This report responds to a request by the Assistant Secretary of the Army (Acquisition, Logistics, and Technology) to the National Research Council (NRC) to examine the current theoretical and experimental understanding of the key issues surrounding protection materials, identify the major challenges and technical gaps for developing the future generation of lightweight protection materials, and recommend a path forward for their development. While underscoring the paramount need for lightweight materials, the charge included requirements to consider multiscale shockwave energy transfer mechanisms and experimental approaches for their characterization over short timescales, as well as multiscale modeling techniques to predict mechanisms for dissipating energy.

Accordingly, two NRC boards—the National Materials Advisory Board1 and the Board on Army Science and Technology—established the Committee on Opportunities in Protection Materials Science and Technology for Future Army Applications to investigate opportunities in protection materials science and technology for the Army. What follows is the evaluation developed by that committee.

The report considers exemplary threats and design philosophy for the three key applications of armor systems: (1) personnel protection, including body armor and helmets, (2) vehicle armor, and (3) transparent armor. For each of these applications, specific constraints drive the armor design and thus the ultimate choice of protection materials.

In developing its recommendations, the committee assessed current knowledge and gaps in that knowledge as it sought to prioritize the various types of lightweight protective materials and armor systems for future research. Key areas and research challenges for protection materials discussed in these pages include the following:

- Penetration mechanisms in metals and alloys, ceramics and glasses, and polymeric materials (Chapter 3).

- Failure mechanisms in cellular-sandwich materials due to blast (Chapter 3).

- Current capabilities for modeling and simulation of protection materials and material systems on scales ranging from the atomic to the macroscopic, including a discussion of state-of-the-art modeling and simulation tools (Chapter 4).

- The state of the art in experimental methods, including defining the length and timescales of interest, evaluating material behavior at the relevant high-strain rates, and investigating shock physics, dynamic failure processes, and impact phenomenology (Chapter 4).

- Ceramic armor materials, including crystalline and amorphous ceramics, ceramic powders, processing and fabrication techniques, and transparent crystalline ceramics (Chapter 5).

- Fibers, including the effect of fiber diameter on strength in high-performance fibers, microstructural advances to approach the theoretical maximum tensile strength and modulus, and the need for mechanical tests at high strain rates and pressures (Chapter 5).

- Ballistic fabrics, including ballistic testing, failure mechanisms, and interactions among fibers and among yarns during loading (Chapter 5).

- Metals and metal-matrix composites and their desirable attributes, especially those of low-density metals such as magnesium alloys (Chapter 5).

- Fabrication and assembly of armor systems, with an emphasis on adhesives for armor and transparent armor, including (1) general considerations for selecting an adhesive interlayer and (2) testing, simulation, and modeling of adhesives and armor systems (Chapter 5).

______________

1In January 2011 the National Materials Advisory Board (NMAB) and the Board on Manuacturing and Engineering Design combined to form the National Materials and Manufacturing Board. The move underscored the importance of materials science to innovations in engineering and manufacturing.

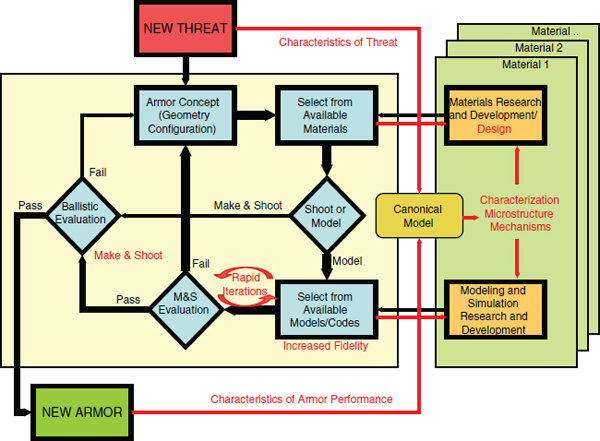

FIGURE S-1 New paradigm for armor development. The new design path for armor provides enhanced and closer coupling of the materials research and development community and the modeling and simulation community, resulting in significantly reduced time for development of new armor. This new approach connects the armor design process to the materials research and development community through canonical models to deal with the restricted information problem. The elements of armor system design are not themselves new, but the emphasis shifts from design-make-shoot-redesign to rapid simulation iterations, and from designing with off-the-shelf materials to designing that exploits materials for their protective properties. The feedback loop between armor system design and material design contrasts with current practice, in which a one-way flow puts new materials on the shelf to be tried in the make-shoot-look process.

Findings and recommendations pertaining to these areas and research challenges appear in Chapters 3 through 5. The single overarching recommendation is repeated here in the summary, along with the four key recommendations in the main text.

OVERARCHING RECOMMENDATION

The conclusion of this study is that the ability to design and optimize protection material systems can be accelerated and made more cost effective by operating in a new paradigm of lightweight protection material development (Figure S-1). In this new paradigm, the current armor system design practice, which relies heavily on a design-make-shoot iterative process, is replaced by rapid iterations of modeling and simulation, with ballistic evaluation used selectively to verify satisfactory designs. Strong coupling with the materials research and development community is accomplished through canonical models that translate armor system requirements (often data with restricted access) into characterizations, microstructures, behaviors, and deformation mechanisms that an open research community can use in designing new lightweight protection materials. The principal objective of this new paradigm is to enable the design of superior protection materials and to accelerate their implementation in armor systems. This new paradigm will build upon the multidisciplinary collaboration concepts and lessons from other applications documented in the report Integrated Computational Materials Engineering.2 It can be focused on the most promising opportunities in lightweight protection materials, bringing such current products as ceramic plates and polymer fiber materials well beyond their

______________

2NRC. 2008. Integrated Computational Systems Engineering: A Transformational Discipline for Improved Competitiveness and National Security. Washington, D.C.: The National Academies Press.

present state of performance and opening the possibility for radically new armor system solutions to be explored and optimized in tens of months rather than tens of years.

Overarching Recommendation. Given the long-term importance of lightweight protection materials to the Department of Defense (DoD) mission, DoD should establish a defense initiative for protection materials by design (PMD), with associated funding lines for basic and applied research. Responsibility for this new initiative should be assigned to one of the Services, with participation by other DoD components whose missions also require advances in protection materials. The PMD initiative should include a combination of computational, experimental, and materials testing, characterization, and processing research conducted by government, industry, and academia. The program director of the initiative should be given the authority and resources to collaborate with the national laboratories and other institutions in the use of unique facilities and capabilities and to invest in DoD infrastructure where needed.

This overarching recommendation requires actions in four important elements of the PMD initiative.

RECOMMENDATIONS

Element 1—Fundamental Understanding of Mechanisms of Deformation and Failure Due to Ballistic and Blast Threats

The first element of the PMD initiative would be to develop better fundamental understanding of the mechanisms of high-rate3 material deformation and failure in various protection materials, discussed in Chapter 3. As part of the new paradigm, armor development should be considered not from the viewpoint of conventional bulk material properties but from the viewpoint of mechanisms. The deeper fundamental understanding could lead to the development of more failure-resistant material compositions, crystal structures, and microstructures and to protective materials with better performance. Moreover, by identifying the operative mechanisms and quantifying their activity, mathematical damage models can be written that may allow computational armor design. Chapter 3 discusses failure mechanisms for the several classes of materials.

Recommendation S-1/6-1. The Department of Defense should establish a program of sustained investment in basic and applied research that would facilitate a fundamental understanding of the mechanisms of deformation and failure due to ballistic and blast events. This program should be established under a director for protection materials by design, with particular emphasis on the following:

- Relating material performance to deformation and failure mechanisms. Developing models and data for choosing materials based on their ability to inhibit or avoid failure mechanisms as opposed to choosing them based on bulk properties as measured in quasi-static and dynamic tests.

- Developing superior armor materials by identifying compositions, crystalline structures, and microstructures that counteract observed failure mechanisms and by establishing processing routes to the synthesis of these materials.

- Reducing the cost of production of protection materials by improving the processes and yields and by enhancing the ability to manufacture small lots.

Element 2—Advanced Computational and Experimental Methods

The second element of the PMD initiative would be to advance and exploit the capabilities of the emerging computational and experimental methods discussed in Chapter 4. The first objective is to predict the ballistic and blast performance of candidate materials and materials systems as a prelude to the armor design process. The second objective is to define requirements that will guide the synthesis, processing, fabrication, and evaluation of protection materials. The PMD initiative would develop the next generation of

- DoD advanced protection codes that incorporate experimentally validated, high-fidelity, physics-based models of material deformation and failure, as well as the necessary high-performance computing infrastructure;

- Experimental facilities and capabilities to assess and certify the performance of new protection materials and system designs, as well as provide insight into fundamental material behaviors under relevant conditions with unprecedented simultaneous high spatial and temporal resolution; and

- Collaborative infrastructure for encouraging direct communication and improved cooperation between modelers and experimenters, through both (1) the establishment of collaborative environments and (2) requirements in proposals when the specific research topic is well served by such collaboration.

The high-priority opportunities identified in Chapter 4 will need sustained investment and program direction to advance computational and experimental capabilities. The envisioned computational capabilities must be developed in partnership with a strong experimental effort that identifies the dynamic mechanisms of material behavior. These mechanisms must be understood and modeled for the activity to be successful, the material characteristics and properties must be known for the simulations to be carried out, and the outcomes of the computational modeling must be validated.

______________

3Ballistic velocities typically range from several hundred to several thousand meters per second and can lead to strain rates of up to 105 s–1.

Recommendation S-2/6-2. The Department of Defense should establish a program of sustained investment in basic and applied research in advanced computational and experimental methods under the director of the protection materials by design (PMD) initiative, with particular emphasis on the following:

- Dynamic mechanism characterization. Identify and characterize (1) the failure mechanisms underlying damage to a material caused by projectiles from weapons and detonations and (2) the compositional and microstructural features of each constituent of the material, as well as the material’s overall structure. An enhanced experimental infrastructure will be needed to make progress in high-resolution (time and space) experiments on material deformation and failure characterization.

- Code validation and verification. Focus on multiscale, multiphysics material models, integrated simulation/experimental protocols, prediction with quantified uncertainties, and simulation-based qualification to help advance the predictive science for protection systems.

- Challenges and canonical models. Periodically propose open challenges comprising design, simulation, and experimental validation that will convincingly demonstrate the PMD. Each challenge problem must address the corresponding canonical model and must result in quantifiable improvements in performance within that framework.

Element 3—Development of New Materials and Material Systems

The third element of the PMD initiative is the development and production of new materials and material systems whose characteristics and performance can achieve the behavior validated in modeling and simulation of the new armor system. The recommendations in this element target the most promising opportunities identified in Chapter 5.

Recommendation S-3/6-3. The Department of Defense should establish a program of sustained investment in basic and applied research in advanced materials and processing, under the director of the PMD initiative program, with particular emphasis on the following:

- A sustained effort to develop a database of high-strain-rate materials for armor.Material behavior and dynamic properties must be measured and characterized over the range of strains, strain rates, and stress states in the context of penetration and blast events. Develop a comprehensive database of materials that exhibit high-strain-rate behavior and consider them as materials of interest. The PMD director should designate a custodian for this database and arrange for experimental results of the PMD program to be provided to the database and shared with the research community. The database should include ceramics, polymers, metals, glasses, and composite materials in use today and should be expanded as new materials are developed.

- —Opaque and transparent ceramics and ceramic powders. The intrinsic properties of opaque and transparent ceramics and ceramic powders are not yet fully realized in armor systems. There is need for understanding at the atomic, nano-, and micron levels of how powders and processing can be designed and manipulated to maximize the intrinsic benefits of dense ceramic armor and reduce production costs.

- —Polymeric, carbon, glass, and ceramic fibers. There is an opportunity to develop finer diameter and more ideally microstructured polymeric and carbon fibers with potentially a two- to fivefold improvement in specific tensile strength over the current state of the art. Such improvements would significantly reduce the weight of body armor.

- —Polymers. In addition to polymer fibers, thermoplastic and thermoset polymers are used as monolithic components and also serve as matrixes in various composites. Improved measurements of and models for the deformation mechanisms and failure processes are needed for thermoplastic- and thermoset-based protection materials.

- —Magnesium alloys. The very low density of magnesium provides potential for the development of very lightweight alternatives to traditional metallic materials in protection material systems. The basic understanding of strengthening mechanisms in magnesium should be advanced, especially the development of ultra-fine-grained magnesium alloys through severe plastic deformation. Magnesium-based fibers are also worthy of exploration.

- Adhesives and active brazing/soldering materials. Development of adhesives and active brazing/soldering materials and their processing methods to match the elastic impedance of current materials while minimizing the thermal stresses will improve the ballistic and blast performance of panels made of bonded armor, including transparent armor.

- Test methods. Advances are needed in test methods for determining the high strain rates (103 to 106 s–1) and dynamic failure processes of (especially) fibers, polymers, and ceramics. Results should be passed on to the designated database of materials with high-strain-rate behavior.

- Material characterization. The characterization of, composition, crystalline structure, and microstruc-

ture at appropriate length scales is a key task that will need more attention to take advantage of the improved experimental tools for quantifying initial and deformed microstructures.

- Cost reduction. Advances are needed to reduce the cost of producing protection materials by improving their processing and yield and by improving small-lot manufacturing capability.

- Processing science and intelligent manufacturing. Advances are needed in basic understanding of and ability to model the consequences of material processing for performance and other characteristics of interest. Intelligent manufacturing sensing and control capabilities are needed that can maintain low variance and produce affordable protection materials, even in relatively low volumes.

Element 4—Organizational Approach

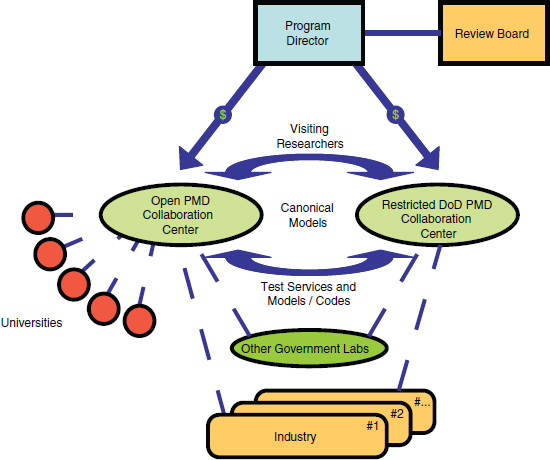

The fourth element of the PMD initiative is an organizational construct for multidisciplinary collaboration among academic researchers, government laboratories, and industry, in both restricted-access and open settings. The PMD initiative will need strong top-level leadership with insight into both the open and restricted research environments and the authority to direct funding and set PMD priorities. The program will require committed funding to ensure long-term success and should be subject to periodic external reviews to ensure that high standards of achievement are established and maintained. To meet these requirements, the committee recommends the notional DoD organizational approach depicted in Figure S-2.

Recommendation S-4/6-4. In order to make the major advances needed for the development of protection materials, the Department of Defense should appoint a PMD program director, with authority and resources to accomplish the following:

- Plan and execute the PMD initiative and coordinate PMD activities across the DoD.

- Select an existing facility to be the DoD center for PMD and fund a research director and the staff, equipment, and programs needed by the PMD initiative;

- Award a competitive contract for an open access PMD center whose mission would be to host and foster open collaboration in research and development of protection materials;

- Establish an external review board to conduct periodic reviews of programs in both centers; and

- Provide liaison with the Department of Energy, the National Institute of Standards and Technology, and other government laboratories on matters related to PMD.

The sponsor asked that the committee suggest an organizational structure for the path forward and a teaming approach for it. In considering the sponsor’s request that the study report not include restricted material, which would have precluded wide dissemination to the research and development communities, the committee recognized the broader issue of the role restricted information plays in impeding research collaborations.4Such limitations are prudent and necessary but require periodic review to ensure they are consistent with the current state of open knowledge and do not unnecessarily restrict the exchange of information with an open research community when such an exchange would be beneficial to national security.

The chapters that follow develop the rationale and conclusions that underpin the detailed recommendations in Chapter 6 and identify needed actions in the four elements of the initiative.

__________

4A detailed discussion of the effects on research of classification guidelines, security, and export control is beyond the scope of this study.