfer processes is to study single-molecule devices. Mark Reed of Yale University is studying such systems by addressing isolated organic molecules in a self-assembled monolayer using an AFM tip.1 The work is focused on the molecule as a device; the greatest benefit will be in understanding of molecule-to-molecule electron transfer.

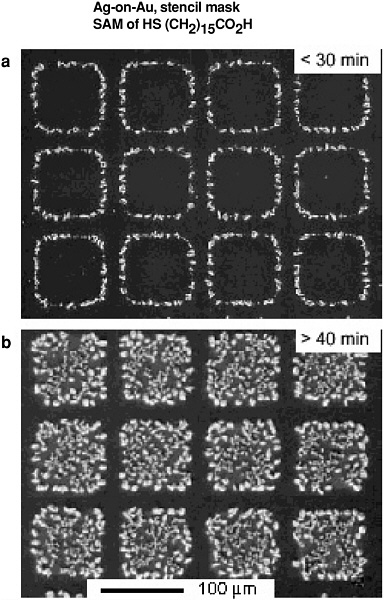

The processing methods being used for the most effective organic electronics depend on evaporation in vacuum of the active layers onto structures defined by photolithography. This is too expensive and slow. Printing methods are attractive but the resolution is not yet good enough. Methods that depend on self-assembly and selective deposition at boundaries where surface energy changes look most promising. Starting from studies of biomineralization, Aizenberg et al. (1998) have demonstrated mineral growth on surfaces with a linewidth of 10 microns (see Figure 7-3).

Another unmet need of molecular electronics is cost-effective flexible packaging systems. Organic LEDs, for instance, have aluminum electrodes that are very vulnerable to corrosion and oxidation and highly water-

FIGURE 7-3

Calcite crystals grown on self-assembled monolayers on a patterned surface: (a) at short times, the deposition follows the outline of the pattern; (b) at longer times, the deposition reveals a resolution higher than the starting pattern. SOURCE: Reprinted by permission from J. Aizenberg et al. (1998). Copyright 1998 by Macmillan Magazines Limited, London.

sensitive electron conductors. They can be packaged as sealed modules between glass sheets. There is a need for an impermeable, transparent, and flexible packaging system. This could be a bioinspired multilayered

organic/inorganic structure. Though no such material currently exists, biology may offer a way forward. Biological organisms came into being when the planet had a reducing atmosphere of methane and carbon dioxide. When photosynthesis caused oxygen levels to rise, special methods had to evolve to prevent destructive oxidation. Biomimetic active barriers that would deplete the water and oxygen that penetrate the system may provide part of the solution to this problem.

A challenging target for research in organic electronics is to create interfaces between cells, especially in the brain, and conventional electronics. This is being addressed by many groups, including those of Theodore Berger at the University of Southern California and Carolyn Bertozzi at Berkeley. Berger told the panel about implanting electrodes into living slices of tissue from the hippocampus.2 Bertozzi discussed modification of cell surfaces to promote attachment to synthetic materials.3 There is a host of applications awaiting better cell-machine communication. In current medical devices there is always an infection problem when wires or tubes penetrate the skin for extended periods. At present, interfaces, between nerve cells and silicon in vitro and between nerves and implanted devices, lead to cell death. There is evidence that conducting polymers may provide a more biocompatible interface. A stable interface could be used to allow amputees to control prostheses, for more direct man-machine communication, and to enhance such functions as sensing and memory.

Smart Materials/Sensors

Perhaps the most advanced smart materials at this time are sensors that translate their detection of defined targets into measurable optical, electrical, or mechanical changes. Many other organisms do this far more effectively than humans, demonstrating greater discrimination and sensitivity, sometimes approaching the detection of single molecules or photons. Dogs can distinguish individual humans by smell. Other organisms have exceptional senses of taste, touch, hearing, and sight. Biology thus offers

the possibility that individual soldiers, friend or foe, could be distinguished from a distance when sight and hearing are limited. Chemical or biological agents could also be detected before their concentrations reach toxic levels. In nature, a wide variety of mechanisms have evolved to achieve this kind of detection, any one of which could have an important military application. Lobsters and other crustaceans, for example, identify small differences in odor concentrations by flicking a pair of antennules, dragging them through the water to bring the chemosensory hairs that line them into contact with odor molecules (Koehl et al., 2001).

Quite different philosophies seem to guide sensor use in the biological and the synthetic worlds. Synthetic systems, such as the automobile engine, tend to rely on a few sensors, each highly reproducible and quite linear in its response to one variable. Biological sensing relies on large numbers of sensors that are very nonlinear, are time-dependent, and respond to multiple variables. Studies make it clear that a viper uses its heat sensors in combination with vision and chemical sensing on the tongue, making it very difficult to establish the role of each individual sense. In biology, the eyes of higher animals are perhaps the only stand-alone sensors, giving data that is separately interpreted. In many other animals eyes seem to act more as optical sensors than as cameras. Sensory data are usually interpreted only in the context of the full data stream for all the senses. Thus, cooling of the skin coupled with stimulation of the hairs means wind; without the hair sensor signal, it means extreme cold or evaporative cooling.

Mechanical sensors of animals can be separated into exteroreceptors, such as tactile sensors that sense changes in the environment, and proprioreceptors that allow control of the motion of the body. In mammals the proprioreceptors are embedded in the muscles, tendons, and joints. The most numerous sensors are the muscle spindles. These organs, which are 4-10 mm long, are incorporated in numbers from 50 to 500 per gram of muscle; the hand and neck have especially high densities. The entire human body has some millions of spindles. Muscle spindles are connected in parallel with the muscle and sense changes in length. In mammals, the Golgi tendon organs are located at the junction between the muscle and the tendon that connects it to bone. While the muscle spindles are sensitive to passive stretching of the muscle, the Golgi tendon organs are in series with the muscle and so sense the load on the muscle.

In biomimetic terms, insects can be seen as parallel to many types of equipment; there is an external protective shell around delicate internal

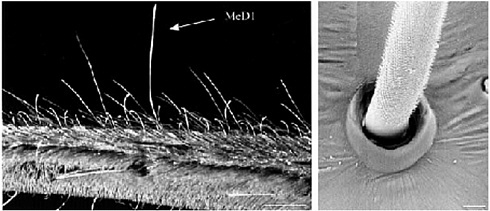

organs. Arthropod cuticle contains integrated mechanoreceptors. One group of these is associated with sensing hairs; they act as exteroreceptors to provide information about the environment. A second group is associated with holes in the external skeleton, the cuticle. These proprioreceptors allow control of the motion of the animal by providing information about strains in the skeleton (Barth, 2002). Measurements of cuticular strain and response from spider legs subjected to applied loads gives a threshold sensitivity of about 50 microstrain (see Figure 7-4).

Insofar as insects can be viewed as prototype autonomous vehicles, there is clearly a particular DoD interest in this area. A consequence to be expected with the advent of printable electronics would be the embedding within equipment of many sensors that would provide continuous information about the device’s state of operation and the surroundings. An initial stage in the process could be the development of smart skins for machinery. The availability of this information flow would then require control algorithms that allow an effective range of responses. There are many studies of embedded sensors for health monitoring and damage detection in composite materials and concrete structures. Fiber Bragg gratings are the most promising sensor (McKenzie et al., 2000), but there is not yet a simple way of integrating many sensors into a structure. There is a need for new miniature strain sensors with a simple readout. In insects, much mechanical sensing is through hairs that penetrate the cuticle. There is currently no way of making equivalent synthetic systems.

We need a much better understanding of biological molecular identification systems. Specific sensors, such as the moth antenna, are said to be able to detect a single airborne molecule of pheromone from the female. Specific biological sensing presumably operates as a lock-and-key, or more precisely as an induced-fit-through-conformational-change system where a set of intermolecular interactions are defined by the geometry of a receptor site and a complex target molecule. Recent advances in studies of cell-surface interactions have shown that short peptide sequences (such as RGD) can be specifically recognized. Likewise, supramolecular chemistry is now showing that several hydrogen bonds between two molecules of constrained geometry are sufficient for a strong and specific bonding interaction. If we wish to design molecular sensors, we need a better understanding of the relationship between molecular geometry and binding specificity. A critical issue is the preservation of the biological

FIGURE 7-4

Tactile hairs on a spider leg. (Left) Metatarsus, scale bar 1 mm. (Right) Hair and cuticular socket, scale bar 10 microns. SOURCE: Reprinted by permission from J.T. Albert et al. (2001). Copyright 2001 by Springer-Verlag GmbH & Co. KG.

activity of cells and biological molecules used as sensing elements in a nonbiological environment.

Another area that is key to improved chemical sensor development is biomimetic amplification systems to parallel biological transduction mechanisms that facilitate detection of very small amounts of a chemical. There are at least two approaches. In the clotting system, binding of a few molecules of protein to a damaged surface sets off a cascade that results in a large amount of product. These systems can be intrinsically unstable unless they are backed with damping systems to eliminate subcritical responses. A second approach is to engineer a cell to produce fluorescent protein in response to a given stimulus. This case relies on activation of a gene, production of nucleic acid, and ribosomal protein synthesis, which will cause the response to be much slower. Whichever mechanism is used, amplification can be provided by immobilized cells in the sensor. This in turn requires that there be systems for maintaining cells for long periods of time before the sensor is used. It should be realized that this equipment will be stored, handled, and distributed more like food or medical supplies than like conventional equipment.

Power Sources

Batteries Batteries are a limiting factor in many devices. For example, laptop computer progress is stymied by a typical battery life of less than 8 hours for any acceptable battery weight. Thus, lighter power supplies, either fuel cells or batteries, are needed.

Batteries are composed of electrodes, electrolyte, case, and connections. Both the electrodes and electrolyte are multifunctional; there is a need for electrochemical activity, rapid transport of ions, mechanical stability to volume changes on cycling, and resistance to mechanical shock. The biological answer—hence the biomimetic solution—would be a complex composite structure integrating active components, conducting channels, and mechanical support. While composite structures have been considered for these tasks, they start from what can be made simply. As already discussed under structural materials, there is a need to design and build arbitrarily complex hierarchical structures, rather than simply characterizing those that appear from various types of processing. A research effort in this area should incorporate processing methods, modeling, and characterization tools at the nanometer, micron, and millimeter levels.

Recent years have seen intensive progress in new battery systems, especially secondary (rechargeable) lithium batteries. While there have been significant improvements, equipment makers still want far more energy than batteries can deliver at an acceptable weight. Batteries are characterized by both energy density and power density. Higher power density can almost certainly be achieved by going to multicell stacks of very thin layers with a hierarchical structure to minimize diffusion distances and internal resistance. Improved energy densities will either require fuel cells or wholly new systems.

Fuel Cells Fuel cells represent an attractive alternative to batteries. One could view the nervous system as an electrical system powered by glucose through oxidative phosphorylation. In the Krebs cycle, glucose is oxidized through a series of steps and the energy of each step is used to convert ADP (glycolysis and adenosine diphosphate) to ATP (adenosine triphosphate). ATP functions as the immediate energy source for many cellular processes, including muscle action. The process is efficient; about 70 percent of the energy available from glucose oxidation is converted into energy available from ATP.

There is a clear possibility of using similar biochemical or chemical routes to produce small-scale power. Glucose or sucrose would provide a cheap, convenient, and safe energy source. Table 7-1 shows that glucose has 70 percent of the energy density of methanol. Because the biological process uses electron-transfer proteins, a glucose-powered fuel cell can be based on enzymatic oxidation or on chemical catalysis. Prototype cells have been produced by a number of groups. Chen et al. (2001) recently described a fuel cell based on two carbon fibers, 2 cm long by 7 microns in diameter, that produced 0.6 microwatts, enough to power a simple CMOS device.

In both batteries and fuel cells, we have long recognized that the distance scale is the key to power density. Diffusion is fast over short distances, while thick electrolytes and electrodes require high ion mobility that compromises our structural choices. There is a clear need to build large structures with short effective length scales, just as a large mass of muscle has many interdigitated small units.

The Panel on Functional Organic and Hybrid Materials emphasizes the need for new methods to make polymers with well-defined sequences, analogous to proteins. Coupled to this must be methods to predict the structure and properties of the polymers, since the possible combinations are far too numerous to explore experimentally. Windle has considered the issues of multiscale modeling of polymers. His approach is to extract characteristic parameters from molecular modeling and use these to construct a simplified model at a higher level. In some cases the molecular

TABLE 7-1 Energy Density and Other Properties of Glucose, Compared with Chemicals More Commonly Considered for Producing Power

|

|

ΔcH° (kJmol–1) |

ΔcG° (kJmol–1) |

n |

E° |

kJ/g |

kJ/cm3 |

|

Hydrogen |

–285 |

–237 |

2 |

1.23 |

119 |

0.011 |

|

Methane |

–890 |

–818 |

8 |

1.06 |

51 |

0.037 |

|

Methanol |

–726 |

–702 |

6 |

1.21 |

22 |

17.37 |

|

Glucose |

–2808 |

–2865 |

24 |

1.23 |

16 |

24.57 |

|

Octane |

–5471 |

–5297 |

50 |

1.10 |

48 |

66.10 |

|

SOURCE: The Department of Chemistry of the University of Hong Kong. Available at <http://chem.hku.hk/~fuelcell/chem_fuel_cell.htm>. Accessed October 12, 2001. |

||||||

information is reinserted once a higher level structure has been determined. Similar methods will be needed to design complex fine-scale composites that could mimic biological structure and function. Previous remarks about the need for flexible barrier materials for organic electronics also apply to batteries and fuel cells. Battery casings impose rigidity and are a significant source of weight.

Medical Applications

Chemical and Biological Warfare

Over 20 countries worldwide are developing chemical weapon (CW) capabilities, and at least 10 countries are working actively on biological weapon (BW) agents, and delivery vehicles. CW agents (e.g., phosgene, chlorine, chloropicrin, cholinesterase inhibitors) are relatively cheap and readily obtainable. They may be categorized as blistering agents or toxins against the nervous system, blood, and the respiratory functions. BW agents (bacteria, viruses, ricksettiae, genetically engineered microorganisms) are typically more potent than their CW counterparts, do not require massive stockpiles, are easy to conceal, and are produced with equipment that is commercially available with no legal restriction. Many agents are classified as midspectrum, between chemical and biological: Among them may be toxins from biological sources that adversely regulate pain, sleep, and blood pressure and act as physical and psychological incapacitants. Novel threats emerge from the engineering of biological entities to provide these with additional stability, resistance to antibiotics, or new delivery characteristics, or to make them nondetectable by engineered biosensors or the body’s immune system. Additional threats derive from the release of toxic industrial chemicals (TICs) in the course of conventional warfare, as highlighted in the Yugoslavian theater.

The technology of sensors, even against conventional threats, is currently deficient, as highlighted by the experience in the Gulf War, and requires massive materials science and engineering-based advances to meet its C/BW mission.4 Among reported deficiencies are limited standoff and liquid agent detection, potential for high false-alarm rates, weak single-individual biodetection technology, and slow response to central-

ized coordination. DoD research is directed to devices that will overcome such deficiencies, perhaps hand-held devices usable for detection, identification, quantification, and mapping of battlefield threats, as well as medical diagnosis and monitoring. These are expected to be all-agent capable and reprogrammable for detecting emerging threats. The fundamental scientific and technological advances required to accomplish these lofty objectives were discussed in Opportunities in Biotechnology for Future Army Applications (NRC, 2001), in particular as they relate to sensing and the battlefield environment (Chapter 3). One crucial conclusion emerging from the NRC report is that materials science and materials micro/nanotechnology have played a dominant role in contemporary breakthroughs in the detection and manipulation of biological molecules by way of sensors technology, micro/nanofluidics (e.g., Harrison et al., 1992; Desai et al., 1999), DNA chips (e.g., Christel et al., 1998), and protein chips (e.g., Bashir et al., 2001). It may well be expected that materials science and engineering will be on the forefront of the breakthroughs necessary for adapting and further evolving C/BW applications and civilian protection programs.

The 2001 NRC report also addresses biology-based electronics and computing technology (Chapter 4), biologically inspired materials (Chapter 5), biologically inspired solutions for logistics requirements, and novel technologies for the health and performance of warfighters (Chapter 7).

Wound Identification and Healing

Most battlefield casualties in conventional warfare result from uncontrolled bleeding. It is thus essential to develop methods, and the associated technology platforms, for (1) rapid triaging of battlefield wounds, (2) communication of the results to centralized and distributed battlefield coordination units, (3) summoning and deploying appropriate medical assistance, and (4) delivering medical treatment on-site while waiting for the medics to arrive (the required treatment includes hemostasis, antibacterial intervention, shock therapy, and possible reconstruction of damaged tissue).

The NRC (2001) has identified remote triaging of wounds, wound healing, and wounded tissue reconstructive engineering as primary R&D areas. Two of the five highest-priority areas identified pertain centrally to wound identification and treatment: self-replicating systems for wound healing; and shock therapeutics. An Army RFP was recently issued for the establishment of a major nanotechnology center with the primary objective

of integrating wound triage and treatment technology directly into the warfighters’ uniforms.5 It said:

Regardless of the injury mechanism (e.g., infection, trauma, surgery), several critical factors are common to the wound-healing process. These factors include an adequate blood supply to the healing tissue, resolution of associated infections, infiltration of the wound site by inflammatory cells followed by mesenchymal cells, and finally the deposition of neoconnective tissues and epithelial tissues.

An adequate blood supply to injured tissue has long been recognized as vital to healing. Cupping, the practice of applying a cup heated by a flame over the site of injury, was used for centuries to ensure blood flow to topical wounds. Today, angiogenic factors can be delivered to the sites of injury to stimulate the formation of new blood vessels.

Hyperbaric chambers have been devised to increase oxygen concentration for cells at the site of injury and thereby increase their viability and rate of proliferation. Acupuncture, massage therapy, and a variety of poultices have been used to create the optimal wound-healing environment, especially for recalcitrant nonhealing wounds.

Wounds have been categorized by their severity, depth, and chronicity. Each category has its own standards of care. However, the principles of cleanliness, wound covering, tissue apposition, and protection from physical trauma while tissues return to their normal physiologic state apply to all wounds.

A variety of coverings are used for acute and chronic wounds. Dressings range from totally occlusive dressings that do not allow fluid (and allow little gas) to pass from the wound to the outer environment, to partially occlusive or nonocclusive dressings that remain permeable to both fluids and gases. Dressings may or may not carry antiseptic or antibiotic compounds. In general, wound coverings for acute traumatic wounds are adequate for treating infections and protecting wounds from further injury. However, there is a pressing need for wound coverings that simultaneously provide, protect, and deliver a stimulus for healing. Stimulation for healing is especially important for large injuries when “space” must be “filled”: In natural healing, large pockets at sites of injury are filled with fluid (usually plasma, blood, or both), which then creates a barrier to rapid healing. Therefore, dressings that not only cover the wound but also

stimulate the formation of new blood vessels and the deposition of connective tissue would greatly improve wound care. Bioerodable polymeric biomaterials specifically designed for biological and mechanical responses in vivo, such as those developed in the laboratories of R. Langer and others (Wise, 2000), provide the basis for these needed improvements but their introduction is hampered by quality issues and cost.

There is an inevitable gap between in vitro phenomena that occur under carefully controlled conditions, such as ideal concentrations of growth factors that have predictable effects on selected cell lines, and practical situations that involve the complex of mammalian systems and a plethora of different growth factors (both stimulatory and inhibitory) in environments complicated by infection, tissue necrosis, and external extremes. Although several angiogenic growth factors have been identified, controlling their activity in vivo remains elusive, probably because we lack understanding of the extracellular milieu of growth factors in vivo. Although the sources of growth factors have been identified (e.g., endothelial cells, macrophages, fibroblasts), the mechanisms that stimulate their controlled release and the three-dimensional ultrastructure in which they naturally reside are not well understood. It should therefore not be surprising that growth factors attached to synthetic polymers like polylactic acid and Marlex mesh are not particularly effective. Similarly, bioartificial membranes comprised of selected molecules, such as hyaluronic acid or purified Type I collagen laced with a variety of growth factors, usually fail to produce the desired effect in clinical situations.

Many synthetic and natural materials have been investigated for treating wounds in both military and civilian applications (e.g., Germain and Auger, 1995). Among these are wide classes like biodegradable polymers and biomodified materials that slowly release growth factors, blood-clotting agents, angiogenic inductors, or other potentially beneficial molecules. Despite the multitude of approaches and the investment of significant private and public resources, wound healing by material apposition is still far from being achieved.

Two types of possible solutions may be envisioned; both require significant advances in materials science and technology. The first solution is better materials, specifically materials that can arrest blood loss, impede infection, counteract shock, and foster biological regeneration. Multiplicity of function would presumably require composite materials, comprising a single or multiple matrix, with interdispersed biological molecules that are released over desired periods of time. The second solution, favored in the

NRC (2001) report, is to use biological self-replicating systems (e.g., Gentzkow et al., 1996). These systems integrate living cells into synthetic scaffolds for in vitro generation of the desired product (e.g., skin replacement) or even implantation of regenerating bioreactors at the wound site. Major breakthroughs in biomaterials science and engineering are needed to produce scaffolds that allow for such cell/material hybrid bioreactor to perform their desired functions in vivo.

Human Performance Enhancement

Though any material or technology can be viewed as a human performance enhancement, this review will concentrate on direct modifications to the human body. An example is the use of materials to strengthen the living skeleton. Applying new materials science to the management of human disease would certainly help DoD to maintain the health and readiness for duty of personnel. However, in this section we are considering the role of materials in increasing human performance substantially beyond the optimal native condition of the human body. This panel believes that many operations would have dramatically improved chances for success if nominal body performance is enhanced.

Examination of current enhancements/aids to the human body is informative. The enhancements shown in Table 7-2 are all heavily dependent on materials science. Materials science will continue to be critical in further advances, which will also be important for disease management.

While a body systems approach might be considered, the panel chose to examine possibilities by functional capability. An advantage of this approach is that optimizing overall performance has to be considered even while trade-offs become apparent. For example, if we want a soldier to be able to run faster, we will have to consider strength to weight in skeletal structure, improved muscle-tendon-bone attachments, improved flexibility and lubrication of moving body parts, changed energy use and waste production, the physical size of the limbs, and the effects on lifespan of body parts and the individual. Table 7-3 considers a reasonable number of functions and points out areas of needed research. Much enabling technology for advances in human performance comes from materials specialists. Such advances include materials for structure and function to create artificial tissues, the ability to manipulate cells and add biochemical groups to them, and advances in microfluidics to allow precision release of physiologic and pharmacologic molecules. Embedded sensor, analog, and logic circuitry (smart materials) will be needed.

TABLE 7-2 Current Human Enhancements and the Materials Enhancements They Depend On

|

Human Enhancement Technology |

Materials Enhancement |

|

Contact and intraocular lenses |

Transparency, fluid biocompatibility |

|

Hearing aids |

Ear mold softness, microcircuits, batteries |

|

Cochlear prostheses |

Electrode compatibility |

|

Tooth implants |

Hardness, durability, anchoring |

|

Larynx implants |

Elasticity |

|

Silicone implants |

Biocompatibility, natural feeling |

|

Joint and bone replacements |

Hardness, durability, bone compatibility |

|

Artificial blood |

Membrane permeability, ductility |

|

Vascular pumps, implants, and stents |

Vascular lining, flexibility |

|

Renal dialysis |

Membrane permeability |

TABLE 7-3 Human Body Functions That Could Potentially Be Enhanced and the Materials Advances Required

|

Body Function |

Materials Advances Required |

|

Locomotion/muscular activity |

Energy sources for muscles, electronic implants for muscle tone, increased structural integrity for tendons and bone: microfluidics, micromaterial engineering |

|

Nervous system control signals |

Understanding signal transmission and materials improvements for nerves: tissue engineering |

|

Energy management |

Energy uptake, enhanced long-term delivery to tissue, improved waste removal: molecular coatings, enhanced excretion |

|

Oxygen management |

Improved gas exchange for uptake and excretion, artificial blood: surfactant development, tissue surrogates |

|

Physical integrity |

Skin, eye, and mucous membrane protection: tissue integrity, protection from radiation |

|

Thermoregulation |

Heat retention and rejection, energy recycling: smart materials that recognize the external environment |

|

Cognition/mental states |

Energy and toxin management for the central nervous system: drug delivery systems |

To take advantage of the advances in materials technology in the area of human performance, there needs to be an interactive review of the issues and an awareness of the possibilities. Human performance specialists need to provide materials specialists with information on limiting factors. This may require new studies to better define the limitations. For example, physiologists should be able to determine if supranormal walking endurance will be limited by delivery of oxygen and energy or buildup of lactic acid. In a complementary fashion, advanced materials need to be described to physiologists so that they can contemplate how to take advantage of the advances. Human performance enhancement as a new area of work particularly needs an informed multidisciplinary approach. A specific forum must be created to take the specialists beyond their academic disciplines or even the disease mitigation mindset (i.e., research in medicine) and give them the information to be creative.

RESEARCH AND DEVELOPMENT PRIORITIES

Biology can affect every area of DoD needs of the next several decades. In some areas, i.e., improved battlefield medicine and biological warfare agent identification or interdiction, solutions may be found in specific biological molecules, cells, or systems; in other cases, i.e., smart materials or lightweight structural materials, biology may point the way to improved strategies for material design and synthesis. Where biological molecules or cells are the active component of a device, the challenge to the materials community is not only incorporation of the sensing entity but, perhaps more important, the preservation of biological function in a nonbiological environment. The common theme for all these technologies, research areas, and applications is using biological paradigms to solve problems of materials design, materials synthesis, and system assembly.

The panel selected the following research and research management priorities as critical for realizing the opportunities for bioinspired and bioderived materials research for meeting future defense needs.

Improving Fundamental Understanding of the Relationships Between Biological Structure, Properties, and Evolution and Materials Design and Synthesis

Recent studies of biological systems have clearly shown that large numbers of molecules, structures, and systems in living organisms possess

attractive materials properties that are beyond the reach of current nonbiological synthetic approaches. Examples are as follows:

-

The natural fabrication processes of hierarchical, systems-oriented biological structures, spanning the size range from nanometers to the macroscopic, lead to impressive and highly desirable performance.

-

The combination of mechanical properties displayed by bone and the instantaneous, highly selective, single-molecule sensitivity of biosensing systems on cell membranes are two examples of the attractive properties and performance of hierarchical, biological systems.

-

Many molecules, structures, systems, and natural fabrication processes have the potential to serve as the basis for materials with enhanced properties for defense applications, either directly adapted or as a pattern for nonbiological mimics.

Increasing Communication of DoD Material Needs to Biological and Physical Scientists

Progress at the interface between biological and physical scientists is hampered by educational differences and a general lack of communication, especially the lack of communication of DoD materials needs to the biological community. Biology offers a rich source of strategies for solving material problems; conversely, the materials science paradigm offers a systematic methodology for identifying biologically relevant materials. Increasing communication across disciplinary boundaries is likely to produce dramatic benefits to both communities.

Basic Research into Biological Molecules, Structures, Systems, and Processes to Lay the Groundwork for Their Use, or Their Use as Models, in Serving the Materials Needs of DoD

Fundamental understanding of the relationships between biological structure, properties, and materials synthesis is required if DoD is to take advantage of any new bioinspired or bioderived material. Biological toughening of materials, as exemplified by nacre, tendon, and bone, offers useful models for the next generation of armor/damage-resistant materials. Biological control of primary structure and the resultant enhanced perfor-

mance, as exemplified by the toughness of dragline silk, is a paradigm for materials by design.

Identification and Development of Biocompatible Materials to Enable in Vivo Implantable Devices

In vivo detection strategies to identify toxins and pathogens, including masked agents, may enable the detection of a single agent molecule. New materials for implantable, multifunctional, and tissue-interactive devices are required: Emphasis should be placed on materials for the microfluidic movement of biologically active molecules to specific tissues and on materials to interface with electrically active tissues.

Development of Packaging Technologies to Preserve the Biological Function of Biologically Enabled Devices

Preservation of the biological function of biological molecules is a key driver for the next generation of biologically enabled devices. Because current strategies are inadequate, this area must have high priority.

REFERENCES

Aizenberg, J., A.J. Black, and G.M. Whitesides. 1998. Controlling local disorder in self-assembled monolayers by patterning the topography of their metallic supports. Nature 394(6696):868-871.

Albert, J.T., O.C. Friedrich, H.E. Dechant, and F.G. Barth. 2001. Arthropod touch reception: Spider hair as rapid as touch detectors. J. Comp. Phys. A—Sens. Neural and Beh. Phys. 187(4):303-312.

Barth, F.G. 2002. A Spider’s World: Senses and Behavior. Berlin: Springer-Verlag.

Bashir, R., R. Gomez, A. Sarikaya, M.R. Ladisch, J. Sturgis, and J.P. Robinson. 2001. Adsorption of avidin on microfabricated surfaces for protein biochip applications. Biotechnology and Bioengineering 73(4):324-328.

Chen, T., S.C. Barton, G. Binyamin, Z. Gao, Y. Zhang, H. Kim, and A. Heller. 2001. A miniature biofuel cell. J. Am. Chem. Soc. 123(35):8630-8631.

Christel, L.A., K. Petersen, W.A. McMillian, and M.A. Northrup. 1998. Rapid, automated nucleic acid probe assays using silicon microstructures for nucleic acid concentration. Journal of Biomedical Engineering 121(1):22-27.

Desai, T.A., D.J. Hansford, L. Kulinsky, A.H. Nashat, G. Rasi, J. Tu, Y. Wang, M. Zhang, and M. Ferrari. 1999. Nanopore technology for biomedical applications. Biomedical Microdevices 2(1):11-40.

Gentzkow, G.D., S.D. Iwasaki, K.S. Hershon, M. Mengel, J.J. Prendergast, J.J. Ricotta, D.P. Steed, and S. Lipkin. 1996. Use of dermgraft, a cultured human dermis, to treat diabetic root ulcers. Diabetes Care 19(4):350-354.

Germain, L., and F.A. Auger. 1995. Tissue engineered biomaterials: Biological and mechanical characteristics. Pp. 699-723 in Encyclopedic Handbook of Biomaterials and Bioengineering, Part B: Applications, Vol. 1, D.L. Wise, ed. New York: Marcel Dekker.

Harrison, D.J., A. Manz, Z. Fan, H. Ludi, and H.M. Widmer. 1992. Capillary electrophoresis and sample injection systems integrated on a planar glass chip. Anal. Chem. 64(17):1926-1932.

Heringdorf, F.J.M.Z., M.C. Reuter, and R.M. Tromp. 2001. Growth dynamics of pentacene thin films. Nature 412(6846):517-520.

Kaplan, D.L. 2002. Spiderless spider webs. Nature Biotechnology 20:239-240.

Koehl, M.A.R., J.R. Koseff, J.P. Crimaldi, M.G. McCay, T. Cooper, M.B. Wiley, and P.A. Moore. 2001. Lobster sniffing: Antennule design and hydrodynamic filtering of information in an odor plume. Science 294(5548):1948-1951.

Lakes, R.1993. Materials with structural hierarchy. Nature 361(6412):511-515.

Lazaris, A., S. Arcidiacono, Y. Huang, J.F. Zhou, F. Duguay, N. Chretien, E.A. Welsh, J.W. Soares, and C.N. Karatzas. 2002. Spider silk fibers spun from soluble recombinant silk produced in mammalian cells. Science 295(5554):472-476.

McKenzie, I., R. Jones, I. Marshall, and S. Galea. 2000. Optical fibre sensors for health monitoring of bonded repair systems. Compos. Struct. 50(4):405-416.

National Research Council. 2001. Opportunities in Biotechnology for Future Army Applications. Washington, DC: National Academy Press. Available online at <www.nap.edu/catalog/10142.html>. Accessed January 15, 2002.

Siegel, R.W. 1993. Exploring mesoscopia—The bold new-world of nanostructures. Physics Today 46(10):64-68.

Wainwright, S.A., W.D. Biggs, J.D. Currey, and J.M. Gosline. 1982. Mechanical Design in Organisms. Princeton, NJ: Princeton University Press.

Wise, D.L. 2000. Biomaterials and Bioengineering Handbook, D.L. Wise, ed. New York: Marcel Dekker.