Management of High-Level Radioactive Wastes from the Mayak Production Association and Plans for the Creation of an Underground Laboratory*

Yu. V. Glagolenko

Institute of the Geology of Ore Deposits, Petrography, Mineralogy, and Geochemistry

Russian Academy of Sciences

VITRIFICATION TECHNOLOGY

In accordance with the Russian policy on solidification of high-level radioactive wastes, our enterprise has conducted a program for the creation of a complex for the vitrification of high-level liquid wastes. Implementation of this program has involved the following stages:

-

1969–1971: creation of laboratory facilities for the solidification of solutions in a glass furnace using direct electrical heating

-

1973–1977: testing of pilot facilities using model radionuclide-labeled solutions

-

1986–1988: start up of the complex and regular operation of the first electric furnace

-

1991–1997: regular operation of the second electric furnace

-

2001: regular operation of the third electric furnace

The first unit of the vitrification shop included two EP-500 electric furnaces, each capable of processing 500 liters of solution per hour. One furnace, which was put into operation in 1986, was used for one year and then shut down due to contamination of the water-cooled current feeds of its molybdenum electrodes. During its period of operation, the unit processed 997 cubic meters of high-level wastes with an activity of about 4 million curies.

The operation of the electric furnace revealed a number of shortcomings in its design, primary among which were the less-than-optimal location of the electrode racks and their inefficient cooling. These factors led to the unplanned shutdown of the first electric furnace and the reconstruction of the backup unit.

Trial run operations in the vitrification section began in September 1990, and in January 1991 the rebuilt EP-500/1-r furnace was put back in operation. Tests on model solutions were conducted over the next six months, and in July 1991 the unit began processing high-level wastes, with these operations continuing for five and a half years. The second unit in the vitrification section, which included two electric furnaces—EP-500/3 and EP-500/4—was put into operation in 2001.

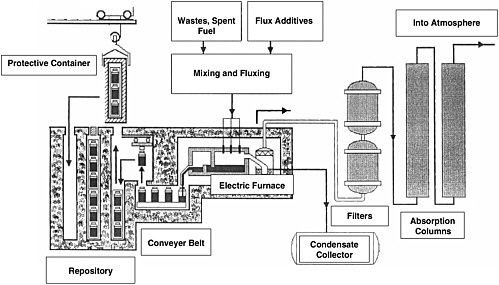

The design for the vitrification section is based on the process of electric arc melting of phosphate glass from waste solutions and flux additives in an electric glass furnace using direct electric heating. As illustrated in Figure 1, the basic technical outline of the process for the vitrification of high-level radioactive wastes includes the following elements:

-

solution preparation section, including a chain of various containment vessels

-

vitrification section, including an electric furnace with systems for solution correction, glass pouring, power supply, and cooling

-

gas treatment section, consisting of a number of gas cleaning devices and filters

-

transport section, including a moving conveyer, a chamber for the assembly of cases, and a protective shield

-

storage facility for the vitrified wastes

The technical process is carried out as follows. Liquid radioactive wastes from the repository go into a vessel where the solutions are prepared for processing. In this vessel the solution mixture is brought to a specific standard through the addition of calculated amounts of phosphoric acid and sodium nitrate. After being prepared in this manner, the solution is transferred through a number of vessels into an automated displacement elevator, from which the solution flows into the electric furnace directly onto the surface of the molten glass. At the same time that the radioactive waste solution is released into the furnace, the solution is dosed with a reducing agent (ethylene glycol) in order to create a loose foamy layer on the molten surface and reduce unwanted movement of radionuclides.

When the solution contacts the molten surface, there follows a sequence of processes by which the solution is turned to steam, the salts are dried and denitrated, and the oxides are melted. The resulting steam gas mixture moves through a gas pipe into the gas treatment system, which consists of the following devices: a sparger-refrigerator, crude and fine purification filters, ruthenium tetroxide extraction columns, and a fine purification filter and an absorption

column for extracting nitrates. The treated gases are then discharged through a pipe into the atmosphere, while the condensate that has accumulated in the sparger-refrigerator is sent for further processing to regenerate the nitric acid.

The molten glass is then transferred through the forehearth into an accumulation zone. As it builds up, the glass is periodically poured into 200-liter containers. The containers are filled with a pouring device and then the filled vessels are moved to a packaging chamber with the help of a conveyer belt. In the packaging chamber the glass-filled containers are packed in steel cases, three to a case. The case lids are hermetically welded shut, after which the cases of glass-filled containers are put into another protective housing and then placed in the repository. The repository is made up of a network of concrete emplacement holes. Each hole holds two cases, around which cooling air is circulated.

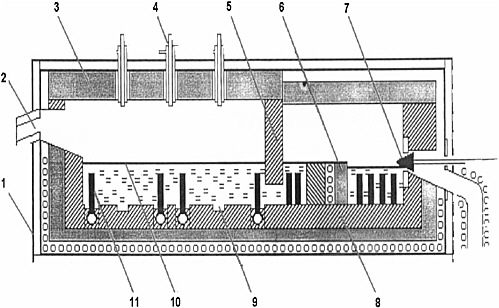

The design of the basic electric glass furnace device is shown in Figure 2. The furnace is a rectangular basin constructed of baddeleyite-corundum beams. The interior of the baddeleyite-corundum walls is lined with blocks and bricks made from clay-fired refractory material. The vault is composed of fire-resistant concrete. The furnace is housed in a hermetically sealed stainless steel structure. The space between the fire-resistant casing and the furnace structure is filled with quartz sand and refractory chips. Below the unit and up to the level of the molten glass, the side walls of the furnace structure are equipped with water-cooled refrigeration pipes.

The interior of the basin is divided into three zones for melting, transfer, and accumulation. The lower part of the partition has two transfer channels, through which the molten glass moves from the melting zone into the transfer and accumulation zones. The transfer zone is separated from the accumulation zone by a skimmer block that serves to keep the glass in the melt zone at a constant level. The lower part of the accumulation zone features two pouring devices, one for regular use and one backup unit. In the lower part of the melting zone there is a water-cooled gas pipeline that links the furnace with the sparger-refrigerator. The input solution in the electric furnace is dosed out by means of three water-cooled feeders installed in the vault.

Electricity is supplied to the furnace through water-cooled tubular stainless steel cables with attached molybdenum electrodes in the form of cylindrical bolts. In the melt zone there are two pairs of current feeder cables, each with 10 electrodes, while the transfer zone has one pair with two electrodes per cable and the accumulation zone has one pair with four electrodes per cable. The technical characteristics of the electric furnace are presented in Table 1.

From the start of operation until May 2003 the complex processed 15,331 cubic meters of fluxed high-level radioactive solutions with a total activity of 364 million curies and produced 2946 metric tons of aluminophosphate glass. The volume and activity of the vitrified high-level wastes are shown in Table 2.

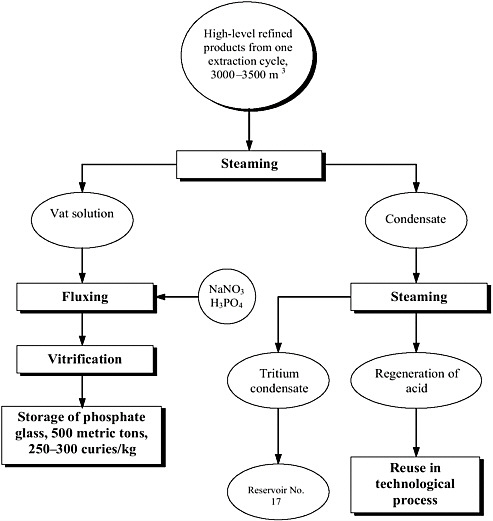

The current technological set-up for the processing of high-level wastes is illustrated in Figure 3. The refined products formed as a result of extraction

TABLE 1 Technical Characteristics of the EP-500/1-r Electric Furnace

|

Parameter |

Value |

|

Solution processing capacity |

400–450 liters per hour |

|

Solution input |

Continual |

|

Glass output |

Periodic, 500 kilograms per pour |

|

Melt temperature |

Up to 1200°C |

|

Required power, in kilowatts |

|

|

Melt zone |

Up to 500 |

|

Forehearth zone |

Up to 20 |

|

Accumulation zone |

Up to 120 |

|

Dimensions, in meters |

|

|

Length |

9.55 |

|

Width |

4.20 |

|

Height |

3.20 |

|

Area of melt surface, in square meters |

|

|

Melt zone |

10.7 |

|

Forehearth zone |

0.8 |

|

Accumulation zone |

2 |

|

Level of melt, in millimeters |

|

|

Melt zone |

350 |

|

Forehearth zone |

350 |

|

Accumulation zone |

240–350 |

|

Water used for cooling, in cubic meters/hour |

180–200 |

TABLE 2 Volume and Activity Data for Vitrified High-Level Radioactive Wastes

|

Period of Operation |

2/10/1987–2/20/1988 |

1/9/1991–1/4/1997 |

6/20/2001–5/4/2003 |

Totals |

|

Equipment model |

EP-500/2 |

EP-500/1-r |

EP-500/3 |

|

|

Solution processed (in cubic meters) |

998 |

11,460 |

2873 |

15,331 |

|

Total activity (in millions of curies) |

4 |

278 |

82 |

2200 |

|

Glass produced (in metric tons) |

162 |

2200 |

584 |

2946 |

processing of spent fuel are steamed to reduce their volume, with the remaining substances being fluxed with sodium nitrate and phosphoric acid and then sent to the EP-500/3 electric glass furnace. As a result, up to 500 metric tons of aluminophosphate glass with a total activity of 250–300 curies per liter are produced over the course of a year, with this glass being stored in a specially equipped aboveground repository. Condensates from the steaming of the refined products and from the process of vitrifying the fluxed solutions are transferred for regeneration of the nitric acid, which is reused in the technical process, while the tritium condensate is discharged into a storage reservoir.

The primary shortcoming of the existing system is the large volume of active glass that must be stored and the relatively low activity of the vitrified product. Therefore, prospects for the development of the high-level waste processing facility are tied to the use of recently developed partitioning technology that makes it possible to separate out the most ecologically dangerous radionuclides into discrete fractions. As a result of this separation the majority of the wastes may be categorized as mid-level, while the separated fractions of strontium-cesium and transuranic elements may be solidified using small-volume remote-controlled equipment. Modernization of the existing facility to incorporate the partitioning concept would make it possible to optimize the technological

FIGURE 3 Existing system for high-level radioactive waste processing.

system from an economic standpoint by minimizing high-level waste volumes and consequently reducing costs first for temporary storage and then for permanent burial of solidified partitioned wastes.

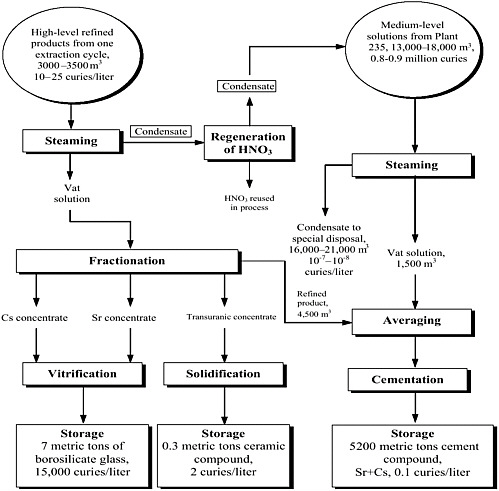

A promising design for this sort of system for high-level radioactive waste processing is presented in Figure 4. In accordance with this system the high-level wastes are first steamed and then subjected to preliminary processing using fractionation technology. The separated fractions of strontium, cesium, and transuranic elements are solidified into borosilicate glass in the amount of 7.0–7.5 metric tons per year with a total activity of up to 15,000 curies per liter and into mineral-like ceramic (monazite) in the amount of 300 kilograms per year with a total activity of 2 curies per year for alpha radionuclides. One special feature of the system is its capacity for simultaneously processing mid-level refined prod-

FIGURE 4 Promising system for processing high-level and medium-level wastes using preliminary fractionation.

ucts from the fractionation process and mid-level wastes from the fuel element processing plant by vitrification in the EP-500 electric furnace, with the output being blocks of aluminophosphate glass with an activity of no more than 1.2 curies per liter for strontium and cesium. Plans call for blocks of highly thermal-resistant borosilicate glass produced by this process, as well as ceramic compound containing transuranic elements, to be stored in geological formations, while the aluminophosphate glass is to be first held for temporary storage and then sent for burial in a near-surface sarcophagus.

The aluminophosphate glass, which contains 23–26 percent sodium oxide by mass, 14–19 percent aluminum oxide by mass, and 52–54 percent phosphorus oxide by mass, is characterized by a sodium-leaching rate of 10−5–10−6 g/cm2/hour. Comparative tests of samples of borosilicate and aluminophosphate glasses conducted in 1994 by specialists from the Savannah River Technology Center showed practically identical results for the leaching of the basic matrix components.

In addition to monazite, researchers are currently studying titanates, zirconotitanates, and aluminosilicates, all of which include radioisotopes in their crystal structures through the isomorphic replacement mechanism, as possible highly resistant mineral matrixes for actinide and rare earth elements. Also effective for the immobilization of actinides are mineral matrixes composed of zirconolite and murataite, which are three orders of magnitude more mechanically stable than aluminophosphate glasses.

PLAN FOR AN UNDERGROUND LABORATORY AT THE MAYAK PRODUCTION ASSOCIATION

From the 1960s through the 1980s specialized geological survey organizations carried out comprehensive prospecting studies in areas adjoining the Mayak Production Association in northern Chelyabinsk Oblast to search for geological formations that would be suitable for the burial of liquid radioactive wastes. As a result of experimental studies it was concluded that this area lacked the necessary geological conditions for ensuring the reliable isolation of such wastes. The question of storing liquid wastes at Mayak is not currently under consideration.

In order to implement the end stage of the technology for managing radioactive wastes, a concept for the deep burial of solid radioactive wastes in geologic formations is being developed at Mayak in accordance with the Unified Federal Targeted Program for Russia’s Nuclear and Radiation Security (2000–2006).

Underground burial is deemed the most environmentally, technically, and economically rational means of reliably isolating radioactive wastes from the ecosphere for the entire period during which they might present a potential radiobiological danger. This method makes it possible to guarantee a socially acceptable risk level in all instances with regard to possible releases of radionuclides into the sphere of human habitation regardless of cause.

Using real operating data provided by Mayak, the All-Russia Scientific Research and Design Institute for Industrial Technology (VNIPIPromtekhnologia) and the Russian Academy of Sciences Institute of the Geology of Ore Deposits, Petrography, Mineralogy, and Geochemistry are currently analyzing various options for managing wastes from spent fuel reprocessing. They are also making a comparative assessment of the ecological safety of permanently isolating radioactive wastes underground, taking into account their content of the most dangerous long-lived radionuclides, the formation of daughter radionuclides, and the dynamics of changes in the total heat exchange of various waste fractions.

To date, researchers have completed initial geological, geophysical, and hydrogeological studies with regard to the selection and evaluation of promising sites for the construction of deep underground storage facilities in accordance with existing regulatory requirements for the safe burial of radioactive wastes. The basic conclusions drawn from the results of this research are as follows:

-

The geological environment of the region surrounding Mayak is well studied to a depth not exceeding 200 meters.

-

The volcanic andesite-basalt rocks that make up the central block of the sanitary-protective zone at the Mayak site are suitable for the reliable isolation of radioactive wastes. They have low effective porosity (~0.2–0.4 percent) and high mechanical and thermal resistance.

-

The Mayak area is characterized by intensive but irregular tectonic violation. In the least violated geologic blocks, which are located between major faults, two areas have been identified as promising potential locations for an underground laboratory and subsequently as a radioactive waste isolation site.

The following areas for future work have been defined for the next stage in the process of creating a site for the deep burial of radioactive wastes:

-

detailed study of promising sites, to be conducted with the help of test wells and a range of intrawell, site, and deep-level geophysical studies

-

evaluation of the tension-deformation status of the sites at depths where the future underground laboratory would be located and reconstruction of the tectonic-dynamic situation in the geologic past

-

creation of a geodynamic model of the Mayak region and evaluation on this basis of the probable development of tectonic processes during the timeframes required for the long-term isolation of high-level radioactive wastes

-

determination of a site for the placement and construction of an underground laboratory

The main objectives for constructing an underground laboratory lie in establishing the correctness of design solutions being developed with regard to the burial of radioactive wastes in promising sites within rock formations and con-

firming in practice that the input data being used are reliable and well founded. The comprehensive research being carried out in the laboratory must provide adequate information and quantitative parameters on the isolation capacities of the rock environment and the engineering barriers to be constructed, make recommendations on the optimization of technological processes, and resolve fundamental problems regarding the management of solidified radioactive wastes, methods of their isolation, and the interaction of wastes with the environment.

Regardless of the design for the facility, scientific research work in the underground laboratory is to include the following, as well as other topics:

-

provision of a repository for vitrified wastes

-

detailed studies aimed at proving that the site selected and the types of rocks surrounding it meet the demands necessary for ensuring the reliable isolation of wastes

-

study of the thermal, mechanical, and sorption properties of the surrounding rock

-

determination of the physicomechanical parameters of the structural-tectonic blocks, evaluation of lithostatic and tectonic violations, and study of the condition of the rock massif and underground structures under the influence of natural and man-made factors

-

study of the effect of technological burdens (thermal, radiation, and chemical impacts) on the condition of the rock massif and on heat and mass transfer conditions

-

study of the isolation capacities of various materials and engineering barrier designs under the influence of natural and engineered factors

-

experiments on the distribution of nuclides within the selected site in the rock massif after the burial of real wastes

-

study of the behavior and stability in real conditions of forms of solidified wastes and their packaging

-

study and evaluation of the qualities, means, and methods of controlling processes within the rock massif

-

development of equipment and technology for managing wastes and isolating them in real underground conditions

During the period of construction and operation of the underground laboratory, personnel are to make and further develop technical decisions on the design of the underground solidified waste sarcophagus and the entire cycle of operations from the delivery of wastes until their final isolation.

VNIPIPromtekhnologia has recommended to Mayak a well-type underground laboratory that would serve as a center for the development of technologies for the underground isolation of solidified radioactive wastes from radiochemical plants and of spent nuclear fuel. Considering the complexity of the geological and hydrogeological conditions in the volcanogenic sedimentary com-

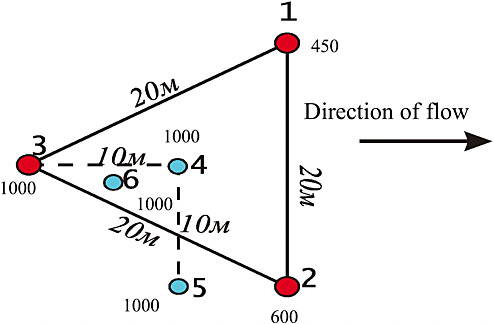

FIGURE 5 Plan for the location of test wells for the experimental laboratory.

plex of rocks that has developed in the Mayak region, a group of wells should be drilled within the promising site. One option for their possible placement is shown in Figure 5.

One important task for the laboratory is to study the process of the migration of products due to leaching from the repository. Therefore, a technical well (well 1) and observation wells (wells 2–6) must be placed, taking into account the most likely direction of underground water movement.

In the first stage, wells 1, 2, and 3 are to be drilled at the corners of an equilateral triangle in order to determine the direction of filtration of water in underground crevices at depths of more than 250 meters. All wells are therefore to be drilled from 0 to 300 meters at an initial diameter of 214 millimeters and cased with fully cemented 194-millimeter steel columns.

From 300 to 450 meters (well 1) and 300 to 600 meters (wells 2 and 3) the wells are to be drilled at a diameter of 151 millimeters without casing.

In the second stage, after the direction of natural flow filtration is determined, wells 4 and 5 are to be drilled, one in the direction of underground water flow movement and the other perpendicular to it. From the depth of 0 to 300 meters they are initially to be drilled at a diameter of 132 millimeters. This interval is to be cased with a fully cemented 127-millimeter steel column. From 300 to 450 meters the well diameter is to be 112 millimeters with the bore remaining open.

After geomigration studies are completed, wells 3, 4, and 5 are to be drilled to a depth of 1000 meters. Detailed experimental filtration and geomigration studies are conducted on the open part of the cut. Based on the results of hydrochemical and radiochemical research, studies are to be made on the effective rate of flow of underground water through fractured zones, the sorption properties of rock with regard to particular isotopes, and the migration of radionuclides in underground water under specific geological conditions. For this purpose, well geophysics methods (thermometry, gamma well logging, and resistivity measurement) will be used, and water samples will be taken for chemical and radiochemical analysis.

On the basis of the data obtained, mathematical models will be prepared along with forecasts of the migration of specific isotopes in particular zones of increased permeability within the rock massif.

Another aspect of no small importance is the study of thermal physical processes associated with the underground isolation of high-level radioactive wastes. The rock will be heated at specified depths, with the temperature regime and condition of the rock to be monitored. This will also facilitate a study of mass transfer and of the destruction of the rock under the influence of increased temperatures under natural conditions. After completion of a study of hydrodynamic characteristics and migration parameters of the filtration zones in the massif, well 3 will be turned into a technical well, which will serve as the location for the heat source, and wells 4 and 5 will be turned into observation wells. Well 6 will be drilled at a distance of 5 meters from the technical well with the same design features as wells 4 and 5.

To facilitate the study of the process of leaching of radioactive products by underground water, the technical well could be equipped with matrices containing either imitation high-level wastes or real vitrified wastes. This process would be monitored using observation wells 4, 5, and 6. Wells 1 and 2 will become research wells for application with a number of technological issues.

During the drilling efforts, detailed descriptions of the cores will be made, and samples will be taken to determine the content and physical, mechanical, and geochemical properties of the rock. A series of hydrogeological studies, for example, evacuation, discharge, and water sampling for chemical analysis, and geophysical studies, for example, stationary types of well logging, alpha well logging, gamma-gamma well logging, expenditure measurement, and resistivity measurement, are to be carried out in each well.

Completing the necessary temperature and radiation measurements and evaluations of violations in the rock massif requires creating a multichannel monitoring system that is adequate to handle both the quantity of simultaneously measured parameters and the types of measurements needed. Information collected from the measuring instruments must go to a central control point, with the results to be recorded in a form that is convenient for further processing.

The following two options are under consideration to facilitate obtaining the necessary information from the observation wells:

-

installation of a stationary system of sensors that could be replaced by an analog system if necessary

-

collection of measurements using well logging methods

The equipment at ground level must be designed to ensure the ability to raise and lower instruments into the wells and to provide for uninterrupted observation capabilities over a long period.

Research and development efforts regarding the lowering of vitrified waste cases are to be carried out in well 2, which is to be equipped with mechanisms for raising and lowering objects. The design and technical characteristics of these mechanisms must ensure not only the accident-free lowering and placement of the cases in the well hole but also their extraction for the necessary studies after a given period of time has passed.

After the raising and lowering operations are fully studied, research can then be conducted on the technology for applying buffer materials for isolating containers of radioactive waste.

Studies are planned regarding the physical-chemical processes occurring during the storage of wastes in a well with the aim of discovering possible changes in the physical-chemical and physical-mechanical properties of the environment in the “case-well-rock-liquid phase” system. Research is being carried out under natural and laboratory conditions. Objectives for the laboratory research include the following:

-

verification of predictive data on gas separations during the underground waste storage process

-

detection of changes in rock properties due to the effects of radiation

The following work is required to develop predictive assessments and ensure that the necessary data are available for the project:

-

determination of the threshold dose at the start of surface destruction of minerals and evaluation of the permissible time of exposure at various doses

-

study of the effect of temperature and irradiation on the physical-mechanical properties of various types of rock

-

study of the transformation of water content during irradiation and at temperatures from 20 to 200°C

-

study of a group of minerals and their compositions in the aim of using them as barriers to isolate the cases of wastes from the surrounding geological environment

Plans call for collecting initial data under natural conditions regarding the stability of construction materials under the influence of various natural and engineered burdens. For this purpose samples of various materials, for example, steel and concrete, are to be lowered into well 1 and kept there for two to three years.

The following determinations must be made based on the results of the research to be carried out in the underground laboratory:

-

suitability of the selected site for the burial of solidified high-level radioactive wastes

-

basic design and technical elements to be used in the construction of a sarcophagus for solidified high-level wastes

If the results of scientific research conducted in it are positive, the underground laboratory could be turned into an experimental operations storage facility and later developed as the first component of a larger storage facility for solidified high-level wastes.

The underground laboratory is expected to be built in stages. The initial laboratory complex will include one group of wells (four 1000-meter wells, one 600-meter well, and one 450-meter well). Once the lab is in full operation, the scientific research program calls for three groups of wells as described above to be located in various points in the promising site.

Costs for the initial complex total about $2 million, with the entire underground laboratory complex to cost around $5 million.

Creation of the country’s first such laboratory will allow the facility to become a research and demonstration center that will promote the comprehensive study of problems associated with the underground storage of solidified radioactive wastes and the demonstration of technical solutions and underground waste isolation methods.