1

Introduction

BACKGROUND

At the request of Congress and the public, the Army is designing full-scale chemical agent destruction pilot plants that will use neutralization (hydrolysis) with water or caustic (NaOH solution) to destroy the stockpiled chemical munitions at Pueblo Chemical Depot (PCD), Colorado, and at Blue Grass Army Depot (BGAD) in Kentucky. This program, formerly called the Assembled Chemical Weapons Assessment program, is now the Assembled Chemical Weapons Alternatives (ACWA) program. In 2003, the Army issued a request for proposal (RFP) to design, build, operate, and close a full-scale pilot plant facility at Blue Grass Army Depot. A system contract was awarded to the Bechtel Parsons Blue Grass Team, a joint venture formed by Bechtel National, Inc., and Parsons Engineering. The teaming subcontractors are Battelle, General Physics, General Atomics, and the Washington Demilitarization Company. See Appendix A for a summary of the responsibilities of these participants.

In August 2003, as mentioned above, at the Army’s request, the NRC formed this committee to assist in the evaluation of the designs for full-scale chemical agent destruction pilot plants at PCD and BGAD.

This report contains the ACWA Design Committee’s current assessment of the initial design for the Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) supplemented by some information on the intermediate design. This chapter describes the ACWA program, the NRC’s role in the program, the characteristics of the chemical weapons stockpile and chemical agents stored at BGAD, and the design-build strategy required by the Program Manager for Assembled Chemical Weapons Alternatives (PMACWA) and being used by the contractor and presents a brief description of the design.

Assembled Chemical Weapons Alternatives Program

In 1996, in response to local opposition to the use of incineration, the U.S. Congress passed Public Laws 104-201 and 104-208 that (1) froze funds for construction of chemical agent destruction pilot plants at PCD in Colorado and at BGAD in Kentucky, (2) required the Army to demonstrate at least two alternatives to incineration to destroy assembled chemical weapons, (3) directed the Department of Defense (DOD) to establish a program with a program manager who was not previously associated with the Army’s chemical demilitarization program, and (4) required the Army to coordinate these activities with the NRC. This resulted in the creation of the ACWA program. In 1999, Congress passed Public Laws 106-79 and 106-52 requiring the Army to consider all feasible technology alternatives for destroying the chemical weapons at BGAD in Kentucky, where munitions containing both mustard and nerve agents are stored. The Defense Acquisition Board issued an Acquisition Decision Memorandum on February 3, 2003, that approved neutralization followed by supercritical water oxidation (SCWO) for full-scale pilot plant testing at BGAD. An RFP to design, build, operate, and close a chemical agent destruction pilot plant at Blue Grass was issued on February 7,

2003, and the Record of Decision (ROD), which documented the DOD’s selection of technologies for BGCAPP, was signed on February 27, 2003.1 The RFP and ROD specified that hydrolysis followed by SCWO was to be used and that all hazardous materials should be destroyed on site. The selection of all other unit operations was left to the RFP respondents. As mentioned above, the Army awarded the contract to the Bechtel Parsons Blue Grass Team, which submitted the initial design to the Army on July 29, 2004. However, this initial design was not made available to the ACWA Design Committee until early 2005 after it had passed operational security and International Traffic in Arms Regulations review.

Involvement of the National Research Council in the Assembled Chemical Weapons Alternatives Program

In response to the congressional guidance in 1997, the NRC formed the Committee on Review and Evaluation of Alternative Technologies for Demilitarization of Assembled Chemical Weapons (known as the ACW I Committee) to evaluate alternative technologies to incineration for the disposal of chemical stockpiles at PCD and BGAD (NRC, 1999, 2000). The Army subsequently requested that the NRC further evaluate ongoing ACWA program developments until technology selections for these sites were made. A second NRC committee, the Committee on Review and Evaluation of Alternative Technologies for Demilitarization of Assembled Chemical Weapons: Phase II (known as the ACW II Committee) was formed, largely from the membership of the ACW I Committee. This committee completed its work when technologies for the two sites were selected (NRC 2001a, 2001b, 2002a, 2002b, 2002c).

In August 2003, as mentioned above, at the Army’s request, the NRC formed this committee to assist in the evaluation of the designs for full-scale chemical agent destruction pilot plants at PCD and BGAD.

STATEMENT OF TASK

The Army requested that the NRC ACWA Design Committee review and evaluate the Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) and BGCAPP design plans. The committee published its first report, Interim Design Assessment for the Pueblo Chemical Agent Destruction Pilot Plant, in January 2005 (NRC, 2005). The current report presents an interim evaluation of the BGCAPP design based largely on the initial design and presentations made to the committee by the ACWA program staff and the Bechtel Parsons Blue Grass Team. The statement of task is as follows:

The Program Manager for Assembled Chemical Weapons Alternatives (PMACWA) has awarded contracts for the design, construction, systemization, pilot testing, operation and closure activities aimed at destroying the assembled chemical weapons stockpiles at the Pueblo Chemical Depot and Blue Grass Army Depot. Chemical neutralization-based technologies form the basis for destroying the agent and energetic materials associated with both stockpiles, along with new or adapted processes for preparing weapons for disposal and treating secondary waste streams generated during the primary neutralization processing step. These facilities differ from previously constructed baseline incineration facilities and from those constructed for bulk chemical agent disposal. To assist the PMACWA, the NRC will initially examine planning documentation and designs for the Pueblo and Blue Grass facilities and provide comments and recommendations. Separate reports will address the specific issues for each facility.

The NRC will:

-

Assess planning documentation for design and construction of the Pueblo and Blue Grass facilities.

-

Assess process and facility designs of the Pueblo and Blue Grass Chemical Agent Destruction Pilot Plants.

-

Consider design issues raised by permitting considerations and public acceptability (e.g., design aspects of facility closure).

-

Produce reports within three months following the date the initial and intermediate designs are provided to the NRC for Pueblo and Blue Grass.

DESCRIPTION OF THE BLUE GRASS CHEMICAL MUNITIONS STOCKPILE

The munitions stored at the BGAD contain either GB, VX, or Levinstein mustard agent (H). Table 1-1 lists some of the physical properties of the pure chemical agents GB, VX, and pure distilled mustard, called HD. Table 1-2 lists the types and quantities of munitions stored at BGAD for each type of agent. Additional details and schematic drawings of the weapons stored at BGAD are provided in Appendix B.

Nerve agent VX is a low-volatility liquid that has a high boiling point and can adhere to surfaces for days or weeks. Nerve agent GB is a liquid with volatility similar to that of water and therefore evaporates relatively rapidly. These two nerve agents are highly toxic and lethal in both liquid and vapor forms. They are absorbed by respiration or skin contact and can kill in a

TABLE 1-1 Physical Properties of the Pure Forms of Chemical Agents at BGAD

|

Agent Characteristic |

Nerve GB |

Nerve VX |

Blister HDa |

|

Chemical formula |

C4H10FO2P |

C11H26NO2PS |

C4H8Cl2S |

|

Molecular weight |

140.10 |

267.38 |

159.08 |

|

Boiling point (°C) |

150 (extrapolated) |

292 (extrapolated) |

218 (extrapolated) |

|

Freezing point (°C) |

−56 |

≤ 51 |

14.5 |

|

Vapor pressure (mm Hg) |

2.48 at 25°C |

0.000878 at 25°C |

0.106 at 25°C |

|

Volatility (mg/m3) |

18,700 at 25°C |

12.6 at 25°C |

75 at 0°C (solid) 906 at 25°C (liquid) |

|

Surface tension (dynes/cm) |

26.5 at 20°C |

32.0 at 20°C |

43.2 at 20°C |

|

Kinematic viscosity (cSt) |

1.28 at 25°C |

12.26 at 20°C |

3.52 at 20°C |

|

Liquid density at 25°C (g/cm3) |

1.0887 |

1.0083 |

1.27 |

|

Solubility (g/100 g of distilled water) |

100; soluble in organic solvents |

5 at 25°C; best solvents are dilute mineral acids |

0.092 at 22°C; soluble in acetone, CCl4, CHCl3, tetrachloroethane, ethyl benzoate, ether |

|

Heat of vaporization (cal/g) |

82.9 |

71.8 |

94 |

|

Heat of combustion (cal/g) |

5,600 |

8,300 |

4,500 |

|

aThe blister agents are labeled H, HD, and HT. Mustard, the active ingredient in all these blister agents, is bis (2-chloroethyl) sulfide, or (ClCH2CH2)2S. HD, called the distilled mustard, is nominally pure mustard agent. H, often called Levinstein mustard, was approximately 70 percent pure mustard agent and 30 percent impurities at the time of manufacture. However, the stored H mustard agent has deteriorated over time and its physical properties are highly variable. H is the only form of mustard agent stored at Blue Grass Army Depot. SOURCE: Based on data provided to the ACWA Design Committee by the Army and drawn from Abercrombie, 2003. |

|||

matter of minutes by interfering with respiratory and nervous system functions.

Because GB is volatile, it presents the greatest respiratory risk to workers and the public, so munitions containing GB are usually destroyed first. At other storage sites, some munitions containing GB have been found to contain either a gel or crystals formed from the stabilizer added to the chemical agent. Thus, the munitions containing GB at BGAD could also contain crystals or gel.

Mustard blister agents are skin vesicants that evaporate very slowly.2 Mustard agent is hazardous on contact or as a vapor. Mustard agent is only slightly soluble in water and is very persistent in the environment. The active ingredient is bis(2-chloroethyl) sulfide, (ClCH2CH2)2S, called HD. H is approximately 70 percent HD and 30 percent impurities formed during the synthesis process. These impurities are polysulfides such as (ClCH2CH2)2Sn, where n = 2, 3, and other compounds containing sulfur. The mustard agent munitions at BGAD contain only the H form. Sampling of 155-mm H projectiles at other sites indicates that they contain agent material that is approximately 30 percent liquid and 70 percent solids.3 Current information on the constituents in these liquid and solid phases of the stored H can be found in Appendix C.

M55 rockets pose the greatest storage risk because each contains approximately 20 pounds of M28 propellant, a double-base propellant composed of nitroglycerine, nitrocellulose, plasticizers, a burn-rate modifier (lead stearate), and a stabilizer. The original

TABLE 1-2 Description of the Chemical Weapons in the BGAD Stockpile

|

Item |

Fill |

Quantity |

Agent per Munition (lb) |

Total Agent (tons, rounded) |

Energeticsa |

Energetics Weight per Munition (lb) |

Total Energetics Weight (tons, rounded) |

|

155-mm projectile, M110 |

H |

15,492 |

11.7 |

91 |

Tetrytol |

0.41 |

3 |

|

8-inch projectile, M426 |

GB |

3,977 |

14.4 |

29 |

None |

|

|

|

115-mm rocket, M55 |

GB |

51,716 |

10.7 |

277 |

Composition B, |

3.2 |

74 |

|

|

M28 propellant |

19.1 |

449 |

||||

|

115-mm rocket warhead, M56 |

GB |

24 |

10.7 |

0.13 |

Composition B |

3.2 |

0.035 |

|

155-mm projectile, M121/A1 |

VX |

12,816 |

6 |

38 |

None |

|

|

|

115-mm rocket, M55 |

VX |

17,733 |

10.1 |

89 |

Composition B, |

3.2 |

26 |

|

|

M28 propellant |

19.1 |

154 |

||||

|

115-mm rocket warhead, M56 |

VX |

6 |

10.1 |

0.03 |

Composition B |

3.2 |

0.0086 |

|

aSee Table 4-2 for a complete listing of the energetics compositions. SOURCE: Adapted from data provided to PMACWA on the Munition Items Disposition Action System (MIDAS) by the MIDAS team in July 1997. |

|||||||

composition of the propellant is discussed in Chapter 4. In storage, the propellant slowly decomposes exothermically, forming nitrogen dioxide, which in turn can catalyze further decomposition. The stabilizer reacts with the nitrogen dioxide and prevents the autocatalytic action. However, these munitions have been stored since the 1950s and 1960s and their stabilizer concentration continues to slowly decrease, increasing the risk of a catastrophic event as time goes by. The rocket body is partially fabricated of aluminum, which is susceptible to corrosion by GB, creating a situation that has resulted in agent leakage, also increasing the risk of autoignition (U.S. Army, 2002). Although M55 rockets present the greatest storage risk at BGAD, the risk of autoignition remains relatively low in comparison with other possible (and still low probability) accidental ignition events (U.S. Army, 2002).4 Historically, it has been observed that rockets containing VX are less likely to develop leaks than those containing GB. When routine inspections of the stockpile storage igloos reveal the presence of leaking rockets (or other munitions), the munitions are overpacked, stored, and handled separately. The leaking munitions for each agent will be destroyed at the end of the respective campaign for each munition type. Because the changeover from one agent to another is expensive and lengthy, delaying leaker destruction until all nonleakers have been destroyed would require three additional agent changeovers and would not be reasonable.

A small number of M56 rocket warheads, the agent-containing portion of the M55 rockets, will be processed in the same way as M55 rockets. Since the M56 warheads have no propellant (or rocket motor), the only energetic materials in the M56 rocket warhead sections are those in the bursters and in the fuzes (see Table 4-2).

The only projectiles stored at BGAD that have any energetic materials are the 155-mm H-filled projectiles, which have a tetrytol burster but no propellant. Neither the 8-inch projectiles containing GB nor the 155-mm projectiles containing VX have any energetic materials. Besides munitions, a large amount of secondary waste, including dunnage and wastes generated by process operations, maintenance activities, and facility closure must also be processed at BGCAPP. Tables 1-3 and 1-4 itemize the total amounts of process wastes and secondary wastes, respectively, that must be processed.

DESIGN STRATEGY FOR BGCAPP

The Army procurement contract for BGCAPP is similar to the one issued for PCAPP. It called for bidders to propose an integrated approach to the full scope

TABLE 1-3 BGCAPP Process Wastes (pounds)

TABLE 1-4 BGCAPP Secondary Wastes (pounds)

of necessary activities from design through construction, operations, and eventual decommissioning or closure of the facility. Taking the closure requirements into consideration in the design is expected to simplify and reduce the cost of the closure process.

The BGCAPP project is divided into three phases. For each phase, there is a contract and permit decision point. Phase I includes the design, construction, systemization, pilot testing, and demilitarization of GB contained in rockets and projectiles. Phase II includes the demilitarization of VX and H munitions, but some form of demonstration may be required before full-rate processing is permitted. In Phase III, the site is closed, which includes decontamination and decommissioning of all process equipment, systems, and structures.

As required by the contract, the activities of the

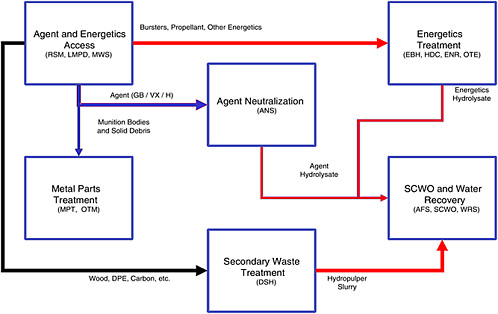

FIGURE 1-1 Block flow diagram for BGCAPP: ANS, agent neutralization system; DSH, dunnage shredding and handling; AFS, aluminum filtration system; WRS, water recovery system. SOURCE: Adapted from John Ursillo, BGCAPP Process Design/TRRP Manager, “Process design overview,” briefing to the committee on September 22, 2004.

Bechtel Parsons Blue Grass Team include all design, procurement, facilities construction, process components fabrication and testing, installation, systemization, operations, and eventual closure. Included are safety analysis, licensing and environmental permitting, technical risk assessment, using lessons learned from operations at other chemical agent disposal facilities, and interfacing with the local community concerning all of these activities.

SCOPE OF THE REPORT

This report primarily assesses the initial design (~30 percent complete design) for the BGCAPP. It is based on an initial design review held at Parsons in Pasadena, California, on August 2 and 3, 2004, and on presentations to the committee at its September 22-24 and November 17-19, 2004, meetings. The November meeting included a site visit to General Atomics in San Diego to observe an energetics batch hydrolyzer (EBH) and SCWO unit. Several members of the committee also attended two reviews of the intermediate design presented at Parsons on February 7-10, 2005, and at Aberdeen Proving Ground on February 15, 2005.

The available design information on the BGCAPP design was preliminary in nature. The omission of a discussion on particular aspects of this design should not be taken to suggest approval or disapproval by the committee.

BRIEF DESCRIPTION OF THE BGCAPP PROCESS

According to the initial design, and as depicted in Figure 1-1, the pilot plant entails six major processing steps to disassemble projectiles and rockets and to destroy the chemical agents and energetic materials: (1) chemical agent and energetic materials are accessed

by disassembling the munitions; (2) energetic materials are removed and destroyed by hydrolysis with caustic; (3) chemical agent is destroyed by hydrolysis with caustic or water; (4) the products of the hydrolysis of the chemical agent and energetic materials, called hydrolysates, are then treated further by SCWO; (5) metals and other solids are decontaminated by heating; and (6) other potentially hazardous wastes are shredded, converted to a slurry, and treated by SCWO.

Unpack Area

The munitions are transported from their storage igloos in enhanced onsite containers to the container handling building, where they are stored awaiting processing. Then they are moved to the unpack area, where they are removed from their pallets for processing on one of two lines: a rocket input line or a projectile input line. The munitions are separated into three feed streams: (1) liquid chemical agent and agent-contaminated wash water, (2) contaminated metal parts, and (3) energetic materials. The dunnage is processed separately.

M55 Rocket Processing

From the unpack area, each rocket, still in its firing tube, is individually conveyed to the punch and drain station in an explosion containment room. The machine punches holes in the top and bottom of the agent cavity to drain the agent from the warhead. The agent is sent to a storage tank in the agent neutralization area. A water jet flushes the remaining agent and any solids from the rocket. This wash water is also sent to the agent neutralization area. The drained and washed rocket, still containing energetics, is moved to the rocket shear machine (RSM) where it is cut into segments. These segments are then sent to the EBHs.

Projectile Processing

The projectiles with bursters are placed on trays in the unpack area and conveyed to the linear projectile/ mortar disassembly (LPMD),5 machine where each lifting lug is removed. This is followed by removal of the burster charge, which is then sent to energetics hydrolysis. The projectiles next proceed to the munitions washout system (MWS), where a hydraulically controlled ram forces and crimps the burster well into the projectile body, allowing the liquid agent to drain out. A high-pressure water jet on the ramming tool cleans out any remaining agent as well as any gel and crystals. The agent and contaminated water are sent to storage tanks in the agent neutralization area. The munitions bodies are returned to their tray and then conveyed to the metal parts treater (MPT), where they are heated to at least 1000°F for more than 15 minutes to destroy any remaining agent prior to release as decontaminated process waste. Projectiles without bursters are placed on trays in the unpack area and moved to a nose closure removal station and, subsequently, to the MWS for agent removal and to the MPT for decontamination.

Agent Neutralization

The agent and wash water are sent from their respective storage tanks to the agent neutralization stirred reactors (ANRs), where the combined streams are treated with caustic or hot water until the agent has been destroyed to the level required. The resulting solution, called hydrolysate, is sent to intermediate storage and then to the SCWO reactors for further treatment.

Energetics Treatment

Parts from rockets and projectiles containing energetic materials are conveyed from the RSM and LPMD to the EBHs, where the energetic material is hydrolyzed with hot caustic solution. The energetic hydrolysate is sent to the energetics neutralization system to complete the hydrolysis. Aluminum dissolved in the hydrolysate is removed by precipitation and filtration. The hydrolysate is then sent to intermediate storage, blended with agent hydrolysate, and finally then to the SCWO reactors for further treatment. Solids, including metal parts, not dissolved in the EBHs are carried to a heated discharge conveyor (HDC), where they are heated to over 1000°F for more than 15 minutes. Then, via a cooling conveyor, they are moved to a collection bin for head space sampling to verify that they are safe for discharge to an appropriate waste disposal site.

Offgas Treatment Systems

All process offgas streams flow through an offgas treatment system prior to release to the munitions de-

militarization building (MDB) heating, ventilation, and air conditioning (HVAC) system. There are three process offgas treatment systems in the BGCAPP: the MPT offgas treatment system (OTM) processes off-gases from the MPTs and ANRs; the energetics offgas treatment (OTE) system treats offgases from the EBHs, energetic neutralization reactors (ENRs), and HDCs; and the dunnage emission control system. Available details of the operation of each process offgas treatment system are reviewed in the respective chapters on the processes. The treated offgas and all other vapors and particulates generated in the MDB flow with the cascaded ventilation air to the MDB HVAC system activated charcoal filters. The filtered air is discharged to the atmosphere via the MDB ventilation stack.

Finding 1-1. Although preliminary designs have been completed for most BGCAPP systems, the committee could only partially evaluate the treatment systems for metal parts offgas and energetics offgas because the designs had not been fully resolved. Elements needing resolution include the type of bulk oxidizer and related equipment, redundancy in the systems, the handling of other related offgas streams (from ENRs and ANRs and hydrolysate storage tanks), and the location of the offgas system equipment.

Recommendation 1-1. The OTM and OTE designs should be resolved as quickly as possible since they are key elements in determining the layout of the MDB and its overall throughput performance.

Integrated Operation and Throughput Management

The various steps and associated hardware have been modeled in both a three-dimensional computer-assisted drawing and design mode and by an iGrafx Process 2003 modeling and simulation package for throughput analysis (Bechtel Parsons, 2004c). The three-dimensional design modeling is an ongoing activity to ensure constructability, operability, and ease of maintenance. It is used to support assumptions regarding operations and maintenance performance in the iGrafx throughput analysis. The throughput analysis is done early on to assist in establishing the number and availability of unit operations required to maintain the design throughput. The throughput analysis is especially important because BGCAPP combines batch processes and continuous processes.

Buffer storage has been added between nearly all the unit operations or process steps to optimize the throughput of the overall plant. For example, the initial design provides for over 2,000,000 gallons of hydrolysate storage capacity prior to treatment in the SCWO reactors. This peak storage need occurs when processing rockets at maximum throughput rates in Phase II. Considerably less capacity is required at other times. This buffer storage results from a consideration of the maximum processing rates for weapons and the time required to analyze the hydrolysate. These buffer storage requirements, including tanks and processing units, are elements of the overall design and are reflected in the three-dimensional computer-assisted drawing and design model.

To optimize throughput, several spare processing units have been included for critical units. For example, the MWS will have spare cavity access machines (CAMs), and only one of the two MPTs and brine recovery systems will operate at any one time. The five SCWO reactors operate continuously, but individual units must be taken out of service for periodic maintenance. Only four of the five units are used for hydrolysate processing. The fifth unit, for dunnage processing, can be used, if necessary, as a spare hydrolysate unit. Other redundancies are included wherever there are critical components.

The iGrafx Process 2003 is a modeling and simulation package that permits discrete-event evaluation of the duration of a process step, the capacity of the step, and the resources or activities of the step. It permits the analysis of timing, quantities, and maintenance data for each step of a process. While the iGrafx package was used to develop process rates and buffer requirements for each step of the process, availability analyses done for various process steps and the plant itself leave many questions unanswered.6 Train mechanical availability is the product of the assumed or measured mechanical availability of the various directly coupled subsystems affecting the train. For example, the train availability of the H projectiles is the product of the availabilities of coupling the LPMD to the EBH with the MWS, or 0.9 × 0.9 × 0.9 = 0.72, or 72 percent. As suggested by the example, the anticipated equipment availabilities are all essentially taken as 90 percent and are based on

TABLE 1-5 Overall BGCAPP Train Availability, Including Facility Shutdown

|

Period |

Campaign |

Train Mechanical Availability (%, rounded) |

Facility Availability (%) |

Overall Availablitya (%) |

||

|

Rocket |

Projectile |

Rocket |

Projectile |

|||

|

Shakedown and ramp-up |

GB |

69 |

81 |

90 |

62 |

73 |

|

Performance test |

|

69 |

81 |

90 |

62 |

73 |

|

Post-pilot |

|

69 |

81 |

75b |

52 |

61 |

|

Shakedown and ramp-up |

VX |

69 |

81 |

90 |

62 |

73 |

|

Performance test |

|

69 |

81 |

90 |

62 |

73 |

|

Post-pilot |

|

69 |

81 |

75b |

52 |

61 |

|

Shakedown and ramp-up |

H |

— |

73 |

90 |

— |

66 |

|

Performance test |

|

— |

73 |

90 |

— |

66 |

|

Post-pilot |

|

— |

73 |

75b |

— |

55 |

|

aIncludes planned facility shutdown. SOURCE: Adapted from Bechtel Parsons, 2004c. |

||||||

TABLE 1-6 Average Processing Rates, Including Train Availability

|

Period |

Campaign |

Peak Rate (rounds/hr) |

Train Mechanical Availability (%, rounded) |

Facility Availability (%) |

Average Processing Rates (rounds/hr, rounded)a |

|||

|

Rocket |

Projectile |

Rocket |

Projectile |

Rocket |

Projectile |

|||

|

Shakedown and ramp-up |

GB |

20 |

15 |

69 |

81 |

90 |

12 |

11 |

|

Performance test |

|

20 |

15 |

69 |

81 |

90 |

12 |

11 |

|

Post-pilot |

|

20 |

15 |

69 |

81 |

75b |

10 |

9 |

|

Shakedown and ramp-up |

VX |

24 |

26 |

69 |

81 |

90 |

15 |

19 |

|

Performance test |

|

24 |

26 |

69 |

81 |

90 |

15 |

19 |

|

Post-pilot |

|

24 |

26 |

69 |

81 |

75b |

12 |

16 |

|

Shakedown and ramp-up |

H |

— |

26 |

— |

73 |

90 |

— |

17 |

|

Performance test |

|

— |

26 |

— |

73 |

90 |

— |

17 |

|

Post-pilot |

|

— |

26 |

— |

73 |

75b |

— |

14 |

|

aThis rate is the expected plant average processing rate for each rocket or projectile line and considers the train mechanical availability and the facility availability. bIncludes planned facility shutdown. SOURCE: Adapted from Bechtel Parsons, 2004c. |

||||||||

projected availabilities of the various steps, some based on operational data from the Johnston Atoll Chemical Agent Disposal System and Tooele Chemical Agent Disposal Facility and some based on subsystem complexity and test data of the various pieces of hardware. In the latter case, most are engineering estimates from first-of-a-kind hardware that are marginally prototypical and certainly not demonstrated or proven in a continuous, integrated operational mode. Tables 1-5 and 1-6 indicate, respectively, overall train availability, including facility shutdown, and average processing rates, including train availability.

With regard to facility availability during normal operations, the throughput and availability analysis takes account of various external causes of downtime amounting to some 98 days per year (including holidays, sched-

uled and unscheduled maintenance, and externally caused shutdowns), or 75 percent maximum facility availability. However, because maintenance and adjustment requirements cause facility processing time to be curtailed to 40 percent during shakedown and ramp-up periods, additional facility-wide shutdowns are not expected later on, and the total facility availability is assumed to be 90 percent during these periods.

Finally, overall availability is the product of the two percentages, train and facility availability, for rockets and projectiles. When these availabilities are then applied to the peak processing rates given in Table 1-6, the average processing rates for rockets and projectiles are calculated as indicated. The weeks needed to process the inventory are derived from these numbers—allowing for various testing periods, ramp-ups, and changeovers.

Finding 1-2. The committee believes that the proposed schedule for operations at BGCAPP as an integrated, first-of-a-kind plant is probably unrealistically optimistic given the vagaries of small spills, process upsets, start-up integrations, shutdowns, difficult maintenance and repair procedures, and unplanned interventions.

Recommendation 1-2. The Army and its contracting team should be prepared to modify the operations schedule as design and construction proceed.

PERMITTING CONSIDERATIONS AND PUBLIC ACCEPTABILITY

Regulatory Permitting Activities

The National Environmental Policy Act (42 U.S.C. §§ 4321-4347) requires the preparation of an environmental impact statement (EIS) for federal actions that may affect the environment. The U.S. EPA has given the Kentucky Department of Environmental Protection (KDEP) authority to implement the National Environmental Policy Act process. The important steps include (1) issuing a Notice of Intent (NOI) to prepare an EIS, (2) preparing a draft EIS, (3) having a public comment period for the draft EIS, (4) preparing a final EIS, (5) issuing a Record of Decision (ROD), and (6) applying for a research, development, and demonstration (RD&D) permit.

An NOI to prepare an EIS for the design, construction, operation, and closure of a facility for the destruction of chemical agents and munitions at BGAD was posted in the Federal Register on December 4, 2000 (Federal Register, 2000). The EIS would examine potential environmental impacts of the following destruction facility alternatives: a baseline incineration facility, a full-scale facility to pilot test an alternative technology successfully demonstrated by the ACWA program, and no action (an alternative that would continue the storage of the chemical agent munitions at the BGAD). If any reasonable alternatives were identified during the environmental analysis process, they would be considered. The NOI indicated that incineration (also referred to as baseline incineration) has already been tested safely and successfully in full-scale facilities. Alternatives to baseline incineration for assembled chemical weapons destruction have been tested at the demonstration level, but not in pilot-scale or full-scale facilities. Furthermore, any alternative technology must be in accordance with Sec. 142 of Public Law 105-261, which requires three findings: (1) the alternative technology would have to be determined to be as safe as and as cost effective as baseline incineration, (2) it must also be capable of completing destruction of the stockpile by either the Chemical Weapons Convention destruction date or the date the BGAD stockpile would be destroyed if baseline incineration were used, whichever comes later, and (3) it must comply with federal and state health and safety laws.

In May 2002, KDEP released for public comment its draft EIS for the destruction of chemical agents and munitions stored at BGAD. The EIS considered the environmental impacts of no action, incineration, two neutralization technologies, and electrochemical oxidation. The final EIS, submitted in December 2002, incorporated all comments received on the draft. It considered four alternatives for the destruction of the BGAD stockpile: (1) baseline incineration, (2) chemical neutralization followed by supercritical water oxidation, (3) chemical neutralization followed by supercritical water oxidation and gas-phase chemical reduction, and (4) electrochemical oxidation. Based on the analyses in the EIS, KDEP could not say which of the four alternatives would be environmentally preferable. The EIS considered the overall impacts from chemical demilitarization activities to be minor.

The ROD, issued on February 27, 2003, by the deputy assistant secretary of the Army, documented DOD’s decision to approve neutralization (hydrolysis) followed by SCWO as the technology for full-scale pilot testing at BGAD. The ROD states: “A variety of

factors were considered in making this decision, including, but not limited to, mission needs, cost, schedule, environmental considerations, public and local community concerns, and compliance with the CWC.” The ROD accepts the statement in the EIS that “none of the four alternatives can be identified as environmentally preferable.” The reason given is that the impacts on land use, water use, process waste generation, air, and endangered species were judged to be similar and minor. The ROD does not provide any detail on the other factors the Army considered in making its decision (ROD, 2003).

The purpose of the full-scale pilot testing is to demonstrate that neutralization followed by SCWO, when operated at full scale, is capable of safely and effectively destroying the chemical agents and munitions bodies stored at BGAD. In making its decision, DOD considered all comments received during the scoping meetings, public meetings, and the public comment period associated with the preparation of the EIS. The ROD also noted that due to increased security concerns and a desire to increase the probability of meeting the extended Chemical Weapons Convention treaty destruction deadline, the Defense Acquisition Executive directed the ACWA program to investigate ways to accelerate the destruction of the chemical stockpile at BGAD.

Prior to submission of the RD&D permit application, the Bechtel Parsons Blue Grass Team held a public meeting on the contents of the application at Eastern Kentucky University on January 22, 2004. More than 120 people attended.

The RD&D activity described in the current permit application will be conducted iteratively with the development of the facility. Data will be directly fed back to the design team so that the information can be used to improve and validate the process.

In parallel with the RD&D activity and in accordance with the Clean Air Act, an air permit application for enclosed air at BGCAPP was submitted to the KDEP in September 2004. A separate stand-alone construction and Clean Air Act Title V operating permit for BGCAPP was requested to allow more effective management of the monitoring, record keeping, and reporting of air emission sources during construction and operations. A separate Title V Permit for BGAD would then be issued based on total air emissions from the existing BGAD operations, to include proposed BGCAPP operations. When BGCAPP operations are completed and the pilot plant’s Title V Permit and indoor air permit are rescinded, the permit for BGAD would not be affected—that is, the original permit would remain in effect.

Public Participation Outside the Formal Permitting Processes

There are several other mechanisms through which the public can be represented and its concerns addressed. They include the Blue Grass Chemical Stockpile Outreach Office (BGCSOO), the Kentucky Chemical Demilitarization Citizens’ Advisory Commission (CAC), and the Chemical Destruction Community Advisory Board (CDCAB).

The BGCSOO, located in Richmond, Kentucky, and supported by DOD, is dedicated to increasing public involvement. BGSCOO assists the community in obtaining information on all aspects of the chemical weapons stockpile. It offers a variety of resources to the public and provides a forum for the public to provide input.

The CAC is made up of nine members appointed by the governor of Kentucky. Seven are local citizens and two are representatives of state agencies that work closely with the chemical weapons disposal program. The CAC provides a link between the public and the Army. The members provide a local perspective to the Army so that the public is as actively involved as possible in the disposal program. The CAC has a statutory duty to advise the Army on chemical demilitarization at BGAD. Since doing so may be beyond the capabilities of the nine CAC members, the CDCAB was formed to provide assistance and advice on major policy issues. CDCAB is a diverse group that represents the views and concerns of the public regarding the disposal program. Its primary objectives are to keep the public informed and to guide it in decision making. CDCAB meetings are independently facilitated by the Keystone Center. By providing input from the community, CDCAB plays an important role in the ultimate decisions.

Voting members of the CDCAB include the members of the CAC and representatives of local government entities, boards of education, chambers of commerce, Eastern Kentucky University, Berea College, the Madison County Ministerial Association, banks, hospitals, the NAACP, environmental organizations, civic groups, and elected state officials.

Included as nonvoting members are representatives from BGAD, KDEP, the Kentucky Department of

Emergency Management, PMACWA, Bechtel Parsons Blue Grass, and representatives of federal elected officials.

ORGANIZATION OF THE REPORT

This chapter provides a concise background, describes the stockpile at BGAD, introduces the committee’s task and the contractor’s design-build approach, gives a brief overview of the process and a throughput analysis, reviews the permitting process, and describes the venues available for public involvement. Prior reports and documents are cited for the reader who may wish to have more detailed information. Chapter 2 discusses the technical risk assessment and technical risk reduction program; Chapter 3, the delivery and disassembly operations; Chapter 4, core processes for agent and energetics destruction; Chapter 5, treatment of hydrolysates and residual wastes; and Chapter 6, general design considerations for BGCAPP.