4

Coal

INTRODUCTION

Coal is the nation’s (and the world’s) most abundant fossil fuel. Domestic recoverable reserves amount to 6000 quadrillion Btu (quads), which is part of a total domestic resource of about 80,000 quads and a world resource crudely estimated at about 300,000 quads. Of this huge supply, we currently consume about 14 quads each year, or less than 0.3 percent of domestic recoverable coal reserves. In contrast, as noted in chapter 3, the nation extracts each year almost 10 percent of its 420-quad recoverable reserves of oil and natural gas.

The substitution of coal for natural gas and oil on a large scale, either directly or through synthetic coal-derived substitutes, would on these grounds seem a ready-made solution to the nation’s energy problems. The simple arithmetic of availability, however, does not tell the whole story. Doubling or tripling the use of coal will take time, investments amounting over the years to hundreds of billions of dollars, and determined efforts to solve an array of industrial, economic, and environmental problems.

Unlike oil and gas consumption, coal use is limited not by reserves or production capacity generally, but rather by the extraordinary industrial and regulatory difficulties of burning it in an environmentally acceptable and, at the same time, economically competitive manner. Coal is chemically and physically extremely variable, and it is relatively difficult to handle and transport. Its use produces heavy burdens of waste matter and pollutants. Even at its substantial price advantage, Btu for Btu, it cannot compete with oil and natural gas in many applications because of the

expense of handling and storing it, disposing of ash and other solid wastes, and controlling emissions to the air. Only in very large installations, such as utility power plants and large industrial boilers, is coal today generally economic and environmentally suitable to burn. Domestic coal production capacity today exceeds economic demand, and this may well remain true until the end of the century.1

The health problems associated with coal affect both its production and its use. The health of underground miners presents complex and costly problems, for example, and is in need of better management; black lung is the notable instance. At the other end of the fuel cycle, the evolving state of air pollution regulations to deal with the emissions of coal combustion complicates planning for increased demand, and thus in turn inhibits investment in mines, transportation facilities, and coal-fired utility and industrial boilers.

The future is obscured also by a number of more speculative, less easily surmountable problems, which may result in further regulatory restrictions on the use of coal. Chief among these is the risk that before the middle of the next century, emissions of carbon dioxide, an unavoidable (and essentially uncontrollable) product of fossil fuel combustion, may produce such concentrations in the atmosphere as to produce large and virtually irreversible alterations in the world’s climate. (See chapter 9.) Also worrisome is the water-supply situation, which could limit synthetic fuel production or electricity generation unless large-scale and possibly expensive steps are taken to minimize water consumption and manage water supplies. This is already a limiting factor in some western locations, but the eastern coal regions may be approaching trouble too.

Coal-fired power plants burned nearly 70 percent of U.S. coal production in 1977, producing more than 45 percent of the nation’s electricity. Most of this was in large, centralized facilities with generating capacities of 300 megawatts (electric) (MWe) or more, designed to produce base-load power. (Smaller, less efficient oil- and gas-fired units and small, older coal units serve intermediate and peak loads.) Industry used one fifth of national production, slightly more than half of that in coke plants and the rest to produce steam and dry process heat. Almost all the rest (about 8 percent) was exported, mainly to make coke. Imports were less than 1 percent of U.S. production.

In the future, the market for coal can be widened. Development of efficient, relatively clean coal power cycles for use in smaller electricity-generating units decentralized to serve local loads, for example, will be attractive to industry and to utilities with power plant siting problems. Coal use for industrial process heat and chemical feedstocks will be harder to stimulate, especially in smaller installations, because of the expense and difficulty of handling the coal and the various wastes and emissions from

its combustion. In small units, the capital and operating costs of dealing with this inconvenient fuel are proportionally larger than in larger ones. The domestic and foreign market for metallurgical coal (used in blast furnaces, smelters, and chemical plants) amounts to 15–20 percent of the nation’s coal production; it is tied primarily to the world steel industry and is not expected to grow rapidly in the near future.

Over the next 10–20 years some of the obstacles to increased demand will weaken as new technologies increase the efficiency and convenience of using coal, and as the prices of oil and gas rise while their reliability of supply declines. A number of the advanced electric power cycles for coal, now under development, would be suitable for smaller installations, and their relatively clean environmental characteristics would make it possible to locate them near users of their power. For smaller industrial users the fluidized-bed combustion and synthetic fuel processes now undergoing development would be especially valuable.

Department of Energy regulations under the Powerplant and Industrial Fuel Use Act of 1978 (Public Law 95–620) will, when implemented and enforced, further improve the outlook for coal by banning oil and gas as fuels in most new power plants and large industrial heating units.

This is not to imply that all the problems of coal use are solvable, or that coal can become the mainstay of the U.S. energy sector over the long term. Its environmental costs will remain high; mining and burning 2 or 3 times the present output of coal, even if it is done efficiently and with care, will be difficult (and increasingly expensive) if coal’s contributions to air and water pollution and land degradation are to be kept from increasing.

With the foregoing in mind, we see the following as the prime objectives of national coal policy in the coming decades.

-

Provide the private sector with strong investment incentives to establish a synthetic fuel industry in time to compensate as domestic and imported oil supplies begin to decline (probably some time near 1990).

-

Continue the broad research and development program in fossil fuel technology to widen the market for coal by increasing the efficiency and environmental cleanliness with which it can be used.

-

Improve health in the mines by strengthening industrial hygiene and by performing the necessary epidemiological research. The black lung problem especially should be clarified. (See chapter 9.)

-

Devote the necessary resources to supporting long-term epidemiological and laboratory studies of the public health consequences of coal-derived air pollutants to put air quality regulation on a firmer scientific basis that allows more confident and efficient setting of standards, on which industry can depend in its long-range planning. (See chapter 9.)

-

Develop a long-range plan, recognizing that coal presents some

-

serious environmental and occupational health and safety problems, and that it does not relieve the nation of its need to develop truly sustainable energy sources for the long term.

By 1985, given reasonably coherent policy and successful research and development, annual domestic demand for coal should approach 1 billion tons (about 20–25 quads). Commercial techniques for using coal will have changed little, but some synthetic fuel technologies will be on the verge of commercialization, and improved techniques for direct coal combustion will begin to enter the market. Knowledge of the environmental impacts of coal production and use (especially the public health consequences of coal-derived air pollutants) should be improved to the point that the current regulatory uncertainties can be reduced.

As the year 2010 is approached, coal use in the United States may reach 2 billion tons annually. By then, some of the clean, efficient techniques of coal use now being developed should attain full commercialization, and knowledge of the environmental and public health characteristics of coal may be sufficient for confident standard setting. At the same time, however, water supply will be increasingly critical, and the first signs of climatic effects from carbon dioxide emissions may be appearing. It is at about this time that truly sustainable energy sources must begin to become available, to provide new flexibility for energy policy and to relieve some of the pressure on coal.

For now, however, there is little room for maneuver. Coal must be used in increasing quantities, and mainly with the current technologies, until at least the turn of the century, regardless of what happens with respect to such alternatives as nuclear fission or solar energy. However, because of the variety of environmental and social problems it presents, it cannot indefinitely provide additions to energy supply. To keep these problems under control in the meantime, it would be wise to approach coal conservatively, with an eye especially to its environmental risks.

RESOURCES

RANK AND QUALITY

Coal is an extremely complex and variable material whose structure is inadequately understood despite centuries of use. The increased demand for coal is accelerating the effort to better understand its behavior and the nature of its effluents and by-products, under both direct use and conversion to synthetic fuels.

Coals are classified by rank according to the state of “coalification” they

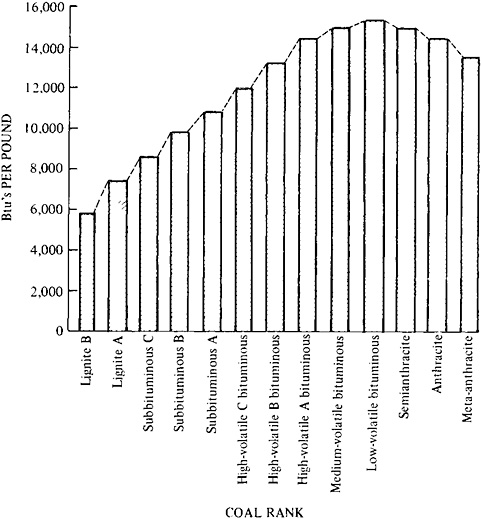

have reached.2 The categories of rank, which roughly indicate the stage of coalification, are, from lowest quality to highest, lignite (two varieties), subbituminous (three varieties), bituminous (five varieties), and anthracite (three varieties). (See Figure 4–1 and Table 4–1.)

Low volatility and high carbon content together make anthracite the slowest and cleanest burning coal, qualities which made it the most desirable residential and commercial heating fuel before the advent of heating with oil and natural gas. However, for making coke the best coal is low-volatile bituminous. Per pound, the percentage of ash is lower and the Btu content is higher in low-volatile bituminous than in anthracite. The agglomerating or caking nature of bituminous coal, however, makes it ill suited for certain types of coal gasification processes, which become clogged by the fused carbon material. These processes require noncaking coal, which is usually subbituminous—a rank found almost exclusively in the West. Some gasification processes have been developed to use either type of coal.

The quality of coal is determined in general by two classes of material: (1) the organic remains of plants and (2) inorganic substances contributed by the plants, by water seepage, and by the surrounding geological matter, generally referred to as mineral matter. The organic portion of coal consists of carbon rings linked by chains that contain nitrogen, hydrogen, sulfur, and oxygen. Many products therefore arise when coal is heated. These products may be commercially useful, but may also be potentially hazardous; they include small amounts of carcinogens, mutagens, and respiratory irritants. The inorganic or mineral portion of coal usually constitutes from 9 percent to about 30 percent of the coal by weight. It includes up to half the sulfur and small, potentially toxic amounts of antimony, arsenic, beryllium, cadmium, mercury, lead, selenium, zinc, heavy radionuclides, and asbestos.3

Sulfur products are currently the most important of all pollutants released by coal combustion (chapter 9); their health effects are the most widely discussed, and they are by far the most costly to control. Sulfur in coal occurs mostly in a form that is either combined with the coal material (“organic”) or attached to, but physically distinct from, the coal (“inorganic” or “mineral”). (An additional small amount occurs as a sulfate, a product of weathering.) The distinction between organic and inorganic sulfur is important because inorganic sulfur can be removed in large part by washing prior to combustion; the organic form, under most washing processes in use today, cannot. In coals with very low total sulfur content by weight (less than 0.6 percent), most of the sulfur is organic; but when total sulfur makes up a greater percentage of the coal, the amount of inorganic sulfur is greater, commonly about 50 percent.

Emissions of sulfur dioxide (SO2) are measured in terms of pounds per

FIGURE 4–1 Comparison of heat values per pound (moist, mineral-matter-free basis) of coal of different ranks (Btu’s per pound). Source: Adapted from Paul Averitt, Coal Resources of the United States, January 1, 1974, U.S. Department of the Interior, Geological Survey Bulletin 1412 (Washington, D.C.: U.S. Government Printing Office (Stock No. 024–001–02703), 1975), p. 17.

million Btu of fuel burned. For enforcement purposes, the Environmental Protection Agency (EPA) assumes that all the sulfur in the coal is released as sulfur dioxide, the weight of which is twice that of sulfur. The ceiling on emissions is 1.2 lb of sulfur dioxide per million Btu, which under earlier EPA regulations could be met by burning coal with 0.6 lb or less of sulfur per million Btu.4 In May 1979, however, the EPA imposed additional control requirements on new plants (construction or alteration begun after

TABLE 4–1 Composition of Some American Coals

|

Typea |

Proximate Analysisb (percent) |

Elementary Analysisc (percent) |

Heating Valued (Btu per pound) |

|||||||

|

Moisture |

Volatile Matter |

Fixed Carbon |

Ash |

S |

C |

H2 |

O2 |

N2 |

||

|

Anthracite |

2.5 |

6.2 |

79.4 |

11.9 |

0.60 |

93.5 |

2.6 |

2.3 |

0.9 |

14,500 |

|

Bituminous |

|

|

|

|

|

|

|

|

|

|

|

Low volatile |

1.0 |

16.6 |

77.3 |

5.1 |

0.74 |

90.4 |

4.8 |

2.7 |

1.3 |

15,600 |

|

Medium volatile |

1.5 |

23.4 |

64.9 |

10.2 |

2.20 |

87.6 |

5.2 |

3.3 |

1.4 |

15,600 |

|

High volatile A |

2.5 |

36.7 |

57.5 |

3.3 |

0.70 |

85.5 |

5.5 |

6.7 |

1.6 |

15,000 |

|

High volatile C |

12.2 |

38.8 |

40.0 |

9.0 |

3.20 |

79.2 |

5.7 |

9.5 |

1.5 |

12.400 |

|

Subbituminous |

|

|||||||||

|

A |

14.1 |

32.2 |

46.7 |

7.0 |

0.43 |

80.9 |

5.1 |

12.2 |

1.3 |

12,100 |

|

C |

31.0 |

31.4 |

32.8 |

4.8 |

0.55 |

74.0 |

5.6 |

18.6 |

0.9 |

8,800 |

|

Lignite |

37.0 |

26.6 |

32.2 |

4.2 |

0.40 |

72.7 |

4.9 |

20.8 |

0.9 |

7,600 |

|

aThe analyses are meant to give an idea of the range of variation among coal types. There is considerable variation within each type, as well. bProximate analysis totals 100 percent by weight. cElementary analysis totals 100 percent by weight on a dry, ash-free basis. dHeating value is on a moist, mineral-matter-free basis. Source: Adapted from U.S. Environmental Protection Agency, Electric Utility Steam Generating Units: Background Information for Proposed Particulate Matter Emission Standards, Office of Air Quality Planning and Standards (Springfield, Va.: National Technical Information Service (PB-286–224), 1978), Table 3–6. |

||||||||||

September 18, 1978) that limit the possibility of using low-sulfur coal as the sole means of meeting the standard (The sulfur content of coals in the major U.S. producing areas ranges from 0.3 to 4.7 lb per million Btu.)5 The regulations and their impact are discussed in more detail in the section of this chapter entitled “Air Pollution Regulation and Control.”

DISTRIBUTION OF RESOURCES

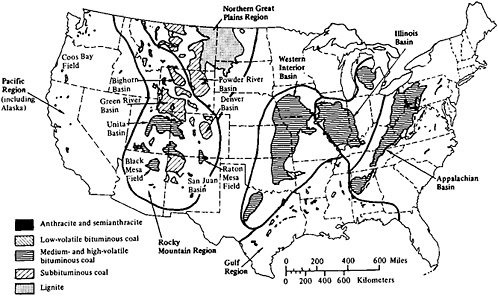

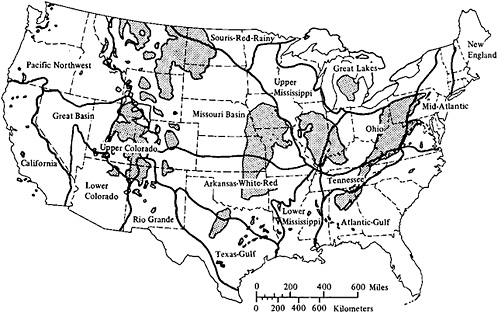

While recoverable quantities of coal are found in at least 32 states (see Figure 4–2), 90 percent is found in only 10 states, distributed among four regions. These regions and states are the Appalachian basin (chiefly, in order of deposit tonnage, West Virginia, Pennsylvania, Ohio, and eastern Kentucky), the Illinois basin (also called the Eastern Interior region—Illinois, western Kentucky, and Indiana), and the Northern Great Plains and Rocky Mountain regions (Montana, Wyoming, Colorado, and North Dakota).

A broad distinction is drawn between types of U.S. coal based on whether they are located east of the Mississippi (Appalachian and Illinois basins) or west (the Western Interior, Northern Great Plains, Rocky Mountain, Gulf, and Pacific regions). There are major differences between eastern and western coals, based on their different conditions of formation. The major deposits east of the Mississippi are generally the oldest and deepest, and are therefore of highest rank. Most western coals were formed about 150 million years later than eastern coal, at shallower depths; their coalification is less advanced, and their energy and carbon content are therefore generally lower, than those of eastern coal. Created from different plants and under different geological conditions, western coal has a carbon structure and mineral content generally different from that of eastern coal; these characteristics must be allowed for and sometimes counteracted in designing boilers, controlling effluents, and choosing coal for coking or for conversion to synthetic fuels.6 (Boilers, for instance, suffer an efficiency loss when a nondesign coal type is substituted for the type originally intended.) Lastly, much eastern coal was formed under salt water, giving it a high sulfur content compared to most western coal, which formed under fresh water.

U.S. coal is generally in huge beds, ranging in thickness from a few inches to more than 100 ft, that extend with some interruptions for up to 30,000 mi2. The major Appalachian deposit is the Pittsburgh bed, which, because of size, the high heat value of the coal it contains, and its use in the creation of the Pennsylvania iron and steel industry, has been called the most important single mineral deposit in the United States. Fairly uniform and continuous over 6000 mi2 of western Pennsylvania, West Virginia, Ohio, and Kentucky, the Pittsburgh bed yielded through 1973 an

FIGURE 4–2 Coal fields of the coterminous United States. Source: Adapted from Paul Averitt Coal Resources of the United States, January 1, 1974, U.S. Department of the Interior, Geological Survey Bulletin 1412 (Washington, D.C.: U.S. Government Printing Office (Stock No. 024–001–02703), 1975), p. 5; and U.S. Department of Energy, Energy Information Administration, Coal Data (Washington, D.C.: U.S. Government Printing Office (DOE/EIA-0064), 1978), p. 1.

estimated 9 billion tons or about one fifth of total U.S. production to that date, with much still remaining.7

The largest unbroken concentration of coal in the United States is the remarkable Wyodak bed, centered in Cambell County, Wyoming. This bed penetrates the surface continuously along a line extending for 120 miles at thicknesses ranging from 25 ft to 150 ft. To a depth of 200 ft, it contains an estimated 15 billion tons of strip-minable coal (or about 20 times total U.S. output in 1976). To a depth of 2000 ft, it contains perhaps 100 billion tons of coal.8 (Given the low heating value of this coal and current prices, however, these deeper deposits are not now economically recoverable.)

Coal resources are generally reported in short tons. The latest U.S. Bureau of Mines estimate of the tonnage in U.S. coal beds that are legally and economically accessible (called the reserve base) is 438 billion tons, about 32 percent of it accessible by surface mining. The reserve base is part of a total U.S. coal resource estimated, much less reliably, at 4 trillion tons.

In terms of the reserve base, practically all anthracite is found in Pennsylvania underground-minable deposits; all but 16 percent of bituminous deposits are found east of the Mississippi; all subbituminous deposits are found in the West; all lignite is found in surface deposits, practically all of it in Montana, North Dakota, Texas, and Colorado. The distribution of the U.S. reserve base by coal rank, type of mining, and region is shown in Table 4–2.

The distribution of coal energy resources is also of interest. The Bureau of Mines reserve base tonnages were converted to recoverable reserves and to corresponding average energy content figures by the Congressional Office of Technology Assessment using a recovery factor of 57 percent in underground mines and 80 percent in surface mines.9 The resulting regional distribution of recoverable coal reserves by energy content and method of mining is summarized in Table 4–3.

Table 4–3 shows a distribution of recoverable reserve energy that is not far different from the distribution of reserve base tonnages. This is because, in comparison to the eastern coal, the lower energy of western coal is compensated for by its greater recoverability.10

DISTRIBUTION OF PRODUCTION

In 1976 (the most recent year of output unaffected by the 1977–1978 coal strike), surface mines yielded 57 percent of U.S. coal production tonnage. In that year, Appalachia supplied 60 percent of U.S. coal, with 45 percent of the region’s output produced by surface mines; the Interior supplied 24 percent, about two thirds of it surface mined; and the West supplied 16 percent, practically all of it surface mined.

The most important of the 26 producing states in 1976 were all east of

TABLE 4–2 Distribution of U.S. Coal Reserve-Basea Tonnage by Coal Rank and Type of Mining (percent)

|

Region |

Coal Rank |

Total Surface |

Total Deep |

Grand Totalb |

|||||||

|

Anthracite |

Bituminous |

Subbituminous |

Lignite |

||||||||

|

Surface |

Deep |

Surface |

Deep |

Surface |

Deep |

Surface |

Deep |

||||

|

Eastc |

<0.5 |

2 |

9 |

35 |

0 |

0 |

<0.5 |

0 |

9 |

37 |

46 |

|

Westd |

<0.5 |

<0.5 |

2 |

6 |

14 |

25 |

7 |

0 |

23 |

31 |

54 |

|

TOTALb |

<0.5 |

2 |

11 |

42 |

14 |

25 |

8 |

0 |

32 |

68 |

100 |

|

aLegally and economically accessible deposits reported by the U.S. Bureau of Mines as of January 1, 1976, to be 438.3 billion short tons. Figures shown here are independently rounded. bTotals may not add due to rounding. cAppalachian and Eastern Interior basins (see Figure 4–2). dWestern Interior, Gulf, Northern Great Plains, Rocky Mountain, and Pacific (including Alaska) coal regions (see Figure 4–2). Source: U.S. Department of Energy, Coal Data—A Reference, Office of Energy Data and Interpretation, Energy Information Administration (Washington, D.C.: Energy Information Administration Clearinghouse (DOE/EIA-0064, Order no. 704), 1978), p. 2. |

|||||||||||

TABLE 4–3 Distribution of U.S. Recoverable Reserve Coal Energya by Method of Mining (percent)

|

Region |

Surface |

Deep |

Total |

|

Eastb |

11 |

36 |

47 |

|

Westc |

25 |

28 |

53 |

|

TOTAL |

36 |

64 |

100 |

|

aReserve base is made up of economically and legally accessible deposits. Recoverable reserves calculated at 80 percent of surface, and 57 percent of deep, reserve base, Recoverable reserve coal energy is an estimated 6334 quads. bAppalachian and Eastern Interior basins (see Figure 4–2). cWestern Interior, Gulf, Northern Great Plains, Rocky Mountain, and Pacific (including Alaska) coal regions (see Figure 4–2). Sources: Calculated from Office of Technology Assessment, The Direct Use of Coal: Prospects and Problems of Production and Combustion (Washington, D.C.: U.S. Government Printing Office (052–003–00664–2), 1979), p. 63. For the combined deep and surface reserve base energy in Alaska and Washington, multiplied by 60 percent for an estimate of total recoverable reserve energy in those states, Francis X.Murray, ed., Where We Agree: Report of the National Coal Policy Project, 2 vols., sponsored by the Center for Strategic and International Studies, Georgetown University (Boulder, Colo.: Westview Press, 1978), vol. 2, p. 395. |

|||

the Mississippi: Kentucky (21 percent of the U.S. total), West Virginia (16 percent), Pennsylvania (13 percent), Illinois (8 percent), and Ohio (7 percent), all of which are states with large reserves. Two states with small reserves but fairly large outputs were Virginia (6 percent of the 1976 output) and Alabama (3 percent). Two states with very large reserves but comparatively small outputs were Montana and Wyoming (each with about 4 percent of the U.S. total). Montana and Wyoming were the largest western producers and have the fastest growing productions in the nation. On a Btu basis, the East’s share of total output would be larger, and the West’s smaller, than the tonnage shares shown here.11 Table 4–4 shows the share of recoverable reserves, production, and consumption for 1976, by census region.

The extent to which U.S. coal production will shift to the West’s easily mined, surface, low-sulfur deposits depends on the willingness of the federal government, which owns perhaps 55–60 percent of western deposits, to lease new, large tracts of land assembled into “logical mining units.”12 It will also depend on water-use policy in the West, on transportation rates, and in the longer run, on the progress of coal liquefaction and gasification technology. The mining industry estimates

that the current short-term U.S. coal production capacity is roughly 15–20 percent greater than output, which reflects the fact that the most critical short-term constraints on increased coal use are in the demand sector.13

In 1977, coal provided about 14 quads (or 18.4 percent) of the 76.6 quads of energy consumed in the United States. Electric utility boilers consumed 10.7 quads, or about 77 percent of total coal consumption; about 13 percent, or 1.7 quads, was consumed in the manufacture of coke for steel; and other industries consumed 1.4 quads, or 10 percent, primarily as boiler fuel. Less than one fifth of a quad was distributed at retail, primarily as a commercial and residential fuel.14 In the utility market, coal competes with oil, natural gas, and nuclear power; in the industrial boiler market, it competes with oil and natural gas.

CONSUMPTION

INTRODUCTION

The expansion of coal consumption is and will continue to be limited by constraints on demand. Under the National Energy Plan (NEP) of 1977, which called for a near doubling of coal use by 1985, industrial coal consumption was projected to increase at nearly 12 percent annually, and electric utility coal consumption at about 6 percent.15 The nation’s utilities may be able to meet the forecast rate of increase, because under the Powerplant and Industrial Fuel Use Act of 1978 (Public Law 95–620) they are limited almost entirely to coal and nuclear power for new base-load generating capacity. The industrial projections of the NEP appear optimistic, however, given the small scale of many industrial installations now using oil and gas, and the consequently large investments required in new coal-handling facilities, expensive exhaust-gas scrubbers, and the like, (It should be noted that Congress failed to enact some of the plan’s key coal-use incentives.)

In addition, rapid changes in the regulation of coal mining and combustion render the future economics of coal use rather uncertain. New surface-mining legislation, for example, will no doubt decrease somewhat the current cost advantage enjoyed by surface-mined coal over deep-mined coal. Newly proposed air pollution regulations, which would require all new large coal-fired units to install desulfurization equipment, will raise the cost of burning coal and reduce the economic advantage of low-sulfur western coal as a means of meeting air quality requirements. Until the economic implications of these and other regulatory actions are fully understood, coal will not find ready acceptance in many applications, especially in smaller industrial applications, where the costs per unit of heat tend to be greater than in larger operations such as utilities and large industrial establishments.

TABLE 4–4 1976 Recoverable Reserves, Production, and Consumption of U.S. Coal, by Census Region (percent of total tons)a

|

Census Regionb |

Recoverable Reservesc |

Annual Productiond |

Annual Consumptione |

|

New England |

0 |

0 |

0.1 |

|

Middle Atlantic |

6.3 |

13.4 |

12.8 |

|

East North Central |

21.9 |

19.0 |

30.4 |

|

West North Central |

5.1 |

2.6 |

8.9 |

|

South Atlantic |

9.4 |

22.1 |

15.5 |

|

East South Central |

6.9 |

25.5 |

11.8 |

|

West South Central |

1.3 |

2.7 |

2.6 |

|

Mountain |

47.5 |

13.8 |

7.1 |

|

Pacific |

1.7 |

0.7 |

1.2 |

|

aColumns may not add due to rounding. bCensus regions divide the states as follows: New England includes Maine, Massachusetts, Rhode Island, New Hampshire, Vermont, and Connecticut; Middle Atlantic includes New York, New Jersey, and Pennsylvania; East North Central includes Ohio, Indiana, Illinois, Michigan, and Wisconsin; West North Central includes Minnesota, Iowa, Missouri, North Dakota, South Dakota, Nebraska, and Kansas; South Atlantic includes Delaware, Maryland, Virginia, West Virginia, North Carolina, South Carolina, Georgia, and Florida; East South Central mcludes Kentucky, Tennessee, Alabama, and Mississippi; West South Central includes Arkansas, Louisiana, Oklahoma, and Texas; Mountain includes Montana, Idaho, Wyoming, Colorado, New Mexico, Arizona, Utah, and Nevada; and Pacific includes Washington, Oregon, California, and Alaska. cSource: Calculated from Office of Technology Assessment, The Direct Use of Coal: Prospects and Problems of Production and Combustion, (Washington, D.C.: U.S. Government Printing Office (052–003–00664–2), 1979), p. 63. dSources: Calculated from U.S. Department of Energy, Coal—Bituminous and Lignite in 1976, Office of Energy Data and Interpretation, Energy Information Administration (Washington, D.C.: Energy Information Administration Clearinghouse (DOE/EIA-0118/1 [76], Order no. 703), 1978), p. 11; and U.S. Department of Energy, Coal—Pennsylvania Anthracite in 1976, Office of Energy Data and Interpretation, Energy Information Administration (Washington, D.C.: Energy Information Administration Clearinghouse (DOE/EIA-0119, Order no. 705), 1978), p. 3. eSources: Coal—Bituminous and Lignite in 1976 (see footnote d), p. 58; and Coal—Pennsylvania Anthracite in 1976 (see footnote d), p. 25. Calculated as percentage of total shipments by region of destination. Remainder of total shipments, 9.6 percent, allocated to export, dock storage, and rail and lake vessel fuel. |

|||

It seems almost certain that the 1985 target of the 1977 National Energy Plan—1.2 billion tons of coal per year—will not be met. Electric utilities will probably continue to be the major consumers, with industrial consumption of secondary importance as a source of demand. How much the demand for input energy in these two sectors will grow depends generally on the level of economic growth, the impact of conservation efforts, the pace of substitution of electricity for other forms of energy, and the amount of nuclear generating capacity that is installed.

Given recent trends, a plausible assumption about electricity production is that it will grow from 2.2 trillion kilowatt-hours (kWh) in 1978 at a modest 4 percent annually to 2.9 trillion kWh in 1985. If recent utility plans for a roughly 50–50 split in the distribution of new capacity between coal-fired and nuclear units holds true, the additional 170 million tons of demand for utility coal in 1985 will be about 35 percent higher than the 1978 level, requiring a 25 percent boost in total output. Few power plants now burning oil or gas will convert to coal, except for some that were originally designed to burn coal.

Large increases in industrial coal demand for steam and process heat are not likely through 1985. The coal demand of this sector has shrunk more than 10 percent since 1972, and most existing plants face many difficulties in attempting to convert to coal and in burning it.

Beyond 1985, the possibilities of course become more varied. To begin to grasp their range, we will again assume that through 1985 electricity output rises at a 4 percent annual rate, with the total increase shared equally by coal and nuclear fission. Thereafter, we assume a 3 percent annual growth rate for electricity output. If we assume that 1 trillion kWh will be supplied by oil, gas, hydroelectric, wind, solar, geothermal, and tidal generating plants by 2010, then 5 trillion of the 6 trillion kWh being generated in that year will come from nuclear and coal-fired plants (with the distribution of new capacity again split equally between the two plant types).

Nuclear capacity contributed 0.275 trillion kWh in 1978, which would rise to about 0.6 trillion kWh for 1985, and 1.7 in 2010, and require that 3.3 trillion kWh be produced by coal in 2010. Based on utility coal conversion efficiency measured in 1978, this would require 1640 million tons of coal, 3.4 times as much as utilities consumed in 1978 and 2.5 times total 1978 domestic coal production. Any shortfall in nuclear capacity would of course increase this demand.

By 2010, however, utilities will not be the only significant source of demand for coal. Advanced coal-based generation technologies are now undergoing development. Atmospheric fluidized-bed combustion may make coal use more economic for industry, and fuel cells using gas from coal may be economic in decentralized load-following applications. The

successful development of technologies to extract gases and liquids from coal could prove to be the biggest source of demand for coal as an indirect industrial substitute for oil and natural gas. It would also yield fuels attractive to utilities as alternatives to the direct use of coal.

ELECTRICITY GENERATION FROM COAL

The following discussion uses utility generating stations as a model for large-scale coal combustion in general. Utility boilers fired by coal are quite similar to industrial ones, though generally larger. Air quality regulations apply in essentially the same ways to both. The Powerplant and Industrial Fuel Use Act of 1978, when its regulatory provisions are formalized, will impose similar, though probably somewhat less restrictive, constraints on industrial oil and gas burning as on consumption of these fuels by electric utilities. The industrial nonenergy uses of coal—as a chemical feedstock and in metallurgy—will be discussed later.

Most large utility power plants use pulverized coal, burned in a suspension of fine particles to generate steam to drive the electric generator’s turbine. A 1000-MWe coal-fired powor plant consumes about 2.5 million tons of coal each year and produces approximately 6.5 billion kWh of electricity. With flue gas desulfurization equipment it occupies an area of about 600–700 acres, which houses the plant and allows for disposal of the various solid wastes produced in the course of 35–40 years of useful life. From site selection to power production, it takes about 7–8 years to obtain regulatory clearances, build the plant, and make final operating adjustments.

Before the advent of sulfur dioxide controls, coal-fired base-load power plants could convert about 40 percent of the coal’s chemical energy to electricity; the rest was rejected to the environment as heat. The power demands of sulfur dioxide scrubbers and other control equipment that will be required on new plants will reduce coal-to-electricity efficiencies to about 38 percent. In addition, the EPA-proposed increases in regulatory requirements for emission control and waste disposal are estimated to add over $150 per kilowatt (electric) (kWe) of generating capacity to the capital costs of large plants, which without such measures would cost $550/kWe (1976 dollars). The pollution control costs are dominated by the costs of sulfur dioxide scrubbers and waste disposal; a great deal of development work, with the aim of increasing efficiencies and decreasing costs of power plants that are acceptably clean and efficient, is being carried on. Advanced methods of coal combustion will be discussed later.

Air Pollution Regulation and Control

The policy problem of greatest significance to the near future of coal consumption is undoubtedly the question of air pollution and its control. Under the authority of the Clean Air Act of 1970 and its 1977 amendments, the federal government directly and indirectly regulates the siting of fossil-fueled utility and industrial boilers, as well as their permissible emissions of particulates, sulfur oxides, and nitrogen oxides. Other considerations may arise under the Clean Water Act, the National Environmental Policy Act, the National Historic Preservation Act, the Endangered Species Act, and other regulations, but it is the provisions of the Clean Air Act that apply most consistently and with most force.

The Clean Air Act sets national ambient air quality standards (NAAQS) for atmospheric concentrations of sulfur dioxide, nitrogen dioxide, and particulate matter. These are enforced in a variety of ways to control emissions from different stationary and mobile pollution sources. The requirements are different not only for different types of sources, but also for different regions. The act divides the nation into 247 air quality control regions, and charges the states with developing strategies for meeting the applicable ambient pollutant standards. In regions that are already in violation of the ambient standards, any new pollution source must meet the lowest attainable emission rate and at the same time secure from other sources in the region reductions in emissions that more than offset its own. In areas where the air is cleaner than required by the NAAQS (so-called “prevention of significant deterioration” areas), emissions are regulated to prevent significant increases in ambient concentrations of particulate matter and sulfur dioxide. Regulations covering certain other pollutants (including nitrogen dioxide and hydrocarbons) will be promulgated in late 1979.

In addition to the standards regulating ambient air quality, and thus the siting of plants, the Environmental Protection Agency promulgates and enforces regulations limiting the emissions of individual plants. Under the authority of the 1977 amendments to the Clean Air Act, EPA proposed new, tighter standards governing the sulfur dioxide, nitrogen dioxide, and particulate emissions of all new or substantially modified fossil-fueled steam power generating units that consume more than 250 million Btu of fuel energy per hour.16 This is equivalent to about 10 tons of coal per hour—enough to fuel a 10-MWe unit. The standards apply, regardless of the ambient air quality, to plants whose construction or alteration begins after September 18, 1978.

The standards, made final in May 1979, set ceilings on the emissions of the three above-mentioned pollutants, and in the case of sulfur dioxide impose the further requirement that “potential” emissions (those that

would prevail if completely uncontrolled) be reduced by certain percentages, depending on the sulfur content of the coal. The percentage reduction requirement in effect means that all regulated coal-fired power plants must install flue-gas scrubbers to remove sulfur. The use of low-sulfur coal thus is no longer acceptable as the sole means of reducing sulfur emissions at a power plant; this is expected to reduce the market for low-sulfur western coal in the Midwest and East, but the magnitude of the reduction and its precise effect on western coal production are very uncertain.

The new standards, and for comparison the previous ones, are briefly as follows.

-

For sulfur dioxide, the previous standard simply limited emissions to 1.2 lb per million Btu of fuel consumed. The new standard retains this upper limit, but imposes a percentage reduction requirement of 70–90 percent, depending on the sulfur content of the coal.

-

For particulates, the old emission limit was 0.1 lb per million Btu. The new standard limits particulate emissions to 0.03 lb per million Btu, and in addition limits the opacity of exiting flue gas.

-

For nitrogen dioxide, the previous standard limited emissions to 0.7 lb per million Btu. The new standard allows emissions of between 0.5 and 0.8 lb per million Btu, depending on the type of coal burned.

Discussions to follow describe these standards and their implications in more detail.

A recent econometric study17 suggests that, while the tightened emission standards will raise the cost of coal-generated electricity by about 15–20 percent at power plants that install sulfur oxide scrubbers, the overall price of electricity would not rise by more than about 4 percent even by the year 2000, given a number of countervailing assumptions. For example, utilities with flue-gas desulfurization equipment could switch to cheaper, higher-sulfur coal; other fuels, including nuclear, would be available and increasingly competitive; and some plants built before the standards took effect would still be in operation.

Although nuclear generation capacity will be somewhat cheaper than coal-fired capacity in many locations, it will be installed at a rate limited by regulatory and associated investment risk considerations, with coal making up the balance of the installed generating capacity, regardless of emission standards. Up to at least the mid-1990s no electrical energy source other than these two will make appreciable contributions to the nation’s new generating capacity. Therefore, according to this econometric study, the emission standards will have little effect on total coal demand. Of course, these results are sensitive to variations in electricity growth

rates and the future role of nuclear power. Shortfalls in nuclear projections would tend to raise the average electricity price by requiring more new coal-fired plants subject to the new emission standards.

Given the assumptions of the model—that coal and nuclear are the only options for new generating capacity and that the availability of nuclear power will be limited by noneconomic factors—information on the environmental and health effects of coal emissions will have enormous economic value, determining whether there will be investments of many billions of dollars for emission control equipment. The range of scientific uncertainty and controversy over the impacts of emissions is much wider than for the much more widely publicized case of low-level radiation in connection with nuclear power (chapter 9). Yet, while the potential costs to the economy, and even the costs in additional energy and water resources required, are hundreds of times the cost of acquiring the information that is needed to make better-informed decisions, past and present expenditures in assessing the impacts of coal combustion are minuscule compared with the corresponding efforts in the nuclear field. Unfortunately, it will be nonetheless necessary to expand the use of coal greatly in the immediate future; in fact the largest expansion may well be required in the next 10–15 years, during which we will not have an adequate base for definitive decisions. In the absence of such a base we are forced to pay the price for standards set at levels that may prove overly conservative in the light of improved knowledge.

Sulfur Oxides Under the authority of the 1977 Clean Air Act Amendments, the Environmental Protection Agency has proposed new, more stringent standards for reducing sulfur and other emissions. The standards apply to new and substantially altered (after September 18, 1978) fossil-fueled boilers burning more than 250 million Btu/hr (about 10 tons of coal, 40 barrels of residual fuel oil, or 250 thousand ft3 of gas). For coal or other solid fuel, the standards limit sulfur dioxide emissions to a maximum of 1.2 lb per million Btu consumed. In addition, the proposed regulations would require sulfur emissions to be reduced by 70–90 percent from the uncontrolled levels, with the precise reduction determined by the effort required to reduce emissions to the threshold value of 0.6 lb per million Btu. These percentage reduction requirements could be met by any combination of flue-gas desulfurization, coal cleaning, conversion to synthetic fuels, or other means of removing sulfur before, during, or after combustion. Sulfur removed by a coal pulverizer or in bottom ash or fly ash would also be included in the calculation. The percentage reduction requirement in effect mandates the use of sulfur dioxide scrubbers on all plants to which the standards apply.

At present, there are two commercial means of removing sulfur from coal. First, a good deal of the inorganic sulfur, included as pyrites, is removed by mechanical cleaning and washing. This removes about 70 percent of the coal’s inorganic sulfur (which may range from 60 percent of total sulfur in Appalachian coals to very small amounts in some western coals) and is almost entirely ineffective in removing organic sulfur. Thus, ordinary treatment of this type can remove at best about 40 percent of the total sulfur, too little to meet the proposed requirements.

The second means, upon which most operators of large boilers will have to rely in the future, is to “scrub” the combustion gases with a technique known as flue-gas desulfurization (FGD). In essence, FGD involves bringing the sulfur-oxide-laden exhaust gases into contact with some substance with which the sulfur oxides can react so that they can be removed from the gas stream. The various FGD schemes are distinguished from one another by whether a wet or dry scrubbing agent is used and whether the used scrubbing agent is thrown away or regenerated for reuse, with the captured sulfur as a separate by-product.

About 11.5 gigawatts (electric) (GWe) of coal-fired generating capacity have been fitted with FGD systems. Another 17–18 GWe of capacity now under construction will include FGD systems, and additional capacity amounting to about 27 GWe is scheduled to be in operation with scrubbers by 1985.18 Thus, by 1985, about 56 GWe of coal-fired generating capacity (out of a total of 300 GWe) will include FGD systems.

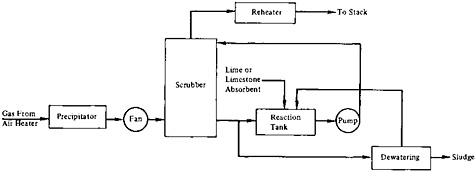

At present, the predominant commercially available FGD process is wet scrubbing with lime or limestone. Figure 4–3 is a schematic diagram of such a system. The lime or limestone absorbent is introduced into the reaction tank along with scrubber effluent and water recycled from the dewatering section. The mixture is pumped to the top of the scrubber and sprayed down into the gas. A stream of effluent from the scrubber is drawn off and dewatered, producing a sludge that must be disposed of as solid waste. A typical unit using such a system and burning 2 percent sulfur coal will produce about 200 lb of sludge (dry weight) for each ton of coal burned. A 500-MWe plant equipped with a lime or limestone FGD system requires over its lifetime a 560-acre sludge disposal pond 40 ft deep.

These systems, in their 15 years of service in the electric utility industry, have been plagued by design and operating problems that have limited their reliability. Scaling and corrosion of pipes and valves have been especially important problems, necessitating frequent maintenance and careful chemical control. These problems are gradually being brought under control, but the devices are by no means simple to operate, and they raise the operating costs of the power plants significantly. They consume large amounts of electrical and thermal energy (thus decreasing the overall coal-to-electricity efficiency of the power plants in which they are installed

FIGURE 4–3 Generalized lime or limestone flue-gas desulfurization system for coal-fired utility plant.

by about 5 percent); and they consume large amounts of water (0.5–1.5 tons per ton of coal),19 a feature which could raise serious siting problems, especially in the West. The costs of specific installations vary from place to place, but the capital costs typically may be $80–$120/kWe of generating capacity (1975 dollars), with annualized operating costs (capital charges plus operating and maintenance costs) of about 5.5 mills/kWh.20 This would add perhaps 15–20 percent to the typical power plant’s capital cost, and a slightly smaller percentage to annualized operating costs.

Although lime or limestone scrubbing is the most fully developed FGD technology, better processes may be available soon. The nearest to commercial adoption appears to be the regenerable double-alkali process, which uses a recyclable alkali metal hydroxide to neutralize the sulfur oxides; its main advantage is that it lessens the problem of scaling. The Wellman-Lord process, which uses a combination of sodium scrubbing and thermal stripping, is also fairly near to commercial maturity. Several other techniques show somewhat longer term promise.

Fluidized-bed combustion, now under development for use in industrial and utility boilers, holds the potential for somewhat more economical sulfur oxide control, and in addition should reduce nitrogen oxide emissions. It is described below in the section entitled “Advanced Technologies for Coal Combustion.”

Nitrogen Oxides The 1977 Clean Air Act Amendments, as interpreted by the Environmental Protection Agency in the proposed New Source Performance Standards, limit nitrogen oxide (NOx) emissions in new steam boilers consuming more than 250 million Btu of fuel per hour to 0.50–0.80 lb per million Btu, depending on the rank of coal used. These standards are based, according to the EPA,21 on the emission levels

achievable with combustion modification techniques (that is, without the use of scrubbers or chemical systems).

Nitrogen oxides formed during coal combustion draw nitrogen from both the coal and the air in which it burns. The amount formed depends on flame temperature, the amount of excess air in the flame, the length of time the combustion gases are maintained at the elevated temperature, and the rate of quenching. Higher flame temperatures and excess air foster nitrogen oxide production, as does rapid cooling.

At present, the only available means of lowering NOx, emissions in coal-fired boilers is to modify the design and operating characteristics of combustion equipment. One successful approach is to design boilers for two-stage combustion, with the first stage deficient in air and the second causing complete combustion by the injection of additional air. Burner arrangements that yield lower combustion temperatures are also effective, as are restricting air intake, recirculating flue gases, and injecting water into the fire box. Combinations of these methods are reported to lower NOx emissions from larger utility boilers by 40–50 percent.22

Atmospheric fluidized-bed combustion, because of its lower combustion temperatures, will produce less than half the NOx per ton of coal produced by conventional combustion. Pressurized fluidized-bed combustors should do even better.

Particulates The new EPA proposed standards for utility boilers would limit overall emissions of particulate matter to 0.03 lb per million Btu and at the same time set standards for the opacity of existing flue gases. They would require that particulate emissions be reduced by over 99 percent of the uncontrolled emissions. These standards are based on the use of “well designed and operated” baghouses or electrostatic precipitators.23

There are four types of particulate control systems—mechanical collectors, electrostatic precipitators, wet scrubbers, and fabric filter baghouses. They vary greatly in cost and effectiveness; sometimes two types are used in series, with a cheap but relatively inefficient system serving as a first stage to lower the load on the more efficient and costly second stage. All methods of control are more effective in capturing the larger particles; it is probably the smaller, respirable particles that pose the greater danger to health, however, as explained in chapter 9.

Mechanical collectors use gravity, inertia, or centrifugal forces to separate the particles from the gas. Some, for example, consist simply of enlarged chambers in the gas stream, which slow the gas flow and allow the heavier particles to settle. Others depend on induced centrifugal swirling motions in the gases; the particles in these devices are moved by centrifugal force to the outer walls and drop to the bottom of the chamber,

where they can be removed. The units are simple and relatively inexpensive to install and maintain. Because they depend on the masses of the particles, they work best on the larger particles. Because of their low cost and relative ineffectiveness against small particles, they are often used as first-stage cleaners in connection with more efficient (and more expensive) devices.

Electrostatic precipitators consist of high-voltage discharge electrodes and grounded collection plates, between which the flue gases pass. Particles are charged by ions emitted by the discharge electrode and move toward the collection plate, where they can be collected and removed. The devices can remove as much as 99.9 percent (by weight) of the particles in the flue gas, but they too are most effective on larger particles. Capital costs of such systems for large boilers burning medium- or high-sulfur coal are about $25/kWe of generating capacity. With low-sulfur fuel, they are more expensive, because the particles produced in burning such coal tend to be electrically more resistive. To compensate, the precipitators can be enlarged, they can be placed in a hotter part of the flue gas stream (where the high temperatures reduce the particles’ resistivity), or the flue gas can be treated with some substance that reduces resistivity. The third of these options may, however, add some pollutants to the gas, and it is generally used only as a last resort.

Wet scrubbers use water to wash solid particles out of the gas stream. These devices are rather expensive to install and operate and are not widely used for particulate control, though some installations exist.

Fabric filter baghouses are the most effective of all particulate control methods against small particles, but the pressure drop involved in forcing the gas through the necessary fine filters increases operating costs. The devices have been used in industrial particulate control for many years, but the high temperatures and corrosive chemicals in coal combustion gases, among other problems, have limited their use with utility boilers. Improved, heat- and chemical-resistant filters have been developed recently, making this option more attractive to utilities. In view of the importance of small, respirable particles in the health effects of coal combustion, it is likely that filter devices will see increased use in the future, and they warrant vigorous development.

Advanced Technologies for Coal Combustion

A number of new approaches to electricity generation, aimed at improved efficiency, lower costs, or reduced environmental impacts, are under development. None of those about to be described is yet available for commercial use, but all show sufficient promise to support important research and development efforts.

Fluidized-Bed Combustion The technique known as fluidized-bed combustion is a promising alternative to scrubbers for meeting sulfur oxide emission standards. It involves burning the coal in a mixture with limestone (to absorb sulfur), suspended turbulently in the stream of combustion air rising from beneath the bed. This method of combustion allows the coal to be burned at lower temperatures than are normal in today’s pulverized coal burners at 1500°F–1600°F rather than about 3000°F. The lower combustion temperatures substantially reduce emissions of nitrogen oxides. The process is under development now, particularly for small units; the current development goals are high efficiency, durability, low emissions of nitrogen and sulfur oxides, and reliability. These seem attainable in the next few years, and it is conceivable that fluidized-bed combustion systems could be in use for industrial boilers in little more than a decade. Their use in large utility boilers will come later.

There are two approaches to fluidized-bed combustion, atmospheric and pressurized. The first, combustion at atmospheric pressure, is the simpler in design and operation. It is considered a first step toward more economical use of high-sulfur and slagging coals, and because of its relative simplicity it would be especially suitable for small-scale use in commercial and industrial boilers and cogeneration systems. It is on the verge of wide commercialization now; the first few vendors are appearing.

The pressurized (perhaps 6–16 atm) version of this technology is much more complicated and much less well developed. It promises, however, higher efficiencies and lower sulfur and nitrogen oxide emissions than atmospheric fluidized-bed combustion. It holds high promise for larger scale use, as in utility power generation.

Combined-Cycle Generation The combined-cycle approach to power generation holds a good deal of promise in the relatively near term as a means of using coal efficiently and cleanly. The combined-cycle configuration—using the exhaust heat of a gas turbine first stage to raise steam for a steam turbine second stage—is inherently the most efficient power cycle available. This makes it potentially feasible to extract power efficiently and economically from coal even through the intermediary of synthetic fuels, with their inherent conversion losses.

At present there are about 15,000 MWe of combined-cycle capacity in the Western world; the average unit capacity is about 150 MWe.24 Most of this capacity has been installed in the last 10 years. Almost all the plants are fueled by petroleum distillate or natural gas, though the use of heavier

fuels is becoming more common as the ability of gas-turbine components to withstand fuel impurities improves.

The combined-cycle configuration provides a likely application for pressurized fluidized-bed combustion systems. The hot combustion gas from the combustor could be cleaned of most particulates and expanded through a gas turbine, the exhaust from which could raise steam for a steam turbine. The high efficiency of the pressurized combustor would allow overall efficiencies somewhat higher than now achievable in even the best conventional plants. A 13-MWe demonstration of this approach, funded by the Department of Energy, is to begin operation in the early 1980s.25 The fluidized-bed approach could be modified if the problem of particulate carry-over to the turbine proves serious. Combustion gases, instead of being sent directly to the turbine, could be sent instead to a high-temperature heat exchanger using an inert working fluid such as helium, which in turn could heat a closed-cycle gas turbine first stage. This would protect the gas turbine blades but entail a loss of efficiency because of the temperature drop in the heat exchanger.

Another strong possibility is the so-called gasification-combined-cycle approach. In this configuration, a medium-Btu gasifier would be integrated with a combined-cycle power plant, essentially as a means of precombustion emission control. Eventually, coal-to-electricity efficiencies of up to 45 percent (far above the 35 percent typical of standard scrubber-equipped steam turbines fed by pulverized coal) should be attainable, though this will require a good deal of work, especially in developing materials and cooling methods for turbines capable of operation at inlet temperatures well over the 2000°F now possible. Refinement of the gasification system will also be necessary. Such highly efficient systems are unlikely to come into wide use before the late 1990s, but they could be very important for industrial cogeneration, as well as utility power generation, in the decade after 2000.

The nearer term demonstration of gasification-combined-cycle plants is also of some interest, however The first integrated gasification-combined-cycle plant in this country is being designed as a demonstration funded by Texaco, Southern California Edison, and the Electric Power Research Institute. Construction is intended to begin in 1981, and operation in 1984. The unit as planned will have a capacity of 110 MWe, with a 75-MWe gas turbine and a 35-MWe steam turbine, and will consume 1000 tons of coal per day.26 The turbine components will be essentially standard commercial units, and the gasifier will be a scaled-up version of a second-generation, medium-Btu Texaco gasifier that has been operated in Germany for about a year at 150 tons/day. The main problems at this early stage in the project are integrating the gasifier fully with the generating components so that gas can be produced as needed during load fluctuations; improving the

operating characteristics of the gasifier’s waste-heat boiler; and modifying the combustion process to control nitrogen oxide formation.

Sulfur oxide and particulate control in gasification-combined-cycle plants should be relatively simple matters of scrubbing the gas before combustion (far cheaper than scrubbing the emissions of conventional power plants). This is one of the potential attractions of the concept: Even tightening the current sulfur emission standards by an order of magnitude is estimated to increase generating costs in such a system by only 7–8 percent.27

Fuel Cells Fuel cells convert fuel energy to electricity electrochemically rather than thermally. They are essentially nonpolluting, practically noiseless, and potentially very efficient. Furthermore, they are modular in construction and can be installed in units ranging in capacity from a kilowatt or so to several megawatts. They could be used in small installations distributed near load centers, since siting problems should be minimal even in densely populated urban areas. A 4.5-MWe demonstration will take place in New York City in the next few years.

In concept and operation, a fuel cell is very simple. It is essentially an electrolyte between two electrodes. A hydrogen-rich fuel is exposed at one electrode and an oxygen-rich gas (such as air) at the other. The hydrogen at one electrode splits into hydrogen ions and electrons, which move separately toward the oxygen, with which they combine as water. The hydrogen ions move through the electrolyte, and the electrons through an external circuit as electrical current.

Current fuel cell technology uses phosphoric acid as the electrolyte; however, carbon monoxide in the fuel would interfere with cell performance, so that relatively cheap low-Btu gas from coal is not a suitable fuel. Second-generation fuel cells will use a molten carbonate electrolyte, which can tolerate carbon monoxide; they will be more efficient than the first-generation fuel cells (about 45 percent, as compared to 40 percent), and are expected to produce power at lower cost.

Fuel cells can maintain this efficiency over a wide range of loads, unlike conventional power generation units, which are markedly less efficient at part power than at their rated capacities. Fuel cells have nearly constant efficiency from 25–100 percent of rated power output, and can respond within seconds to large changes in load. Pollutant emissions (mainly from the fuel processing section) would be an order of magnitude below the levels set by current emission regulations.

The ease of siting, the modular construction, the environmental characteristics, and the efficiency and operating flexibility of this concept mean that fuel cells could be a major source of coal-derived energy by the early twenty-first century, especially for intermediate load following. It

may be easy to apply fuel cells to those processes which can make effective use of the waste heat, such as industrial cogeneration and integrated utility systems to provide electricity and heat for on-site residential and commercial use.

Magnetohydrodynamic Generation Like fuel cells, magnetohydrodynamic (MHD) technology is a means of producing electricity without the need for a turbine—in this case by expanding hot, electricity-conductive gas (such as fuel combustion gases treated to conduct electricity) through a magnetic field. The interaction of the accelerated, conducting gas with an intense transverse magnetic field induces an electric field in the gas. If electrodes are present to collect the current, then electric power can be supplied to an external load. The emissions from an MHD plant would be almost free of sulfur, even if raw coal combustion gases were used, because the potassium salt used to render the gas conductive would combine with the sulfur, which would be separated out as the potassium was recycled. Efficiencies of as much as 50 percent, from coal to electricity, could be achieved using raw coal combustion gases.28 Exhaust gases are at high temperatures, and their heat could be captured and used in a steam turbine bottoming cycle. MHD as a commercial technology for using coal to generate electricity is more than 20 years away, and will make no major contribution to energy supply in the period with which this study is concerned.

Energy Storage Electric utilities for years have used energy storage to derive benefit from off-peak power generated by base-load plants. It is obvious that wide adoption of any suitably efficient energy storage procedure would allow large coal-fired and nuclear base-load stations to serve increasing amounts of the load; and that this would provide further scope for the use of coal in utilities, while minimizing the need for additional generating capacity. The savings in oil and gas, which now fire most of the intermediate and peaking generators, could be very great.

Except in utilities well endowed with hydroelectric dams, the only method of bulk power storage now used—and the most economical source of peaking power in many situations—is pumped hydroelectric storage. This technique entails pumping water uphill with off-peak power, then running it downhill through turbines to help meet intermediate and peak loads. This system is economical and efficient, but takes up large land areas (mainly for the reservoirs); in many places sites are unavailable, though systems with their lower reservoirs underground have been suggested. The storage alternative most nearly available as a supplement is to compress air in underground caverns, then extract energy by running the air through

turbines. If fuel is fed into the air stream before it enters the turbine, a combustion turbine can be used and the result is very efficient and economical peaking power. The use of medium-Btu gas from coal would obviate the need for additional oil and gas. Sites for such plants are less limited by topography than those for pumped hydroelectric installations. A 290-MWe compressed-air storage plant burning natural gas, the first of its kind, is being used in Huntdorf, Federal Republic of Germany, for peaking. It has been in operation only since November 1978, but so far has proved very economical as a source of peak power.29

A number of other approaches, including batteries, thermal storage, flywheels, superconducting magnets, and hydrogen electrolyzed from water with off-peak power, are being developed.30 None is sufficiently advanced to assume commercial service over the coming 10 years.

Cogeneration The cogeneration of electricity and heat is very attractive as a fuel conservation measure, as explained in chapter 2. The development of small- and medium-sized coal-fired units, with suitable environmental characteristics, would allow more flexibility in matching the demands for steam and electricity; it would also make coal increasingly suitable as a replacement for oil and gas in cogeneration projects or decentralized integrated utility systems for apartment or office complexes, hospitals, and the like. There would be some difficulties in fuel delivery and ash removal, but this option should be studied carefully.

SYNTHETIC GAS FROM COAL

Coal gasification has been a commercial operation for more than 150 years. It was carried on in many cities in the United States until the years after World War II, when cheap natural gas began to be transported through the long-distance pipelines built to carry petroleum for the war effort. By the mid-1950s the domestic industry had virtually disappeared. Europeans continued to gasify coal and substantially improved the gasification technology until the 1950s, when Middle Eastern oil and Dutch natural gas began to displace the European coal-derived gas industry; very few new coal-to-gas plants have been constructed.

None of the gasification technologies currently available for commercial use produces gas with a heating value equivalent to that of natural gas, which is essentially all methane. The gases from the conversion processes are mixtures of carbon monoxide and hydrogen, with small amounts of methane distilled from the coal; these “low-Btu” gases have heating values of 150–300 Btu/ft3, as compared with natural gas at 1000 Btu/ft3. Some changes in process conditions (for example, substituting oxygen for air

during the partial combustion that produces the gas) can increase the heating value to about 500 Btu/ft3; gas of 300–500 Btu/ft3 is known by convention as “medium-Btu gas.” Medium-Btu gas, however, can be converted to high-Btu gas, fully equivalent to natural gas, though no commercial installations are in use.

Virtually all coal gasification processes entail similar steps. First, the coal is crushed. (If coking coal is to be used in certain gasification processes, it is necessary to pretreat it after crushing to destroy its fusing properties, generally by heating it in a mixture of steam and air or oxygen.) The coal is fed to a gasifier where it is heated in the presence of air or oxygen. Depending on the type of gas to be made, the resulting low- or medium-Btu gas may be treated with steam to adjust the ratio of carbon monoxide and hydrogen (the so-called shift reaction), after being cleaned of impurities. This is followed by a second cleaning to remove carbon dioxide and hydrogen sulfide. If high-Btu gas is desired, the clean medium-Btu gas is passed through a methanation step, in which the raw gas is reacted over a catalyst to produce essentially pure methane.

Low- and Medium-Btu Gas

The low-Btu gas produced by an air gasification system has a heating value too low to be economically transported or used in equipment designed for natural gas. It could, however, be used to power on-site industrial boilers and electric power generating equipment. As explained earlier, combined-cycle generating plants fueled by coal gasifiers appear to offer the potential of efficient and relatively low-cost electric power generation as well as environmental benefits over direct coal firing.

When oxygen is used in the gasifier instead of air, the gas produced can have a heating value 30–50 percent that of natural gas, essentially because it is not diluted with nitrogen from the air. Costs are increased by the need for an oxygen-generating plant, but the higher quality medium-Btu gas requires less cleaning than low-Btu gas and can in addition be transported economically for distances of 150 miles or more. Industrial gas users who must convert from natural gas may find medium-Btu gas preferable, especially if their access to petroleum is restricted. Medium-Btu gas may also serve as a fuel for combined-cycle generating plants, as explained earlier.

The commercially available processes for low- and medium-Btu gas production were all developed in Europe. The predominant processes are the Lurgi, the Winkler, and the Koppers-Totzek, all of which use oxygen and steam but differ in the method of bringing these reactants into contact with the coal. A number of improved processes are undergoing development here and abroad.

High-Btu Gas

High-Btu gas, equivalent in heating value to natural gas at 1000 Btu/ft3, could serve as a direct replacement for natural gas in existing pipelines and distribution systems. The projected price (roughly $4–$5 5 per million Btu (1977 dollars)) is about half that of electricity (though much more than that of natural gas). The choice between high-Btu gas and electricity rests on the final cost to the consumer per useful Btu, that is, the cost of the delivered gas or electricity times a factor to allow for the efficiency of end-use. In residential services the advantage of gas for cooking is clear. For space heating, particularly with heat pumps, and for air conditioning, the case is not clear. The alternative of using high-Btu gas is a very important one, because there are some 40 million residential gas customers, 85 percent of whom use gas for space heating. Furthermore, there is a large and efficient gas distribution system already in place, representing an investment of several billion dollars. The allocation of emphasis between gas and electricity as the ultimate products of coal use must be decided carefully for each region, considering the value of using gas distribution systems where they already exist.

The most nearly available high-Btu coal gasification technique is the methanation of medium-Btu gas. The Lurgi process has been tested as a source of the raw gas, and some improvements in this process have been made in the past few years with the aim of better suiting it as a component of a high-Btu gas system. There is need, however, for more economical gasification processes than the “first-generation” Lurgi technique. Thus, a number of second- and third-generation processes are under development, with some of the more advanced projects under combined industry-government funding.

Of the second-generation processes now under investigation, a number have been subjected to pilot plant tests over the past few years. Among the prime objectives is to produce raw gases of high methane content and thus to reduce the need for oxygen in the gasifier. Among the federal development projects are the HYGAS process, which has been operated in a 3-ton/hr pilot plant by the Institute of Gas Technology, and the two-stage Bi-Gas process, which can use all types of coal and is being tested in a 120-ton/day pilot plant at Homer City, Pennsylvania. Private industry is investigating many other approaches in smaller scale facilities.

Third-generation processes promising much improved thermal efficiencies and lower costs are also being investigated through feasibility studies and very small experimental reactor tests. The two such processes emphasized in the federal research and development program are hydrogasification, which produces high-Btu gas by direct reaction of coal

with hydrogen, and catalytic gasification, which eliminates the shift reaction and methanation steps entirely.31

Underground Coal Gasification

Production of low- or medium-Btu gas from coal in situ, by injecting air or oxygen into coal seams, has a number of attractive features. First, more than 90 percent of the nation’s coal resource is inaccessible to mining; some of this could be gasified in place. Of particular interest in the federal research and development program are “steeply dipping beds,” or those that slope more than 35 degrees from the horizontal; such beds in the United States are estimated to contain more than 100 billion tons of coal,32 and coal in these formations may be easier to gasify in situ than that in conventional beds.

Underground coal gasification has several potential health, safety, and environmental advantages over conventional mining followed by gasification. It requires less land disruption, uses less water, brings less solid waste to the surface, and probably creates less air pollution. The most important environmental uncertainties are the potential for contamination of groundwater, and in some cases the hazard of subsidence of the surface over gasified seams. This kind of development must be accompanied by intensive environmental research and monitoring.

Several different methods are being investigated. The most advanced is the linked vertical well method, used to produce low-Btu gas from western coal by air injection. Work on this process began in 1972 and several pilot tests have been quite successful. The Department of Energy estimates that commercialization of the process could begin by 1987 if the product is competitive in price.33 Experiments have also been performed in the production of medium-Btu gas by oxygen injection.

The gas could be used for electricity generation at the gasification site, for the local generation of process heat (for which medium-Btu gas would be especially well suited because it can be economically transported moderate distances), as a raw material for chemical feedstocks, or for conversion to high-Btu gas. One estimate suggests that in situ gasification could eventually provide as much as 1.5 quads of energy in the region surrounding the Rocky Mountains.34

Product Costs

After a comparison of many synthetic gas cost estimates, one authority calculated that a Lurgi high-Btu gas plant yielding 10.4 million standard cubic feet per hour could operate at a cost (1977 dollars) of roughly $4.50 per miilion Btu.35 However, all such estimates are highly speculative and