3

Previous Analyses and Experience with Wingtip Modifications on Existing Aircraft

This chapter reviews the results of previous studies and deployment of wingtip devices on existing commercial and military aircraft. On the commercial side, the experience and decision processes of aircraft manufacturers as well as two operators (airlines) are described. On the military side, one transport aircraft (the C-17) already has winglets as original equipment, and others (e.g., the KC-135 tanker) have been evaluated for this modification. In some cases, military airplanes are closely related to commercial analogues (e.g., the C-32 is based on the Boeing 757-200) and can benefit from wingtip modification studies that have been conducted for the commercial aircraft. In other cases, the aircraft are military-unique (e.g., the C-5), and the evaluation of their suitability for wingtip modifications would have to start from the beginning. Military-unique aircraft for which no previous wingtip modification studies are available are discussed in the next chapter. This chapter concludes with a summary of the lessons that can be learned from past experience with wingtip devices that could help with deciding on military wingtip device retrofits.

EARLY RESEARCH PROGRAMS

NASA-Led Research: ACEE

The Aircraft Energy Efficiency (ACEE) program was initiated by the Department of Energy (DOE) and the National Aeronautics and Space

Administration (NASA) in 1975 as a 10-year effort to advance aircraft performance and increase fuel economy by 40 to 50 percent per unit distance. The technological opportunities for doing this included more fuel-efficient engines, lighter weight structures, and better aerodynamic designs.1

The winglet concept was evaluated and tested extensively by NASA in its 8-Foot Transonic Pressure Tunnel from 1974 to 1976. In July 1976, NASA published a general design approach that summarized the aerodynamic technology involved in winglet design. The tunnel tests indicated that, for typical subsonic transport aircraft configurations, induced drag could be reduced by about 20 percent and the aircraft lift-to-drag ratio (L/D) could be increased by about 9 percent. This improvement in L/D is more than twice as great as that achieved by the comparable wingtip extension producing the same wing-root bending moment.2,3 In coordination with the ACEE program, Boeing, McDonnell Douglas, and Lockheed studied the impact of winglets on near-term derivative aircraft. The results of these efforts and additional efforts by the airframe manufacturers are described below.

COMMERCIAL EXPERIENCE

There are a number of very successful applications of winglets and wingtip extensions in the world’s commercial airplane fleet. These programs have been successful for a number of reasons, most notably because they have enhanced the economic value of the subject commercial airplanes. These wingtip device strategies have been employed both on new design aircraft and as postproduction retrofits on existing aircraft. The following is a summary of the strategies employed by the main commercial airframe manufacturers and two commercial airlines.

Airframe Manufacturers

Boeing

Boeing 7-Series aircraft have been manufactured by the “heritage” Boeing Commercial Airplanes Company in the Seattle area. The first in-production winglet produced by Boeing was for the 747-400, an improved Boeing 747 introduced in the late 1980s. The wingtip modification introduced on the 747-400 included a 6-ft per side wingtip extension and a canted 6-ft per side highly swept winglet (see Figure 3-1). The purpose of the wingtip modification was to improve the cruise aerodynamic efficiency of the airplane and, to a certain extent, differentiate the -400 model of the 747 family from the earlier -100/200/300 models. The tip modification increased the cruise L/D approximately 4 percent (less than half of the upper limit of 9 percent suggested by wind tunnel tests in the ACEE program, see above), with much of the improvement coming from the span extension. The L/D increase gives an equivalent increase in fuel efficiency.

Boeing introduced the 737 Next-Generation (NG) aircraft in the late 1990s without a tip device. Several years after entry into service, the Boeing

FIGURE 3-1 Boeing 747-400 with swept, canted winglets. SOURCE: Reproduced by permission of Boeing.

FIGURE 3-2 Boeing 737-NG with blended winglets. SOURCE: Reproduced by permission of Boeing.

Business Jets (BBJ) Company accepted a proposal to test a set of blended winglets4 on the 737-BBJ from Aviation Partners Incorporated (API), a small Seattle-based aircraft modification company. The API design was a relatively large winglet, 8 ft long, installed on a relatively small commercial airliner. API required the intimate product knowledge of the original equipment manufacturer (OEM), Boeing, to be able to successfully integrate this winglet with the airplane structure and systems. In a joint flight development program with Boeing, the API winglet demonstrated a 4-5 percent block fuel reduction on the 737-NG series of aircraft (Figure 3-2).

The original design of the 737-NG wing allowed the winglet to be installed with only minor modifications to the wing structure. Owing to its nonstrength design features such as minimum gages required for hail and lightning protection, stiffness requirements for flutter, and design conservatism, the outer wing of the 737-NG had sufficient structural margins to

accommodate the winglet readily. This made retrofitting the API winglets to the 737-NG technically and economically feasible. The BBJ market was a good trial for the winglets in that owners and operators of these airplanes wanted a high-tech look for their airplanes as much as they wanted efficiency benefits. Once the development work for the BBJ application had been completed, extending blended winglets to the commercial fleet of the 737-NG became a business decision that was accelerated by the rapid rise in fuel prices and economies of scale for large-volume production of winglets. Following the successful certification of the BBJ and commercial retrofit winglet design, Boeing then modified the in-production 737-NG design to accommodate the winglets, and that has become the almost de facto standard configuration for the 737-NG. Several thousand sets of 737-NG winglets had been ordered through the end of 2006 by the overwhelming majority of 737-NG operators.

Based on the success of the 737-NG winglet design, Aviation Partners Boeing (APB) was formed after Boeing purchased a minority interest in API. APB then developed a retrofit-only winglet installation for the Boeing 757 airplane (Figure 3-3). While the 757 is no longer in production, there are approximately 1,000 airplanes in service with the potential for another 20 years of life. APB was ultimately able to develop a retrofit package that uses the same winglet as the 737-NG on the 757. This was accomplished by developing a 17.5-in. tip extension that provides a transition from the 757 wingtip to the 737-NG wingtip, thus enabling a common interface to the existing winglet contour. Because of this tip extension and because the 757 wing did not provide as much excess structural margin as the 737-NG wing, the weight penalty of the 757 installation is considerably larger than that of the 737-NG. The total 757 installation weighs 1,358 lb versus approximately 340 lb for the 737-NG. However, the 757 tip extension also increases the efficiency gains for the installation, resulting in a block fuel savings potential of up to 5 percent, depending on mission range. A number of large domestic 757 operators, including American Airlines, Continental Airlines, and Northwest Airlines, have now opted for the APB winglet retrofit.

APB is also pursuing winglet retrofits for several other Boeing 7-Series aircraft. Recently, a retrofit winglet was certified for earlier models of the 737 family (737-300/400/500). This fleet went out of production in 1998, but there are still approximately 2,000 aircraft in service with decades of remaining life. APB is also investigating the feasibility of a winglet retrofit for the 767 family and the earlier models of the 777 family. An earlier pro-

FIGURE 3-3 Boeing 757 with retrofit blended winglets. SOURCE: Courtesy of Adrian Pingstone.

gram to develop an improved winglet installation for the 747-400 was not successful. The lesson from this experience is that not every airplane is a good candidate for further modifications. Success depends on aerodynamic compatibility and structural features such as strength margins and flutter margins.

Boeing took a different approach to improve the performance of its latest models of the 767 and 777 families. Both the 767-400ER and the 777-200LR/300ER incorporate a raked wingtip span extension design (Figure 3-4).5 Similar in effect to winglets, the raked tips provide a reduction in cruise fuel burn and improved takeoff performance at the expense of longer wingspan. Boeing chose these designs because market studies indicated that the airplanes would still be able to use the same infrastructure as the older airplanes they would replace. The 767-400ER would be replacing DC-10 and L-1011 aircraft and competing with Airbus A330 aircraft, and the 777-200LR/300ER would be replacing or competing with Boeing 747-200/300/400 and Airbus A340 aircraft. In addition, the raked tip offers a

FIGURE 3-4 Boeing 767-400ER with raked wingtips. SOURCE: Reproduced by permission of Boeing.

takeoff performance advantage over winglets because it improves not only drag but also lift, both of which are important for takeoff. Finally, the raked tip proved to be more efficient structurally because its design provides more aeroelastic relief than winglets for critical structural design conditions. The engineering trade-off for winglets versus raked tip extensions is a close call, and for these two aircraft families—767 and 777—the design space was more favorable for the raked tips than the winglets.

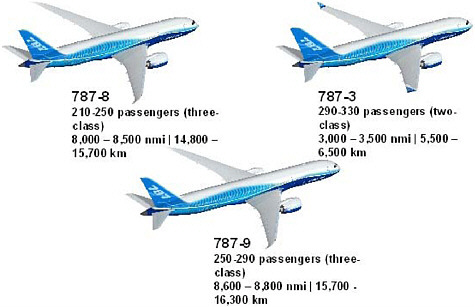

Boeing is currently designing a new family of long-range, wide-body transports, the 787 family (Figure 3-5). The 787 is intended to replace the 767 family and the Airbus A300/A330/A340 families. For reasons similar to the design solutions discussed for the 767-400ER and 777-200LR/300ER, Boeing selected a raked tip for the base 787-8 airplane. For growth versions of the 787, an even larger raked tip is envisioned, because the airplane will easily fit in the infrastructure that exists for the airplanes that it will replace. However, for the shorter range 787-3 model, which will be used for regional

FIGURE 3-5 The Boeing 787 family, featuring various wingtip modifications. SOURCE: Reproduced by permission of Boeing.

transport to smaller airports, the market asked for a smaller span that would be more compatible with DC-10/L-1011/A300/767 operations. To satisfy that market, Boeing has shortened the span of the 787-3 wing and recovered some of the lost efficiency by developing a large vertical winglet. That design was still evolving at the end of 2006, and at this writing the precise outcome is still to be decided. The 787 strategy does provide an excellent example of the design trades that need to be made in order to decide which wingtip solution is appropriate for a given aircraft.

McDonnell Douglas Heritage Commercial Aircraft

Aircraft produced by the McDonnell Douglas Corporation, now part of Boeing, continue to be a large segment of the installed fleet of commercial airplanes. The two main families include the small twinjet DC-9/MD-80/MD-90/Boeing 717 models and the large trijet DC-10/MD-10/MD-11 models.

The trijet family has had numerous winglet studies conducted, including work done in cooperation with NASA in the 1970s and 1980s. The

FIGURE 3-6 McDonnell Douglas MD-11 with dual winglets. SOURCE: Reproduced by permission of Boeing.

DC-10 work in the early 1980s culminated in a flight test demonstration program that validated a 2-3 percent cruise efficiency improvement over the original DC-10 design, depending on the height of the winglet utilized.6 However, a production winglet design was not incorporated until the design of the MD-11, a derivative of the DC-10 (the military KC-10 is also a derivative of the DC-10). The winglet configuration included a large upward-canted winglet and a small downward-canted winglet, as shown Figure 3-6. The selection of the dual winglet configuration was driven by the additional cruise drag benefit of the added span offered by the lower winglet and the favorable aerodynamic interactions between the upper and lower winglets at low-speed, high-angle-of-attack conditions. This configuration was developed in the early days of computational fluid dynamics (CFD) codes, when the original 747-400 winglet was being developed. Today’s CFD capabilities

are much improved; the Navier-Stokes codes are considered capable of generating more accurate results and have been used in the latest aircraft designs to reach a successful design more quickly and with less wind tunnel testing.7 In both cases the selected design philosophies might have been different had the current CFD capabilities and design lessons learned been available. Nevertheless, both the 747-400 and DC-10/MD-11 winglet designs have provided substantial airplane performance benefits to their products. The dual winglet design developed for the DC-10 has only been incorporated into the production MD-11 aircraft. Although the winglet was not flight tested separately from other aerodynamic modifications, it has been credited with a performance benefit of 2.5 percent.8 To date, there has not been a retrofit program for the DC-10 aircraft.

The Douglas twinjet family has also been the subject of wingtip redesign studies. In the early 1980s, the DC-9 was redesigned as the MD-80, including a wing root insert and a wingtip extension. These changes provided more wing area, more wing span, and increased fuel volume, allowing increases in payload and range for this aircraft family. Also included in the MD-80 transformation were new, higher thrust/higher efficiency engines and an elongated fuselage. The wingtip extension for the MD-80 was notable in that it was a constant chord design, allowing the existing tip fairing and navigation light design to be retained. However, the wingtip extension and span loading were not optimized for efficient long-range cruise, as some other designs have been. The result of that is that the MD-80 wingtip devices do not show significant fuel economy benefits.

APB has investigated a retrofit design for the DC-9 family. Those design studies have not been successful in creating a viable business case. Projected block fuel burn reductions of less than 2 percent are offset by substantial modification costs. The limited potential for the DC-9 is a result of the existing wing structure, which hinders installation of a large winglet, as was possible on the Boeing 737 family. Since the DC-9 has been out of production since the early 1980s, the fleet size has shrunk and the fleet has aged, making the business case for a retrofit winglet or wingtip not as attractive as that for the Boeing 737 and 757 families.

Just as Boeing and McDonnell Douglas were merging in 1997, a new derivative of the DC-9 family emerged as the renamed Boeing 717. That aircraft essentially combined the airframe of the original DC-9 with new engines and new systems. Since nearly 200 Boeing 717 aircraft were delivered before production terminated in 2006, there may still be a retrofit potential for this very new fleet. However, since the airframe is essentially a DC-9, it is unlikely that an outcome better than the projected reduction of 2 percent or less is possible without a significant structural modification of the aircraft. As of late 2006, no retrofit solutions for the twinjet family were being pursued.

Airbus Industries

There are two distinctly different winglet design strategies apparent on the commercial aircraft produced by Airbus Industries. The first is a “tip fence” concept, employed on the A310/A320/A380 families. The tip fence is a small dual winglet configuration with highly swept, nearly vertical upper and lower partial-chord winglets (Figure 3-7). For both the A310 and A320, the size of these winglets indicates that they were installed to take advantage of structural margin in the wings, since both aircraft were initially certified with plain wingtips.

A similar configuration was included in the initial rollout configuration of the A380, which was certified in December 2006. The design that preceded the A380, the design for the A330 and A340, had large, single-canted and highly swept winglets similar to the 747-400 configuration (Figure 3-8).

In 2006, Airbus flight tested several winglet designs on the A320 that appear to be similar to the 737-NG blended winglets. According to media reports, Airbus has decided not to offer these winglets for production or retrofit because the aerodynamic efficiency benefits determined from flight testing were not sufficient to overcome the very large weight increase needed for the installation. Airbus also expressed concern over potential long-term effects on the structural integrity of the wing due to stress imparted by winglet forces.9 An implication to be drawn is that the wing may require significant structural modifications in order to accommodate the additional loads and/or flutter requirements of the large winglets. The Airbus experi-

ence provides a valuable lesson on the difficulties that may be encountered in the design of winglets for retrofit to an existing aircraft.

Airlines

A number of airlines throughout the world have ordered or retrofitted some of their aircraft with winglets. The following summarizes the rationale and results for two commercial airlines that have chosen to modify their in-service aircraft with winglet devices.

Southwest Airlines

In 2000, when the price of oil reached $27 per barrel, Southwest Airlines conducted a study to retrofit a portion of its existing Boeing 737 fleet of aircraft with winglets as a means of reducing fuel burn. Although the proposed modifications held the potential for market expansion and increased revenue due to improved range and takeoff gross weight performance and other performance considerations, as well as the residual value of the modified aircraft, the original study payback period was based solely on the financial justification provided by reduced fuel burn.10 The intent was to demonstrate the required performance benefits with no degradation in operational capability.11

The study of the 737-700 indicated a block fuel burn improvement (total fuel burn from engine start at the beginning of a flight to engine shutdown at the end of that flight) of 2.4 percent for flight segments of 500 nmi to a maximum of 4.0 percent for flight segments of 2,000 nmi. This improvement translated into a potential annual fuel savings of up to 110,000 gallons per aircraft for the modified fleet.12

With a projected payback period of 2 years for the first batch of modified 737 aircraft, the fuel burn savings satisfied financial and operational considerations for Southwest and the first order for winglets was placed in 2003. The modification process was coordinated through a Boeing Service Engineering team that operated as the single point of contact between

Southwest and APB in order to improve communications and program management. Southwest planned for a 7-day out-of-service time for each aircraft winglet modification, but its experience demonstrated that the modification could be accomplished in 3 or 4 days.13

In addition to the planned fuel savings, the modification demonstrated some increase in takeoff gross weight (TOGW) capability. As a result, the airline has benefited from an increase in stage lengths by adding takeoff fuel at facilities where the aircraft were previously limited by TOGW.14

The potential issues of ground damage, lightning strike, and hangar clearance that constituted the airline’s internal justification for the modification program have proven to be of no consequence. Southwest reports that there have been no appreciable costs or operational limitations tied to crew training, technical data, or the like.

The success of the 737-700 modification program has motivated Southwest to initiate a new proposal for older 737-300 aircraft that lack a suitable wing structure. The extra weight for this modification is estimated to be 783 to 801 lb. This proposal is based on a projected block fuel burn improvement of 2.6 percent for a 500 nmi stage and 4.4 percent for a 2,000 nmi stage and could save up to 100,000 gallons of fuel per aircraft per year.15 Because the wing structure must be modified, the out-of-service time to complete the winglet modification for the 737-300 aircraft is estimated to be 14 days.16 The results of the Southwest 737 winglet modification program are summarized in Table 3-1.

TABLE 3-1 Southwest Airlines 737 Winglet Modification Summary

|

Aircraft Type |

Retrofit Weight Increase (lb)a |

Production Weight Increase (lb)b |

Increase in Wing Dimensions Attributable to Winglets |

Block Fuel Savings (%) |

|

737-700 (non-provisioned wing) |

340 |

N/Ac |

8 ft 2 in. (height) 6 ft 4 in. (span) |

2.4 to 4.0 |

|

737-700 (provisioned wing) |

241 |

220 |

8 ft 2 in. (height) 6 ft 4 in. (span) |

2.4 to 4.0 |

|

737-300 |

783 to 801 |

N/Ac |

7 ft 6 in. (height) 8 ft 10 in. (span) |

2.6 to 4.4 |

|

aDifference between the weight of the aircraft manufactured without winglets and the weight of the aircraft after retrofitting with winglets. bDifference between the weight of the aircraft manufactured without winglets and the weight of the aircraft with winglets. cAircraft are not manufactured with winglets as original equipment. SOURCE: Data from APB. |

||||

American Airlines

Following an extensive study, American Airlines decided in 2004 to add winglets to its long-range international fleet of 20 757-200ER aircraft.17 The decision was made subsequent to a detailed business planning effort. American considered the following costs and benefits in its winglets business case:18

The business case for installing winglets considers the following costs:

-

Materials (hardware, software, consumables),

-

Labor,

-

Tooling,

-

Spares for inventory,

-

Expected maintenance (repairs, inspection, replacements),

-

Out of service (lost contribution),

-

Ferry costs,

-

Fuel (use forward-fuel-curve-based futures market),

-

Airport gating loss, modifications, or flexibility costs, and

-

Maintenance hangar modifications at bases and airports.

The business case for installing winglets considers the following benefits:

-

Improved fuel burn,

-

Engine derate,

-

Possible new markets due to increased range,

-

Additional payload, and

-

Change in residual value of the aircraft.

Other factors for consideration:

-

Lease agreements,

-

Coordinating modifications with other base maintenance visits, and

-

Economic life of aircraft.

American found that the winglet was supported on the basis of fuel conservation alone if a high NPV discount rate was used,19 and it contracted with APB to manufacture the winglets. The negotiation yielded a single extra kit to install on one of American’s 737-800s as a test case for the benefits on that fleet of aircraft. Prior to the modification program, American’s 737-800 fleet was operating at an average +2.2 percent fuel burn over the specification, or book, level (worse than design level).20 The modification program had the potential to return fuel burn to book level or better. The first winglets were installed on the 737-800, and the modified aircraft became operational in October 2005.

Whether the winglets are original equipment or retrofitted, the weight penalty for the aircraft is 380 lb. As with Southwest’s installation on its 737-700s, the vertical portion of the winglet adds 8 ft 2 in. to the height of the wing, while the horizontal portion of the winglet modification adds 4 ft 7 in. to the wingspan.

The modified 757-200ER aircraft was released to service in December 2005. The weight added by the winglet modification was approximately 1,400 lb. To mitigate the added weight, American obtained an increase in the certified maximum zero fuel weight. The effect on wing geometry for the winglet modification is an increase in wing height of 8 ft 2 in. and an increase in wingspan of 9 ft 9 in.

American used two separate methods (actual flight burn data and aircraft performance monitoring software) to calculate the fuel savings realized by the winglet modification of its 737 and its 757 aircraft. Those calculations demonstrate a fuel savings for the 737-800 aircraft of 3.2 percent when compared to its 737-800 nonwinglet fleet. This equated to 32 gal of fuel saved per flight hour.21

The modified 757-200ER fleet demonstrated a fuel savings of 3.3 percent in comparison with its unmodified 757-200ER fleet, a fuel savings of 40 gal per flight hour.22 Both findings are in line with reports of savings from other operators of similar aircraft.23

The results of American’s 737-800 and 757-200ER winglet modification programs are summarized in Table 3-2.

American concluded that there were no changes in flying qualities, and the Federal Aviation Administration (FAA) required no changes to the flight simulators of either fleet as a result of the winglet modifications. The FAA deemed that the flight crew training requirements could be satisfied with appropriate technical manuals.

The added winglets improved the takeoff performance of American’s aircraft and gave them greater takeoff gross weight capability. These resulting improvements expanded the airline’s market potential by giving it access to previously climb-limited airports (generally high-altitude, high-temperature, or short-field airports). American has taken advantage of these new capabilities and thereby increased its revenue.24

TABLE 3-2 American Airlines 737-800 and 757-200ER Winglet Modification Summary

|

Aircraft Type |

Retrofit Weight Increase (lb)a |

Production Weight Increase (lb)b |

Increase in Wing Dimensions Attributable to Winglets |

Block Fuel Savings (%) |

|

737-800 (non-provisioned wing |

520 |

N/Ac |

8 ft 2 in. (height) 4 ft 7 in. (span) |

3.2 |

|

737-800 (provisioned wing) |

380 |

380 |

8 ft 2 in. (height) 4 ft 7 in. (span) |

3.2 |

|

757-200ER |

1,358 |

N/Ac |

8 ft 2 in. (height) 9 ft 9 in. (span) |

3.3 |

|

aDifference between the weight of the aircraft manufactured without winglets and the weight of the aircraft after retrofitting with winglets. bDifference between the weight of the aircraft manufactured without winglets and the weight of the aircraft with winglets. cAircraft are not manufactured with winglets as original equipment. SOURCE: Data provided by APB and American Airlines. |

||||

MILITARY EXPERIENCE

C-17

The C-17 was designed by the McDonnell Douglas Corporation, now a part of the Integrated Defense Systems component of the Boeing Company (Figure 3-9). Winglets were incorporated into the design for reasons relating to taxi clearance, turning radius, maneuverability, and parking. In particular, the Air Force wanted to limit the wingspan to that of the C-141 to make the C-17 compatible with facility infrastructure. Clearly, it was preferable to achieve the desired airplane cruise performance by adding winglets rather than increasing the wingspan.

A number of these design considerations led to the final winglet configuration on the C-17. Early C-17 designs included upper and lower winglets. However, the lower winglet was eliminated after it was determined that the cruise performance goals could be met with a single upper winglet configuration; that ground clearance requirements would be problematic with the lower winglet; and that the lower winglet would result in higher manufacturing and maintenance costs. The planform and placement of the C-17 winglet were also driven by exterior lighting requirements.

FIGURE 3-9 The Air Force’s C-17 with winglets.

The winglet was shown in wind tunnel testing to reduce cruise drag approximately 2.5 percent. Also, no additional buffeting was observed for takeoff or landing configurations during flight testing.25 However, while these benefits are considered to be substantial, the C-17 winglet was developed in a low Reynolds number (RN) wind tunnel. The low RN environment can produce misleading results with regard to drag, buffet, pitching moment, and loads because the flow phenomena are different from those at the much higher RN of the full-scale flight vehicle. Also, the C-17 configuration was developed in the 1980s before the full-scale National Transonic Facility Wind Tunnel and before modern Navier-Stokes CFD tools. With these new capabilities, the current C-17 winglet design could be more accurately assessed. These new tools, together with lessons learned from other winglet designs, might make it possible to improve the C-17 winglet design, and thereby cruise drag, another 1 percent or more.26

C-32

The C-32 is a military derivative of the Boeing 757-200 commercial aircraft and is used for government executive transport. APB offers a retrofit package for this aircraft, and a contract was awarded in October 2006 for installation of this package on the four C-32 aircraft in the Air Force inventory.

KC-135

A number of studies have been conducted over the years to determine the suitability of adding winglets to the KC-135 aircraft, which is closely related to the Boeing 707. Some of the pioneering work on winglets was conducted at NASA in the mid-1970s on the KC-135. That work was followed by several Air Force contracts with Boeing to investigate the design space for winglets on the KC-135 and included extensive wind tunnel testing. That work, in turn, determined that winglets could greatly improve cruise efficiency. An improvement in the L/D of nearly 8.5 percent was reported, along with an estimated empty weight increase of approximately 600 lb, for a net performance improvement of nearly 7.5 percent.27 The winglet selected for this work was nearly 9 ft in length, slightly larger than the production winglets on the 737-NG.

The improvement predicted for this winglet on the KC-135 is considerably larger than that for any winglet that has actually been incorporated into an airplane. In the 1970s, it was speculated that the KC-135 would be an excellent candidate for winglets because the wing was overloaded relative to the ideal elliptical span load, which would presumably allow the winglet to load more optimally. While that explanation may have had some merit, it would not be surprising if the current methods used to design and analyze winglets were to arrive at a less optimistic prediction. Certainly it is now known that the aeroelastic impact of the winglet on the wing’s twist must be considered, and that should decrease the benefit somewhat. Nevertheless, the work conducted in the 1970s suggests that a significant benefit could accrue from using winglets on the KC-135 and that the structural requirements for installation appear to be manageable.

Later the Air Force conducted a flight test of winglets on a KC-135. The published report on that flight test indicated good agreement with

the analytical and wind tunnel testing when known differences between the tests were accounted for.28

SUMMARY OF COMMERCIAL AND MILITARY EXPERIENCE

The commercial airframe manufacturers began testing winglet installations for several aircraft more than 20 years ago. At the time many of these ideas were first proposed, fuel prices were not sufficiently high to justify retrofit costs. However, the retrofit idea took off once fuel prices started rising, and airlines saw the need to use more economical aircraft for longer-range missions. Cost-benefit analyses conducted by the airlines (American Airlines and Southwest Airlines) indicated that winglet retrofit programs on appropriate aircraft would pay for themselves within about 2 years based on the fuel savings alone.

The Boeing 737-NG became the flagship for the retrofitting of commercial fleets with winglets. It was an aircraft that was well suited since it needed very little structural upgrade, was easily modifiable, and proved to have 3-5 percent fuel burn improvements depending on mission length and other factors. The installation takes only 4 or 5 days, and the aircraft have had no negative operational issues nor have they needed any change to flight operational procedures or training of crew.

The winglet-modified Boeing 757 shows similar fuel burn improvements, and this makes it ideally suited for secondary European markets from the U.S. East Coast. It actually has allowed using a smaller aircraft that was originally intended for domestic use, turning it into an efficient international aircraft.

The commercial experience is that wingtip modifications make sense if one can achieve a 3-5 percent fuel burn improvement, if careful engineering analysis shows that the aircraft have sufficient structural integrity to easily accept wingtip extensions or winglets, and if the modifications are relatively easy to install. The airlines have been able to overcome with little difficulty the initial concerns relating to the added wing height and wingspan in hangars, at gates, and on taxiways.

Only one military-unique aircraft, the C-17, features winglets. Designers had a choice of either increasing the wingspan or using winglets to achieve the desired performance, and winglets were chosen because they

minimize problems relating to taxi clearance, turning radius, maneuverability, and parking. However, the C-17 design was done before modern analysis and optimization tools were fully developed, and application of these tools could further improve the C-17’s aerodynamic performance.

As discussed earlier, the retrofit potential of some other military aircraft, such as the KC-10 (based on the DC-10 airframe) and the KC-135 (which is closely related to the Boeing 707 airframe), has been studied and found promising. Other military-unique aircraft, such as the C-5, would require extensive engineering analysis before a judgment could be made. In Chapter 4, the committee reviews all the candidate aircraft in the Air Force inventory and recommends those that merit careful consideration for tip device retrofits.