4

Energy for Heat

BACKGROUND

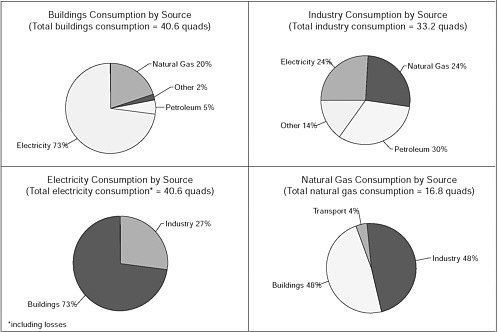

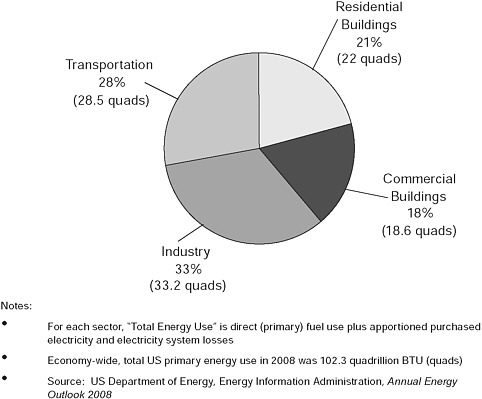

An evaluation of the externalities of energy used to produce heat as an end use is important because heat energy represents about 30% of U.S. primary energy usage.1 Unlike the chapters on the electricity-production and transportation sectors, this chapter does not present a detailed assessment of externalities associated with all uses of all energy sources for heat. Rather, this chapter presents the committee’s assessment of air-pollution damages from present uses (and uses expected in 2030) of natural gas for heat by residential and commercial sector buildings (see Box 4-1 for sector definitions) and presents some comparisons of natural gas and electricity use for heat. The industrial sector is discussed only qualitatively, because published statistics do not differentiate clearly between fuel used for heating and fuel used as feedstocks for manufacturing processes. Figures 4-1 and 4-2 show the overall energy use in the United States by sector, the details of building and industrial energy consumption by source, and the consumption by sector of electricity and natural gas (EIA 2008b). Natural gas is the

|

BOX 4-1 Definition of Residential, Commercial, and Industrial Sectors Residential sector: An energy-consuming sector that consists of living quarters for private households. Common uses of energy associated with this sector include space heating, water heating, air conditioning, lighting, refrigeration, cooking, and running a variety of other appliances. The residential sector excludes institutional living quarters. NOTE: Various programs of the U.S. Energy Information Administration differ in sectoral coverage. Commercial sector: An energy-consuming sector that consists of service-providing facilities and equipment of: businesses; federal, state, and local governments; and other private and public organizations, such as religious, social, or fraternal groups. The commercial sector includes institutional living quarters. It also includes sewage treatment facilities. Common uses of energy associated with this sector include space heating, water heating, air conditioning, lighting, refrigeration, cooking, and running a wide variety of other equipment. NOTE: This sector includes generators that produce electricity and useful thermal output primarily to support the activities of the above-mentioned commercial establishments. Industrial sector: An energy-consuming sector that consists of all facilities and equipment used for producing, processing, or assembling goods. The industrial sector encompasses the following types of activity: manufacturing (NAICS codes 31-33); agriculture, forestry, fishing, and hunting (NAICS code 11); mining, including oil and gas extraction (NAICS code 21); and construction (NAICS code 23). Overall energy use in this sector is largely for process heat and cooling and powering machinery, with lesser amounts used for facility heating, air conditioning, and lighting. Fossil fuels are also used as raw material inputs to manufactured products. NOTE: This sector includes generators that produce electricity and useful thermal output primarily to support the above-mentioned industrial activities. SOURCE: Glossary accessed at the Energy Information Administration (EIA) Web site http://www.eia.doe.gov/. |

major fuel used for heat in buildings. However, buildings also consumed about 5% of the 39.7 quadrillion British thermal units (quads) of petroleum used in 2008; industry consumed about 25%. Industrial consumption of petroleum includes the petroleum refining industry, which in turn provides 70% of petroleum used as fuel in transportation.

Approximately 20% of total energy consumed in the United States is attributed to nonelectric use in the industrial sector (for both heating and feedstock); about 10% is attributed to nonelectric use in commercial and residential buildings. Building-sector energy is predominantly used for heating. The industrial and building sectors are also the consumers of almost all electricity generation—about 40% of the U.S. primary energy usage. Damages associated with electricity production were evaluated in Chapter 2.

FIGURE 4-1 Total U.S. energy use by sector, 2008. SOURCE: EIA 2008b.

The types of damages considered by this committee and associated with end uses of electricity are relatively small compared with those associated with electricity generation.

This chapter provides approximate estimates of damages associated with the use of natural gas for heating applications in the industrial and building sectors. The technologies used in these sectors vary in type, size, and age and are widely distributed, but they mainly burn natural gas. The industrial sector uses some petroleum and small amounts of other primary fuels. The magnitude of associated externalities is strongly influenced by the amount of a particular fuel used and the locations of use.

Most industrial processes and buildings have operating lives of three or more decades, so, in addition to new installations to meet growth in demand, only a few percent of the existing stock is replaced each year. Much

of the existing building and industrial plant stock is thirty or more years old and employs older technologies. Therefore assessing externalities associated with future energy use needs to consider the upgrading of existing systems (“retrofits”) as well as the introduction of new technologies. The America’s Energy Future (AEF) report Real Prospects for Energy Efficiency in the United States (NAS/NAE/NRC 2009d) has been used as a major resource for the materials presented in this chapter.

Residential building sector emissions are generally distributed in the same manner that population is distributed. Commercial buildings are located in urban areas and suburban towns and villages. Industrial-fuel use is more concentrated in industrial areas, and varies by industry. Because of differences in scale and characteristics of the combustion processes, local health effects and other effects will be somewhat different, and these are identified and discussed in general. Greenhouse gas (GHG) emissions enter a common atmosphere and are not sensitive to location of the emission. Other externalities may exist but are not quantified in this chapter.

The committee used the methodology of the Air Pollution Emission Experiments and Policy (APEEP), with all the caveats described in detail in prior chapters and in Appendix C, to assess damages related to energy use for heat in the buildings and industrial sectors. The primary fuel, natural gas, is estimated to have relatively low nonclimate-change damages per kilowatt-hour compared with coal or wood, for example. We have not estimated damages associated with home heating by coal or biomass fuels because they are a relatively small part of the total energy mix for that use and because recent trends in increased use of natural gas fireplaces are expected to reduce damages related to coal or biomass use for space heating. Only about 12% of U.S. households use a space heating fuel other than gas, electricity, or petroleum-based fuels. At present, there is no other primary energy source that can be readily substituted for natural gas on a wide scale to provide further reduction of such damages. Therefore, opportunities for future reductions of nonclimate-change damages from energy use for heat in the building sectors, in particular, are likely to occur mainly through the incorporation of energy efficiency in the building structures and heat energy systems, as well as the inclusion of localized energy technologies, such as solar thermal water heating or geothermal heat pumps.

HEAT IN RESIDENTIAL AND COMMERCIAL BUILDINGS

Buildings in the United States consume about 39% of U.S. primary energy, although 73% of this energy is delivered in the form of electricity. The remaining 27% of the energy is primarily used for heating purposes. NAS/NAE/NRC (2009d) provides a detailed description of buildings in the residential and commercial sectors in the United States and describes

present status and a portfolio of future opportunities for reducing energy consumption in both sectors. In the past, energy for heating was a modest and affordable portion of annual building operating expenses. As energy prices have risen, more attention is now being given to energy conservation through investments in efficiency and in behavioral changes. Building codes are just starting to reflect this trend, but the construction industry, which uses many standardized building components and construction methods, is reluctant to change because a move toward building more innovative structures would require new investments and training and also increase costs. However, many “green” buildings are emerging from forward-thinking architects and design firms for wealthier clients, and the public is becoming more aware of these possibilities.

The residential building stock in the United States in 2005 consists of 111 million households, including 80 million single family homes, 24 million multifamily housing units, and nearly 7 million mobile homes (EIA 2009). Homes typically last 100 years or more; household electric appliances usually last for 10-20 years; and furnaces and water heaters last about 10 years.

There are about 5 million commercial buildings in the United States (2003) that have about 75 billion square feet of floor space (EIA 2008e, Table A1). Commercial buildings have life spans of 50 years or longer.

This section of the report looks separately at energy use for heat in residential and in commercial buildings for estimation of present externalities and implications for 2030 externalities. For each of these sectors, because of the large existing building stock, options for retrofit of old buildings and possibilities for improved new technologies and designs need to be considered.

The report America’s Energy Future: Technologies and Transformation (NAS/NAE/NRC 2009a) finds the following:

-

“Studies taking several different approaches are consistent in finding the potential for large, cost-effective energy savings in buildings … amounting to a 25-30% energy savings for the buildings sector as a whole over 20-25 years. If these savings were to be achieved, it would hold energy use in this sector about constant, in contrast to the current trend of continuing growth.”

-

“There are substantial barriers to widespread energy efficiency improvements in buildings. But a number of factors are counteracting these barriers. Drivers of increased energy efficiency include rising energy prices, growing concern about global climate change and the resulting willingness of consumers and businesses to take action to reduce emissions, the movement towards ‘green buildings,’ and growing recognition of the significant nonenergy benefits offered by energy efficiency measures.”

Residential Buildings

The major uses of energy for heating in residential buildings are water heating and space heating. The U.S. Energy Information Administration (EIA 2009i) data showed that in 2005, for 111 million households, energy use for space heating was 4.3 quads, and for water heating, it was 2.1 quads. Because 40% of water heaters are electric, roughly 1.2 quads can be attributed to the use of natural gas for water heating. This total energy-for-heat estimate for 2005 of about 5.5 quads is consistent with the 2007 sector-use numbers for liquid fuels and natural gas of 6.2 quads, allowing for some growth in the number and size of residential buildings. Renewable sources of energy provide a small part of the total and would be expected to produce smaller externalities than the fossil fuels in generating heat.

Commercial Buildings

The major uses of energy for heat in commercial buildings are for space heating and water heating. EIA reported that 2.37 quads of energy were used for space heating in 2003 (EIA 2008e). About 0.5 quads were reported for water heating and 0.2 quads for cooking. Because some of these uses are provided by electricity, an estimate for nonelectric heating for water heating and cooking is about 0.4 quads. This results in an energy-for-heat estimate for commercial buildings of about 2.8 quads total in 2003 (for 58.5 billion square feet of floor space). A 2005 survey of industrial and commercial boilers in the United States (EEAI 2005) reported that there were almost 163,000 industrial and commercial boilers in the United States that consumed about 8.1 quads of fuel energy per year. The report stated that the total rated capacities for the 120,000 smaller commercial facility boilers was 1.1 million Btu (MMBtu)/h and estimated that these commercial boilers consumed about 3 quads of the 8.1 quads reported for total boiler usage. This estimate can be compared with the 2007 commercial buildings estimate in Table 4-1 of 3.9 quads (for 75 billion square feet of floor space), indicating that the 2007 increase mostly reflects the expansion in total floor space.

Much of the expansion in floor area is due to construction of strip malls. Looking forward, the DOE Annual Energy Outlook (EIA 2009e) estimates that commercial building energy use will increase 32% (1.1% per year) by 2030.

HEAT IN THE INDUSTRIAL SECTOR

The U.S. industrial sector (see Box 4-2) consumes about one-third of the U.S. energy supply, but only about 21% of the total supply comes from nonelectric energy use. Of the 21 quads of nonelectric energy consumed in

TABLE 4-1 U.S. Nonelectric Energy Consumption by Source and End-Use Sector: Years 2007 and 2030 (EIA Estimates) (in Quadrillion Btu)

|

Energy Source |

Industrial Sector |

Residential Sector |

Commercial Sector |

|

Liquid fuelsa |

9.96/8.35 |

1.35/1.10 |

0.63/0.59 |

|

Natural gas |

8.02/8.47 |

4.86/5.06 |

3.10/3.53 |

|

Coal |

1.83/2.23 |

0.01/0.01 |

0.07/0.06 |

|

Renewablesb |

2.07/3.89 |

0.43/0.50 |

0.12/0.12 |

|

Total |

21.88/22.94 |

6.65/6.67 |

3.92/4.30 |

|

NOTE: Total U.S. primary energy consumption in 2007 was 101.92 quads; in 2030, total U.S. energy use is projected to be 112.35 quads. aLiquefied petroleum gases, kerosene, distillate fuel oil, residual fuel oil, and gasoline. bHydropower, wood and wood waste, and municipal solid waste. ABBREVIATION: EIA = Energy Information Administration. SOURCE: EIA 2009e. |

|||

|

BOX 4-2 Energy for Heat in Steel Manufacture Iron ores are mined as minerals in oxidized form. After cleaning and separation, the iron ore is reduced to pig iron in a coke-fueled blast furnace. Coke is the char material produced by heating bituminous coal in a sealed oven for 10 or more hours to drive off volatile “coal gases,” resulting in a char material called coke. Without proper effluent treatment, coke ovens can emit substantial amounts of dust and a wide range of emissions that come from various criteria pollutants. In a blast furnace, iron ore is reduced to pig iron by reaction with the coke and the formation of CO2. Energy was needed to produce the coke, but the coke reactions add some energy to the blast furnace. Further heat is required in additional refining steps in a basic oxygen furnace or an electric arc furnace. When iron products are recycled, a much smaller amount of heat energy is needed to remelt them in an electric arc furnace than is needed in producing pig iron from mineral ores, partly because the reducing agents are not needed. Although it is difficult to compare “virgin” and “recycled” steel because nearly all steel is composed of some mix of recycled steel, the underlying processes are somewhat indicative of the difference between the two.Worrell et al. (2008, Table 1.1) gave “best practice” estimates of 14.8-17.8 GJ/tonne for a basic oxygen furnace and 2.6 GJ/tonne for a 100% scrap electric arc furnace. |

the industrial sector in 2007, about 8 quads of it may be attributable to “nonfuel” purposes, such as the use of petroleum refining by-products in asphalt, feedstock for petrochemical products, and coal in the production of coke for steel making (EIA 2007, Table 1.5).2 However, although asphalt,

plastics, and similar products sequester some carbon from the feedstock, most of the industrial uses generate carbon dioxide (CO2) emissions as a result of processing operations—in some cases more than would be generated from direct fuel combustion, if the process itself generates CO2. In addition, as more industrial production has moved offshore, energy embodied in imported goods is not counted in the EIA statistics. Ultimately, some petrochemical products may end up in waste streams that are used as an energy feedstock.

Estimation of Industrial Use of Energy for Heating

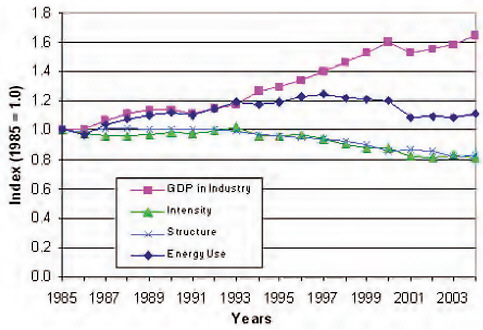

Table 4-1 presents EIA industrial energy use estimates by primary fuel type for 2007 and presents their use projections to 2030. DOE’s Annual Energy Review suggests facility heating in the industrial sector consumes about 10% of electricity and natural gas (EIA 2008a). Figure 4-3 presents energy use, energy intensity, output, and structural effects in the industrial

FIGURE 4-3 Energy use, energy intensity, output, and structural effects in the industrial sector, 1985-2004. DOE uses input-output analyses to assess energy use across all U.S. industrial activities. Intensity is energy consumption per unit of demand for energy services (for example, per kilowatt hour, vehicle miles traveled, or, nationally, gross domestic product); structural effects attempt to account for variability across the spectrum of industry operations (see EIA 2003). SOURCE: DOE 2008b, Figure I1.

sector from 1985 to 2004. Table 4-1 indicates that the major industry-sector fuel sources generating externalities are about 10 quads of liquid fuels (liquefied petroleum gases, kerosene, distillate fuel oil, residual fuel oil, and gasoline), 8 quads of natural gas, and about 2 quads of coal. The mix includes about 2 quads of energy use from “renewables” (primarily hydropower, wood, and wood waste) and municipal solid waste. The two largest industrial sectors in terms of fossil-fuel consumption are the petroleum refining industry and the chemical industry. The petroleum industry in 2002 used about half of its 6 quads of total net energy use for feedstock (not associated with producing such energy products as gasoline and jet fuel); the chemical industry used more than half of its 6 quads of total net energy use for feedstock (NAS/NAE/NRC 2009d). Coal is mostly used to make coke and carbon black, but a portion of the coke ends up as heat energy in steel making. Therefore, it is only possible to make fairly crude estimates of energy use for heat in the industrial sector; estimating externalities associated with such uses is subject to even more uncertainty.

Industrial boilers are used to generate steam for a wide variety of industries and industrial processes. The 2005 survey of industrial and commercial boilers in the United States (EEAI 2005) cited earlier in the commercial sector discussion, reports that there are almost 163,000 industrial and commercial boilers in the United States that consume about 8.1 quads of fuel energy per year. Of that, about 5 quads is accounted for by industrial boilers; about 60% (3 quads) of this energy is supplied by natural gas. The industrial manufacturing sector accounts for 43,000 of the boilers, but these are of larger capacity than those used in commercial heating applications. The report presents total rated capacities for these industrial boilers at 1.6 MMBtu/h. Nonmanufacturing industrial boilers include those used in agriculture, mining, and construction. These 16,000 units have a nameplate capacity of 0.26 MMBtu/h. The remaining boilers use a diversity of fuels, often by-products of the industry involved. For example, the paper industry uses biomass waste streams to fuel 48% of its boilers (rated capacity 0.4 MMBtu/h); the primary metals industry utilizes process heat for 42% of their boilers (rated capacity 0.1 MMBtu/h); and the refining industry uses refinery by-products to fuel 49% of their boilers (rated at 0.2 MMBtu/h).

Because the U.S. industrial sector is so diverse and EIA energy statistics do not necessarily correspond to energy use for heat in this sector, the externalities attributable to industrial energy use for heat are difficult to separate from externalities associated with energy use for other industrial processes (Box 4-2).

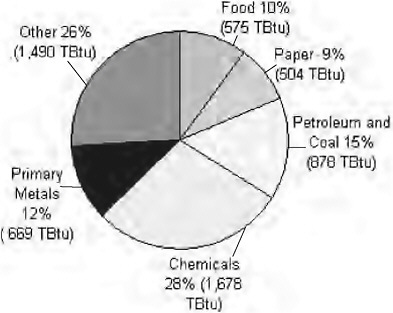

Natural gas is the major fuel used for heating in the industrial sector. Figure 4-4 shows how its use was distributed among manufacturing sectors in 2002. Total industrial-sector natural gas consumption in 2002 was reported to be 6.47 quads with 5.8 quads used for heating and 0.67 quads used for feedstock purposes (for example, chemicals and fertilizer). Con-

FIGURE 4-4 Manufacturing sector consumption of natural gas as a fuel by industry, 2002. SOURCE: EIA 2006c, Figure 5.

sumption in 2007 was reported to be 8.02 quads, but the general distribution by industry sector is probably still representative.

The economic downturn at this time in the United States in progress as this report was being written is likely to reduce industrial activities to some extent. Nevertheless, the following adjusted 2007 EIA data (EIA 2009e) for the industrial sector are taken as the baseline for making rough estimates of externalities associated with heating uses in industry in our report.

-

Petroleum: 10 quads – 3 quads used as feedstock = 7 quads net

-

Natural Gas: 8 quads – 2 quads used as feedstock = 6 quads net

-

Coal: 1.8 quads = 1.8 quads net

-

Renewables (treat as biomass): 2.1 quads = 2.1 quads net

ESTIMATES OF EXTERNALITIES ASSOCIATED WITH ENERGY USE FOR HEAT

It is much more difficult to make reliable estimates of the unpriced damages associated with energy use for heating in the buildings and industrial sectors than to evaluate such impacts for electricity generation or for transportation. However, because about 30% of U.S. primary energy is

used for heating purposes, it is important to attempt a quantification of associated damages even if detailed estimates are not possible. The residential and commercial sector estimates are somewhat more tractable than those for the industrial sectors, where some of the energy use reported by DOE statistics does not sufficiently delineate fuels used as feedstocks.

Table 4-1 shows that 75% of the energy used in the residential and commercial building sectors is natural gas. About 19% comes from liquid fuels (with somewhat higher health impacts), about 5% comes from renewables; and less than 1% comes from coal. Detailed data were not available on county-level consumption of wood for heating and so a comparable damage estimation method for wood was not possible in this study. The industrial-sector impacts involve more fuels and more diverse activities.

The focus of externalities considered in this chapter are health effects associated with criteria-pollutant-forming emissions from fuel combustion. GHG emission externalities that are linked to present and future changes in climate and the associated impacts are discussed in Chapter 5.

Residential Buildings: Damage Estimates for Criteria Air Pollutants

As shown in Table 4-1, iquid fuels and natural gas predominate in non-electric energy consumption in residential buildings, and a small amount of coal is used. Consumption associated with “renewables” are of a diverse and smaller magnitude. Therefore, the focus here is on natural gas directly burned for heating purposes; some comparisons are made with electricity used for heating in buildings.

As noted previously, potential externalities from consuming natural gas for heat could arise not only from the on-site combustion but also from the upstream supply chain of extraction and distribution of the gas. The committee estimated damages attributable to criteria-pollutant-forming emissions from combustion on-site, but we were not able to estimate damages from such emissions from upstream activities because of data and modeling issues. Few studies have estimates these upstream emissions (for example, Jaramillo et al. 2007), and these estimates were limited to only nitrogen oxide (NOx) and sulfur oxide (SOx) emissions and showed large uncertainty ranges. Because modeling the upstream extraction and distribution damages from criteria-pollutant-forming emissions would need to be allocated to more than 300,000 wells and associated pipelines across the United States (compared with the existing database of power plants for electricity production in Chapter 2 and the roughly 100 plants for automobile production in Chapter 3), we elected not to estimate them. This is not to say the externalities would be negligible; Jaramillo et al. (2007) estimated significant upstream emissions of NOx and SOx (ranges of 0.009-0.3 and 0.006-0.03 lb/MMBtu, respectively) associated with North American natural gas

compared with the combustion emissions (0.094 and 0.0006 lb/MMBtu); however, the process of allocating natural gas use to the thousands of potential point and area sources, given such large uncertainty ranges in the literature, was deemed intractable because of the lack of time and resources available. Thus, we focused on criteria-pollutant-forming emissions from on-site combustion.

Our estimates of combustion externalities come from multiplying county-level consumption with county-level damages. The county-level consumption and criteria-pollutant-forming emissions of residential natural gas are taken from the EPA National Emissions Inventory (NEI) for 2002 (EPA 2008d). These emissions by county at ground level are multiplied by estimated county-level health and other damages per ton of criteria-pollutant-forming emissions from the APEEP model and are subject to the model’s assumptions and limitations (see Chapters 1, 2, and 3).

The results are county-level health and ecosystem externality estimates, which are then normalized by the 2002 NEI’s consumption of natural gas by county to estimate damages per thousand cubic feet (MCF) of gas.

Table 4-2 shows the national range across more than 3,000 U.S. counties of estimated damages from air pollutants (excluding CO2, which is considered later), assuming the value of a statistical life (VSL) is $6 million ($7.2 million in 2007 U.S. dollars [USD]). Variability is a result of county differences. The median damage estimate is approximately 11 cents/MCF

TABLE 4-2 Residential Sector Natural Gas Use for Heat: National Damage Estimates from Air Pollutants (Excluding Greenhouse Gases) (Cents/MCF)a (Damage Estimated from 2002 NEI Data for 3,100 Counties)

(the mean is approximately 35 cents/MCF). These estimates are unweighted; weighting the damages by county population of the source emissions would lead to an average of about 30 cents/MCF. As previously indicated, we do not include the upstream life cycle of sulfur dioxide (SO2) emissions related to natural gas—such emissions are low. With the residential price of natural gas at about $10/MCF,3 the mean health-related externalities from criteria-pollutant-forming emissions are about 1% of the price. Aggregate damages (unrelated to climate change) were approximately $500 million (2007 USD).

As done in the Chapter 2 on electricity, it is relevant to consider the regional variation within the United States for the externalities from heating. Table 4-3 illustrates the damage estimates on a census region basis). The median estimates of damages related to criteria-pollutant-forming emissions from different regions are similar to the national level, ranging from 6 cents/MCF to 14 cents/MCF (2007 USD). The regional breakdown highlights the large range of externalities in the South compared with other regions, but these outliers occur because of rounding errors in estimating externalities of counties with very low consumption of natural gas. Regardless, the 90th percentile values in the South still represent damages at only 5% of the price of natural gas.

These results can be used to compare the damages from natural gas combustion for heating with damages associated with using electricity for heat. From Chapter 2, production of coal-fired electricity has mean damages weighted by net generation from criteria-pollutant-forming emissions of $0.032/kWh, and gas-fired electricity has a mean externality of at least $.0016/kWh (excluding CO2). Scaling these numbers using the weighted average national grid in Table 2-1 of Chapter 2 (48.5% coal and 21.3% gas) results in average damages near $0.016/kWh (excluding CO2; 2007 USD). Likewise the median damages from electricity would be estimated as 0.485 × 1.8 + 0.213 × .036 = 0.87 + $0.0088/kWh (excluding GHGs; 2007 USD).

The obvious comparison to show is heating a house with natural gas versus heating a house with electricity at the national level (grid average). The average amount of electricity used to heat a house in the United States is 2,100 kWh (EIA 2009i, Table SH7). The average amount of natural gas used to heat a house is 49,000 cf. (49 MCF). Using the numbers above, we would say the estimated mean damages of electricity for heating, excluding GHGs, would be calculated as $0.016 × 2,100 = $34/year (2007 USD), and the estimated mean damages for natural gas would be $0.35 × 49 = $17/year (2007 USD). The estimated median damages of electricity

TABLE 4-3 Residential Sector Natural Gas Use for Heat: Regional Damage Estimates (Excluding Greenhouse Gases)a (Cents/MCF) (Damage Estimated from 2002 NEI Data for 3,100 Counties)

|

|

Mean |

Standard Deviation |

5th Percentile |

25th Percentile |

50th Percentile |

75th Percentile |

95th Percentile |

|

MIDWEST |

|

|

|

|

|

|

|

|

SO2 |

0.4 |

2 |

0 |

.05 |

.15 |

.22 |

.49 |

|

NOx |

35 |

290 |

4 |

7 |

11 |

15 |

36 |

|

PM2.5 |

0.8 |

7 |

.05 |

.1 |

.18 |

.34 |

1.1 |

|

VOCs |

1 |

9 |

.06 |

.13 |

.25 |

.44 |

1.4 |

|

NH3 |

0.4 |

2 |

0 |

0 |

0 |

.03 |

2.6 |

|

Total (unweighted) |

46 |

370 |

5 |

9 |

14 |

19 |

47 |

|

NORTHEAST |

|

|

|

|

|

|

|

|

SO2 |

0.38 |

0.34 |

0 |

.19 |

.3 |

.47 |

1.0 |

|

NOx |

10 |

12 |

0 |

3.5 |

6.3 |

11 |

34 |

|

PM2.5 |

0.8 |

1.1 |

0 |

0.23 |

0.5 |

1 |

2.8 |

|

VOCs |

1.1 |

1.3 |

0 |

0.35 |

0.71 |

1.5 |

3.4 |

|

NH3 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

|

Total (unweighted) |

16 |

17 |

2 |

6 |

11 |

18 |

51 |

|

SOUTH |

|

|

|

|

|

|

|

|

SO2 |

0.4 |

1.1 |

.03 |

.09 |

0.2 |

0.34 |

1.1 |

|

NOx |

24 |

79 |

2.1 |

4.8 |

7.8 |

13 |

64 |

|

PM2.5 |

0.92 |

3.1 |

.09 |

.17 |

0.31 |

0.64 |

2.5 |

|

VOCs |

2 |

10 |

0 |

0.15 |

0.3 |

0.72 |

4.2 |

|

NH3 |

0.5 |

3 |

0 |

0 |

0 |

0 |

1.3 |

|

Total (unweighted) |

33 |

107 |

3.4 |

6.8 |

11 |

18 |

93 |

|

WEST |

|

|

|

|

|

|

|

|

SO2 |

.27 |

1.7 |

0 .06 |

.08 |

.13 |

.41 |

|

|

NOx |

12 |

66 |

.18 |

2.9 |

4.4 |

6.5 |

16 |

|

PM2.5 |

0.5 |

2.7 |

0.02 |

0.05 |

.09 |

.21 |

1.8 |

|

VOCs |

.32 |

1.6 |

.02 |

.06 |

.09 |

.18 |

.83 |

|

NH3 |

.03 |

.3 |

0 |

0 |

0 |

0 |

.05 |

|

Total (unweighted) |

16 |

88 |

1.7 |

4 |

6 |

8.8 |

22 |

|

NOTE: This table reports the same data as in Table 4-2 aggregated by census region. Two hundred counties, for which relatively few emissions data were available, were excluded to avoid skewing the distribution in an unrealistic way. aTotal damages (cents/MCF) are in 2007 U.S. dollars; other damages are in 2000 U.S. dollars. ABBREVIATIONS: MCF = thousand cubic feet; NEI = National Emissions Inventory; SO2 = sulfur dioxide; NOx = nitrogen oxides; PM2.5 = particulate matter smaller than 2.5 microns; VOCs = volatile organic compounds; NH3 = ammonia. |

|||||||

and natural gas used for heat would be $19/year and $5/year respectively. Thus, the nonclimate damages from heating with gas instead of electricity are almost an order of magnitude less. Using the range of natural gas nonclimate-change damages would lead to results three times lower than electricity for heating at the 5th percentile, but at the 95th percentile, these natural gas damages would be about the same as nonclimate damages from using electricity for heating.

Commercial Buildings: Damage Estimates for Criteria Air Pollutants

Following a similar method, the externalities for commercial sector heating from burning natural gas were estimated. Unlike data available for the residential sector, the 2002 NEI emissions inventory did not include corresponding estimates of natural gas consumption for the commercial sector in each county. Thus, the consumption of commercial sector natural gas was estimated by using AP-42 emissions factors for carbon monoxide (CO) of 84 lb/MCF, which do not vary drastically across combustion technologies (but adds some uncertainty to the committee’s estimated consumption by county). When using this proxy, the total estimated consumption of natural gas in the commercial sector was 2.2 million MCF (or 2.2 thousand MMCF), somewhat lower than the EIA estimate for 2002 of 3.1 million MCF. Table 4-4 shows the national level range of externalities from

TABLE 4-4 Commercial Sector Natural Gas Use for Heat: National Damage Estimates from Air Pollutants (Excluding Greenhouse Gases) (Cents/MCF)a (Damage Estimated from 2002 NEI Emission Data for 3,100 Counties)

commercial (EIA 2009e) combustion of natural gas, the results being very similar to those for the residential sector. The median externality excluding GHG emissions, 11 cents/MCF, is plausible given its similarity to the residential damage estimate. Given the similarity, the externality estimates by census region for the commercial sector are not shown. Aggregate damages are about $300 million (excluding damages related to climate change) (2007 USD).

Externalities Associated with Industrial Energy Use for Heating

Unfortunately a parallel analysis for externalities from heating in the industrial sector could not be undertaken because of several challenges. The level of detail for the residential and commercial sectors in the NEI, including fuel consumption by county, was not available for the industrial sector. While the NEI has estimates of emissions from industrial activities by county, disaggregating the emissions to include only estimates from the use of fuels for heating, and from industrial activities that would not be included elsewhere in this report, proved too problematic to overcome. Thus, the committee was able to make only qualitative assessments of these externalities.

Externalities associated with present energy uses for heat in the industrial sector might be approximated by using estimates of the externalities that are associated with the use of the particular energy source in electricity generation. These are the externalities caused by the production, processing, transportation, and combustion of the particular fuel (petroleum, natural gas, biomass, or coal) in electricity power plants, scaled by the annual use factors for the industrial sector and the electricity generating sector. This method gives approximate results for GHG emissions but is very crude for estimates of local health and environmental impacts because of large differences in emissions from power plants, and those associated with a wide range of industrial facilities that use energy for heat as a part of wider manufacturing activities. Specific local health and environmental effects are different for industrial locations, so the estimates are subject to considerable uncertainty. The EIA provides national and regional (Northeast, Midwest, South, and West) data for energy use by industry according to the North American Industry Classification System (NAICS) codes (EIA 2007, Table 3.2). Unfortunately many of the details are missing in regional summaries because errors are too high or because specific plants might be identified. Therefore, it was not possible to identify the locations of large emitters that might have more significant local health and environmental effects.

Table 4-1 shows that natural gas use in the industrial sector, less use for feedstock, was about 6 quads in 2007. This usage is actually smaller than the 8 quads of natural gas used in the residential and commercial building sectors. Therefore, in the absence of more detailed information, it may be

assumed that the health and environmental externalities of this usage are probably of the same order or less than the impacts associated with natural gas use for heat in buildings. A very rough order of magnitude estimate of average externalities associated with the industrial sector use of natural gas is therefore 11 cents/MCF, excluding GHG damages. Thus, the 6 quads of natural gas used for industrial heat would generate about $600 million in damages.

The other large use of fuel for industrial energy is associated with liquid fuels (about 7 quads). Half of this use is associated with only three sectors—paper, chemicals, and petroleum refining—the last of which has already been included as part of the life-cycle upstream externality estimates made for the transportation sector use of petroleum fuels.

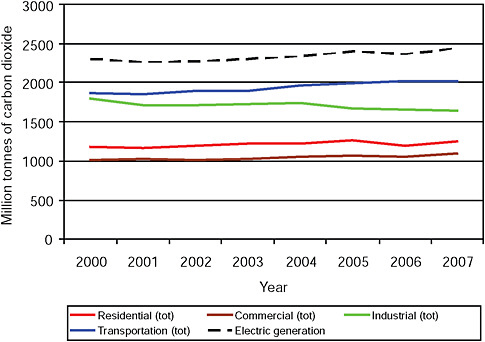

Table 4-1 infers that the nonelectric use of energy in the industrial sector is almost double that of the residential and commercial building sectors combined. However, when feedstock use is taken out of the fuel mix for the industrial sector, the remaining use of energy for heat is probably about equivalent to the residential and commercial building sectors. Figure 4-5 also shows that the GHG emissions from the industrial sector have been declining since 2000, and the building sectors show only small increases.

The EIA energy use projections for 2030 incorporate some consid-

FIGURE 4-5 Greenhouse gas emissions in the United States by sector. Totals include electric power use distributed across the end-use sectors. SOURCE: EIA 2008f.

eration for the incorporation of energy efficiency improvements to offset energy demand from growth in industrial capacity (EIA 2009e). These projections are based on present energy policies and could vary considerably if new policies are adopted. The estimates for nonelectric usage show a very small growth in energy use between now and 2030. Three efficiency studies, discussed later in this chapter, indicate that there is a good potential for achieving about 10-15% overall improvement in efficiency in the use of energy to produce heat in the industrial sector if more aggressive energy policies are adopted in the future (Interlaboratory Working Group 2000; IEA 2007; McKinsey 2007). Therefore, nonclimate externalities in 2030 might be about the same as those associated with the fuel uses that exist today—or they might be reduced by 10-15%. The most likely source of reducing externalities per unit of heat would be from changes in the electricity sector, as emissions from natural gas are relatively small and already well-controlled.

When considering externalities from heat in 2030, potential changes in energy sources should be considered. Over such a short time frame, substantial infrastructure replacements or changes (for example, by moving from electricity or gas to an alternative) are unlikely to occur. Instead, alternative sources of natural gas, such as those from shale deposits or from increased imports of liquified natural gas (LNG), are more likely to become prevalent. Our analysis has presumed domestically sourced natural gas for estimating externalities, both because LNG imports are currently small and because estimating the health damages from global operations was not possible. However the upstream emissions of LNG have been estimated to be somewhat higher. Thus, the externalities estimated here are low because they do not consider these upstream extraction emissions from any sources of natural gas.

EMISSIONS OF GREENHOUSE GASES

Figure 4-5 shows the GHG emissions (in millions of metric tonnes4 of CO2 per year) for each of the end-use sectors. The sector estimates also include electricity use apportioned to use within the sector. To estimate the GHG emissions associated with heating uses, it is necessary to deduct the electricity component (also shown in Figure 4-5).

-

2007 residential and commercial sector emissions = 1,250 + 1,087 – (0.73)(2,433) = 561 million tonnes of CO2 (618 tons). This amount is roughly equivalent to about 10 quads of natural gas.

-

2007 industrial sector emissions = 1,640 – (0.27)(2,433) = 983 million tonnes of CO2 (1,084 tons).

For natural gas, each MCF generates about 1,000 MMBtu on average and generates about 120 pounds of CO2 (about 0.05 tonnes or 0.06 tons of CO2). Methane, the major component of natural gas, is a GHG itself if it enters the atmosphere through leakage. It has a warming potential about 25 times that of CO2.5 However, EPA (2009i) estimated that such leakage amounts to about 3% of total U.S. CO2-equivalent (CO2-eq) emissions (excluding water vapor) attributable to energy-related activities in 2007. Nitrous oxide (N2O) is also a GHG, but the emissions from its use are a very small share of total GHG emissions.

In the sections above, the committee estimated externalities from criteria-pollutant-forming emissions from the residential and commercial building sectors. Aggregate damages from combustion of natural gas for direct heat are estimated to be about $1.4 billion per year (2007 USD), assuming the magnitude of effects resulting from heat production in industrial activities is comparable to those of the residential and commercial sectors. These estimates did not include emissions of GHGs. Emissions of GHGs associated with burning natural gas can be estimated in a fairly straightforward manner, about 120 lb (0.06 tons) of CO2-eq/MCF (EPA AP-42). Although the committee did not estimate damages related to criteria-pollutant-forming emissions from upstream activities because of spatial and geographical modeling concerns, we did estimate the emissions of upstream GHGs from natural gas from literature sources. Jaramillo et al.(2007) summarized estimates of upstream natural gas emissions of 15-20 lb CO2-eq/MCF for North American sources or 30-70 lb CO2-eq /MCF for LNG, adding about 15% and 40% to the emissions, respectively. Thus, in the near term, where domestic natural gas remains the dominant source, the emissions factor is likely to be approximately 140 lb CO2/MCF (including upstream methane emissions), and in the long term, where LNG or shale gas is increased as part of the mix, the average emissions factor could be 150 lb CO2-eq/MCF.

POTENTIAL DAMAGES REDUCTIONS IN 2030

Residential Buildings

The major options for reducing heating energy demand in the future are presented in more detail in NAS/NAE/NRC (2009d). The report focuses on the potential for reducing total energy consumption in the residential sector, where primary energy used to provide electricity is much greater than the consumption of nonelectric primary energy for heat. The ways to reduce energy use for heating mainly focus on better insulation of the building

envelope and use of higher efficiency methods for water heating. The main possibilities for existing and new buildings include the following:

-

Existing buildings:

-

Addition of insulation to exterior walls and under roofs.

-

Replacement of old windows with high performance windows.

-

Replacement of old furnaces with higher efficiency devices.

-

Use of control systems to minimize heating of unoccupied spaces (except to prevent freezing of water pipes) and to lower temperatures at night.

-

Addition of solar thermal water heating.

-

Behavioral changes, such as reducing thermostat settings, sensible opening and closing of windows and shades, wearing warmer clothing to lower indoor set temperatures during the heating season (and cooler clothing to higher set temperatures during the cooling season).

-

Reducing air leakage from the building (with care to assuring that indoor air quality is not compromised—some heat exchangers are available to preheat inlet air with warm exhaust air).

-

-

New construction:

-

Energy efficient design for site location—using passive solar heating, shading, geothermal heat pump systems, combined heat and power systems, high efficiency walls and windows, natural ventilation for warm climates, smart control systems, and many other techniques (see Box 4-3).

-

Behavioral changes to accommodate to smaller living spaces per capita or more desirable multiple dwelling units designed for energy efficiency.

-

Projecting how improvements in the heating demand for residences might evolve to a 2030 time period seems highly uncertain, although some improvements to at least offset sector growth appear feasible. As of 2008, the DOE’s Annual Energy Outlook forecasted energy use in the residential sector to increase by 16% (0.4% per year) by 2030. The trends resulting from current financial issues are also likely to keep the 2030 energy use in this sector stable or reduced relative to 2007. This potential is discussed in the AEF.report (NAS/NAE/NRC 2009d).

Commercial Buildings

Because space heating requirements are largely determined by the building envelope characteristics, there are limited opportunities for reducing the heating energy requirements for existing buildings. Replacement of

|

BOX 4-3 Zero-Energy Concept Home Architects and engineers currently discuss the prospects of residences that have zero net demand for energy. This “zero-net” demand does not imply that the buildings have no energy demand; rather the buildings have technologies integrated into them (such as solar panels or geothermal wells); thus, they do not demand energy from beyond what the home is able to supply itself. Achieving such a goal depends on several innovative design changes in the residential housing industry. First, technologies need to be cost-effectively scaled to what can fit within the space and budget of a house. Second, to be able to generate enough of its own energy needs, a house needs to be designed to achieve much lower energy use regardless of energy source. Such designs include using advanced lighting (for example, solid-state lighting, also known as LED lighting), orienting the house to take advantage of sunlight, and improving insulation. Design for efficient utilization of space is also important to eliminate the need for heating and cooling of rarely used floor area. These measures reduce the demand for energy and allow the on-site energy-generating technologies to better supply this needed level of demand, making the “zero-energy” goal possible. |

windows, upgrading of furnaces, boilers, and heat distribution systems may offer some improvement, but such investments may have limited cost-effectiveness except for much older or larger buildings. The AEF report (NAS/NAE/NRC 2009d) focuses primarily on larger efficiency gains that can be achieved through improvements in the use of electricity. Ironically, large amounts of waste energy from electric devices, such as those from inefficient electronic power supplies that give off heat, may reduce the heating load required for a commercial building (but increase the cooling load in warm weather).

New commercial buildings offer many more opportunities for investing in new designs to reduce heating energy requirements. Because commercial floor space has been expanding rapidly over the past decade, this space may be an area for innovative new buildings that greatly reduce their thermal energy (energy for heating) footprints. The U.S. Green Business Council has developed the Leadership in Energy and Environmental Design (LEED) Green Building Rating System, which uses third-party experts to evaluate new commercial buildings (or renovations of existing facilities) for their overall environmental and community performance and award ratings based on criteria that include energy efficiency of design and construction, as well as ease of maintenance, quality of working environment, and waste minimization (U.S. GBC 2008). The highest LEED rating is “platinum,” followed by “gold,” “silver,” and “certified.” The DOE has expanded its

Energy Star program to include green building design and makes available a variety of resources for the improved design, construction, and operation of commercial buildings (DOE 2009c). Investment in improved efficiency reduces energy use and eliminates any externalities that would be associated with the energy use avoided.

Case Study of Passive Solar Design

One of the approaches listed in Box 4-3 for a hypothetical “zero-energy home” is the incorporation of passive solar design principles. Unlike most of the other technologies listed in this report (and the NAS/NAE/NRC reports), passive solar is not an energy-generating technology.

Passive solar design uses the light and heat of the sun to offset what would otherwise be energy or fuel use in a building. For example, using more skylights in the ceiling and arranging the layout so that the light is able to permeate wide areas of the living space reduces the amount of electricity needed for lighting. Similarly, creating south-facing windows allows the heat of the sun to enter the building and reduce needs for heating by other means.

There are multiple considerations for incorporating passive solar design and various cost trade-offs. It was not feasible for the committee to assess how the impacts of a passive solar house might compare with a traditional fossil-energy-fueled building, and no significant literature was found to have quantified the relevant trade-offs. For direct heat, south-facing windows with special glazing are used that then allow sunlight to enter and reflect off dark masonry floors, which absorb heat. This stored heat then is slowly released while the home cools later in the day (reducing the heating load). Heavier walls can be designed to store and release heat to even out variations between day and night outdoor temperatures. Solar heating can also drive natural circulations within buildings and provide more comfort without circulating devices requiring purchased energy. Case studies have shown massive energy reductions (up to 90%) for comparable new buildings; retrofits are more limited in their ability to reduce impacts and externalities because of various fixed design choices in the existing structures.

Although the operating phase of the building may require substantially less energy (and thus result in far lower externalities from heat production), the initial construction or renovation of the building along passive solar design principles may result in significant externalities from manufacturing new insulation, windows, or other intensive construction materials. These initial impacts can be apportioned over the total operating life of the building to provide life-cycle annual impacts. A full comparison of these externalities is outside the scope of this study but should be considered before viewing a passive solar house as being externality-free.

Integrated Planning Opportunities

Construction and retrofit of residential and commercial buildings can use integrated design principles with a goal of improving the buildings’ environmental and economic performance over their operating lifetimes. Integrated planning is more effective when initiated early in the design and construction process (for example, subsurface geothermal systems or siting for incorporation of photovoltaic or passive solar systems) but can also have benefits for retrofits. Combined heat and power (CHP) systems are now available that generate electricity and use the waste energy for heating purposes. When building designs reflect the extremes of local climate, operation of the building reduces both heating and cooling loads. Commercial buildings generate waste streams that can be used for energy on-site or off-site. Incorporation of recycled components into building materials is another way to reduce the life-cycle impacts of buildings. Construction debris represents a substantial component of the waste stream, and much of this debris can be recycled or converted to thermal energy and electricity with proper environmental control. Like energy, water conservation and reuse is another important component—as is indoor air quality and its associated health and productivity impacts.

Industrial Facilities

NAS/NAE/NRC (2009d) devotes a chapter to the potential for energy efficiency improvements in the industrial sector and provides specific examples of how individual industry sectors can reduce energy demand through approaches including use of waste heat, and more efficient new technologies. The report looks at total energy use, including electricity and thermal energy use. It notes that the most energy-intensive industries (for example, petroleum refining, aluminum, iron and steel, and chemicals) have already placed high emphasis on efficiency of use, especially in domestic facilities.

Some improvements in these industries are possible; however, larger improvements seem available in the pulp and paper industry and through waste energy utilization and use of combined heat and power systems. When energy costs are a smaller fraction of total costs, companies may pay less attention to investing in efficiency. However, as energy prices increase, industry is geared to respond with innovations in efficiency, more utilization of waste heat, and new processes to reduce its energy consumption. Nevertheless, industry is more reluctant to initiate investment in energy efficiency when future energy prices are uncertain or volatile. Likewise, under poor market conditions, expenditures for process improvements are likely to be deferred.

Several studies cited in NAS/NAE/NRC (2009d) estimate the poten-

tial for further energy efficiency savings in the U.S. industrial sector as a whole:

-

Savings potential of 18-26% (IEA 2007).

-

Savings potential of 3.9 quads of energy reduction (about 12%) in 2020 (McKinsey 2007).

-

Savings potential of 16.6% from 2000 to 2020 with advanced policies (Interlaboratory Working Group 2000).

With continuing emphasis on energy efficiency in industry and likely increases in the cost of energy, energy use for industrial heating in 2030 will probably be somewhat lower than levels in 2007. NAS/NAE/NRC (2009a) finds the following:

-

“Independent studies using different approaches agree that the potential for improved energy efficiency in industry is large. Of the 34.3 quads of energy forecast to be consumed by U.S. industry in 2020 (EIA 2008b), 14 to 22% could be saved through cost-effective energy efficiency improvements (those with an internal rate of return of at least 10 percent or that exceed a company’s cost of capital by a risk premium). These innovations would save 4.9 to 7.7 quads annually.”

-

“Additional efficiency investments could become attractive through accelerated energy research, development, and demonstration. Enabling and crosscutting technologies—such as advanced sensors and controls, … and high temperature membrane separation—could provide efficiency gains in many industries as well as throughout the energy system ….”

SUMMARY

Externalities associated with heat production come from all sectors of the economy—residential and commercial buildings and industry. Most heat is generated from combustion of natural gas or from electricity. Combustion of natural gas results in relatively lower emissions compared with emissions from coal combustion, which is the main energy source for electricity generation. Therefore, damages related to providing heat directly from natural gas combustion are much less than damages related to use of electricity for heat. The better emissions performance of natural gas for direct heat also is reflected in the externality estimates of 11 cents/MCF (2007 USD) each for residential and commercial use, excluding GHGs. These results do not vary much regionally, although some counties have much higher externalities than others. Assuming industrial externality is 11 cents/MCF, aggregate damages from combustion of natural gas for direct heat is approximately $1.4 billion per year. The industrial sector contribution to this estimate reflects only natural gas use for heat generation. Including externalities from

petroleum combustion, which is on the same scale of energy use as natural gas for industrial heat generation, would lead to a higher estimate of aggregate damages from energy use for heat. Available data are insufficient to conduct a parallel analysis of industrial activities that generate useful heat. This situation could be improved with greater attention by EIA to collecting fuel consumption data by county and to provide additional resolution to emissions from disaggregated industrial activities.

The results represented here are the result of an end-use assessment—that in terms of providing heat, natural gas has lower externalities than electricity. It is not an assessment of how or where to use natural gas, which can be used for direct combustion or indirectly as a fuel for generating electric power.

Overall Implications of the Results

-

Aggregate damages associated with criteria-pollutant-forming emissions from the use of energy (primarily natural gas) for heating in the buildings and industrial sectors are low relative to damages from energy use in the electricity-generation and the transportation sectors.

-

GHG emissions associated with the use of energy (primarily natural gas) for heating in the buildings and industrial sectors are low relative to GHG emissions associated with transportation and electricity production because natural gas carbon intensity is lower than that of coal and gasoline.

-

The largest potential for reducing damages associated with the use of energy for heat lies in greater attention to improving the efficiency of energy use. NAS/NAE/NRC (2009a) suggests a potential for improving efficiency in the buildings and industrial sectors by 25% or more—with the likelihood that emission damages in these sectors could be held constant in spite of their growth between now and 2030.

Future Research Needs

-

Assessment of energy use and its impacts in the industrial sector in particular (but in all sectors to some extent) could be improved by more extensive databases that contain details about specific forms of energy use and associated waste streams. Such databases should be designed so that life-cycle analysis of alternatives can be made without inadvertent double counting.

-

A more quantitative assessment of industrial sector externalities done collaboratively by the government and industry would be valuable in informing priority setting for future initiatives to reduce the externalities associated with industrial operations. Such an assessment was not possible in this study largely because of data limitations.