Summary

In 2007 the National Highway Traffic Safety Administration (NHTSA) requested that the National Academies provide an objective and independent update of the technology assessments for fuel economy improvements and incremental costs contained in the 2002 National Research Council (NRC) report Effectiveness and Impact of Corporate Average Fuel Economy (CAFE) Standards. The NHTSA also asked that the NRC add to its assessment technologies that have emerged since that report was prepared. To address this request, the NRC formed the Committee on the Assessment of Technologies for Improving Light-Duty Vehicle Fuel Economy. The statement of task, shown in Appendix B, directed the committee to estimate the efficacy, cost, and applicability of technologies that might be used over the next 15 years.

FINDINGS AND RECOMMENDATIONS

Overarching Finding

A significant number of technologies exist that can reduce the fuel consumption of light-duty vehicles while maintaining similar performance, safety, and utility. Each technology has its own characteristic fuel consumption benefit and estimated cost. Although these technologies are often considered independently, there can be positive and negative interactions among individual technologies, and so the technologies must be integrated effectively into the full vehicle system. Integration requires that other components of the vehicle be added or modified to produce a competitive vehicle that can be marketed successfully. Thus, although the fuel consumption benefits and costs discussed here are compared against those of representative base vehicles, the actual costs and benefits will vary by specific model. Further, the benefits of some technologies are not completely represented in the tests used to estimate corporate average fuel economy (CAFE). The estimate of such benefits will be more realistic using the new five-cycle tests that display fuel economy data on new vehicles’ labels, but improvements to test procedures and additional analysis are warranted. Given that the ultimate energy savings are directly related to the amount of fuel consumed, as opposed to the distance that a vehicle travels on a gallon of fuel, consumers also will be helped by addition to the label of explicit information that specifies the number of gallons typically used by the vehicle to travel 100 miles.

Technologies for Reducing Fuel Consumption

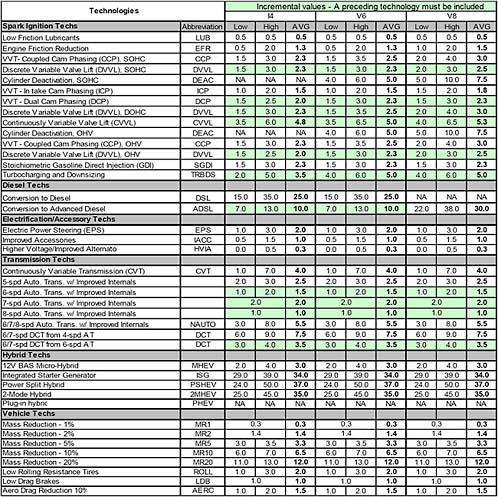

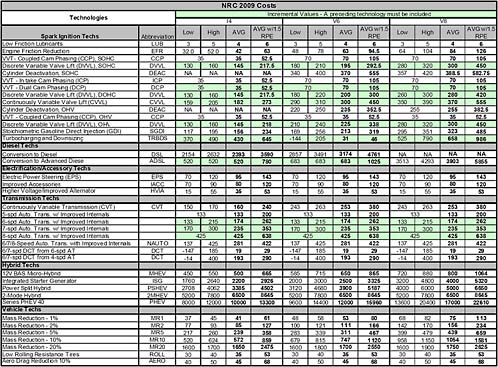

Tables S.1 and S.2 show the committee’s estimates of fuel consumption benefits and costs for technologies that are commercially available and can be implemented within 5 years. The cost estimates represent estimates for the current (2009/2010) time period to about 5 years in the future. The committee based these estimates on a variety of sources, including recent reports from regulatory agencies and other sources on the costs and benefits of technologies; estimates obtained from suppliers on the costs of components; discussions with experts at automobile manufacturers and suppliers; detailed teardown studies of piece costs for individual technologies; and comparisons of the prices for and amount of fuel consumed by similar vehicles with and without a particular technology.

Some longer-term technologies have also demonstrated the potential to reduce fuel consumption, although further development is required to determine the degree of improvement, cost-effectiveness, and expected durability. These technologies include camless valve trains, homogeneous-charge compression ignition, advanced diesel, plug-in hybrids, diesel hybrids, electric vehicles, fuel cell vehicles, and advanced materials and body designs. Although some of these technologies will see at least limited commercial introduction over the next several years, it is only in the 5- to 15-year time frame and beyond that they are expected to find widespread commercial application. Further, it will not be possible for some of these technologies to become solutions for significant technical and economic challenges, and thus some of these technologies will remain perennially 10 to 15 years out beyond a moving reference. Among its provisions,

TABLE S.1 Committee’s Estimates of Effectiveness (shown as a percentage) of Near-Term Technologies in Reducing Vehicle Fuel Consumption

|

|

|

NOTE: Some of the benefits (highlighted in green) are incremental to those obtained with preceding technologies shown in the technology pathways described in Chapter 9. |

the Energy Independence and Security Act (EISA) of 2007 requires periodic assessments by the NRC of automobile vehicle fuel economy technologies, including how such technologies might be used to meet new fuel economy standards. Follow-on NRC committees will be responsible for responding to the EISA mandates, including the periodic evaluation of emerging technologies.

Testing and Reporting of Vehicle Fuel Use

Fuel economy is a measure of how far a vehicle will travel with a gallon of fuel, whereas fuel consumption is the amount of fuel consumed in driving a given distance. Although each is simply the inverse of the other, fuel consumption is the fundamental metric by which to judge absolute improvements in fuel efficiency, because what is important is gallons of fuel saved in the vehicle fleet. The amount of fuel saved directly relates not only to dollars saved on fuel purchases but also to quantities of carbon dioxide emissions avoided. Fuel economy data cause consumers to undervalue small increases (1-4 mpg) in fuel economy for vehicles in the 15-30 mpg range, where large decreases in fuel consumption can be realized with small increases in fuel economy. The percentage decrease in fuel consumption is approximately

equal to the percentage increase in fuel economy for values less than 10 percent (for example, a 9.1 percentage decrease in fuel consumption equals a 10 percent increase in fuel economy), but the differences increase progressively: for example, a 33.3 percent decrease in fuel consumption equals a 50 percent increase in fuel economy.

Recommendation: Because differences in the fuel consumption of vehicles relate directly to fuel savings, the labeling on new cars and light-duty trucks should include information on the gallons of fuel consumed per 100 miles traveled in addition to the already-supplied data on fuel economy so that consumers can become familiar with fuel consumption as a fundamental metric for calculating fuel savings.

Fuel consumption and fuel economy are evaluated by the U.S. Environmental Protection Agency (EPA) for the two driving cycles: the urban dynamometer driving schedule (city cycle) and the highway dynamometer driving schedule (high-way cycle). In the opinion of the committee, the schedules used to compute CAFE should be modified so that vehicle test data better reflect actual fuel consumption. Excluding some driving conditions and accessory loads in determining CAFE discourages the introduction of certain technologies into the vehicle fleet. The three additional schedules recently adopted by the EPA for vehicle labeling purposes—ones that capture the effects of higher speed and acceleration, air conditioner use, and cold weather—represent a positive step forward, but further study is needed to assess to what degree the new test procedures can fully characterize changes in inuse vehicle fuel consumption.

Recommendation: The NHTSA and the EPA should review and revise fuel economy test procedures so that they better reflect in-use vehicle operating conditions and also provide the proper incentives to manufacturers to produce vehicles that reduce fuel consumption.

Cost Estimation

Large differences in technology cost estimates can result from differing assumptions. These assumptions include whether costs are long- or short-term costs; whether learning by doing is included in the cost estimate; whether the cost estimate represents direct in-house manufacturing costs or the cost of purchasing a component from a supplier; and which of the other changes in vehicle design that are required to maintain vehicle quality have been included in the cost estimate. Cost estimates also depend greatly on assumed production volumes.

In the committee’s judgment, the concept of incremental retail price equivalent (RPE) is the most appropriate indicator of cost for the NHTSA’s purposes because it best represents the full, long-run economic costs of decreasing fuel consumption. The RPE represents the average additional price consumers would pay for a fuel economy technology. It is intended to reflect long-run, substantially learned, industry-average production costs that incorporate rates of profit and overhead expenses. A critical issue is choice of the RPE markup factor, which represents the ratio of total cost of a component, taking into account the full range of costs of doing business, to only the direct cost of the fully manufactured component. For fully manufactured components purchased from a Tier 1 supplier,1 a reasonable average RPE markup factor is 1.5. For in-house manufactured components, a reasonable average RPE markup factor over variable manufacturing costs is 2.0. In addition to the costs of materials and labor and the fixed costs of manufacturing, the RPE factor for components from Tier 1 suppliers includes profit, warranty, corporate overhead, and amortization of certain fixed costs, such as research and development. The RPE factor for in-house manufactured components from automobile manufacturers includes the analogous components of the Tier 1 markup for the manufacturing operations, plus additional fixed costs for vehicle integration design and vehicle installation, corporate overhead for assembly operations, additional product warranty costs, transportation, marketing, dealer costs, and profits. RPE markup factors clearly vary depending on the complexity of the task of integrating a component into a vehicle system, the extent of the changes required to other components, the novelty of the technology, and other factors. However, until empirical data derived via rigorous estimation methods are available, the committee prefers the use of average markup factors.

Available cost estimates are based on a variety of sources: component cost estimates obtained from suppliers, discussions with experts at automobile manufacturers and suppliers, publicly available transaction prices, and comparisons of the prices of similar vehicles with and without a particular technology. However, there is a need for cost estimates based on a teardown of all the elements of a technology and a detailed accounting of materials and capital costs and labor time for all fabrication and assembly processes. Such teardown studies are costly and are not feasible for advanced technologies whose designs are not yet finalized and/or whose system integration impacts are not yet fully understood. Estimates based on the more rigorous method of teardown analysis would increase confidence in the accuracy of the costs of reducing fuel consumption.

Technology cost estimates are provided by the committee for each fuel economy technology discussed in this report. Except as indicated, the cost estimates represent the price an automobile manufacturer would pay a supplier for a finished component. Thus, on average, the RPE multiplier of 1.5 would apply to the direct, fully manufactured cost to obtain the average additional price consumers would pay for a technology. Again, except where indicated otherwise, the

cost estimates provided are based on current conditions and do not attempt to estimate economic conditions and hence predict prices 5, 10, or 15 years into the future.

Spark-Ignition Gasoline Engine Technologies

Spark-ignition (SI) engines are expected to continue to be the primary source of propulsion for light-duty vehicles in the United States over the time frame of this report. There have been and continue to be significant improvements in reducing the fuel consumption of SI engines in the areas of friction reduction, reduced pumping losses through advanced valve-event modulation, thermal efficiency improvements, cooled exhaust gas recirculation, and improved overall engine architecture, including downsizing. An important attribute of improvements in SI engine technologies is that they offer a means of reducing fuel consumption in relatively small, incremental steps. This approach allows automobile manufacturers to create packages of technologies that can be tailored to meet specific cost and effectiveness targets, as opposed to developing diesel or full hybrid alternatives that offer a single large benefit, but at a significant cost increase. Because of the flexibility offered by this approach, and given the size of the SI engine-powered fleet, the implementation of SI engine technologies will continue to play a large role in reducing fuel consumption.

Of the technologies currently available, cylinder deactivation is one of the more effective in reducing fuel consumption. This feature is most cost-effective when applied to six- cylinder (V6) and eight-cylinder (V8) overhead valve engines, and typically reduces fuel consumption by 4 to 10 percent at an incremental RPE increase of about $550. Stoichiometric direct injection typically affords a 1.5 to 3 percent reduction in fuel consumption at an incremental RPE increase of $230 to $480, depending on cylinder count and noise abatement requirements. Turbocharging and downsizing can also yield fuel consumption reductions. Downsizing—reducing engine displacement while maintaining vehicle performance—is an important strategy applicable in combination with technologies that increase engine torque, such as turbocharging or supercharging. Downsizing simultaneously reduces throttling and friction losses because downsized engines generally have smaller bearings and either fewer cylinders or smaller cylinder bore friction surfaces. Reductions in fuel consumption can range from 2 to 6 percent with turbocharging and down sizing, depending on many details of implementation. This technology combination is assumed to be added after direct injection, and its fuel consumption benefits are incremental to those from direct injection. Based primarily on an EPA teardown study, the committee’s estimates of the costs for turbocharging and downsizing range from close to zero additional cost, when converting from a V6 to a four-cylinder (I4) engine, to almost $1,000, when converting from a V8 to a V6 engine. Valve-event modulation (VEM) can further reduce fuel consumption and can also cause a slight increase in engine performance, which offers a potential opportunity for engine downsizing. There are many different implementations of VEM, and the costs and benefits depend on the specific engine architecture. Fuel consumption reduction can range from 1 percent with only intake cam phasing, to about 7 percent with a continuously variable valve lift and timing setup. The incremental RPE increase for valve-event modulation ranges from about $50 to $550, with the amount depending on the implementation technique and the engine architecture.

Variable compression ratio, camless valve trains, and homogeneous-charge compression ignition were all given careful consideration during the course of this study. Because of questionable benefits, major implementation issues, or uncertain costs, it is uncertain whether any of these technologies will have any significant market penetration in the next 10 to 15 years.

Compression-Ignition Diesel Engine Technologies

Light-duty compression-ignition (CI) engines operating on diesel fuels have efficiency advantages over the more common SI gasoline engines. Although light-duty diesel vehicles are common in Europe, concerns over the ability of such engines to meet emission standards for nitrogen oxides and particulates have slowed their introduction in the United States. However, a joint effort between automobile manufacturers and suppliers has resulted in new emissions control technologies that enable a wide range of light-duty CI engine vehicles to meet federal and California emissions standards. The committee found that replacing a 2007 model year SI gasoline power train with a base-level CI diesel engine with an advanced 6-speed dual-clutch automated manual transmission (DCT) and more efficient accessories packages can reduce fuel consumption by about 33 percent on an equivalent vehicle performance basis. The estimated incremental RPE cost of conversion to the CI engine is about $3,600 for a four-cylinder engine and $4,800 for a six-cylinder engine. Advanced-level CI diesel engines, which are expected to reach market in the 2011-2014 time frame, with DCT (7/8 speed) could reduce fuel consumption by about an additional 13 percent for larger vehicles and by about 7 percent for small vehicles. Part of the gain from advanced-level CI diesel engines comes from downsizing. The estimated incremental RPE cost of the conversion to the package of advanced diesel technologies is about $4,600 for small passenger cars and $5,900 for intermediate and large passenger cars.

An important characteristic of CI diesel engines is that they provide reductions in fuel consumption over the entire vehicle operating range, including city driving, highway driving, hill climbing, and towing. This attribute of CI diesel engines is an advantage when compared with other technology options that in most cases provide fuel consumption benefits for only part of the vehicle operating range.

The market penetration of CI diesel engines will be strongly influenced by both the incremental cost of CI diesel power trains above the cost of SI gasoline power trains and by diesel and gasoline fuel prices. Further, while technology improvements to CI diesel engines are expected to reach market in the 2011-2014 time frame, technology improvements to SI gasoline and hybrid engines will also enter the market. Thus, competition between these power train systems will continue with respect to reductions in fuel consumption and to cost. For the period 2014-2020, further potential reductions in fuel consumption by CI diesel engines may be offset by increases in fuel consumption as a result of changes in engines and emissions systems required to meet potentially stricter emissions standards.

Hybrid Vehicle Technologies

Because of their potential to eliminate energy consumption when the vehicle is stopped, permit braking energy to be recovered, and allow more efficient use of the internal combustion engine, hybrid technologies are one of the most active areas of research and deployment. The degree of hybridization can vary from minor stop-start systems with low incremental costs and modest reductions in fuel consumption to complete vehicle redesign and downsizing of the SI gasoline engine at a high incremental cost but with significant reductions in fuel consumption. For the most basic systems that reduce fuel consumption by turning off the engine while the vehicle is at idle, the fuel consumption benefit may be up to about 4 percent at an estimated incremental RPE increase of $670 to $1,100. The fuel consumption benefit of a full hybrid may be up to about 50 percent at an estimated incremental RPE cost of $3,000 to $9,000 depending on vehicle size and specific hybrid technology. A significant part of the improved fuel consumption of full hybrid vehicles comes from the complete vehicle redesign that can incorporate modifications such as low-rolling-resistance tires, improved aerodynamics, and the use of smaller, more efficient SI engines.

In the next 10 to 15 years, improvements in hybrid vehicles will occur primarily as a result of reduced costs for hybrid power train components and improvements in battery performance such as higher power per mass and volume, increased number of lifetime charges, and wider allowable state-of-charge ranges. During the past decade, significant advances have been made in lithium-ion battery technology. When the cost and safety issues associated with them are resolved, lithium-ion batteries will replace nickel-metal-hydride batteries in hybrid electric vehicles and plug-in hybrid electric vehicles. A number of different lithium-ion chemistries are being studied, and it is not yet clear which ones will prove most beneficial. Given the high level of activity in lithiumion battery development, plug-in hybrid electric vehicles will be commercially viable and will soon enter at least limited production. The practicality of full-performance battery electric vehicles (i.e., with driving range, trunk space, volume, and acceleration comparable to those of vehicles powered with internal-combustion engines) depends on a battery cost breakthrough that the committee does not anticipate within the time horizon considered in this study. However, it is clear that small, limited-range, but otherwise full-performance battery electric vehicles will be marketed within that time frame. Although there has been significant progress in fuel cell technology, it is the committee’s opinion that fuel cell vehicles will not represent a significant fraction of on-road light-duty vehicles within the next 15 years.

Non-engine Technologies for Reducing Vehicle Fuel Consumption

There is a range of non-engine technologies with varying costs and impacts. Many of these technologies are continually being introduced to new vehicle models based on the timing of the product development process. Coordinating the introduction of many technologies with the product development process is critical to maximizing impact and minimizing cost. Relatively minor changes that do not involve reengineering the vehicle or that require recertification for fuel economy, emissions, and/or safety can be implemented within a 2- to 4-year time frame. These changes could include minor reductions in mass (achieved by substitution of materials), improving aerodynamics, or switching to low-rolling-resistance tires. More substantive changes, which require longer-term coordination with the product development process because of the need for reengineering and integration with other subsystems, could include resizing the engine and transmission or aggressively reducing vehicle mass, such as by changing the body structure. The time frame for substantive changes for a single model is approximately 4 to 8 years.

Two important technologies impacting fuel consumption are those for light-weighting and for improving transmissions. Light-weighting has significant potential because vehicles can be made very light with exotic materials, albeit at potentially high cost. The incremental cost to reduce a pound of mass from the vehicle tends to increase as the total amount of reduced mass increases, leading to diminishing returns. About 10 percent of vehicle mass can be eliminated at a cost of roughly $800 to $1,600 and can provide a fuel consumption benefit of about 6 to 7 percent. Reducing mass much beyond 10 percent requires attention to body structure design, such as considering an aluminum-intensive car, which increases the cost per pound. A 10 percent reduction in mass over the next 5 to 10 years appears to be within reach for the typical automobile.

Transmission technologies have improved significantly and, like other vehicle technologies, show a similar trend of diminishing returns. Planetary-based automatic transmissions can have 5, 6, 7, and 8 speeds, but with incremental costs increasing faster than reductions in fuel consumption. DCTs are in production by some automobile manufacturers,

and new production capacity for this transmission type has been announced. It is expected that the predominant trend in transmission design is conversion to 6- to 8-speed planetary-based automatics and to DCTs, with continuously variable transmissions remaining a niche application. Given the close linkage between the effects of fuel-consumption-reducing engine technologies and transmission technologies, the present study has for the most part considered the combined effects of engines and transmission combinations rather than potential separate effects.

Accessories are also being introduced to new vehicles to reduce the power load on the engine. Higher-efficiency air conditioning systems are available that more optimally match cooling with occupant comfort. Electric and electric/hydraulic power steering also reduces the load on an engine by demanding power only when the operator turns the wheel. An important motivating factor affecting the introduction of these accessories is whether or not their impact is measured during the EPA driving cycles used to estimate fuel consumption.

Modeling Reductions in Fuel Consumption Obtained from Vehicle Technologies

The two primary methods for modeling technologies’ reduction of vehicle fuel consumption are full system simulation (FSS) and partial discrete approximation (PDA). FSS is the state-of-the-art method because it is based on integration of the equations of motion for the vehicle carried out over the speed-time representation of the appropriate driving or test cycle. Done well, FSS can provide an accurate assessment (within +/−5 percent or less) of the impacts on fuel consumption of implementing one or more technologies. The validity of FSS modeling depends on the accuracy of representations of system components. Expert judgment is also required at many points and is critical to obtaining accurate results. Another modeling approach, the PDA method, relies on other sources of data for estimates of the impacts of fuel economy technologies and relies on mathematical summation or multiplication methods to aggregate the effects of multiple technologies. Synergies among technologies can be represented using engineering judgment and lumped parameter models2 or can be synthesized from FSS results. Unlike FSS, the PDA method cannot be used to generate estimates of the impacts of individual technologies on fuel consumption. Thus, the PDA method by itself, unlike FSS, is not suitable for estimating the fuel consumption impacts of technologies that have not already been tested in actual vehicles or whose fuel consumption benefits have not been estimated by means of FSS.

Comparisons of FSS modeling and PDA estimation supported by lumped parameter modeling have shown that the two methods produce similar results when similar assumptions are used. In some instances, comparing the estimates made by the two methods has enhanced the overall validity of estimated fuel consumption impacts by uncovering inadvertent errors in one or the other method. In the committee’s judgment both methods are valuable, especially when used together, with one providing a check on the other. However, more work needs to be done to establish the accuracy of both methods relative to actual motor vehicles.

The Department of Transportation’s Volpe National Transportation Systems Center has developed a model for the NHTSA to estimate how manufacturers can comply with fuel economy regulations by applying additional fuel savings technologies to the vehicles they plan to produce. The model employs a PDA algorithm that includes estimates of the effects of interactions among technologies applied. The validity of the Volpe model could be improved by taking into account main and interaction effects produced by the FSS methodology described in Chapter 8 of this report. In particular, modeling work done for the committee by an outside consulting firm has demonstrated a practical method for using data generated by FSS models to accurately assess the fuel consumption potentials of combinations of dozens of technologies on thousands of vehicle configurations. A design-of-experiments statistical analysis of FSS model runs demonstrated that main effects and first-order interaction effects alone could predict FSS model outputs with an R2 of 0.99. Using such an approach could appropriately combine the strengths of both the FSS and the PDA modeling methods. However, in the following section, the committee recommends an alternate approach that uses FSS to better assess the contributory effects of the technologies applied in the reduction of energy losses and to better couple the modeling of fuel economy technologies to the testing of such technologies on production vehicles.

Application of Multiple Vehicle Technologies to Vehicle Classes

Figures 9.1 to 9.5 in Chapter 9 of this report display the technology pathways developed by the committee for eight classes of vehicles and the aggregated fuel consumption benefits and costs for the SI engine, CI engine, and hybrid power train pathways. The results of the committee’s analysis are that, for the intermediate car, large car, and unibody standard truck classes, the average reduction in fuel consumption for the SI engine path is about 29 percent at a cost of approximately $2,200; the average reduction for the CI engine path is about 37 percent at a cost of approximately $5,900; and the average reduction for the hybrid power train path is about 44 percent at a cost of $6,000. These values are approximate and are provided here as rough estimates that can be used for qualitative comparison of SI engine-related technologies and

other candidates for the reduction of vehicle fuel consumption, such as light-duty diesel or hybrid vehicles.

Improvements to Modeling of Multiple Fuel Economy Technologies

Many vehicle and power train technologies that improve fuel consumption are currently in or entering production or are in advanced stages of development in European or Asian markets where high consumer fuel prices have made commercialization of the technologies cost-effective. Depending on the intended vehicle use or current state of energy-loss reduction, the application of incremental technologies will produce varying levels of improvement in fuel consumption. Data made available to the committee from automobile manufacturers, Tier 1 suppliers, and other published studies also suggest a very wide range in estimated incremental cost. As noted above in this Summary, estimates based on teardown cost analysis, currently being utilized by the EPA in its analysis of standards for regulating light-duty-vehicle greenhouse gas emissions, should be expanded for developing cost impact analyses. The committee notes, however, that cost estimates are always more uncertain than estimates of fuel consumption.

FSS modeling that is based on empirically derived power train and vehicle performance and on fuel consumption data maps offers what the committee believes is the best available method to fully account for system energy losses and to analyze potential improvements in fuel consumption achievable by technologies as they are introduced into the market. Analyses conducted for the committee show that the effects of interactions between differing types of technologies for reducing energy loss can and often do vary greatly from vehicle to vehicle.

Recommendation: The committee proposes a method whereby FSS analyses are used on class-characterizing vehicles, so that synergies and effectiveness in implementing multiple fuel economy technologies can be evaluated with what should be greater accuracy. This proposed method would determine a characteristic vehicle that would be defined as a reasonable average representative of a class of vehicles. This representative vehicle, whether real or theoretical, would undergo sufficient FSS, combined with experimentally determined and vehicle-class-specific system mapping, to allow a reasonable understanding of the contributory effects of the technologies applied to reduce vehicle energy losses. Data developed under the United States Council for Automotive Research (USCAR) Benchmarking Consortium should be considered as a source for such analysis and potentially expanded. Under the USCAR program, actual production vehicles are subjected to a battery of vehicle, engine, and transmission tests in sufficient detail to understand how each candidate technology is applied and how they contribute to the overall performance and fuel consumption of light-duty vehicles. Combining the results of such testing with FSS modeling, and thereby making all simulation variables and subsystem maps transparent to all interested parties, would allow the best opportunity to define a technical baseline against which potential improvements could be analyzed more accurately and openly than is the case with the current methods employed.

The steps in the recommended process would be as follows:

-

Develop a set of baseline vehicle classes from which a characteristic vehicle can be chosen to represent each class. The vehicle may be either real or theoretical and will possess the average attributes of that class as determined by sales-weighted averages.

-

Identify technologies with a potential to reduce fuel consumption.

-

Determine the applicability of each technology to the various vehicle classes.

-

Estimate each technology’s preliminary impact on fuel consumption and cost.

-

Determine the optimum implementation sequence (technology pathway) based on cost-effectiveness and engineering considerations.

-

Document the cost-effectiveness and engineering judgment assumptions used in step 5 and make this information part of a widely accessible database.

-

Utilize modeling software (FSS) to progress through each technology pathway for each vehicle class to obtain the final incremental effects of adding each technology.

If such a process were adopted as part of a regulatory rulemaking procedure, it could be completed on 3-year cycles to allow regulatory agencies sufficient lead time to integrate the results into future proposed and enacted rules.

CONCLUDING COMMENTS

A significant number of approaches are currently available to reduce the fuel consumption of light-duty vehicles, ranging from relatively minor changes to lubricants and tires to large changes in propulsion systems and vehicle platforms. Technologies such as all-electric propulsion systems have also demonstrated the potential to reduce fuel consumption, although further development is required to determine the degree of improvement, cost-effectiveness, and durability. The development and deployment of vehicles that consume less fuel will be influenced not only by technological factors but also by economic and policy factors whose examination is beyond the scope of this study. Future NRC committees will be responsible for periodic assessments of the cost and benefits of technologies that reduce vehicle fuel consumption, including how such technologies might be used to meet new fuel economy standards.