The U.S. Air Force weapon system sustainment1 enterprise is extremely large in terms of scope, workforce, and associated costs that amount to billions of dollars annually. When other expenditures, such as selected personnel accounts, fuel, facilities, and utilities are included, the total dollar amount expended is significantly higher.2 As a point of reference for the reader, the Air Force total costs of sustainment activities exceed the operating costs of such industry giants as American Airlines and Delta Airlines.3 As demonstrated by the following comment by the Under Secretary of Defense for Acquisition, Logistics, and Technology, sustainment is a major component of the Department of Defense (DoD) budget:

About $100 billion is procurement of weapons systems—OK, acquisition—but remember that 70 percent of the cost of a weapons system is not acquiring it; it is sustaining it. It’s not buying it; it’s having it, where most of the money is. Said differently, most of the money in

______________

1 Adopted from the 2009 report DoD Weapon System Acquisition Reform Product Support Assessment. This report applies the following definition of weapon system or aircraft sustainment: System sustainment is the package of support functions required to maintain the readiness and operational capability of weapon systems, subsystems, software, and support systems. It encompasses materiel management, distribution, technical data management, maintenance, training, cataloging, configuration management, engineering support, repair parts management, failure reporting and analysis, and reliability growth. Available at https://acc.dau.mil/adl/en-US/328610/file/47489/DoD%20Weapon%20System%20Acquisition%20Reform%20PSA_19%20NOV_Final.pdf. Accessed August 18, 2011.

2 Chapter 3 includes an in-depth discussion of the Air Force expenditures.

3 Chapter 6 includes a discussion of commercial best practices for sustainment.

the budget is spent on sustaining weapons systems that were procured in the past rather than on acquisition programs per se. And we can’t leave that much money out of the better buying power equation [emphasis added].4

In May 2010, DoD introduced the Defense Efficiencies Initiative that seeks to “increase efficiencies, reduce overhead costs, and eliminate redundant functions in order to improve the effectiveness of the DoD enterprise. This effort is focused on reprioritizing how DoD can use resources to more effectively support and sustain the force [emphasis added].”5 The Defense Efficiencies Initiative recognizes the need for improved efficiency and effectiveness to support and sustain the force. This study highlights many sustainment issues and offers recommendations aimed at improving the efficiency and effectiveness of the Air Force weapon system sustainment enterprise.

The Air Force weapon system sustainment enterprise consists of a highly skilled workforce but operates without modern enterprise resource planning tools and with a supply chain that is not structured according to business best practices. In fact, Air Force weapon system sustainment, including the demand to maintain aircraft organically and by contractor logistics support, dwarfs that of commercial airlines and other nations’ Air Forces. The sustainment posture is determined by the number and variety of aircraft, the technology of the systems involved, and the global deployment of the fleet. The fleet’s diversity, which ranges from aircraft designed and deployed in the 1950s to the world’s most advanced high-performance fighters, weighs on the enterprise’s operation. The enterprise has become more complex over time not only because of the fleet’s increased growth and diversity, but also because of global politics and regulations.

The Air Force has been operating on a wartime-like footing for the past 20 years. This extended period of intense operation has been further complicated by multiple theaters of operation and by demand for more diverse and long-duration fighter missions; worldwide airlift; long-range bomber sorties; diverse intelligence, surveillance, and reconnaissance aircraft; and extensive aerial refueling sorties resulting from increasing geopolitical complexity.

Today, sustainment activities are undertaken by numerous offices and organizations, including the Air Force Secretariat; the Air Force Air Staff; the Air Force Materiel Command (AFMC) and its subordinate Product Centers; Air Logistics

______________

4 Ashton Carter, Under Secretary of Defense for Acquisition, Technology, and Logistics. 2011. “Pentagon Efficiency Initiatives.” Remarks given at the Heritage Foundation, Washington, D.C., April 20. Available at http://www.heritage.org/Events/2011/04/Pentagon-Efficiency?query=Pentagon+Efficiency+Initiatives:+Are+They+Enough+to+Stave+Off+More+Defense+Cuts?. Accessed May 2, 2011.

5 DoD. 2010. Defense Efficiencies Initiative. Available at http://www.defense.gov/home/features/2010/0810_effinit/. Accessed April 21, 2011.

Centers (ALCs); and Air Force operational commands. The activities of all of these offices and organizations must be considered in studies of weapon system sustainment. Sustainment is generally program-specific by weapon system. Although policy is made by the Secretariat and Air Staff offices, it is broad and open to interpretation. Sustainment activities may occur in the operating command, but they are generally short-term in nature. The Product Centers and ALCs drive the larger-scale and high-cost sustainment activities. Because of the broad nature of sustainment policy and the number of organizations involved there is no “model” weapon system sustainment program.

Air Force weapon system sustainment has functioned under a variety of concepts and organizations, yet the system has repeatedly met national and global threats, largely because of the dedication of the men and women responsible for the detailed tasks of sustainment. Sustainment activities require significant coordination and communication across a myriad of functions and organizations. At present, this process is largely facilitated by interpersonal relationships rather than clear, concise lines of authority and modern enterprise reporting and planning tools, which results in escalating costs and inefficiencies.

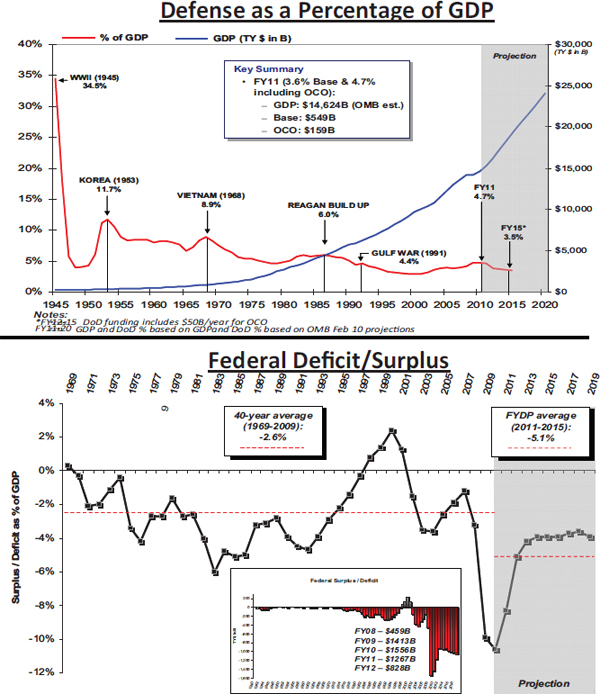

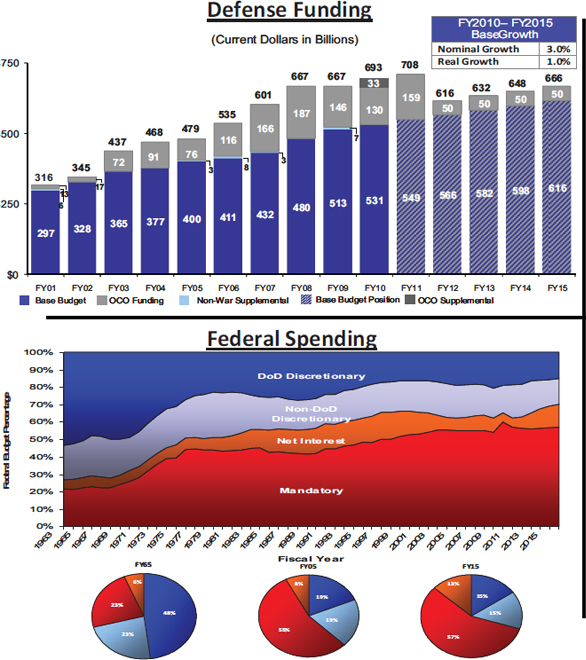

The Air Force’s sustainment activities achieve the desired operational outcomes. However, extraordinary management effort and attention are required to knock down stovepipes that impede efficiencies. Senior officials are consistently frustrated by weak or overly broad policies, minimal governance, and unnecessarily complex organizational structures as they try to improve support postures resulting from enterprise inefficiencies. These systemic shortcomings span the weapon system life cycle—from initial concept development through retirement—for which there is a lack of clear accountability. For the foreseeable future, the Air Force will continue to operate at a high tempo but will face tremendous pressures on its sustainment budget. The increasing costs of sustainment are a concern, because, as the present systems continue to age, they will demand a greater proportion of the overall defense budget. This may not be “sustainable” in the context of the downward pressures on the overall defense budget, shown in Figure S-1.6

STUDY APPROACH

In response to a request from the Deputy Assistant Secretary of the Air Force for Science, Technology, and Engineering, the National Research Council, under the auspices of the Air Force Studies Board, formed the Committee on Examination

______________

6 Blaise J. Durante, Deputy Assistant Secretary for Acquisition Integration, Office of the Assistant Secretary of the Air Force for Acquisition. “Budgeting Considerations Related to Sustainment.” Presentation to the committee, October 21, 2010.

FIGURE S-1

Economic realities will affect defense spending. OCO, Overseas Contingency Operations. SOURCE: Blaise J. Durante, Deputy Assistant Secretary for Acquisition Integration, Office of the Assistant Secretary of the Air Force for Acquisition. “Budgeting Considerations Related to Sustainment.” Presentation to the committee, October 21, 2010.

of the U.S. Air Force’s Aircraft Sustainment Needs in the Future and Its Strategy to Meet Those Needs to address the following terms of reference:7

- Assess current sustainment investments, infrastructure, and processes for adequacy in sustaining aging legacy systems and their support equipment.

- Determine if any modifications in policy are required and, if so, identify them and make recommendations for changes in Air Force regulations, policies, and strategies to accomplish the sustainment goals of the Air Force.

- Determine if any modifications in technology efforts are required and, if so, identify them and make recommendations regarding the technology efforts that should be pursued because they could make positive impacts on the sustainment of the current and future systems and equipment of the Air Force.

- Determine if the Air Logistics Centers have the necessary resources (funding, manpower, skill sets, and technologies) and are equipped and organized to sustain legacy systems and equipment and the Air Force of tomorrow.

- Identify and make recommendations regarding incorporating sustainability into future aircraft designs.

During four data-gathering meetings, senior Air Force leaders, including representatives of several Air Force Major Commands, representatives from the other military departments, senior officials in the Office of the Secretary of Defense, professional staff members from key congressional oversight committees, and senior industry executives provided input to the committee (see Appendix A for biographical sketches of the committee members and Appendix B for meetings and participating organizations). Additionally, the committee held smaller site visits with Air Force and Navy officials, including visits to the three ALCs and the Fleet Readiness Center Southwest. Finally, the committee held two 3-day meetings to finalize its report and findings and recommendations.

The following “Big 7” themes continuously recurred throughout the study and correspond to the recommendations cited: (1) the lack of Air Force processes for sustainment as an enterprise (Recommendations 2-2, 2-3, 3-1, 4-5, 4-7, 4-8, 6-1, 6-3, 6-5, and 6-10); (2) ill-defined Air Force organizational structure for sustain-

______________

7 Many of the presenters to the committee agreed that a budget “train wreck” with respect to sustainment costs is looming. The committee engaged in considerable discussion on how to validate the spontaneous comments regarding out-of-control sustainment costs. The terms of reference did not require the committee to undertake business case analyses related to the report recommendations. Likewise, the committee was purposely not composed to conduct business case analyses related to the report recommendations. However, such analyses of selected recommendations are worthy of future consideration by the Air Force because they would provide insight on whether implementation of the selected recommendations would result in overall long-term reductions in sustainment costs.

ment (Recommendations 3-2, 4-1, and 4-6); (3) modest progress by the Air Force on governance (Recommendations 2-6, 4-2, 4-4, 4-7, 6-6, 6-7, 6-8, and 6-9); (4) lack of a single senior Air Force commander in charge of the entire sustainment enterprise (Recommendation 2-4); (5) metrics that do not adequately measure the key sustainment parameters (Recommendations 2-1, 2-5, 2-6, and 4-9); (6) a spare parts chain that encumbers effective and efficient maintenance production at all levels (Recommendation 4-3); and (7) ineffective processes to develop and transition technology for sustainment (Recommendations 5-1, 6-2, 6-3, and 6-4). The recommendations provided in this report have the potential to (1) focus management and leadership attention with commensurate authority; (2) relieve the stressors of organizational conflicts; and (3) improve efficiencies across the Air Force sustainment enterprise. Chapters 2 through 6 of this report present 45 related findings and 27 recommendations. Below are the key recommendations from Chapters 2 through 6.

KEY RECOMMENDATIONS

The Impact of Regulations, Policies, and Strategies on Sustainment

The lack of clearly defined sustainment goals affects the entire Air Force. Importantly, however, the Air Force can quickly develop a solution to this problem and then refine it over the longer term. The Air Force challenges in the sustainment process begin in the Air Force organizations—i.e., Assistant Secretary of the Air Force (Acquisition) (SAF/AQ), Assistant Secretary of the Air Force (Installations, Environment and Logistics) (SAF/IE), and Air Staff Headquarters (AF/A4/7)—that are responsible for the clarity of policy and process to the subordinate organizations. These headquarters offices should set the tone for Air Force sustainment. In the absence of well-founded policy and instructions, field-level commanders and directors take individual action to sustain their fleet; however, they deserve clear guidance and should be held accountable for execution.

Recommendation 2-1. The Air Force should establish sustainment goals that are specific and can be understood by all acquisition, contracting, engineering, and sustainment professionals. The Air Force should then track these goals and hold key individuals accountable for achieving them.

Recommendation 2-2. The Air Force should conduct a detailed holistic review of all appropriate sustainment policies and directives and build a complementary suite of processes and actions. With regard to the Title 10 mandates, the Air Force should take near- and long-term strategic actions to ensure maximum

compliance. The Air Force should make long-term acquisition decisions and should aggressively pursue opportunities for Centers of Industrial and Technical Excellence.8,9

Recommendation 2-3. The Air Force should select and deploy either a single (preferred) or standard (by type of aircraft) collaborative engineering methodology to determine the processes, procedures, tasks, and frequency of maintenance actions.

Recommendation 2-4. The Air Force should consider formally designating a senior commander, such as the Air Force Materiel Command (AFMC) Commander, as the commander of the entire sustainment process, from concept phase through system retirement, with the responsibility to advise the SAF/ IE, SAF/AQ, and AF/A4/7 on policy and then train, organize, equip, plan, and execute the Air Force’s Integrated Life-Cycle Management (ILCM) processes.

Recommendation 2-5. The Air Force should develop and implement weapon system-level metrics that set aircraft availability levels and the cost of providing that availability, as well as identify who is responsible for attaining both. Furthermore, these measures should be at a level that reflects sustained imple-

______________

8 Quoting, in part, 10 USC § 2466 entitled “Limitations on the Performance of Depot-level Maintenance of Materiel”: “(a) Percentage Limitation.— Not more than 50 percent of the funds made available in a fiscal year to a military department or a Defense Agency for depot-level maintenance and repair workload may be used to contract for the performance by non-Federal Government personnel of such workload for the military department or the Defense Agency. Any such funds that are not used for such a contract shall be used for the performance of depot-level maintenance and repair workload by employees of the Department of Defense.” For additional information, see http://www.law.cornell.edu/uscode/uscode10/usc_sec_10_00002466----000-.html. Accessed July 8, 2011.

9 Quoting, in part, 10 USC § 2474 entitled “Centers of Industrial and Technical Excellence: Designation: Public-Private Partnerships” and enacted November 18, 1997, by Public Law 105-58: “(1) The Secretary concerned, or the Secretary of Defense in the case of a Defense Agency, shall designate each depot-level activity of the military departments and the Defense Agencies (other than facilities approved for closure or major realignment under the Defense Base Closure and Realignment Act of 1990 (part A of title XXIX of Public Law 101-510; 10 U.S.C. 2687 note)) as a Center of Industrial and Technical Excellence in the recognized core competencies of the designee. (2) The Secretary of Defense shall establish a policy to encourage the Secretary of each military department and the head of each Defense Agency to reengineer industrial processes and adopt best-business practices at their Centers of Industrial and Technical Excellence in connection with their core competency requirements, so as to serve as recognized leaders in their core competencies throughout the Department of Defense and in the national technology and industrial base (as defined in section 2500(1) of this title [10 USCS § 2500(1)]).” For additional information, see http://www.law.cornell.edu/uscode/html/uscode10/usc_sec_10_00002474----000-.html. Accessed July 19, 2011.

mentation of process improvement initiatives such as cost-reduction incentives and not just increasing sustainment costs driven by aircraft aging.

Recommendation 2-6. The Air Force should develop and direct a sustainment execution model for weapon systems and major weapon systems modifications that balances the needs of the individual weapon system with the performance goals and cost constraints of the overall sustainment enterprise.

Assessment of Current Sustainment Investments, Infrastructure, and Processes

As noted above, the Air Force currently spends billions of dollars per year to sustain legacy weapon systems. It is likely that the amount of money needed to sustain legacy weapon systems will increase over time as weapon systems become more complex. At the same time, current projections indicate that the Air Force budget will decrease over the remaining life of the Future Years Defense Program. These fiscal realities will lead to difficult choices for the Air Force in terms of sustaining the legacy fleet, recapitalizing the fleet, and modernizing the fleet. Although the latter two efforts are not addressed in this report, the Air Force sustainment enterprise does not, and will not, operate in a vacuum. The budget process must recognize the need for some up-front investments in the sustainment enterprise to increase efficiencies and effectiveness. Consequently, the sustainment of existing weapon systems will demand careful attention and frequent readiness, availability, and cost trade-offs.

Recommendation 3-1. The Air Force should continue funding depot plant and capital equipment and, at the same time, be guided by focused analyses to ensure that constrained funding is provided to the most critical sustainment needs to avoid future support impacts and to meet Title 10 considerations.

Assessment of Air Force Air Logistics Centers

Evaluation of the ALCs considers funds allocation, workforce, skill sets, and organizational structure. The flow of funds for depot maintenance and the Air Force’s flying hour programs has been adequate; however, this might change in the near future. Even though the Air Force considers the ALCs to be the single most important and fundamental key to sustainment, their organizational structure is not adequately resourced, and the executive leadership does not have full command and control of the ALC enterprise. To a severe extent, the supply chain’s ability to provide spare parts to the maintenance organizations is ineffective and disrupts depot maintenance and parts repair. There are mismatches between direct support to production activities and the growth of requirements at the production level. Importantly, a modern enterprise resource planning tool, although promised

as “forthcoming,” is not available, despite being desperately needed. Finally, and disappointingly, despite repeated requests for key measures of effectiveness and efficiency, the only well-defined metric supplied was for aircraft availability, and many more organizations than just the ALCs impact aircraft availability. The ALCs make the current situation work, but the full spectrum of resources needed to make an effective and efficient organization is not available.

Recommendation 4-1. The Air Force should establish streamlined command lines of accountability and authority to give the ALC commanders clear execution authorities to direct process improvements on assigned programs, maintenance activities, and supply support.

Recommendation 4-2. The Air Force should follow in a more timely manner the statutes that require the depot maintenance industrial workforce to be managed according to workload. The Air Force should also ensure that supporting organizations are staffed to support the industrial workloads and that flexible work rules are established to permit more workforce versatility.

Recommendation 4-4. The Air Force should continue its eLog 21 approach to sustainment improvement and should aggressively continue to pursue incremental fielding of the Expeditionary Combat Support System as an enterprise resource planning solution. Strong advocacy for this program should reside with the sustainment commander.10

Recommendation 4-5. The Air Force should focus the same, or arguably more, attention and investment as that given to equipment in the actual weapon system on the tools used for software maintenance. Maintaining currency between test laboratories and actual weapon systems is fundamental for dealing with timing, details of hardware interface behavior, and concurrency.

Recommendation 4-7. The Air Force should review its corporate oversight, management, and support of embedded systems software development and sustainment with foci on (1) greater risk identification and mitigation and (2) enabling Air Force corporate, as opposed to command-specific, decision making. In addition, given Air Force dependence on software to achieve mis-

______________

10 Based on detailed information provided to the committee by the Air Force, the committee concluded that there is a critical need for an Enterprise Resource Planning (ERP) system to help address Air Force sustainment issues. The Expeditionary Combat Support System is being developed with ERP capabilities and will be implemented to meet the Air Force’s need. The committee did not attempt to evaluate the process that selected the specific ERP system or the contractor(s) involved in the development and implementation.

sion capabilities, the Air Force should strongly consider additional education on software sustainment for senior leaders.

Recommendation 4-9. The Air Force should develop key metrics for sustainment that flow to ALC commanders and that highlight the success or shortcomings of ALC activities, drive appropriate behavior for the workforce, and allow Air Force leadership to assess the health of the enterprise and the adequacy of resourcing for the sustainment process regardless of organizational affiliation.

Technology Development and Insertion for Sustainment

The Air Force’s continued reliance on aging aircraft, such as the B-52, C-130H, A-10, F-16, and C-5B, which will exceed their originally designed life spans, will place an emphasis on the increasingly important role of new technologies related to materials, inspection systems, and vehicle health monitoring.11 The Air Force Research Laboratory (AFRL), under the AFMC, is responsible for developing new technologies for Air Force weapon systems. AFRL can point to a long history of attention to sustainment and to many successful transitions of technology to industry and to the ALCs that increased aircraft availability and/or reduced maintenance costs. In recent years, support for sustainment-focused technology has waned because of increased attention to other technical priorities and opportunities, too frequent changes in strategy and process, and reductions in funding for sustainment technology, especially that for the transition process. There is capability within AFRL development programs to affect sustainment costs on existing weapon systems, and justification for increased AFRL investments and foci on sustainment.

At the time this report was being drafted, the Air Force began to implement high-level processes for technology development and insertion. Specifically, it was encouraging to learn that (1) sustainment is clearly identified in the recently released Air Force science and technology plan; (2) a new program element has been established for this area; and (3) the AFMC Commander has ownership of technology development and transition. In addition, as the Air Force moves toward the ILCM concept that is now beginning to appear in high-level plans and visions, it will be necessary to broaden the common understanding of sustainment technologies and to adequately support their inclusion, development, and transition into new weapon systems.

______________

11 Steven H. Walker, Deputy Assistant Secretary of the Air Force for Science, Technology, and Engineering. “Co-Sponsor Discussion of Study Background and Task.” Presentation to the committee, October 20, 2010.

Recommendation 5-1. The Air Force should develop a “technology for sustainment” plan that identifies processes, technical agendas, workforce needs, and required funding resources. Such a plan should be imbedded within the overall ILCM strategy that is being developed by the Air Force.

Incorporating Sustainability into Future Designs

The Air Force and industry have unique capabilities for developing and maturing technology, as discussed in Chapters 5 and 6. When specifically focused, these capabilities can be applied to the incorporation of sustainment features into future designs to complement the traditional focus on system performance. The successful application of lessons learned from field experience is exemplified in some recent designs, and there are evolving human factors techniques that provide tools for integrating new maintenance functions and personnel capabilities. The experience gained from the deployment of more recent weapon systems containing special emphasis on low observable characteristics and significantly more use of software also provides a wealth of data for incorporation of sustainment capabilities into future designs. Discussions with contractors revealed that (1) in one case, much of the activity that resulted in the incorporation of sustainment features into the systems was initiated by the contractor and (2) in the other case, detailed sustainment requirements came from another Service. This again emphasizes the importance of having strong sustainment involvement in all phases of Air Force procurements, beginning with the concept and design phases. Incorporation of sustainment into future designs requires a strong partnership between government and industry.

Sustainment professionals have not been fully involved in the Defense Acquisition Management System (DAMS), from the Materiel Development Decision (MDD) to Production and Deployment (P&D), of recent weapon system programs. As a result, sustainment needs, planning, and costs have not been fully captured. A partnership between all sustainment stakeholders should be established in the initial requirements statements, should continue with the original equipment manufacturer at the earliest possible opportunity, and should drive future sustainment planning and technology insertion. It is important to emphasize the opportunities for government/contractor shared knowledge and alignment with Air Force enterprise programs in this partnership.

Recommendation 6-1. The Air Force should involve its sustainment professionals throughout the DAMS, from MDD to P&D, in all future weapon system development. Funding for sustainment planning and support should be given the same visibility as that for the development of capabilities and performance.

Recommendation 6-3. The Air Force should establish an institutionalized

process for collecting and consistently incorporating desirable design features or applying lessons learned from legacy programs into the requirements for new systems or systems being modified in the support phase of the life cycle and into the internal procedures involved in sustaining these systems.

Recommendation 6-4. The Air Force should place more emphasis and implement additional training for acquisition professionals on the need for, the how to, and the pricing of proper data rights and domain knowledge related to the weapon system.

Recommendation 6-5. The Air Force should commit to establishing processes and resources that support consideration of a blended organic–contractor partnership early in the program life cycle and throughout the deployment and support phases.12

Recommendation 6-9. The Air Force should consider incorporating commercial-like engineering models and data collection and analysis techniques into the appropriate future platforms and contractually require that these efforts be compatible with Air Force data systems.

SUSTAINMENT, RECAPITALIZATION, AND MODERNIZATION: CAN THE AIR FORCE AFFORD TO DO EVERYTHING?

The short answer to this question is no. The high costs associated with Air Force weapon system sustainment will continue to directly impact the procurement of replacement and new systems unless significant numbers of legacy aircraft are retired.13,14 To date, the Air Force sustainment enterprise has been largely successful in meeting the requirements of a 20-year-long, high-operational-tempo period. Going forward, however, high-level Air Force management, hopefully informed by

______________

12 A blended organic–contractor partnership, as specified in the contract award for a weapon system, assigns specific responsibilities for sustainment of a weapon system to both the industry contractor and the organic ALC.

13 Steven Walker, Deputy Assistant Secretary of the Air Force for Science, Technology, and Engineering. 2011. “2012 Budget Request for DoD Science and Technology.” Testimony to the House Armed Services Committee, March 1. Available at http://armedservices.house.gov/index.cfm/hearings?ContentRecord_id=b68a8831-3c7f-4ca2-a901-046b50eaa90d&Statement_id=7ea6c379-4499-4e88-b064-37e7b4d3f2d2&ContentType_id=14f995b9-dfa5-407a-9d35-56cc7152a7ed&Group_id=13e47ffa-0753-47a7-ad5e-1ba7592015c9&MonthDisplay=3&YearDisplay=201. Accessed April 22, 2011.

14 Erin Conaton, Under Secretary of the United States Air Force. 2011. “The Future of the Air Force.” Speech at the Center for Strategic and International Studies, Military Strategy Forum, March 31. Available at http://csis.org/event/future-air-force. Accessed April 24, 2011.

the recommendations in this report, will be called upon to effect organizational and operational improvements to make the Air Force sustainment enterprise more efficient. It cannot be known to what extent this report has been affected by not having insight into internal Air Force deliberations on the Defense Efficiencies Initiative. Even so, the findings and recommendations in this report stand on their own and reflect the synthesis of a voluminous amount of information.

Finally, What if the Air Force were to fully implement the recommendations in this report? Many of the recommendations will focus management and leadership attention with commensurate authority, relieve the stress of organizational conflicts, and improve efficiencies across the board and can be done without investment other than that of personnel time. In addition, the actions recommended throughout the report are expected to achieve long-term cost reductions that can help to produce a strong and affordable Air Force sustainment enterprise. Some recommendations, such as those for dramatically improving the supply of spare parts and implementing an enterprise resource planning system, will require up-front investments but can result in future cost savings. Other recommendations will require up-front expenditures—for example, funding for the most pressing sustainment needs of depot plant and capital equipment—to avoid future support impacts. In summary, this report presents recommendations aimed at improving the effectiveness and efficiency of the Air Force weapon system sustainment enterprise and at driving cost reductions over the long term.