C

NIOSH Mining Ergonomics Research Program Review1

Barbara Silverstein, Ph.D., M.P.H., C.P.E.

Washington State Department of Labor and Industries

NIOSH MINING PROGRAM STRATEGIC RESEARCH PLAN: REDUCTION OF REPETITIVE AND CUMULATIVE MUSCULOSKELETAL INJURIES

This review is based on reading materials prepared by the National Institute for Occupational Safety and Health (NIOSH) Mining Program; a meeting with the mining program associate director, the acting director, and ergonomics researchers from the Pittsburgh and Spokane laboratories; and reviewing mining research program web sites from Australia, the United Kingdom and Canada along with relevant literature.

STRATEGIC GOALS AND OBJECTIVES

The Mining Program seeks to eliminate occupational injuries, illnesses, and fatalities in the mining industry via research and prevention activities in partnership with key stakeholders.

Goal: By 2014, reduce repetitive and cumulative musculoskeletal injuries by 30 percent based on 2003 injury rate.

The intermediate goals of the mining ergonomics program are to

-

Quantify job demands and physical capabilities of miners to develop improved recommendations for work design; and

-

Develop and field-test ergonomic interventions to reduce worker exposure to musculoskeletal risk factors.

The performance measures are to

-

Provide 10 improved designs and work practices by 2009; and

-

Reduce the repetitive and cumulative musculoskeletal injury rate by 25 percent at test mine sites by 2009.

While most traumatic onset injuries have been decreasing in the mining industry, Bureau of Labor Statistics (BLS) and Mine Safety and Health Administration (MSHA) data indicate that work-related musculoskeletal disorders (WMSDs) due to heavy, awkward, or repetitive manual handling and vibration represent a significant proportion of illnesses and injuries in mining. Not all data sources clearly define musculoskeletal disorders. Data from MSHA and BLS (BLS, 2006a, 2006b) indicate that in the past 8 years, there has been a decrease in musculoskeletal disorders in mining by more than 30 percent, thus making the proposed goal quite achievable. Between 1999 and 2003, 4,079 back injuries with 173,000 lost or restricted work days were reported in surface mining, primarily among truck drivers, dozer operators, and front-end loaders; an additional 6,060 overexertion injuries were reported, many in the same occupations (National Safety Council, 2004). According to BLS data (BLS, 2004a) there were 2,380 lost time overexertion injuries in mining in 2004. Among all injuries reported, 25.8 percent occurred after 8 hours of work (BLS, 2004b). While these data are not broken down by injury type, it is reasonable to hypothesize a relationship between overexertion and extended work hours.

Ergonomics research and education activities can contribute enormously to identifying root causes of these disorders and to developing and testing potential solutions and disseminating results to employer and employee partners, as well as equipment manufacturers and regulatory agencies. Although federally funded mining ergonomics research has a longer history, this review is focused on the period since these activities came under NIOSH purview in 1997.

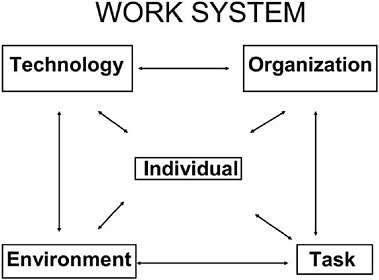

Ergonomics takes into account all the components of a work system (tech-

FIGURE C-1 Components of a work system. Based on Smith and Sainfort, 1989.

nology, organization, task, environment, and individual) and their interactions in order to achieve a balanced system (see Figure C-1). It is within this context that the NIOSH mining ergonomics research portfolio is viewed. More specifically, the focus is related to the strategic goal of reducing cumulative injuries such as work-related musculoskeletal disorders.

The major environmental factors include, for example, uneven surfaces, cramped conditions, noise, temperature, and lighting, which in turn have an impact on constrained and awkward postures, as well as exhaustion. Organizational factors include, for example, hours and shifts of work, degree of social interaction (isolated, team), and degree of structural constraints in determining how the work is carried out. Organization has a direct relationship to the frequency and duration of postures and forces required to do the work. Successful completion of the task determines the output of the work. The technology determines how the work can be completed and can often result in reduced force, repetition, and awkward or sustained postures. At the same time, introduction of new technology may affect physical load bearing, and change predominantly heavy, repetitive work over a long duration to more sedentary work with short bursts of very heavy work. Individuals bring different knowledge, skill, size, strength, experience, and intuition, as well as physical and mental fitness, to the work. Maximizing the balance between

these five components of the work system improves worker health, productivity, and product quality. Imbalance can result in worker injury, poor quality, and/or reduced productivity. Imbalance can lead to both acute traumatic onset injures and cumulative musculoskeletal disorders. Ergonomics research needs to continually evaluate and improve work system balance.

Major ergonomics challenges in the mining industry include rough, heavy, poorly maintained machinery; fatigue; extended work hours; repetitive tasks; undemanding and overdemanding tasks; shift work; errors; and access for maintenance.

The multidisciplinary ergonomics program (nine people in Pittsburgh and three in Spokane) includes expertise in physiology, bioengineering, mining, industrial and mechanical engineering, sociology-psychology, and industrial hygiene, but not cognitive ergonomics. While there is a “human factors” group conducting research in the area of extended shifts on stress, there is no cognitive ergonomics in this group either. Additionally, some interdisciplinary work is being conducted to make maximum use of existing resources. For example, ongoing lighting research may have an impact on the interplay between slips and musculoskeletal disorders. The work of these researchers is being published in peer-reviewed ergonomics and safety journals and presented at professional and industry conferences, as well as at specific worksites. The research and related work are primarily in areas of laboratory-based physical and safety risk factor research, control technology, intervention effectiveness, diffusion and dissemination of research, and transfer activities.

There are impressive laboratories for ergonomics research in the Pittsburgh facility including motion analysis, strength testing, and a human performance research mine with access to mining equipment.

Ergonomics researchers have effectively collaborated with other research groups within the Mining Program and with extramural partners to address overlapping issues. The basic WMSD prevention strategy advocated by the mining ergonomics group includes the following:

-

Partnering with mining stakeholders,

-

Developing solutions with the mines,

-

Advancing ergonomics research and tool development,

-

Ensuring research to practice (r2p) via workshops and industry briefings, and

-

Research impacts of emerging issues such as an aging, experienced workforce and a new inexperienced workforce.

The basic approaches taken to facilitate r2p include

-

Identify immediate or intermediate solutions to problems identified by the industry via off-the-shelf products or from examples used in other industries;

-

Use awareness training and educational activities to transmit the above solutions to the industry partners;

-

Conduct investigative research to identify unknown physiological or biomechanical effects of tasks or use of new technology, using laboratory and simulation testing and field-testing potential solutions.

This approach is quite reasonable to maintain good working relationships where research can be conducted. Care should be taken to ensure that this relationship is not just a consultancy. Research involves the development of generalizable knowledge. Research in this environment would be strengthened by systematic follow-up after possible solutions are introduced to worksites (e.g., evidence of implementation may be documented, but site-specific health effects do not seem to be monitored nor are appropriate comparison groups identified). Improving intervention study designs would increase the generalizability of findings.

The research program moves between simulation studies, laboratory studies, and field studies. Examples of current NIOSH mining ergonomics laboratory and field research examples focus on the following:

Environment

Researchers have recognized that not only is the workforce getting older but highly experienced miners are leaving the mine, leaving more inexperienced miners and mining engineers with increasingly long hours as production demands increase (due to high commodity prices) and more adverse conditions (smaller and/or deeper). Recognizing that teleoperations (remote-controlled) may be needed to address acute traumatic injury risk, ergonomics researchers are aware of the need to evaluate the cognitive side of implementing this technology in a dynamic hazardous environment.

Technology

-

Multifactor evaluation and improvement of mobile equipment-operator interface (related to whole-body vibration, postural sway, posture, and landing force getting out of the cab)

-

Development and testing of low seam shuttle car seat intervention for reducing jarring and jolting injuries

-

Evaluating vertical and horizontal appendage speeds on roof bolters and recommending machine design modifications—this is an example of identifying the need in the field and moving to simulation in the laboratory

Organization

The effectiveness of implementing a participatory ergonomics process in lowering exposure to hazards and reducing WMSDs must be evaluated. The most physically difficult jobs were identified by participants at industry conference focus groups. Five-minute toolbox materials were developed to present problems and possible solutions and test these in the field. Organizationally, this intervention seeks to assess the integration of ergonomics into overall safety-health-work life program structures in small and large mines. In larger companies, a corporate-wide risk assessment tool has been developed along with injury investigation procedures. Attempts are being made to produce ergonomically sound design specifications that will affect purchasing decisions. In the medium-size mining company, after ergonomic risk factor awareness training, 55 concern cards were completed, 22 interventions were completed, an initial 15 percent decrease in postural discomfort resulted where interventions were introduced, and other interventions are currently in progress. Interventions included new equipment and work station adjustment. There was a setback in a smaller mine company that is planning on going from surface to underground mining, although a number of interventions were implemented prior to change in production and product. These are interesting case studies with different organizational structures that may result in generalizable knowledge on program and process implementation and sustainability in this industry. However, more rigorous follow-up of intervention effectiveness will be required to test these methods.

Worker-Task Interface

-

Recognizing that age is associated with greater number of lost workdays due to WMSDs, researchers developed and are evaluating a program for successful aging among miners through ergonomics (SAME) using awareness training and identifying engineering controls for the prevention of cumulative and acute traumatic injuries with a current focus on knee and back injuries. This area of research demonstrates the integration of the three research methods to focus on solving problems identified in the field and via surveillance: developing a biomechanical knee model and evaluating exit from equipment tasks and tread design

-

in order to reduce slip-fall hazards. At the same time, researchers have developed a low-back exposure assessment tool for use by mines. They are testing age awareness training in the field.

-

A small case study has been conducted on implementing an engineering intervention to reduce WMSDs in a dozer blade changing task.

All of these studies use multiple methods (computer simulations, task analyses, operator input, direct measurement, field testing, and employee-employer participation and feedback), taking into account the context in which the machinery or intervention will be used by the operators.

Applied engineering research is the focus of the Mining Program with approximately 20 percent of the 15,000 mines visited in a year. The ergonomics research program uses surveillance data to monitor trends and suggest gaps in research or transfer of research to practice. It also spends a considerable amount of time and resources in the field at different mining sites or meetings and conferences to gather input from stakeholders about their needs (union, company, equipment manufacturers, associations, and external researchers). A third source of inputs is from other countries where mining is also important. This includes various networking mechanisms as well as having visiting researchers participate in NIOSH research projects.

Examples of Research Outputs

Technology Assessment

-

Comparison of physical load and method using fiberglass versus steel bars for hand scaling (sand and salt mines)—depends on location of work height

-

15 percent global adoption of low seam shuttle car design so far

-

Dragline workstation design, and testing—now requested by equipment companies and mines

Exposure Assessment Tools

-

Low-back risk factor checklist development

-

Assessment of cab entry and exit risks for back and other overexertion risks

-

Cab design checklist for mobile equipment used by operating engineers

Process Tools

-

Participatory ergonomics implementation methods in mining based on three different types of company size and organization styles.

New Knowledge

-

Lighter-weight manual scaling bars do not necessarily produce lower physical load on the worker. It depends on the position of the bar with respect to the work and the worker. Workers should position themselves on platforms so the scale points are below knee level. Actually, elimination of manual scaling should be the focus of this research.

-

A roof screen prevents rock fall, but transporting and installing the screen present heavy musculoskeletal loads. During screen transport, analyses show that dragging the screen increases muscle activity more than carrying the screen, and during installation, using rails to slide the screen reduces the load on the back for only that intervention but not for the overall task. Future research will seek to build a roof bolter mockup and develop improved interventions.

-

Miners spend a lot of time on their knees or in awkward squatting postures. These likely accounts for the high incidence of knee injuries seen in the surveillance data. Knee pads present some difficulty for miners and are not always used. In order to understand the mechanisms of injury and the possible improvement in knee pads or some other prevention technology, researchers are constructing a biomechanical knee model to gain more insight into the tasks and barriers to knee injury prevention, develop better knee pads, develop a method to test knee pads, and provide training and better interventions as they become available. Fully implementing this research should result in direct reduction of knee injuries in this industry (of course, it would be better, although perhaps impossible, to develop methods to eliminate the need for kneeling and squatting for prolonged periods).

-

Simulation and fresh frozen cadaver spine testing for compression and endplate failure confirmed the role of torso flexion in low back pain (LBP) and led to developing of improved LBP risk assessment tools.

Review of Transfer Activities

The ergonomics program appears to be very involved in dissemination of information and products based on its research and development activities. The primary mechanisms used for information transfer include the NIOSH web site

(e.g., Ideas to Reduce WMSDs); conference presentations; workshops for engineers, unions, and companies; peer-reviewed papers and conference proceedings; demonstrations; successful inclusion of mining ergonomics materials into web sites of stakeholders; and equipment company salesmen using ergonomics with customers.

Examples of Intermediate Outcomes and Causal Impact

NIOSH identified some 85 publications or presentations related to ergonomics and MSD risk identification, controls, or ergonomics program processes between 1996 and 2004. Examples of underlying work resulting in these publications include the following:

-

Ergonomics process adoption at large (N = 9,000) and intermediate (N = 350) size mining companies, via 21 training sessions and trainee submission of risk factor report cards on jobs, with 22 interventions implemented with good results. The systematic evaluation of risk factor reduction has not been completed by the researchers. However, a repeat discomfort survey indicated 15 percent reduction in discomfort. In the larger company, a metric for program evaluation is being implemented, with job improvements being posted on the company intranet. These activities have led to requests by other companies, unions, and associations to be trained in the participatory ergonomics process. This work led to 11 publications or presentations.

Examples of specific intervention case studies that have been implemented include a dragline work station, water cannon pit station, and seated work control station improvements to prevent carpal tunnel syndrome related to 8-12 hours per day of joystick manipulation.

-

Methods adoption

-

Use of the lumbar support in low seam shuttle cars. This equipment is now available from a large equipment manufacturer. This work also resulted in seven publications or presentations.

-

Use of concern cards in obtaining employee input into the ergonomics process

-

Use of WMSD risk assessment tools in several mines.

-

Integration of participatory ergonomics approaches in a number of mines

-

There has been some difficulty in the program’s ability to track dissemination and implementation efforts based on publications and presentations. This is not unique

to this research group. It has been more responsive than many to industry-specific requests for research and evaluation of technology to improve the health and safety environment in a dynamic, hazardous industry.

Additionally, in a Google search of “mining+ergonomics+research,” virtually all relevant hits eventually refer to the work of NIOSH mining ergonomics research activities. This suggests leadership in this particular area of ergonomics research.

Review of End Outcomes

WMSD Injury Rates

In the NIOSH Mining Briefing Book section on cumulative injuries and musculoskeletal disorders, NIOSH indicated “contributing” to the 34 percent reduction in lost workdays due to these disorders from 1998 to 2004 (NIOSH, 2005). NIOSH proposes a goal of a 30 percent reduction in incidence rate by 2014. It proposes to accomplish this by continuing to integrate ergonomics process into existing health and safety programs and incorporating worker involvement in the process. If it is successful in widespread dissemination of the positive impacts of participatory ergonomics being implemented within health and safety programs, as well as widespread implementation of a number of control measures (e.g., low seam shuttle car seat), it should be able to see a 30 percent reduction in WMSD rates, doing nothing differently.

Review of Other Outcomes

There has been significant production of knowledge to be used by others to improve the mining work environment and reduce musculoskeletal disorders and disability. This has been transmitted via numerous presentations and papers in the scientific and industry communities with considerable evidence of implementation of prevention measures, as well as generation of new research ideas. An example is the Industrial Minerals Association − North America ergonomics conference in 2006 (http://www.ima-na.org/about_ima_na/ergonomics.asp).

Anticipated Outcomes Based on Successful Completion of Current Work and Implementation of Findings by Industry

-

Better mobile equipment cab ergonomics

-

Reduction in knee injuries

-

Reduction in low-back disorders related to back-flexed lifting

-

Industry and worker awareness of the relationship between aging, work, and injury and design work to prevent disability in older workers

-

Reduction in slip and fall-related injuries

Identification of Emerging Areas of Research

To increase the likelihood of meeting the stated goal and performance measures, additional areas requiring research should be considered:

-

Effects of decreasing task variety and increasing monotony on injury

-

Effects of the combination of irregular heavy work and sedentary work on injury

-

Exacerbation of the effects of both of the above when longer hours and more inexperienced miners are added to the equation.

-

Relationship between slips-trips-falls (23 percent of injuries) and material handling injuries (36 percent of injuries)(National Safety Council Injury Facts, 2004) and aging

-

Integration of ergonomics into management systems theory and practice in mining

-

Impact of increased cognitive loading found in mining (use of remote controls, visual, auditory, touch, sensory cues) on musculoskeletal loading

The ergonomics group may not be able to address these important issues with existing resources.

Additional Issues

Resources

This group is doing some very interesting, important work that likely has significant impact on improving health and safety in the mining industry. It appears to have very good working relationships with a variety of stakeholders. This group is also doing a lot of case study type field research. However, intervention research methods are not strong. From the briefing materials, it appears that there were four epidemiologists and one ergonomist listed by scientific specialty in the Mining Program. It is unclear that any of the epidemiologists are working with the ergonomics group. It would be very helpful if they could collaborate either with other NIOSH groups that have epidemiological or intervention study expertise or

with external collaborators in study design and analysis, which would be particularly beneficial when looking at health outcomes.

The reference documents indicate that there has been a concerted effort to document interventions, their usability, and effectiveness, but there is a considerable way to go in terms of field-based study design that can demonstrate evidence-based generalizable knowledge in this area.

Although there was an increase in funding for the cumulative injuries-ergonomics program between 1998 and 2005, it was not commensurate with the proportion of lost-time injuries in this area. In fact the discretionary budget in this area has decreased, likely due to the increase in full-time equivalents from 16 to 20.

REFERENCES

Australian National Occupational Health and Safety Commission. 2006. Health and Safety Management Ergonomics Research in Mining. Available at http://www.nohsc.gov.au/applications/researchDB/mb.aspx?cat=Health%20and%20safety%20management. Accessed April 5, 2007.

BLS. 2004a. Table R4: Number of nonfatal occupational injuries and illnesses involving days away from work by industry and selected events or exposures leading to injury or illness, 2004. Available at http://www.bls.gov/iif/oshwc/osh/case/ostb1514.pdf. Accessed April 12, 2007.

BLS. 2004b. Table R76. Number of nonfatal occupational injuries and illnesses involving days away from work by industry and hours on the job before event occurred, 2004. Available at http://www.bls.gov/iif/oshwc/osh/case/ostb1586.pdf. Accessed April 12, 2007.

BLS (Bureau of Labor Statistics). 2006a. Table R4: Numbers of nonfatal occupational injuries and illnesses involving days away from work by selected worker and case characteristics and major industry division, All United States, private industry (for years 1996-2004). Accessed April 12, 2007.

BLS. 2006b. Table R8: Incidence rates for nonfatal occupational injuries and illnesses involving days away from work per 10,000 full-time workers by industry and selected events or exposures leading to injury or illness, 2005, All United States, private industry (for years 1996-2004). Available at http://www.bls.gov/iif/oshcdnew.htm. Accessed April 12, 2007.

Foster, P., and A. Burton, 2003. Virtual reality in improving mining ergonomics. Pp. 35-39 in Applications of Computers and Operations Research in the Minerals Industry, Symposium Series S31, Johannesburg, South African Institute of Mining and Metallurgy.

Health and Safety Executive. Musculoskeletal 2006. Disorders in Mining a Top Priority. Available at http://www.hse.gov.uk/mining/live.htm. Accessed April 5, 2007.

Kowalski-Trakofler, K., L. J. Steiner, and D. J. Schwerha. 2005. Safety considerations for the aging workforce. Safety Science 43:779-793.

Marras, W. S., and S. A. Lavender. 1991. The effects of method of use, tool design, and roof height on trunk muscle activities during underground scaling bar use. Ergonomics 34(2):221-232.

McPhee, B. 2004. Ergonomics in mining, in-depth review. Occupational Medicine 54(5):297-303.

National Safety Council. 2004. Injury Facts. Itasca, Ill.

NIOSH. 2005. NIOSH Mining Program Briefing Book. Preventing Musculoskeletal Disorders. Available at http://www.cdc.gov/niosh/nas/mining/strategicoutcome9.htm. Accessed April 12, 2007.

NIOSH. Undated. Mining Safety and Health Topic, Ideas to Reduce WMSDs. Available at http://www.cdc.gov/niosh/mining/safetyideas/. Accessed April 5, 2007.

Smith, M. J., and P. C. Sainfort. 1989. A balance theory of job design for stress reduction. International Journal of Industrial Ergonomics 4:67-79.

U.S. Bureau of Labor Statistics. 2006. Tables 1 and 2. Nonfatal injury numbers and rates involving days away from work. Available at http://www.bls.gov/news.release/osh2.toc.htm. Accessed on April 5, 2007.