The need for rapid advances in the effectiveness and affordability of lightweight protection materials and systems is compelling and will continue for the foreseeable future. The experience with body armor and vehicle armor in Iraq and Afghanistan has shown that the weight penalty of today’s materials exacts a significant toll on U.S. forces, both in human terms and in increased costs for equipment, maintenance, and fuel. Escalating threats have greatly accentuated the need for continued rapid development of lightweight armor.

The ideal situation is to have new materials available to meet these challenges. However, while new materials are the subject of research efforts, their introduction into military systems is very slow. As shown in Chapter 1 (Figure 1-3), the advances indicated by the areal density plot of lightweight protection materials have slowed in recent years. The inability to rapidly transition materials with the properties and behavior needed for armor systems is due not to a lack of excellent materials research, but rather to the approach by which protection materials research is accomplished.

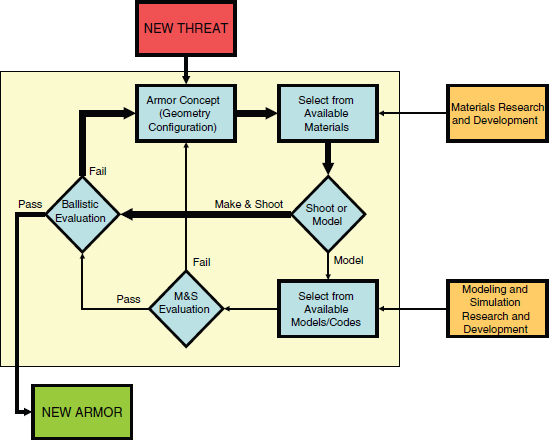

As described in Chapter 2 (see also Figure 6-1), armor

FIGURE 6-1 Current paradigm for armor design. As mentioned in Chapter 2, a shoot-and-look approach is much more prevalent than a modeling approach.

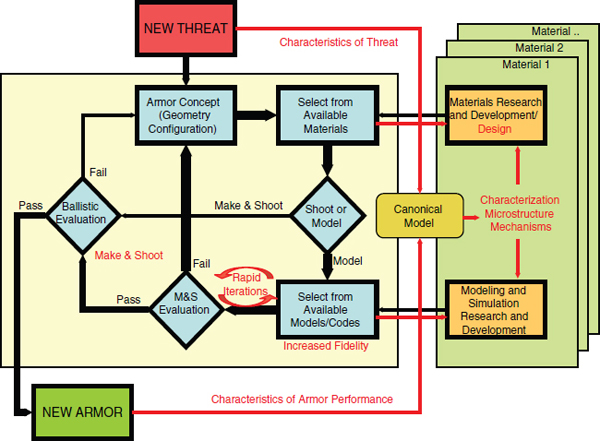

FIGURE 6-2 New paradigm for armor development. The new design path for armor provides enhanced and closer coupling of the materials research and development community and the modeling and simulation community, resulting in significantly reduced time for development of new armor. This path connects the armor design process to the materials research and development community through canonical models to deal with the restricted information problem. The elements of armor system design are not themselves new, but the emphasis shifts from design-make-shoot-redesign to rapid simulation iterations, and from designing with off-the-shelf-materials to designing that explores materials for their protective properties. The feedback loop between armor system design and material design contrasts with current practice, in which a one-way flow puts new materials on the shelf to be tried in the make-shoot-look process.

systems in operational use today are the product of years of heuristic-based advances. Development of the protection materials used in these systems is coupled only loosely to armor system design, with the coupling taking the form of inferred desired properties. The current paradigm of material and system development can be characterized as a design-make-test-redesign-repeat … iterative loop. The time and expense involved in such an approach limit the number of optimization iterations and slow the advance of new material systems that could provide the needed protection with reduced areal density.

The current paradigm and the research programs and organizations that support it are not sufficient to accelerate advances in lightweight protection materials. New research initiatives, organizational structures, and implementation approaches will be needed to increase the rate of progress.

The committee concludes that the ability to design and optimize protection material systems can be accelerated and made more cost effective by operating in a new paradigm for lightweight protection material development (Figure 6-2). In this new paradigm, the current armor system design practice is replaced by rapid iterations of modeling and simulation, with ballistic evaluation used selectively to verify satisfactory designs. Strong coupling with the materials research and development community is accomplished through canonical models that translate armor system requirements (which are often classified) into characterizations, microstructures, behaviors, and deformation mechanisms that an open research community can use. The principal objective of this new paradigm is to enable the design of superior materials and to accelerate their implementation in armor systems. The new paradigm will build on the multidisciplinary collaboration concepts and lessons from other applications documented in Integrated Computational Materials Engineering (ICME),1 which cites many advances and several examples of successful implementation. It advocates pushing the large body

______________

1NRC. 2008. Integrated Computational Systems Engineering: A Transformational Discipline for Improved Competitiveness and National Security. Washington, D.C.: The National Academies Press.

of existing computational materials science to the next step. Unfortunately, while the optimization of the materials, manufacturing processes, and component design is well described in the ICME report, the path forward for protection materials is far more complicated, since designs must deal with highly nonlinear and large deformations typically not encountered in commercial products, where applied stresses are kept well below the elastic limit in the linear regime.

The new paradigm can be focused on the most promising opportunities in lightweight protection materials, bringing such current products as ceramic plates and polymer fiber materials well beyond their present state of performance and opening the possibility for radically new armor system solutions to be explored and optimized in tens of months rather than tens of years.

The added features (indicated in red in Figure 6-2) of the new paradigm compared to the current paradigm are these:

- Canonical models explicitly link armor system design, which is typically done in a restricted setting, to protection materials research and design, which is typically done in an unclassified setting. A particular canonical model puts some aspect(s) of the dynamic protection problem into a standard form to be used as the basis for material system experiments and simulations. Each canonical model abstracts the key features of a threat and an armor configuration and expresses them in unclassified terms of dynamic material properties and behaviors needed to meet protection requirements. Such canonical models would be defined by an individual or group with the appropriate expertise and an intimate knowledge of both restricted and open research and development activity. A particular canonical model provides both material developers and model developers with a benchmark to use to evaluate potential improvements. Benefit:controlled linkage between open and restricted environments and a better match between armor system needs and potential material solutions.

- Design of the material or material system is based on an understanding of failure mechanisms invoked by projectiles or blast loads and uses physics-based modeling and simulation of the material or material system’s behavior or performance within the dynamic. The design modeling and simulation of the material take place prior to the longer iterations that involve physical testing. The rapidity of model iterations makes it possible to explore more alternatives and optimize the material to provide the desired behavior. Benefit: faster development of higher-performance armor materials.

- A feedback loop to the armor system design flow better defines the required material behaviors. Benefit: faster iterations than today’s make-and-shoot process

- and better requirements for achievable material behavior and dynamic properties.

- Simulation can model the consequences of specific process flows on the microstructure and hence the subsequent dynamic behavior and other important attributes (such as cost) before physically making the material. Benefit: higher yields, faster deliveries, lower costs.

Successful implementation of the new paradigm can, by dint of the insights gained from modeling and simulation, give armor system designers the freedom to work with novel as well as established materials to meet performance requirements. It can identify more rapidly than in the past how newly envisioned and to-be-developed materials and systems could create new opportunities for the protection afforded personnel, vehicles, ships, aircraft, and structures at lower weight and cost. The new approach would enable the reliable identification of materials that could be advantageous in protection applications, establish their merits and limitations, drive research and development to exploit the protective capacity of the new materials and systems, and, most importantly, bring about their rapid insertion into the field.

To realize the vision of this new paradigm and achieve these benefits, advances are needed on multiple fronts, including these:

- Better fundamental understanding of the mechanisms by which ballistic penetrators and blast loads interact with material systems at multiple scales, including insights into (1) dynamic properties at large strains, pressures, and high rates that go far beyond the usual quasi-static measures and (2) the resulting material behaviors that affect protection performance (see Chapter 3);

- Better computational approaches (physics-based models and codes for the evolution of failure) coupled with new experimental approaches allowing improved spatial and temporal measurement of damage evolution (see Chapters 3 and 4);

- The ability to design material compositions, crystal structures, microstructures, and composites over length scales from the atomic to the mesoscale to achieve behaviors that are important for protection performance and innovative processes that can synthesize and process these materials affordably (see Chapter 5); and

- An organizational structure and method of dealing with security constraints that will facilitate interaction and information sharing and enable successful basic and applied research to accelerate the development of these improved lightweight protection materials (detailed later in this chapter).

RECOMMENDATIONS FOR PROTECTION MATERIALS BY DESIGN

The recommendations in this section point out a way forward that will address the challenges outlined above by bringing together the efforts of university researchers, government labs, and industry to engage collaboratively in a long-term program of use-inspired fundamental research.

Overarching Recommendation. Given the long-term importance of lightweight protection materials to the Department of Defense (DoD) mission, DoD should establish a defense initiative for protection materials by design (PMD), with associated funding lines for basic and applied research. Responsibility for this new initiative should be assigned to one of the Services, with participation by other DoD components whose missions also require advances in protection materials. The PMD initiative should include a combination of computational, experimental, and materials testing, characterization, and processing research conducted by government, industry, and academia. The program director of the initiative should be given the authority and resources to collaborate with the national laboratories and other institutions in the use of unique facilities and capabilities and to invest in DoD infrastructure where needed.

This overarching recommendation requires actions in four important elements of the PMD initiative:

The first element of the PMD initiative would be to develop better fundamental understanding of the mechanisms of high-rate2 material deformation and failure in various protection materials, discussed in Chapter 3. As part of the new paradigm, armor development should be considered not from the viewpoint of conventional bulk material properties but from the viewpoint of mechanisms. The deeper fundamental understanding could lead to the development of more failure-resistant material compositions, crystal structures, and microstructures and to protective materials with better performance. Moreover, by identifying the operative mechanisms and quantifying their activity, mathematical damage models can be written that may allow computational armor design. Chapter 3 discusses failure mechanisms for the several classes of materials.

Recommendation 6-1. The Department of Defense should establish a program of sustained investment in basic and applied research that would facilitate a fundamental understanding of the mechanisms of deformation and failure due to ballistic and blast events. This program should be established under a director for protection materials by design, with particular emphasis on the following:

- Relating material performance to deformation and failure mechanisms. Developing models and data for choosing materials based on their ability to inhibit or avoid failure mechanisms as opposed to choosing them based on bulk properties as measured in quasi-static and dynamic tests.

- Developing superior armor materials by identifying compositions, crystalline structures, and microstructures that counteract observed failure mechanisms and by establishing processing routes to the synthesis of these materials.

- Reducing the cost of production of protection materials by improving the processes and yields and by enhancing the ability to manufacture small lots.

Element 2—Advanced Computational and Experimental Methods

The second element of the PMD initiative would be to advance and exploit the capabilities of the emerging computational and experimental methods discussed in Chapter 4. The first objective is to predict the ballistic and blast performance of candidate materials and materials systems as a prelude to the armor design process. The second objective is to define requirements that will guide the synthesis, processing, fabrication, and evaluation of protection materials. The PMD initiative would develop the next generation of

- DoD advanced protection codes that incorporate experimentally validated, high-fidelity, physics-based models of material deformation and failure, as well as the necessary high-performance computing infrastructure;

- Experimental facilities and capabilities to assess and certify the performance of new protection materials and system designs, as well as provide insight into fundamental material behaviors under relevant conditions with unprecedented simultaneous high spatial and temporal resolution; and

- Collaborative infrastructure for encouraging direct communication and improved cooperation between modelers and experimenters, through both (1) the establishment of collaborative environments and (2) requirements in proposals when the specific research topic is well served by such collaboration.

The high-priority opportunities identified in Chapter 4 will need sustained investment and program direction to advance computational and experimental capabilities. The envisioned computational capabilities must be devel-

______________

2Ballistic velocities typically range from several hundred to several thousand meters per second and can lead to strain rates of up to 105 s–1.

oped in partnership with a strong experimental effort that identifies the dynamic mechanisms of material behavior. These mechanisms must be understood and modeled for the activity to be successful, the material characteristics and properties must be known for the simulations to be carried out, and the outcomes of the computational modeling must be validated.

Recommendation 6-2. The Department of Defense should establish a program of sustained investment in basic and applied research in advanced computational and experimental methods under the director of the protection materials by design (PMD) initiative, with particular emphasis on the following:

- Dynamic mechanism characterization. Identify and characterize (1) the failure mechanisms underlying damage to a material caused by projectiles from weapons and detonations and (2) the compositional and microstructural features of each constituent of the material, as well as the material’s overall structure. An enhanced experimental infrastructure will be needed to make progress in high-resolution (time and space) experiments on material deformation and failure characterization.

- Code validation and verification. Focus on multiscale, multiphysics material models, integrated simulation/experimental protocols, prediction with quantified uncertainties, and simulation-based qualification to help advance the predictive science for protection systems.

- Challenges and canonical models. Periodically propose open challenges comprising design, simulation, and experimental validation that will convincingly demonstrate the PMD. Each challenge problem must address the corresponding canonical model and must result in quantifiable improvements in performance within that framework.

Element 3—Development of New Materials and Material Systems

The third element of the PMD initiative is the development and production of new materials and material systems whose characteristics and performance can achieve the behavior validated in modeling and simulation of the new armor system. The recommendations in this element target the most promising opportunities identified in Chapter 5.

Recommendation 6-3. The Department of Defense should establish a program of sustained investment in basic and applied research in advanced materials and processing, under the director of the PMD initiative program, with particular emphasis on the following:

- A sustained effort to develop a database of high-strain-rate materials for armor.Material behavior and dynamic properties must be measured and characterized over the range of strains, strain rates, and stress states in the context of penetration and blast events. Develop a comprehensive database of materials that exhibit high-strain-rate behavior and consider them as materials of interest. The PMD director should designate a custodian for this database and arrange for experimental results of the PMD program to be provided to the database and shared with the research community. The database should include ceramics, polymers, metals, glasses, and composite materials in use today and should be expanded as new materials are developed.

- —Opaque and transparent ceramics and ceramic powders. The intrinsic properties of opaque and transparent ceramics and ceramic powders are not yet fully realized in armor systems. There is need for understanding at the atomic, nano-, and micron levels of how powders and processing can be designed and manipulated to maximize the intrinsic benefits of dense ceramic armor and reduce production costs.

- —Polymeric, carbon, glass, and ceramic fibers. There is an opportunity to develop finer diameter and more ideally microstructured polymeric and carbon fibers with potentially a two- to fivefold improvement in specific tensile strength over the current state of the art. Such improvements would significantly reduce the weight of body armor.

- —Polymers. In addition to polymer fibers, thermoplastic and thermoset polymers are used as monolithic components and also serve as matrixes in various composites. Improved measurements of and models for the deformation mechanisms and failure processes are needed for thermoplastic- and thermoset-based protection materials.

- —Magnesium alloys. The very low density of magnesium provides potential for the development of very lightweight alternatives to traditional metallic materials in protection material systems. The basic understanding of strengthening mechanisms in magnesium should be advanced, especially the development of ultra-fine-grained magnesium alloys through severe plastic deformation. Magnesium-based fibers are also worthy of exploration.

- Adhesives and active brazing/soldering materials. Development of adhesives and active brazing/soldering materials and their processing methods to match the elastic impedance of current materials while minimizing the thermal stresses will improve the ballistic and blast performance of panels made of bonded armor, including transparent armor.

- Test methods. Advances are needed in test methods for determining the high strain rates (103 to 106 s–1) and dynamic failure processes of (especially) fibers, polymers, and ceramics. Results should be passed on to the designated database of materials with high-strain-rate behavior.

- Material characterization. The characterization of, composition, crystalline structure, and microstructure at appropriate length scales is a key task that will need more attention to take advantage of the improved experimental tools for quantifying initial and deformed microstructures.

- Cost reduction. Advances are needed to reduce the cost of producing protection materials by improving their processing and yield and by improving small-lot manufacturing capability.

- Processing science and intelligent manufacturing. Advances are needed in basic understanding of and ability to model the consequences of material processing for performance and other characteristics of interest. Intelligent manufacturing sensing and control capabilities are needed that can maintain low variance and produce affordable protection materials, even in relatively low volumes.

Element 4—Organizational Approach

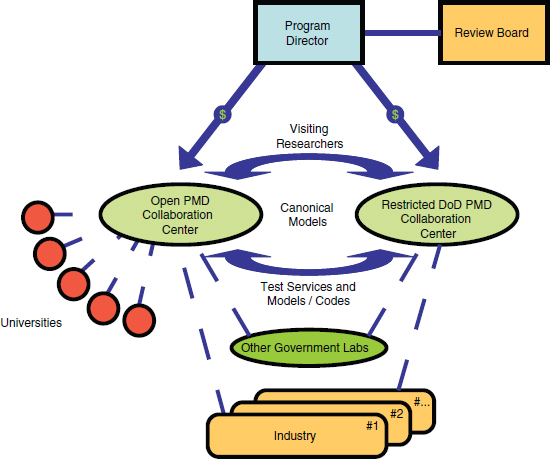

The fourth element of the PMD initiative is an organizational construct for multidisciplinary collaboration among academic researchers, government laboratories, and industry, in both restricted-access and open settings. The PMD initiative will need strong top-level leadership with insight into both the open and restricted research environments and the authority to direct funding and set PMD priorities. The program will require committed funding to ensure long-term success and should be subject to periodic external reviews to ensure that high standards of achievement are established and maintained. To meet these requirements, the committee considered several organizational alternatives, described in the sections below, and concluded that the notional DoD organizational approach depicted in Figure 6-3 includes the features necessary for success.

Recommendation 6-4. In order to make the major advances needed for the development of protection materials, the Department of Defense should appoint a PMD program director, with authority and resources to accomplish the following:

- Plan and execute the PMD initiative and coordinate PMD activities across the DoD;

- Select an existing facility to be the DoD center for PMD and fund a research director and the staff, equipment, and programs needed by the PMD initiative;

- Award a competitive contract for an open access PMD center whose mission would be to host and foster open collaboration in research and development of protection materials;

- Establish an external review board to conduct periodic reviews of programs in both centers; and

- Provide liaison with the Department of Energy, the National Institute of Standards and Technology, and other government laboratories on matters related to PMD.

CRITICAL SUCCESS FACTORS FOR THE RECOMMENDED NEW ORGANIZATIONS

DoD Center for the PMD Initiative

The essential features of the recommended organization are as follows:

- A program director for the PMD initiative who is responsible for planning and overseeing the execution of basic and applied research in both classified and unclassified settings. The director might be organizationally located within the lead service for protection materials, the Department of the Army, but in any event would be responsible for coordinating research and development in lightweight protection materials across the rest of DoD.

- Selection by the above-mentioned program director of an existing DoD organization to become the DoD center for the PMD initiative. This program director would appoint a research director for the center and would organize funding for it. The center would be staffed and equipped for classified research in materials synthesis, processing, and testing, as well as computational facilities to enable materials design and armor design. The DoD center for the PMD initiative would have both internal capabilities and access to external capabilities as needed for advanced modeling and simulation, protection materials synthesis, processing, characterization, fabrication, ballistic and blast testing, and evaluation of protection material systems. This organization would accommodate visiting researchers who would be granted security clearances for the duration of their rotating assignments. It would also provide testing services and evaluation results at both classified and unclassified levels to qualified external researchers.

- An open PMD collaboration center, with a physical experimentation center and virtual collaboration links to distributed academic, government, and industry researchers. This organization and its research

- director would promote collaboration among modelers and experimentalists. The center could facilitate multidisciplinary information exchange and enforce appropriate boundaries for restricted information. It would have both internal facilities and remote access to facilities for experimentation and material characterization. It would also maintain awareness of the open literature and global technology developments and actively enhance them and would provide input to the program director and the staff of the classified center at DoD.

- An external review board, duly constituted to review programs and advise the director in the planning and conduct of research in protection materials, both restricted and open.

- Links to Department of Energy labs, the National Institute of Standards and Technology labs, and other government labs whose research and capabilities are relevant to protection materials research.

The proposed research and development program would require the collaboration of scientists and engineers from DoD research laboratories, other national laboratories, universities, independent research institutes, and commercial companies in settings that can foster collaboration while maintaining boundaries for unclassified, proprietary, export controlled, and classified information.

Given the constraints of current classification guidelines, research and development involving specific threats and vulnerabilities will require access to a facility where restricted research and testing—that is, research that is either classified or otherwise not available for public release—can be conducted. The committee believes designation of an existing DoD organization as the lead laboratory for the PMD initiative would be the best way to meet this need. This open collaboration center would need to have capabilities for the following:

- Materials characterization,

- Model development and simulation against real

- threats,

- Armor system prototyping, and

- Ballistic and blast testing and evaluation against real threats.

Such capabilities exist at the Army Research Laboratory facility in Aberdeen, Maryland, and at other DoD facilities.

To tap the sources of innovation in academia and industry, an environment for collaboration outside restricted governmental facilities would be needed. This open research community would have the following capabilities:

- Experimental facilities for dynamic measurements of material behavior, including in situ visualization of high-rate deformation and failure processes.

- Modeling and simulation capabilities.

- Materials design and processing design capabilities.

- Collaboration between modelers and experimentalists, supported by information sharing and virtual collaboration environments.

- An enclave where classified or restricted information could be exchanged among researchers with the appropriate clearances.

- Physical meeting facilities.

- Proximity or easy transportation access to the DoD PMD center.

The key to success would be to link these two research environments through formal organizational relationships, personnel exchanges, funding and program direction, and processes to translate classified information on threats and materials into canonical models suitable for academic research topics. Procedures would be needed to adapt data from the classified center for use by the open environment.

Of the organizational elements, the newest and most far-reaching area for investment would be the open PMD collaboration center. This center would be a vibrant intellectual engine that attracts the best academic researchers across multiple organizations to address well-defined problems in material design, high-strain-rate experimentation, analytical and computational modeling across the length and timescales, and materials processing for protection applications. It could foster precompetitive collaboration with industry for both fundamental research and technology transfer.

The key features of the open center would include these:

- Academic opportunity for interesting problems, funding, access to state-of-the-art facilities, up-to-date data, workshops, and publications.

- Canonical models that support unclassified research objectives stated in terms of material behaviors or other fundamental phenomena.

- Open competition for new research awards from both the PMD initiative and other basic and applied research sponsors.

- Multidiscipline and multiuniversity collaboration.

- University-industry-government collaboration.

- Means to host visiting researchers.

The committee considered several organizational alternatives that might have the desired attributes of this new entity, including the following:

- Multidisciplinary University Research Initiative (MURI). DoD currently uses MURI awards to support university research that intersects two or more traditional science and engineering disciplines. Teaming in multidisciplinary research helps to transition basic

- research findings to practical application and accelerates research progress by cross-fertilization of ideas. In supporting these team efforts, MURI complements other DoD programs that support university research via single-investigator awards. Typically, awards cover a period of 3 years; 2 additional years are possible. This model is strong on multidiscipline and multiuniversity collaboration but is not typically used for collaboration with industry.3

- University Affiliated Research Center (UARC). This appellation is given to university laboratories that maintain critical competencies in technology and systems that support national defense. University Affiliated Research Centers (UARCs) are awarded as noncompetitive DoD contracts through a provision of the Competition in Contracting Act (CICA) of 1984, as codified in 10U.S.C. 2304(c)(3)(B), which authorized noncompetitive contracts with educational institutions where necessary for DoD to establish or maintain essential engineering, research, and developmental capabilities. UARCs support DoD through a special strategic relationship, wherein they serve as trusted technical advisors free from commercial conflicts of interest. The requirement for maintaining a UARC and its associated funding is driven by the specific needs of sponsoring DoD RDT&E programs. These special needs are manifest in core competencies, specified by the sponsors, which define the scope of services to be provided by the UARC. The current ARL Material Centers of Excellence in Ceramics, Metals, Polymers and Composites are not UARCs but have similar characteristics. The UARC model has to be broadened to provide the type of open competition and academic opportunity envisioned for an open PMD collaboration center.4

- Collaborative Technology Alliance (CTA). CTAs are collaborations between academia, Army labs or centers, and private industry. Their goal is to rapidly transition new technologies to warfighters, thereby enabling the Army’s Future Force. This partnership is at the core of the CTA concept, wherein each partner brings a unique approach to research. Academia, for example, brings cutting-edge innovation; ARL researchers maintain the focus on solving complex Army technology problems; and the industrial partners are able to solve technology bottlenecks and to leverage existing research results. In this way, multidisciplinary research teams bring about the complex technology needed to solve the Army’s complex problems. The program brings world-class research and development talent to bear on meeting Army

______________

3For more information, see http://www.wpafb.af.mil/library/factsheets/factsheet.asp?id=9327.

4For more information, see http://www.hawaii.edu/uhmfs/uarc/Attach_003.UARCMgmt.pdf.

needs for technology. The CTA model has most of the desired characteristics but has traditionally been used when technology advances are driven more by market forces than by government needs, which is not the case in protection materials.5

- Fraunhofer-like institute. Fraunhofer institutes originated in Germany. Affiliated centers have been established in the United States to perform applied research under contract to government and industry for such customers as federal and state governments, multinational corporations, and small- to medium-sized companies. Each center is partnered with a major research university. These partnerships serve as bridges between academic research and industrial needs. Such bridges would fill some but not all the government needs for the open PMD collaboration center.6

- Engineering Research Centers (ERCs) such as those sponsored by the National Science Foundation (NSF). Located at universities throughout the United States, ERCs are a group of interdisciplinary centers that partner closely with industry. Each ERC provides an environment in which academe and industry can collaborate in pursuing strategic advances in complex engineered systems and systems-level technologies that could spawn whole new industries or radically transform the processing technologies, product lines, or service delivery of current industries. Activity within ERCs lies at the interface between the innovation-driven culture of engineering and the discovery-driven culture of science. The centers provide the intellectual foundation for industry to collaborate with faculty and students on producing the knowledge base needed for steady advances in technology, resolving long-range, generic challenges and rapidly transitioning results to the marketplace. The academic opportunity criterion could be well met by incorporating ERC characteristics, but additional features would be needed to give the government a stronger role in guiding the research to meet government needs.7

- University-industry consortium models. Numerous examples of university research consortia, industry research consortia, and membership organizations fall into this category. The committee considered the NSF Industry/University Cooperative Research Centers (I/UCRCs),8 in particular the Ceramic, Composite and Optical Materials Center at Rutgers University,9 to be in this category. It also considered the National Textile Center,10 the Semiconductor Research Consortium,11 and the National Warheads and Energetics Consortium12 as examples. Some of these consortia are federally funded and others operate on industry funding. A common denominator in such consortia is a business case for industry participation. Assuming such a business case can be made, these models, like the CTA model above, could meet most of the desired criteria. The model would need to be tailored to focus on canonical models as the bridge to the government needs.

The committee concluded that none of these models would meet all the needs of an open PMD collaboration center but that the various university and industry consortium models have proven features that the Army could combine to define the contract for such a center.

Time Frame for Anticipated Advances

While it is always problematic to try to predict the future, it is apparent that some areas are ripe for rapid progress and discovery. The committee believes, for example, that increased funding of basic research on high-rate deformation of polymer fibers and ceramics could, within about 10 years (depending on the level of effort), achieve a level of understanding that would rival the current understanding of metals. Progress will be aided as national lab facilities for extremely fast data acquisition during high-rate events become available and as researchers design experiments to take advantage of such facilities.

_________

5For more information, see http://www.arl.army.mil/www/default.cfm?page=93.

6For more information, see http://www.fraunhofer.org/.

7For more information, see http://www.erc-assoc.org/index.htm.

8For more information, see http://www.nsf.gov/eng/iip/about.jsp.

9For more information, see http://www.ccmc.rutgers.edu.

10For more information, see http://www.ntcresearch.org/mission.htm.

11For more information, see http://www.src.org/about/.

12For more information, see http://www.nwec-dotc.org/.