2

Crosscutting Issues

This chapter addresses crosscutting issues identified by the committee that, in its opinion, require attention. Some were addressed in the Phase 1 and 2 reports (NRC, 2005, 2008). The areas addressed here are (1) program decision making, (2) safety, (3) the balance between “short-term” and “long-term” R&D activities, (4) the interface of plug-in electric vehicles with the nation’s electricity delivery system, (5) persisting trends in automotive innovation, and (6) environmental issues associated with different vehicle/energy source pathways. Specific technical areas being addressed by the Partnership are considered in Chapters 3 and 4.

PROGRAM DECISION MAKING

The topics of strategic planning, program management, and decision making within the FreedomCAR and Fuel Partnership are all closely related, and they all critically depend on systems analysis. As described in Chapter 1, the Partnership is a research and development (R&D) program that focuses on critical transportation technology and fuels challenges for vehicles; if successfully met, these challenges could significantly lower U.S. petroleum consumption and greenhouse gas (GHG) emissions. The Partnership’s individual technical teams, which include members from the DOE, national laboratories, the automotive OEMs and suppliers, energy companies and power companies, work primarily at the vehicle component level and on the production, distribution, and delivery of hydrogen; in addition, there is recent attention on the interface between the nation’s electricity delivery system and the charging of electric vehicles (e.g., plug-in hybrid electric vehicles [PHEVs] or all-electric or battery electric vehicles [BEVs]). There are annual DOE program reviews in addition to many DOE-sponsored conferences and work-

shops as well as considerable participation in professional society conferences to help keep everyone in the Partnership technical teams well informed. To these teams are added a vehicle systems analysis technical team (VSATT) and a fuel pathway integration technical team (FPITT). This organizational structure is based on project activities that focus on individual technical issues, as well as on total vehicle system integration and the total fuel chain (see Figure 1-1 in Chapter 1). In addition, there is a broader strategic perspective, which the Executive Steering Group (ESG) provides. The system integration and performance issues require a systems analysis approach on several levels, necessitating a variety of systems analysis tools.

In its previous reports, the National Research Council (NRC) recommended substantial activity to develop systems analysis tools to help the Partnership meet its goals. For example, in its first report it was recommended that “an ongoing, integrated, well-to-wheels assessment be made of the Partnership’s progress toward its overall objectives” (NRC, 2005, p. 9). In its second report, the committee recommended that “the DOE should accelerate the development and validation of modeling tools that can be used to assess the roles of various propulsion system and vehicle technologies and fuels, and utilize them to determine the impact of the various opportunities on the overall Partnership goals of reducing petroleum use and air pollutant and greenhouse gas emissions” (NRC, 2008, p. 13).

The Partnership has made substantial progress on the development and application of these systems analysis tools. Well-to-wheels analysis (the committee now generally uses the term “source-to-wheels”)1 is now routinely used across the Partnership, and modeling and simulation tools are widely used within the technical teams to support detailed design and analysis as well as target setting. The impact on goals is being assessed by integrating information from various models such as the GHG information from the GREET (Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation) model and market interaction information from national energy sector models (MARKAL [Market Analysis] and NEMS [National Energy Modeling System]). The PSAT (Powertrain Systems Analysis Toolkit) model provides vehicle performance information based on goals and targets. Key program target information for advanced diesel vehicles, hybrid electric vehicles (HEVs), PHEVs, and fuel cell vehicles are included in the PSAT vehicle performance modeling. The hydrogen production and delivery targets are assessed with the H2A (Hydrogen Technology) Production and Delivery models. The MARKAL and NEMS models are used to perform sensitivity analyses of the impacts of meeting or not meeting various targets on the market

shares of various light-duty vehicle technologies, as well as on oil savings and environmental impacts.

Overall, as noted, the development and deployment of systems analysis tools and models at the vehicle and fuel pathway level are impressive, and fully responsive to the committee’s specific prior recommendations. However, the systems analysis teams, particularly the VSATT, operate in a support role to the individual technical teams. The application of systems analysis to the overall guidance and management of the Partnership and the determination of technical directions in pursuit of the Partnership’s overarching goals relating to national energy policy are much less transparent. In the Phase 2 report (NRC, 2008, p. 30), the committee said that “there is no lack of technical review of the individual program elements, but what is missing is analysis of the quantitative impact on the overall goals of reducing petroleum use and pollutant and greenhouse gas emissions. Tools for estimating this are being worked on: one example is the Macro System Model (MSM) which is scheduled for completion in 2008.” As of August 2009, the MSM was reported still to be “under development.”

The committee was encouraged to learn at its meeting in October 2009 that the Department of Energy (DOE) has begun using system-level analysis to guide overall program goals and direction, and that sensitivity analysis is being performed on the impact of not meeting different program targets. However, this remains an area in which the committee strongly encourages additional emphasis.

Furthermore, the ESG, charged with overall Partnership guidance, has not met for almost 2 years, leaving an apparent guidance vacuum at the senior leadership level. Although the Partnership has made good progress over this period, it is important that the ESG be fully engaged in the current, ongoing review of the future structure of the Partnership. The committee is assured that this concern is recognized by DOE executive management.

The committee also suggests that the FreedomCAR and Fuel Partnership consider the use of the Oak Ridge National Laboratory (ORNL) consumer choice model to measure the progress of several key advanced vehicles. The reason is that technical progress for advanced vehicles is currently being presented primarily at the subsystem and component levels in a wide variety of units—for example, in terms of fuel economy, range, refueling time, and so on. The lack of a common unit of measure means that the benefits at the subsystem and component levels cannot be combined and compared against cost to get a single value proposition for the collective impact of the advanced technologies on the full vehicle system. The consumer choice model, however, converts the technical advances into the same unit, dollars, thereby allowing the improvements in the value-versus-cost proposition to be estimated.2

In summary, the two systems analysis teams have done excellent work and have made great progress at the micro level, but although there are signs of improvement, it is still unclear to the committee how or if this work is being adequately applied at the senior leadership level to guide overall Partnership direction.

SAFETY

Overview

The transition to alternative-fueled vehicles—whether using electricity, biofuels, or hydrogen—will involve new safety challenges that need to be identified and resolved for each alternative. This section on safety emphasizes the safety of hydrogen systems, but the other alternatives also deserve attention.

An exemplary hydrogen safety record will not ensure the success of fuel cell vehicles and other hydrogen technologies under development by the Partnership and the eventual transition to a hydrogen economy; however, a poor safety record may delay or inhibit the widespread use of hydrogen. The goals and objectives of the broad safety portion of the Partnership are to develop practices and procedures that will ensure safety in the operation, handling, and use of hydrogen and hydrogen systems for all DOE-funded projects and to implement these practices and lessons learned to promote the safe use of hydrogen.

The goals and objectives of the narrower codes and standards portion of the program are as follows:

-

To perform the underlying research to enable codes and standards to be developed for the safe use of hydrogen in all applications, and

-

To facilitate the development and harmonization of domestic and international codes and standards.

The DOE safety, codes, and standards program is focused on hydrogen. Its budget from fiscal year (FY) 2006 to FY 2010 is shown in Table 2-1.

The budget has been robust since FY 2007, but there is a significant reduction for FY 2010. The codes and standards portion is included in the Partnership’s codes and standards technical team. The safety part is administered by DOE Headquarters.

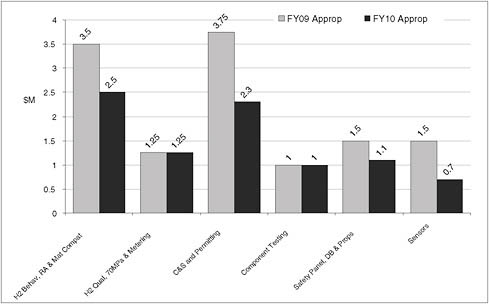

The breakdown of the DOE safety, codes, and standards program into six subprogram elements with funding for FY 2009 and FY 2010 is shown in Figure 2-1. The hydrogen codes and standards subprogram focuses on the research and development needed to strengthen the scientific basis for technical requirements incorporated in national and international standards, codes, and regulations. The subprogram also sponsors a national effort by industry, standards, and model-code development organizations and government to prepare, review, and promulgate

TABLE 2-1 U.S. Department of Energy Safety, Codes, and Standards Funding from FY 2006 through FY 2010

|

Fiscal Year |

Funding ($) |

|

2006 |

4,595,000 |

|

2007a |

13,492,000 |

|

2008a |

15,442,000 |

|

2009b |

12,500,000 |

|

2010 |

8,839,000 |

|

Total |

54,605,575 |

|

aFY 2007 and FY 2008 numbers exclude Small Business Innovation Research and Small Business Technology Transfer (SBIR/STTR) funding. bUnder the Vehicle Technologies Program budget in FY 2009. SOURCE: Response from DOE to committee questions, November 23, 2009. |

|

FIGURE 2-1 U.S. Department of Energy safety, codes, and standards budget allocation, FY 2009 and FY 2010 (millions of dollars), broken down by six subprogram elements. The FY 2009 budget was $12.5 million and the FY 2010 budget was $8.8 million.

NOTE: H2 Behav = hydrogen behavior; RA = risk assessment; Mat Compat = materials compatibility; H2 Qual = hydrogen quality; C&S = codes and standards; DB = database; Props = properties. SOURCE: Antonio Ruiz, U.S. Department of Energy, November 2009.

hydrogen codes and standards needed to expedite hydrogen infrastructure development and to help enable the emergence of hydrogen as a significant energy carrier. The overall goal of the safety subprogram is to understand, develop, and promote the practices that will ensure the safe handling, storage, and use of hydrogen. By promoting hydrogen safety procedures, supporting a research program, and developing information resources, the safety subprogram seeks to help form the basis for the safe use of hydrogen as an energy carrier, now and in the future.

The codes and standards portion of the Partnership, which includes the R&D Roadmap and National Template, funds several organizations developing vehicle-level and component-level safety standards. Considerable progress is being made.

The safety part of the program includes the Hydrogen Safety Panel, a Web-based incident reporting system,3 a bibliographic database,4 and a Best Practices Web site.5 There is also an extensive program on unintentional releases of hydrogen and on hydrogen behavior, safety sensors, and the compatibility of materials with hydrogen.

Hydrogen safety activities in the U.S. Department of Transportation (DOT) are partially funded by the DOE. DOT has a hydrogen-related budget of about $14 million, of which about $10 million is spent on the hydrogen bus program in the Federal Transit Administration (FTA). There may be safety lessons learned from the bus program. The majority of the safety-related work is in DOT’s National Highway Traffic Safety Administration (NHTSA) and DOT’s Pipeline and Hazardous Materials Safety Administration (PHMSA).

Response to Phase 2 Report

The full text of the recommendations discussed in this subsection comes from the Phase 2 report (NRC, 2008) and is reprinted in Appendix D of this report.

-

Recommendation 2-7: DOE should establish a program to address all end-to-end safety aspects. The response relative to vehicle safety is incomplete and refers to nonexistent DOT standards. Analysis can be done on generic vehicle safety issues as well as the end-to-end fuel supply chain. The DOE could choose a national laboratory to lead this effort.

-

Recommendation 2-8: DOT should develop a long-range hydrogen safety plan. Apparently this has been done, and these milestones have been integrated into the codes and standards technical team roadmap.

|

3 |

See <www.h2incidents.org>. |

|

4 |

|

|

5 |

See <www.h2bestpractices.org>. |

-

Recommendation 2-9: The codes and standards technical team should update its roadmap to 2015. This has been done.

-

Recommendation 2-10: DOE should establish a program to collect and analyze safety data on compressed natural gas and hydrogen components, subsystems, vehicles, and fueling stations. A DOT/DOE workshop to begin this process was held in December 2009. The committee suggests that this work be expanded and continued. This work can provide input to an end-to-end quantitative risk analysis.

-

Recommendation 2-11: DOE should convene a panel of outside experts in the hydrogen compatibility of materials. The response was very thorough and included interactions with many stakeholders. A review panel of independent experts was planned for FY 2009. This area should continue to be of high priority.

-

Recommendation 2-12: DOE should accelerate work on delayed ignition of unintended hydrogen releases. The response was very complete and excellent.

In addition to the six recommendations in the Safety section of the Phase 2 report, there was a safety-related recommendation in the Onboard Hydrogen Storage section:

-

Recommendation 3-9: The Partnership should perform studies to determine the risks and consequences of relying on pressurized hydrogen storage. Safety issues should be included in these studies. The response covers everything except the safety risks and consequences of high-pressure storage. It is suggested that a comprehensive program for compressed hydrogen tank safety be developed and executed. Very little tank-level safety testing has been done, and there are new initiatives to reduce the tank weight and cost, which could influence the tanks’ safety performance. An example is the initiative to change the burst margin (discussed below in the subsection entitled “High-Pressure Hydrogen Storage Safety Issues”).

Discussion

This discussion on safety addresses four areas. The committee’s recommendations are presented at the end of this “Safety” section.

1.

End-to-End Safety Analysis for All Vehicle and Fuel Pathways

The Phase 1 report (NRC, 2005) included a safety recommendation for forming a “crosscutting safety technical team.” That was not accomplished and thus was amplified in the Phase 2 report, as follows: “DOE should establish a program

to address all end-to-end safety aspects” (NRC, 2008, p. 12). That recommendation was partially accepted in the Partnership’s responses to the recommendations in the Phase 2 report, although the committee has yet to see any results from that effort.

The Partnership was originally focused primarily on hydrogen/fuel cell vehicles. Now that the program is putting significant emphasis on other propulsion systems and fuels, the safety program should be expanded to cover all of them. The fuel pathways should be examined from source to wheels, and the vehicles studied should include HEVs, PHEVs, biofueled vehicles, and BEVs as well as those powered by hydrogen/fuel cells. The analysis should use a “Life Cycle Assessment” methodology, which is even broader than “cradle-to-grave,” as it includes the recycling or reuse of all elements at the end of life (see the section “Environmental Impacts of Alternative Pathways,” below, as well as the committee’s interim letter report, included as Appendix B in this report).

The six alternate fuels have been defined by the DOE as hydrogen, electricity, natural gas, ethanol, propane (or liquefied petroleum gas [LPG]), and biodiesel. (The committee suggests that the Partnership also add other potential biofuels in addition to ethanol.) The National Renewable Energy Laboratory (NREL) has recently completed a codes and standards “gaps analysis” for each of these fuels, and NREL finds that work needs to be done on many of them, with electricity and hydrogen needing the most attention (Blake et al., 2010).

The demonstrable safety of battery and high-voltage electrical systems is plainly essential for the commercial success of the HEVs, PHEVs, and BEVs.6

At the committee’s August 2009 meeting, the hydrogen production and delivery technical teams said that they still needed more data on hydrogen behavior. The Partnership should ensure that their needs are documented and addressed. The NREL Wind2H2 demonstration project has also asked for help in identifying and streamlining the codes and standards that would be necessary to deploy all of the components and systems needed for a wind-to-hydrogen system or a wind-to-hydrogen storage-to-electricity power plant. These components and control protocols would include the wind turbines, power electronics, electrolyzers, hydrogen stationary storage, and stationary fuel cells.

2.

High-Pressure Hydrogen Storage Safety Issues

For the foreseeable future, compressed hydrogen is the most likely onboard hydrogen storage method for fuel cell vehicles. The need for acceptable vehicle range and trunk space dictates that the pressure vessel accommodate 70 MPa (about 10,000 psi) of gas safely. Containment of the high pressures will likely require pressure vessels to be made of carbon-fiber composite having an interior

|

6 |

For further discussion of battery safety, see in Chapter 3 the section “Electrochemical Energy Storage.” |

liner made either from a metal (e.g., aluminum) or a polymer (e.g., high-density polyethylene). There are strong motivations for reducing the cost and weight of pressure vessels, and it has recently been proposed to reduce the burst pressure ratio of Type 3 and 4 carbon-fiber tanks from 2.25 (beginning of life) to 1.8 (end of simulated life). Also, compressed-gas tanks are susceptible to fire damage and need to be protected from fire by pressure-relief devices. A new generation of such devices can protect the entire length of the tank from localized fire.

Hydrogen can enter a variety of metals and alloys as H+ ions and can seriously degrade the structural properties of the metal. High-strength steels and steel welds are particularly susceptible, aluminum much less so. Hydrogen can also diffuse into polymers as H2 molecules and collect in voids forming blisters and cracks.

Natural gas vehicles use high-pressure gas storage, and many of the hydrogen components and systems are similar. Gathering and analyzing this experience can help ensure that hydrogen vehicles are safer.

3.

Emergency Response Issues and Procedures

There are both crash and fire safety issues related to liquid-fueled, electric, and hydrogen vehicles. Some preliminary emergency response guidelines have been developed by the automobile manufacturers (original equipment manufacturers, or OEMs), the California Fuel Cell Partnership, and the DOE’s HAMMER (Hazardous Materials Management and Emergency Response) facility. In general, these were developed using commonsense judgments and, of course, have differences. It would be useful to do research and risk analyses to contribute to a better understanding of the most effective strategies. One issue is how to identify the type of vehicle and energy storage method (compressed, liquid, or hydride for hydrogen; or liquid fuel for internal combustion engines [ICEs]; or high-voltage batteries for many vehicle types). The fire-fighting techniques for each of these can be very different. What kind of suppressant should be used (water, foam, CO2, special hydride powders, etc.)? A range of vehicles should be considered, including passenger vehicles, medium- and heavy-duty vehicles, and both liquid and gaseous hydrogen delivery trailers. This work should be done in conjunction with the emergency response community and with one or more universities that have fire technology programs. Field experiments should be conducted.

4.

Lack of Visibility of Department of Transportation Efforts

The DOT parts of the safety program are not visible to the committee. Both the NHTSA and PHMSA have significant roles. The Phase 1 report included a recommendation for getting NHTSA more involved (NRC, 2005). In the Phase 2 report, the committee recommended that “DOT should develop a long-range, comprehensive hydrogen safety plan” and that the DOT milestones should be integrated into the codes and standards technical team roadmap to 2015 (NRC,

2008, p. 12). The committee encourages more visibility of the DOT in the R&D that is being conducted and in the various national and international rule-making efforts.

Appropriate Federal Role

Addressing and ensuring safety is an essential federal role. Most of the safety program would not happen without government funding, and all of the work is appropriate.

Recommendations

Recommendation 2-1. The Partnership should establish a program to address all end-to-end safety aspects in addition to the existing codes and standards work. This work should be based on the pathways work and should include production, distribution, dispensing, and the vehicles. It should apply to all six alternative fuels and their associated vehicle types, including the use of high-voltage electricity on many of these vehicles.

Recommendation 2-2. The Partnership should generate and act on a failure modes and effects analysis of the full pressure vessel assembly, which includes the attached components and the human interface at the pump. Accelerated laboratory tests need to be run to identify failure/degradation modes of the pressure vessel and the mechanisms leading to failure. A nondestructive test program needs to be developed to assess pressure vessel integrity, which should serve both as a tool for quality control and as a means of checking for damage in service. The work on the analysis of worldwide natural gas and hydrogen incidents should continue. An R&D program should be established to develop a new generation of pressure-relief devices that can protect the storage tank from localized fire.

Recommendation 2-3. The hydrogen compatibility (including embrittlement) program should be continued. The Partnership should have experts in hydrogen embrittlement review the operating conditions and materials in the high-pressure delivery and refueling stations for potential problem areas, including welds and nonmetallic materials.

Recommendation 2-4. The Partnership should establish an emergency response R&D program with the involvement of emergency responders and research organizations to do fundamental work on the response to incidents involving alternative fuels. High-voltage batteries and electrical systems should also be included.

Recommendation 2-5. The Partnership should fully integrate the DOT safety efforts into the safety and the codes and standards aspects of the FreedomCAR

and Fuel Partnership. All relevant parts of the DOT should be included: those involving passenger vehicles, trucks, the hydrogen bus program, pipelines and hazardous materials, fuel delivery trailers, and others. Alternative fuels should be included. The DOE and the Partnership’s Executive Steering Group should consider adding a high-level DOT representative to the ESG.

BALANCE BETWEEN SHORT-TERM AND LONG-TERM ACTIVITIES

In the Phase 1 and Phase 2 reviews (NRC, 2005, 2008), the committee noted that the distribution of funding as well as overall Partnership efforts between short-term and long-term activities seemed to appropriately favor the long-term projects. Indeed, most project efforts seemed to be devoted directly or indirectly to research leading to technologies for achieving a hydrogen production and delivery infrastructure, effective vehicle onboard hydrogen storage, and vehicle fuel cells that could be mass-manufactured at acceptable costs. This type of distribution seemed appropriate to the committee, since the primary justification for government involvement was considered to be the long-term, high-risk, high-payoff type of R&D that probably would not be done without government participation.

Between Phases 2 and 3, major changes took place in the economic and political forces that help shape and direct such issues. The combination of the near collapse of automobile manufacturing in the United States, the economic problems at least partially associated with trade imbalance including the enormous dollar value of imported petroleum, and the growing national and international concerns with greenhouse gases dramatically changed the picture. Whether or not it proves to be altogether true, the perception was, and is, that there are alternative routes for addressing these problems and that the pursuit of fuel cell vehicles, utilizing hydrogen fuel, represents the longer-term option.

The committee agrees that there are other options, and it identifies three primary alternative routes to reducing U.S. petroleum consumption: (1) vehicles utilizing hydrogen fuel and fuel cell power plants, (2) vehicles with internal combustion engines using biofuels, and (3) greater electrification of the vehicles (e.g., PHEVs or BEVs), thus shifting part of the transportation energy from petroleum to grid electricity. The committee also agrees that of the three, the hydrogen and fuel cells option is expected to be the longer-term option. Even so, the other options also have major issues to be resolved. For example, to make PHEVs, and especially BEVs, practical and affordable requires better battery technologies and lower costs than are currently available. The same is true for biofuels, for which much-improved processes must be developed and abundant renewable feedstocks identified in order to avoid fuels competing with foods. These issues and many others, and given the present circumstances, indicate a need for government-assisted R&D.

With this changed background, the committee believes that it is proper to shift a larger share of the Patnership’s efforts and funding to R&D for nearer-term

technologies. However, the committee also believes that R&D for the longer-term technologies, especially hydrogen and fuel cells, should not be abandoned but should also be continued. Especially with the technical uncertainties associated with any of the technologies being pursued and the unknowns facing the vehicle markets, it is extremely important to have a reasonably balanced portfolio of both short-term and long-term options. The present projected distribution of funds (see Chapter 5) accomplishes both increased efforts for nearer-term technologies and the continuation of an acceptable level of efforts for the longer-term technologies, and therefore the committee believes that this distribution is generally reasonably balanced and appropriate. However, there are technology areas (see Chapters 3 and 4) in which the committee recommends that some increased efforts should be considered.

BATTERY ELECTRIC AND PLUG-IN HYBRID ELECTRIC VEHICLES AND THE U.S. ELECTRIC GRID

In view of the recent formation of the grid interaction technical team and the recent policy and commercial emphasis on PHEVs and BEVs, the committee reviewed the following: (1) the ability of the electric grid to support the entry of the PHEV and BEV and the implications for greenhouse gas reduction, (2) the interface between “smart grid” technologies that manage energy use at the consumers’ premises and on-vehicle recharging and energy management systems, and (3) the reuse of spent batteries from PHEVs and BEVs for U.S. electric grid load management, including the balancing of loads from grid-interactive, renewable energy sources.

Electric Grid: Adequacy and Consequences

Numerous automotive OEMs have scheduled plug-in vehicles, either PHEVs or BEVs, for market entry over the next several years.7 Nevertheless, the impact of these vehicles on the electric grid is not likely to be immediate in the absence of strong market-forcing policies by the federal government. The National Academies’ America’s Energy Future study estimates that the following deployment rates are plausible (NAS/NAE/NRC, 2009):

-

PHEVs could account for 1 to 3 percent of the new-vehicle market by 2020, and 7 to 15 percent by 2035;

-

BEVs could account for 0 to 2 percent of the new-vehicle market by 2020 and 3 to 10 percent by 2035.8

To be sure, more aggressive penetration rates can be described, but the committee has not assumed that these will occur. The bottom line is that in either case, a shift to being a significant percentage of new-vehicle sales involves major transitions that would take decades.

Based on the penetration rates indicated above, the aggregate U.S. electric infrastructure seems quite capable of accommodating the market penetration of BEVs or PHEVs. This is because the aggregate demand that such vehicles could place on the electric infrastructure is small relative to the generating capacity of that infrastructure. For example, 1 million PHEVs charging an average of 3 kWh9 every day for a year would require only about 1 million megawatt-hours (MWh). In contrast, the national electric infrastructure generated 4,157 million net megawatt-hours in 2007 (EIA, 2009). Thus, an analysis by the Pacific Northwest National Laboratory estimated that a PHEV fleet equal in size to 84 percent of all cars and light trucks on the road in 2001 could be charged during off-peak times without building new electricity generation capacity (PNNL, 2007).

However, the aggregate data provide an incomplete guide to policy. First, local grid circuits might become overloaded if the responsible utility fails to anticipate the new demands and/or if the local rate commission fails to provide adequate cost recovery. Furthermore, electric utilities have successfully dealt with the increased loads needed for air-conditioning systems even though these load the grid during times of peak demand. But such increased load during times of peak demand could occur for any new electric load and is not a unique characteristic of BEV/PHEV deployment. More important for policy purposes is the tension between (1) ubiquitous charging opportunities, which would accelerate BEV/PHEV market penetration by relieving consumers of the “range anxiety” widely noted to inhibit electric vehicle (BEV) purchases; and (2) the environmental and cost consequences of recharging vehicles at any time convenient to the driver.

A recent NRC study examined these consequences, and the committee has drawn extensively on that analysis (NRC, 2009): Transitions to Alternative Transportation Technologies—Plug-in Hybrid Electric Vehicles examined market penetration rates for PHEVs far exceeding those used in the America’s Energy Future study cited above (NAS/NAE/NRC, 2009). Even under these circumstances, the NRC analysis agreed with previous studies that the grid capacity is likely to remain adequate for the foreseeable future as long as vehicle charging is during off-peak times. But charging during peak hours raises issues of cost and grid reliability, while charging at any time raises questions of greenhouse gas emissions. The Institute of Electrical and Electronics Engineers (IEEE) P1809 standards committee is working on standards for electric grid-to-vehicle charging.

Cost and Grid Reliability

Recent analyses by the North American Electric Reliability Corporation (NERC) raised concerns about the reliability of the electric power system, especially during peak hours when projected increases in demand over the 10-year NERC planning horizon exceed currently planned capacity additions (NERC, 2008). Charging PHEVs or BEVs during peak hours, though desirable from a consumer perspective, could add to the prospective shortfall in peak capacity. For example, a study by Southern California Edison concluded that PHEVs could account for as much as 11 percent of its system load by 2020, which could increase peak loads by several thousand megawatts if PHEV charging is not properly managed (NRC, 2009).

Greenhouse Gas Implications

More than 70 percent of the net electricity generation by the U.S. power sector derives from fossil fuels, and hence causes GHG emissions. Assuming that these emissions continue indefinitely, the NRC (2009) analysis showed that the PHEV could still offer modest advantages over a highly efficient HEV beginning around 2035. The PHEV shows a marked advantage over a reference case, conventional ICE vehicles with modest efficiency improvements (NRC, 2009). For a BEV, the corresponding advantage in CO2 reduction would be greater.10

Of course, reducing the carbon footprint of the electric grid would increase this advantage even further. For example, a joint analysis by the Electric Power Research Institute (EPRI) and the Natural Resources Defense Council (NRDC) explored the relationship between the grid and the PHEV using nine modeling scenarios for reduced CO2 emissions from U.S. electric power generation (EPRI/NRDC, 2007). EPRI and NRDC concluded that all nine scenarios showed significant GHG reductions attributable to PHEV fleet penetration. According to their models, cumulative GHG savings from 2010 to 2050 could range from 3.4 to 10.3 billion metric tons (MT) of CO2. In contrast, current CO2 emissions from gasoline used in transportation are currently about 1.2 billion MT per year (NRC, 2009). An NRC committee, however, cautioned that the climate benefits of PHEVs are “small unless the grid is decarbonized with renewable energy, nuclear plants or fossil fuel fired plants equipped with carbon capture and storage technologies” (NRC, 2009, p. 5).

Vehicle-Grid Interface

A variety of new companies is entering the local grid market to supply energy management technologies that could influence the recharging and use of BEVs and PHEVs.

Smart Grid

In February 2009, Google announced its entry into the smart-microgrid market with a Web application that displays in real time the home energy consumption of each appliance—and vehicle battery being charged. The software uses “smart” meters that can communicate home energy consumption back to utilities every few minutes. In recent months, Microsoft, Verizon, and AT&T have made similar announcements.

Widely accepted, open-architecture standards for information exchange between vehicles and the electric grid, especially to local smart grids, are essential for the deployment of all plug-in vehicles, whether PHEVs or BEVs. The open-architecture nature of these standards could allow a wide range of information and energy management system developers to enter the market quickly and efficiently. In addition, open-architecture standards could connect vehicle charging with market opportunities for renewable energy, perhaps as a distributed resource. Much progress has been made in developing these standards to serve a variety of vehicle-grid communication purposes. IEEE Draft Standard P1901 for “Broadband over Power Line Networks: Medium Access Control and Physical Layer Specifications” was released for sale to the public at the beginning of 2010 (IEEE, 2010).

Battery Charging and Discharging

Charging parameters for PHEVs and BEVs are dependent on the charge power, charging time, and the size and type of the battery. Charging time varies depending on the distance traveled and on the charger type available. The most common charger available in homes is the Level 1, 120 V AC (volts alternating current), 15 A (amps) (12 A usable) or 20 A (16 A usable). Thus a completely depleted 40-mile PHEV would be charged by this charger in 5 to 8 hours. A Level 2 power outlet of 240 V AC and 40 A circuits would charge the same vehicle in about 1 hour. Level 3, or “fast charging” stations that use 480 V AC and up to 100 kW power output are being considered for commercial or public application; these would charge this vehicle in significantly less time. Lithium-ion (Li-ion) batteries being considered for PHEV and BEV applications can easily be charged with Level 1 and 2 chargers but would require special attention, particularly thermal management, during Level 3 (fast charging). However, the general availability of fast chargers would remove the anxiety of running out of energy during longer drives for BEV customers.

The reuse of batteries from other sources to replace failed battery modules in high-voltage strings (of batteries) has been evaluated many times in past. For example, an Electricity Advisory Committee (EAC) report issued in December 2008 discusses the use of energy stored in hybrid electric vehicle batteries to manage the grid (EAC, 2008). In Section 4.2, Phase 3, EAC (2008, p. 21) states: “Control of the bidirectional electric flow could include payments to owners for use of their automobile batteries for load leveling or regulation and for spinning reserve (the cashback hybrid incentive).” Although BEV/PHEV battery charging may have some benefits in electrical grid management, the highest priority must be given to maintaining the safety and reliability of the battery, the vehicle, and the occupants of the home or other facility where the battery is being charged. These considerations require that battery-charging decisions be reviewed and accepted on the basis of battery data continually taken and stored onboard the vehicle by the intelligent battery charger. This is, of course, no different from charging a portable computer that has an intelligent battery charger, except that each vehicle battery will be larger, more powerful, and more expensive than a small personal computer battery. It is thus important to understand that the use of vehicle battery charging to optimize utility grid loads must be limited by these considerations. More-detailed models of grid use that include specific battery-charging requirements based on external factors such as climate and vehicle usage may be required for an understanding of the full impact on the electric utility grid as the electric vehicle market increases.

The discharging of BEV/PHEV batteries for grid management while the batteries are still on the vehicles also raises issues. Battery performance and life are functions of the number and depth of discharges. Using an expensive battery developed for vehicle propulsion for peak shaving of the utility grid would cause much shorter battery life as well as additional maintenance problems in the vehicle. The effect on battery life and its replacement costs should be analyzed and compared with other methods of utility peak shaving, including large battery systems specifically designed for this purpose.

Other Grid Interface Issues

The expense of installing recharging circuits at the premises of customers who do not have them (townhouse or apartment dwellers, for example) or in public places (theaters or shopping malls, for example) could raise a cost barrier in some cases (NRC, 2009). However, commercial markets for these services are well established, and the value that precompetitive research might add is unclear.

Reuse of Spent Vehicle Batteries

The storage batteries used in PHEVs and BEVs are considered worn out when they are no longer able to deliver at least 80 percent of their rated capacity

under the conditions of use in a specific application. Examples include use in telecommunications standby power installations, uninterruptible power supply (UPS), and utility safety systems.

Battery manufacturers discourage and generally fail to provide warranties in these cases, because resulting imbalances in battery wear across a string often shorten the life of other batteries and hasten string failure. The reuse of PHEV and BEV batteries will make sense only if the new application can make use of battery capacity at rates where significantly more than 80 percent of the battery capacity is still available.

To ensure consumer safety, batteries should be reused only under strict regulations that prohibit their reuse by vehicle customers in unregulated environments. The reuse of spent storage batteries from PHEVs and BEVs will require the development of facilities with trained personnel who test and match the performance of the batteries using appropriate equipment and standard tests and protocols. Creating such a capability will require significant cooperation between battery manufacturers and users for the development of appropriate standards that are based on the state of health of PHEV and BEV batteries. New knowledge must be also acquired regarding battery failure modes as a function of environmental factors, vehicle design, and use modes.

The reuse of PHEV and BEV batteries will thus require significant initial labor and infrastructure expenditures in cooperative efforts with battery suppliers. If this effort is successful, ongoing costs of battery testing and redeployment may still exceed the value of the reused batteries. Past experience with battery reuse provides no guarantee of success in developing a viable reuse program or warranty support from battery vendors. The net effect of battery reuse would be small and depends on many factors that are not known at this time. The first phase of this program should therefore be a detailed analysis of the costs and benefits of this activity versus the costs and benefits of developing a battery-recycling protocol and system. There are recycling plans for consumer Li-ion batteries, but the quantity of batteries and materials to be recycled would be significantly larger for automotive batteries (even at 2 percent penetration). If the first phase of the study shows that recycling may be a viable option for battery reuse, it should be evaluated further.

Recommendations

Recommendation 2-6. The grid interaction technical team should work with state utility regulatory authorities, perhaps through the National Association of Regulatory Utility Commissioners, to ensure that the incentives provided by state regulations mesh well with the national interest in vehicle deployment, reduced oil consumption, and lower greenhouse gas emissions.

Recommendation 2-7. The grid interaction technical team should continue to encourage and, where appropriate, facilitate the ongoing development of open-

architecture standards for smart-vehicle/smart-grid interconnections currently being developed by the Institute of Electrical and Electronics Engineers and the Society of Automotive Engineers. In doing so, the technical team should encourage participation from the purveyors of smart-grid systems and battery suppliers as well as from the electric utility industry.

Recommendation 2-8. Standards for the reuse of electric vehicle batteries should be developed under leadership of the grid interaction technical team, and training materials for the use of these standards should be developed in parallel.

PERSISTING TRENDS IN AUTOMOTIVE INNOVATION: IMPLICATIONS FOR THE FREEDOMCAR AND FUEL PARTNERSHIP

From a strategic perspective, the public issues that motivate the FreedomCAR and Fuel Partnership, chiefly energy and the environment, should be viewed within the context of several persisting trends that will influence the pace and direction of innovation in automobiles and fuels. Some of the most relevant of these are also the most familiar, and thus their implications for the Partnership can easily be overlooked. Here, two of the most relevant persisting trends are briefly analyzed.

Consumer Preferences for Vehicle Cost, Performance, and Safety

Surveys suggest that the total cost of ownership will remain the single most important decision criterion in auto purchases (see, e.g., Oliver Wyman, 2005). In contrast, fuel economy will rise and fall as a decision criterion for consumer purchases as oil prices rise and fall. This implies that vehicles that offer superior fuel economy must not do so at the expense of other attributes desired by the consumer, such as safety and affordability.

Research and innovation are essential, both for fuel economy and for lowering the costs and improving the safety performance of the fuel-saving vehicles. Notwithstanding, economic pressures remain likely to constrain the level of private R&D activities, affecting (1) the amount that can be spent, (2) the strategic purpose of the research efforts, and (3) whether the available R&D funds are spent internally or outsourced. At the same time, manufacturing innovation can improve the ability of automotive OEMs and suppliers to respond better to volatile consumer preferences and to lower vehicle cost. Hence, manufacturing innovation and an efficient innovation process for gaining access to advanced technology, both for vehicles and for the manufacturing processes by which they are made, are becoming essential for competitive success. Vehicle technology is addressed first.

Sources of Vehicle Technology

Increasingly, the sources of advanced technology will arise from outside the traditional automotive OEMs and their top-tier suppliers. Currently, as much as 70 percent of the value added for a new vehicle derives from the supplier networks of the OEM (Dyer and Nobeoka, 2000). For example, microelectronic devices can contribute strongly to the vehicle attributes preferred by purchasers (especially energy-saving and emissions improvements) as well as to cost reductions in the vehicles themselves. Yet many of the most compelling of these devices and software originate from outside the automotive OEMs and suppliers, which would benefit from cost-effective access to these. Hence the management of innovation networks will be central for OEMs to access new technologies and innovative ideas.

In contrast, the auto companies will continue to be a leading source of innovation in whole-vehicle systems—for example, the power train—which will continue to evolve for improved performance and energy savings. But even in power trains, value might be gained from access to technologies originating from outside the traditional industry.

These persistent trends suggest that the FreedomCAR and Fuel Partnership should think beyond R&D and revisit its innovation strategies. Among the strategic issues to consider, the committee suggests the following in the form of recommendations.

Recommendations

Manufacturing

Recommedation 2-9. The Partnership should consider including manufacturing processes among the precompetitive R&D programs. Because its funding originates in the United States, the Partnership should emphasize the technologies and methods most capable of realizing advanced vehicle production in the United States, to the extent that this is feasible.

Standards

Recommendation 2-10. As the basic platform of the automobile becomes more modular, interface standards will be required to enable greater competition among technology alternatives. While specific interface standards have been discussed elsewhere in this report, the Partnership should also consider conducting a more general review of areas in which industry-wide standards could accelerate the pace of innovation and lower its cost.

Inclusive Innovation Architecture

Recommendation 2-11. The Partnership should seek out and implement methods to allow new, nontraditional suppliers—especially, emerging entrepreneurial companies—to participate in the innovation process. The Small Business Innovation Research (SBIR) program can become a highly productive source of innovation, and the Partnership should review its linkages with this program and strengthen them where appropriate.

ENVIRONMENTAL IMPACTS OF ALTERNATIVE PATHWAYS

As noted in both the Phase 1 and Phase 2 reports, it is important to understand and analyze the environmental implications of the full fuel cycle, from source to end use, of a hydrogen economy (NRC, 2005, 2008). Such full-fuel-cycle analyses are also important for any of the other energy source/vehicle combinations (e.g., biofuels for ICE or hybrid vehicles, electricity for PHEVs or BEVs) that are being developed that can potentially reduce the consumption of petroleum and greenhouse gas emissions from light-duty vehicles.

To motivate full-fuel-cycle analysis, note that systems-wide effects associated with various technologies potentially lead to unforeseen and important effects on the environment. One type of unforeseen effect would occur when a technology had superior performance in one phase of the supply chain (e.g., a more efficient engine) but caused changes elsewhere in the supply chain (e.g., in producing fuels for the new engine) that reduced or even canceled the benefits. To cite some examples, there is a debate about whether corn-based ethanol actually reduces fossil fuel use and carbon emissions (Farrell et al., 2006). The high energy cost for liquefying hydrogen inflicts a substantial penalty on the source-to-wheel efficiency of a fuel cell vehicle (Bossel, 2006). A second type of unforeseen effect occurs when a technology designed to mitigate a targeted environmental issue induces other types of environmental impacts. The increased cultivation of corn to produce ethanol, for example, leads to an increased use of fertilizer, which could increase the runoff of nitrogen and phosphorus, in turn widening the areal extent of the dead zone in the Gulf of Mexico (Donner and Kuchari, 2008). Some battery technologies contain toxic materials (such as lead) that, as extensive regulation mandating the collection and recycling of lead-acid batteries shows, could pose an environmental hazard unless properly managed (Lave et al., 1995). Fuel cells and batteries may rely on rare materials such as platinum, possibly inducing resource scarcity (Gordon et al., 2006). In addition, there is increased concern over the life-cycle water use of new energy technologies (Webber, 2007). The committee is not claiming that these undesirable effects will happen but that prior careful and complete analyses are needed to ensure that they do not.

The assessment and management of technology systems constitute a rapidly growing area that is being formalized with research disciplines, journals, and

professional societies. “Industrial ecology”11 is an umbrella concept involving a holistic environmental view of industrial systems, including strategies such as industrial symbiosis to maximize the reuse and recycling of resources (Graedel and Allenby, 2009). Materials flow analysis (MFA) is used in industrial ecology to characterize physical flows in industrial systems (NRC, 2004). Life cycle assessment (LCA)12 is a set of methods and tools to assess supply chain impacts of technology (Hendrickson et al., 2006). LCA is sometimes termed well-to-wheels analysis (more appropriately termed source-to-wheels, as adopted in this report) in the context of vehicle systems.13 Industrial ecology, MFA, and LCA are increasingly used in policy. For example, life cycle assessment of fuel systems has been explicitly included in national policy in the biofuels arena in the Energy Independence and Security Act of 2007 (Public Law 110-140, H.R. 6).

The FreedomCAR and Fuel Partnership has been working to address supply chain effects of technology. Notably the GREET model for source-to-wheels analysis of transport systems developed at the Argonne National Laboratory is well known, and its functionality and coverage are being expanded (ANL, 2009). The systems analysis team is undertaking useful analyses of environmental issues such as the water use and resource constraints associated with alternate fuel pathways.

To understand the impacts across the full fuel cycle of producing, distributing, and using hydrogen, the Phase 1 report recommended that the DOE, in collaboration with the Environmental Protection Agency, should systematically identify and examine the possible long-term ecological and environmental effects of the large-scale use and production of hydrogen from various energy sources. These direct and indirect effects should include effects on land, water, and the atmosphere. In its response dated April 2, 2009, to the recommendations in the Phase 2 report, the DOE concurred with this recommendation (DOE, 2009, p. 23); its Office of Science (SC) is developing a fundamental understanding of the processes involved in the biogeochemical cycling of atmospheric hydrogen. This knowledge will make it possible to perform a comprehensive assessment of the environmental impact of the release of hydrogen to the atmosphere from large-scale use and production. In fact, the DOE supported two studies on the environmental impacts of a hydrogen economy, with a primary focus on atmospheric impacts; the results of the studies

were presented to the committee at its meeting on December 10, 2009.14 Some of the conclusions of these studies are as follows:

-

The adoption of a hydrogen-fuel-cell-based transportation sector would dramatically improve tropospheric and regional air quality. Although there are some concerns about a decrease in stratospheric ozone, impacts would be greatly reduced in most cases.

-

Adaptive soil microbial uptake of hydrogen could provide a powerful negative feedback to future increased hydrogen concentrations and mitigate any adverse impacts on stratospheric ozone.

-

Atmospheric hydrogen effects on structures and embrittlement are not likely to be important.

-

If hydrogen is produced with carbon-free processes, there will be substantial reductions in future atmospheric CO2 concentrations, as well as emissions of importance such as oxides of nitrogen and nonmethane organic gases.

While the work on systems effects of technology under the auspices of the DOE is clearly valuable, the committee has several observations on how efforts addressing environmental impacts of fuel pathways could be improved. First, it is not clear that previous work done by outside groups (e.g., associated with professional societies for industrial ecology and life cycle assessments) is being fully utilized. As mentioned above, there is a significant and growing literature in this field, and it would serve the DOE well to base its efforts in the context of this other work.

Secondly, the committee observed a need for stronger integration between systems analyses and the technical teams. Systems analysis can inform technical teams about targets and choices of what technologies are developed, and, conversely, technical teams can provide information to systems analysis on what technologies need to be evaluated. This feedback loop could be strengthened. For example, the GREET model indicates that the energy intensity of hydrogen liquefaction severely penalizes the source-to-wheels efficiency of fuel cell vehicles powered through this route (Wang, 2002). Energy efficiency, however, is not among the explicit targets for liquefaction technology set for the hydrogen production and the hydrogen delivery technical team (DOE, 2009).15

Recommendation 2-12. The Partnership should undertake a review of the state of methods and case studies that have been carried out on environmental impacts related to the technologies under development. This review would answer some remaining open questions and help direct systems studies so as to maximize their efforts to characterize the environmental impacts of different fuel pathways.

Recommendation 2-13. The Partnership should strengthen the links between the systems analysis teams and the technical teams. In particular, technological goals and targets should include consideration of priorities established in systems analysis, and systems analysis should be conducted on emerging technologies identified by the technical teams.

Recommendation 2-14. The Partnership should consider incorporating the broader scope of a “cradle-to-grave” analysis rather than a “source (well)-to-wheels” approach in program planning from production to recycling in order to better consider total energy consumption, total emissions, and the total environmental impact of various energy/vehicle pathways and technologies.

REFERENCES

ANL (Argonne National Laboratory). 2009. Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Model. Argonne, Illinois. Available on the Web at <http://www.transportation.anl.gov/modeling_simulation/GREET/>.

Blake, C., W. Buttner, and C. Rivkin. 2010. Vehicle Codes and Standards: Overview and Gap Analysis. NREL/TP-560-47336. February. Available on the Web at <www.nrel.gov/publications>.

Bossel, U. 2006. Does a hydrogen economy make sense? Proceedings of the IEEE 94(10):1826-1837.

DOE (U.S. Department of Energy). 2009. Actions and Evidence Report, April 2. Submitted to the National Research Council (NRC) Committee on Review of the FreedomCAR and Fuel Research Program, Phase 3, documenting responses by DOE to recommendations in the Phase 2 report [see NRC, 2008].

Donner, S.D., and C.J. Kuchari. 2008. Corn-based ethanol production compromises goal of reducing nitrogen export by the Mississippi River. Proceedings of the National Academy of Sciences 105(11):4513-4518.

Dyer, J.H., and K. Nobeoka. 2000. Creating and managing a high-performance knowledge sharing network: The Toyota case. Strategic Management Journal, Vol. 21: pp. 346-367.

EAC (Electricity Advisory Committee). 2008. Bottling Electricity: Storage as a Strategic Tool for Managing Variability and Capacity in the Modern Grid. December. Available on the Web at <www.oe.energy.gov/eac.htm>.

EIA (Energy Information Administration). 2009. Electric Power Industry 2007: Year in Review. January 21. Washington, D.C.

EPRI/NRDC (Electric Power Research Institute/Natural Resources Defense Council). 2007. Environmental Assessment of Plug-in Hybrid Electric Vehicles. Volume 1: Nationwide Greenhouse Gas Emissions. July. Available on the Web at <http://my.epri.com/portal/server.pt?open=514&objID=223132&mode=2>.

Farrell, A.E., R.J. Plevin, B.T. Turner, A.D. Jones, M. O’Hare, and D.M. Kammen. 2006. Ethanol can contribute to energy and environmental goals. Science 311:506-508.

Gordon, R.B., M. Bertram, and T.E. Graedel. 2006. Metal stocks and sustainability. Proceedings of the National Academy of Sciences 103(5):1209-1214.

Graedel, T.E., and B.R. Allenby. 2009. Industrial Ecology and Sustainable Engineering. Prentice Hall.

Hendrickson, C.T., L. Lave, and H.S. Matthews. 2006. Environmental Life Cycle Assessment of Goods and Services: An Input-Output Approach. Washington, D.C.: Resources for the Future Press.

IEEE (Institute of Electrical and Electronics Engineers). 2010. Draft Standard P1901 for “Broadband over Power Line Networks: Medium Access Control and Physical Layer Specifications.” Available on the Web at <http://ieeestandards.org/ct.html?rtr=on&s=8nv.1asmo.2vi2.89py.8sly.jenu.coes>.

Lave, L.B., C.T. Hendrickson, and F. McMichael. 1995. Environmental implications of electric cars. Science 268(5213):993-995.

NAS/NAE/NRC (National Academy of Sciences/National Academy of Engineering/National Research Council). 2009. America’s Energy Future: Technology and Transformation. Washington, D.C.: The National Academies Press.

NERC (North American Electric Reliability Corporation). 2008. Long-Term Reliability Assessment: 2008-2017. October. Available on the Web at <http://www.nerc.com/files/LTRA2008v1_2.pdf>.

NRC (National Research Council). 2004. Materials Count: The Case for Material Flows Analysis. Washington, D.C.: The National Academies Press.

NRC. 2005. Review of the Research Program of the FreedomCAR and Fuel Partnership, First Report. Washington, D.C.: The National Academies Press.

NRC. 2008. Review of the Research Program of the FreedomCAR and Fuel Partnership, Second Report. Washington, D.C.: The National Academies Press.

NRC. 2009. Transitions to Alternative Transportation Technologies—Plug-in Hybrid Electric Vehicles. Washington, D.C.: The National Academies Press.

Oliver Wyman (formerly Mercer Management Consulting). 2005. Car Innovation 2015. Available on the Web at <http://www.car-innovation.com/study-content.html>.

PNNL (Pacific Northwest National Laboratory). 2007. Impacts Assessment of Plug-in Hybrid Vehicles on Electric Utilities and Regional U.S. Power Grids. Part 1: Technical Analysis. Available on the Web at <http://www.ferc.gov/about/com-mem/wellinghoff/5-24-07-technical-analy-wellinghoff.pdf>.

Wang, M. 2002. “Fuel Choices for Fuel-Cell Vehicles: Well-to-Wheels Energy and Emission Impacts.” 2002 Fuel Cell Seminar, Palm Springs, California, November 18-21.

Webber, M. 2007. The water intensity of the transitional hydrogen economy. Environmental Research Letters 2:1-7.