Review of the Impact of

Regulations, Policies, and

Strategies on Sustainment

INTRODUCTION

This chapter addresses element 2 of the terms of reference (TOR), that is, “Determine if any modifications in policy are required, and, if so, identify them and make recommendations for changes in Air Force regulations, policies, and strategies to accomplish the sustainment goals of the Air Force.” The committee extensively examined the regulations, policies, and strategies that affect Air Force weapon system sustainment. The sustainment process actually should begin on the day when a warfighter states, “We need a…product” and should continue until the product that evolves from that need is retired to a defense recycling center or, in the case of a weapon system, a reclamation center—often 50 years later. It is estimated that 65 percent or more of the life-cycle costs relate to supporting rather than acquiring the system. 1 Sustainment concepts should be considered alongside of required capabilities at the beginning of the acquisition cycle, but this has not always happened. Nevertheless, progress toward this goal is being made as evidenced by new congressional interest and legislation, updated Department of Defense (DoD) policies, instructions, and reports, and substantial steps by the Air Force to incorporate an enterprise perspective into the acquisition and sustainment

______________

1 Sue Lumpkins, Principal Deputy Assistant Secretary of the Air Force for Installations, Environment and Logistics. “Air Force Studies Board Sustainment Study.” Presentation to the committee, October 20, 2010.

effort. Although significant work remains, there is recognition within the Air Force that sustainment is important, complex, and expensive.

AIR FORCE SUSTAINMENT GOALS

Element 2 of the TOR states, in part, “to accomplish the sustainment goals of the Air Force.” The committee maintained a constant focus on the Air Force sustainment goals, not only for the purpose of addressing them in this report, but also because goals drive organizations. When a goal is generally understood, then there are more likely to be a common purpose and higher probability of success. In its numerous discussions with Air Force personnel, the committee posed the following questions:

- What are the sustainment goals of the Air Force?

- Who sets the goals?

- How are the goals established?

- Who knows the goals?

- How are the goals tracked and to whom are they reported?

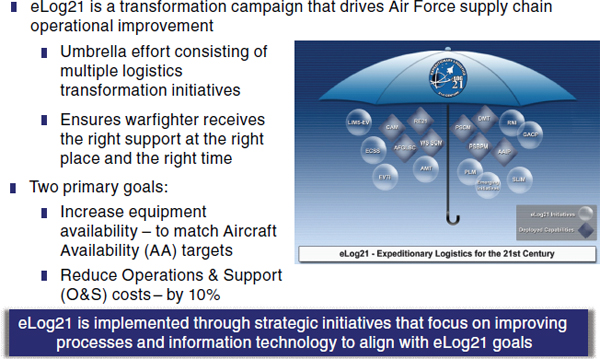

The answers were interesting to say the least. In fact, the majority of respondents were unable to respond in detail. Many talked about aircraft availability (AA), but, as discussed later in this chapter and in Chapter 4, AA is a parameter that has many complex elements.2 Overall, who is in charge of achieving AA is in question. In its search for key sustainment goals, the committee became aware of a measure for improvement over time during a briefing on Expeditionary Logistics for the 21st Century (eLog21), which is a transformational Air Force campaign to drive supply chain improvements. The essence of a goal is represented by the last two bullets in Figure 2-1.

Despite what many people appear to believe, the goals for eLog21 do not also serve as the goals for Air Force weapon system sustainment. AA is far more widely reported than cost parameters as the goal. Committee members engaged various government and industry officials in extensive discussions regarding methodologies for assessing and calculating AA as well as which officials are accountable for AA. Unfortunately, the calculation responsibilities were better defined than the target’s ownership. In fact, after thoroughly investigating AA, the committee concluded that AA ownership is vague at best and that, because there are so many “cooks in the AA kitchen,” no one can be held truly accountable. The report’s discussion of

______________

2 See, for example, the “quad chart” from: Ashton Carter, Under Secretary of Defense for Acquisition Technology, and Logistics. “Strengthened Sustainment Governance for Acquisition Program Reviews.” Memorandum for Secretaries of the Military Departments. April 5, 2010.

FIGURE 2-1

eLog21 defined. SOURCE: Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. “Expeditionary Logistics for the 21st Century (eLog21).” Presentation to the committee, January 17, 2011.

this issue is brief, because the committee found no well-established, documented, top-level sustainment goals with clear ownership for the Air Force.

Finding 2-1. The Air Force does not have (a) consistent, widely understood goal(s) for aircraft sustainment.

Recommendation 2-1. The Air Force should establish sustainment goals that are specific and can be understood by all acquisition, contracting, engineering, and sustainment professionals. The Air Force should then track these goals and hold key individuals accountable for achieving them.

STATUTES, REGULATIONS, AND POLICIES THAT

IMPACT AIR FORCE SUSTAINMENT

Overview

The complexity of the Air Force sustainment enterprise is reflected in the myriad of statutes, regulations, and policies that the Air Force must consider when

performing sustainment tasks. These include legislation that specifies the definition of depot maintenance (10 U.S.C. § 2460), types of work for the maintenance depots and core considerations (10 U.S.C. § 2464), amounts of work to be conducted in the depots, i.e., 50/50 accounting (10 U.S.C. § 2466), and funding levels to be spent on depot maintenance Capital Investment and Process Improvement, e.g., the 6 percent rule (10 U.S.C. § 2476); regulations derived from the mid-1980s’ Acquisition Reform Act and the Weapon System Acquisition Reform Act, which require major acquisition programs to have a weapon system Product Support Manager (PSM) (10 U.S.C. § 805). Additionally, legislation that affects public-private partnerships (10 U.S.C. § 2474) allows for the creation of Centers of Industrial and Technical Excellence that directly affect depot maintenance activities. These centers are designated by the Service Secretaries and offer the industrial complex the opportunity to partner with commercial industry to gain technological investment and better support future technologies. Regulations of state and federal agencies, such as the Environmental Protection Agency, Occupational Safety and Health Administration, and the Federal Aviation Administration also affect all levels of the sustainment process, including military operations around the globe. These regulations are often augmented by DoD and Air Force instructions and policies designed to facilitate interdepartmental and intra-Air Force activities and imposed on every level of maintenance, supply, and transportation operations within the Air Force. Lastly, labor agreements impact many parts of the sustainment process.

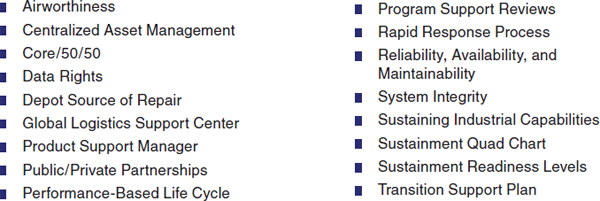

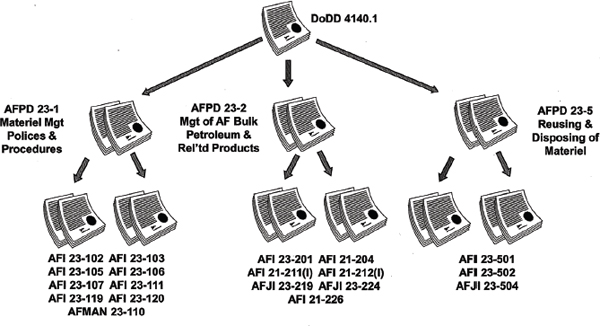

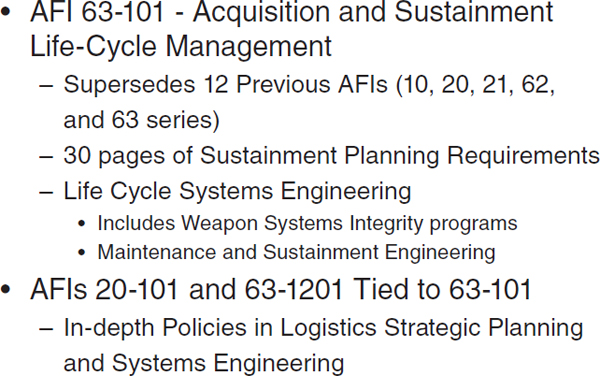

Figure 2-2 highlights the complexity of these statutes, regulations, and policies in the context of the Air Force sustainment enterprise. The realities listed in Figure 2-2 are accepted at face value as policies to be updated over time; however, they address a myriad of influences and players—statutes, policies, programs, strategies, organizations, and more. For example, the 3-year-old Air Force Global Logistics Support Center is responsible for the full spectrum of the Air Force spare parts. (Policy issues remain in the supply arena, and Chapter 4 includes significant coverage of spare parts support.)

With Centralized Asset Management, operations and maintenance funds are consolidated during the execution year to enable the Air Force as a whole to sustain the forces. Core/50/50 refers to legislation that directly affects acquisition strategies and sustainment over the weapon system life cycle. The appointment of a PSM to major programs is dictated by Section 805 of the 2010 NDAA (Weapon System Reform Act above). In fact, every “bullet” in the figure has a profound implication for sustainment. The point of the chart extends beyond the fact that the policy must be updated. The entire acquisition and sustainment environment is tightly woven and cannot be separated into individual elements without considering the effects on the whole. Even more importantly, synchronization of all of these bullets—and many other “topical bullets” like these—is a herculean task. Without well-defined

FIGURE 2-2

Sustainment policy updates to be addressed in Air Force policy. SOURCE: Blaise J. Durante, Deputy Assistant Secretary for Acquisition Integration, Office of the Assistant Secretary of the Air Force for Acquisition. “Budgeting Considerations Related to Sustainment.” Presentation to the committee, October 21, 2010.

regulations and a key commander in charge, long-term positive effects are unlikely to be achieved.

Statutes and Regulations

As stated above, numerous statutes and regulations influence the sustainment process. Throughout the study, the committee reviewed these statutes and regulations and assessed their impacts. Although the statutes principally affect depot maintenance operations and processes, there is without question a number of regulations and policies, including policies from the 1980s’ acquisition reform, that drive DoD and Air Force sustainment practices. In the acquisition area, the Service Acquisition Executive (SAE), Program Executive (PEO), and Single or System Program Manager (SPM) have primacy for decisions on a weapon system during the acquisition process. In today’s operations, it is rare that a major Air Force weapon system program does not have some type of ongoing acquisition event. Consequently, the acquisition community has a constant role in the sustainment process. The 2010 Weapon System Acquisition Reform Act directs major programs to have a PSM. By enacting this legislation, Congress has emphasized the importance of thoroughly considering sustainment in major acquisition programs just as it emphasized through other legislation the importance of the nation’s industrial depot maintenance capabilities.

Legislation affects depot maintenance operations to a large extent, beginning with a definition of depot maintenance by 10 U.S.C. § 2460. The statutory definition of depot maintenance is, at best, ambiguous and subject to interpretation.

In fact, although the definition seems to be widely accepted by most informed personnel, a review of the literature revealed that the Army, Navy, and Air Force take different interpretations of depot maintenance when conducting analyses and reporting. Different interpretations by different services directly impact the development of Core capability requirements and sustainment of workloads, as well as the military’s 50/50 calculations.3 Although the impact on the immediate sustainment process is minimal, it detracts from clear policy execution, which leads to debate on sustainment concepts for Air Force weapon systems. The general sense of those outside the Air Force is that the DoD as a whole must standardize what is and what is not depot maintenance and then report on activities accordingly.4

Because there is debate across the DoD about what is and what is not depot maintenance, it is worth asking the following questions: Does determining what is or is not depot maintenance really make a difference to the outcome of the sustainment process? Doesn’t the work need to be done regardless of what it is called? The answer to the first question is another source of great debate. Without a firm and universally accepted definition of depot maintenance, program managers will make decisions that best optimize their own programs. The answer to the second question is “Yes, however…” Including or not including the various types of work, by definition, affects Core workload determinations, which, in turn, affects maintenance capability and 50/50 work allocations and results.5 10 U.S.C. § 2464, Core Logistics Capability establishes

a requirement to maintain a core depot maintenance capability that is government-owned and government-operated (including government personnel) to ensure a ready and controlled source of technical competence and resources necessary to ensure effective and timely response to mobilizations, national defense contingency situations, and other emergency requirements.6

Core requirement determinations are exceedingly complex. The Air Force performs extensive analyses to determine the wartime taskings for its various aircraft,

______________

3 Logistics Management Institute (LMI). 2011. Future Capability of DoD Maintenance Depots. LG901M2. February. McLean, Virginia: LMI. Section 4, p. 4-2. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=394b31e6-4adc-47ca-a6f5-21547f0751fa. Accessed February 20, 2011.

4 LMI. 2011. Future Capability of DoD Maintenance Depots. LG901M2. February. McLean, Virginia: LMI. Section 1, pp. 1-18. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=394b31e6-4adc-47ca-a6f5-21547f0751fa. Accessed February 20, 2011.

5 LMI. 2011. Future Capability of DoD Maintenance Depots. LG901M2. February. McLean, Virginia: LMI. Section 4, pp. 1-19. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=394b31e6-4adc-47ca-a6f5-21547f0751fa. Accessed February 20, 2011.

6 General Military Law, U.S. Code, Title 10, Section 2472 (February 10, 2010).

the wartime depot maintenance requirements generated by the wartime surge, and then the representative types and mix of work that the depots must supply to meet the wartime surge needs. Then, applying the 50/50 rule (10 U.S.C. § 2466, Distribution of Workload), the Air Force determines the portion of depot maintenance work that can be performed outside of the organic depots, that is, by contractors.

The summary effect of these two statutes was widely discussed by many of the speakers listed in Appendix B. From a process standpoint, many speakers pointed to the effort that goes into determining Core and 50/50 management and 50/50 reporting. There is, however, a much more insidious issue: the primacy of well-intentioned PEOs and SPMs who tend to make sustainment decisions that optimize individual platforms rather than take a more enterprise perspective. For years, this primacy drove decisions that went outside the Core workload process and produced adverse 50/50 spreads. In many cases, short-term economics also drove decisions: it costs program dollars to equip depots to maintain new systems, and such investments can be reduced or eliminated by deciding to use a variety of partnering or full contractor support. This situation was further exacerbated by a lack of checks and balances over decisions that might adversely affect the Air Force sustainment environment. The Air Force Materiel Command (AFMC) Commander acknowledged that he was responsible for sustainment during the year of execution,7 but he did not identify who was responsible for enterprise-level decisions during the planning process. It appears that the inputs prior to the year of execution are not significant, but once in the year of execution, the AFMC Commander must determine how the pieces come together and how to finish the year in compliance with all of the statutes, policies, and directives.

These short-term or longer-term effects place the acquisition community and the sustainment community at great odds. Compliance with statutes conflicts with the desire to bring weapon system economics into balance and to simultaneously support the weapon system at the optimal level. The committee found that there has been no strong arbitrator for sustainment, policies on who can influence or reshape sustainment decisions have been unclear, and SPMs and PEOs have had decision-making authority. Unless an individual of great stature makes a compelling case to the SAE, the decision stands. Consequently, the Air Force has been compelled to closely analyze Core determinations to ensure that it has the capability and capacity to meet wartime needs, and today the Air Force is repeatedly on the verge of breaking the 50/50 rule. As pointed out by the LMI, the services react not to Core analysis and determination, but to the 50/50 re-

______________

7 General Donald J. Hoffman, Commander, Air Force Materiel Command, Wright-Patterson Air Force Base. Personal communication to the committee, December 9, 2010.

porting, which must be certified to the Office of the Secretary of Defense (OSD) and reported to the Congress:

As currently constructed and used, core is viewed more as a reporting requirement than a management tool. More than one senior military official stated that considerable attention was paid to the requirements to comply with 10 U.S.C. §2466, the socalled 50/50 requirement, because the results were reported to Congress, and they anticipated adverse actions for failure to comply. In contrast, core requirements received no visibility above OSD.8

When a violation of the 50/50 rule occurs, the Secretary of Defense must grant a waiver on the basis of a national security determination. The committee was repeatedly told during its visits to Headquarters AFMC, Headquarters Aeronautical Systems Center, and the Air Logistics Centers (ALCs) of the extraordinary lengths the Air Force has taken to avoid violations of the 50/50 rule. The consequences of these actions on finances, readiness, and ALC work loading are discussed in Chapter 4.

The committee discussed at length all of the statutes that affect sustainment and particularly depot maintenance and determined that the Air Force at large has not systematically dealt with Core considerations, the 50/50 workload mix, and other statutory conditions. After meeting with three congressional staffers, the committee doubts that these statutes will change substantially.9 By dealing with these statutes and leveraging U.S.C. 10 § 2474 (Centers of Industrial and Technical Excellence) to the extent possible; the Air Force can reduce some of the stressors on the 50/50 calculation. Additionally, instilling discipline into the overall sustainment determination process could help to eliminate the Core and 50/50 issues.

As dynamic as the legislation is on depot maintenance and acquisition efforts, the committee found little to no statutory language about managing materiel or the spare parts piece of the supply chain. However, the committee did find appropriate DoD instructions and policies on spare parts management and ample Air Force guidance and direction on material management. As Figure 2-3 indicates, the material management policies and instructions are extensive and considered satisfactory from the process and effect perspectives. However, the committee

______________

8 LMI. 2009. Future Capability of DoD Maintenance Depots: Interim Report. LG901M1. December. McLean, Virginia: LMI. Section 4, pp. 4-12. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=be97f304-3d15-4e96-bc24-689f8cb6c633. Accessed February 20, 2011.

9 Peter Levine, Senate Armed Services Committee, General Counsel, Readiness & Management Support Subcommittee, Majority Lead; Lynn Williams, House Armed Services Committee, Readiness Subcommittee, Majority Lead; and Vickie Plunkett, House Armed Services Committee, Readiness Subcommittee, Minority Lead. Presentation to the committee, February 16, 2011.

FIGURE 2-3

Material management. SOURCE: Major General Judith A. Fedder, Director of Logistics, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters United States Air Force. “AF Sustainment Study—Product Support, Material Management, Transportation.” Presentation to the committee, February 14, 2011.

repeatedly observed material shortages to depot repair lines and to a lesser extent field activities and was informed by depot craftsmen of decisions made for some systems to switch from contractor support to organic support. Although the policies may be acceptable, there clearly are some execution issues with regard to material management. Chapter 4 discusses parts availability.

Finding 2-2. Over the years, Title 10 of the U.S. Code, DoD, and the Air Force have issued singular “directives” that have resulted in confusion, inefficiencies, and lack of accountability in the sustainment process. Title 10 is the “law of the land,” and because it is unlikely that any “sea-state-change” will occur, the Air Force must come to grips with its provisions.

Recommendation 2-2. The Air Force should conduct a detailed holistic review of all appropriate sustainment policies and directives and build a complementary suite of processes and actions. With regard to the Title 10 mandates, the Air Force should take near- and long-term strategic actions to ensure maximum compliance. The Air Force should make long-term acquisition decisions and

ESTABLISHING AIR FORCE SUSTAINMENT POLICIES

Sustainment must be thought of as a process and operated from a “systems” perspective. Air Force sustainment policies should establish a systems approach from concept to retirement and should be based on the following:

- Engineering-based decisions with regard to the processes used to sustain an organization’s operational systems;

- A comprehensive approach to gathering and analyzing data;

- A well-defined governance structure designed to ensure compliance with the directives prescribing the sustainment processes;

- Organizational structures optimized and resourced to ensure proper leadership, training, force development, and execution of the sustainment processes;

- A culture of collaboration whereby each of the many acquisition and sustainment functions, processes, and procedures is designed with an understanding of how individual actions affect the entire Air Force warfighting enterprise; and

______________

10 Quoting, in part, 10 USC § 2466 entitled “Limitations on the Performance of Depot-level Maintenance of Materiel”: “(a) Percentage Limitation.— Not more than 50 percent of the funds made available in a fiscal year to a military department or a Defense Agency for depot-level maintenance and repair workload may be used to contract for the performance by non-Federal Government personnel of such workload for the military department or the Defense Agency. Any such funds that are not used for such a contract shall be used for the performance of depot-level maintenance and repair workload by employees of the Department of Defense.” For additional information, see http://www.law.cornell.edu/uscode/uscode10/usc_sec_10_00002466----000-.html. Accessed July 8, 2011.

11 Quoting, in part, 10 USC § 2474 entitled “Centers of Industrial and Technical Excellence: Designation: Public-Private Partnerships” and enacted November 18, 1997, by Public Law 105-58: “(1) The Secretary concerned, or the Secretary of Defense in the case of a Defense Agency, shall designate each depot-level activity of the military departments and the Defense Agencies (other than facilities approved for closure or major realignment under the Defense Base Closure and Realignment Act of 1990 (part A of title XXIX of Public Law 101-510; 10 U.S.C. 2687 note)) as a Center of Industrial and Technical Excellence in the recognized core competencies of the designee. (2) The Secretary of Defense shall establish a policy to encourage the Secretary of each military department and the head of each Defense Agency to reengineer industrial processes and adopt best-business practices at their Centers of Industrial and Technical Excellence in connection with their core competency requirements, so as to serve as recognized leaders in their core competencies throughout the Department of Defense and in the national technology and industrial base (as defined in section 2500(1) of this title [10 USCS § 2500(1)]).” For additional information, see http://www.law.cornell.edu/uscode/html/uscode10/usc_sec_10_00002474----000-.html. Accessed July 19, 2011.

- Outcome-based metrics designed to ensure appropriate availability of the operational systems to ensure mission success.

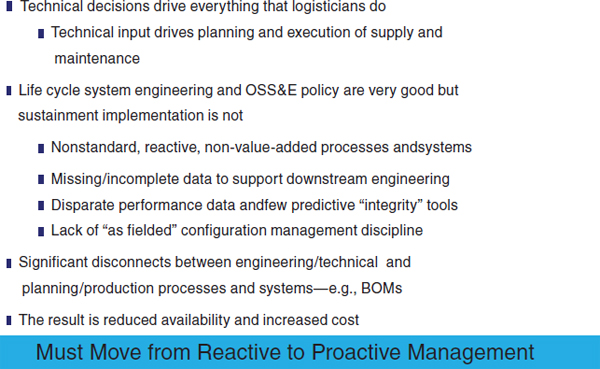

Engineering-based Decisions

As shown in Figure 2-4, the Air Force’s senior sustainment leadership has a fundamental understanding of the challenges presented by the six principles. As a starting point, “Technical decisions drive everything that logisticians do.”12 Sustainment actions proceed on the basis of engineering determinations.

When dealing with complex systems with very distinct technology advances, the DoD must be very deliberate in defining the processes it uses to determine the failure modes likely to occur in systems that are unique, highly advanced, and based on highly complex integration of leading-edge technologies. Neither the DoD nor the Air Force has adopted a single, integrated, fact-based, analysis-derived process for determining the actions necessary to ensure the integrity of operational systems throughout their life cycles even though the Air Force indicates that it has employed the Reliability Centered Maintenance (RCM) and Failure Modes, Effects and Criticality Analysis (FMECA) processes since the late 1970s.

When the Air Force engaged in major outsourcing activities during the 1990s, it did not always stipulate a standardized maintenance management concept to be used by the prospective competitors. The contractors developed individual contract processes and procedures that may or may not have followed Air Force traditional practices. Likewise, the processes to determine the tasks, procedures, and frequencies of maintenance actions to operate and sustain systems vary not only between the ALCs, but also between similar systems within the same ALC. As a result, the Air Force uses several engineering-based processes to sustain its aircraft fleet. Some are based on RCM and FMECA, some are based on the processes developed by the original equipment manufacturer (OEM), some are based on an airline-developed process known as Maintenance Steering Group Three (MSG-3), and some are based on what are best described as hybrids.13,14

As Figure 2-4 outlines, there is good life-cycle management engineering and policy, but the implementation is lacking. The results, highlighted in Figure 2-4,

______________

12 Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. Personal communication with committee members, Pentagon, Arlington, Virginia, February 14, 2011.

13 United States Air Force (USAF). 1980. Military Standard - Procedures for Performing a Failure Mode, Effects and Criticality Analysis MIL-STD-1629A. AMSC N3074. November 24. Available at http://www.everyspec.com/MIL-STD/MIL-STD+(1600+-+1699)/MIL_STD_1629A_1556/. Accessed May 2, 2011.

14 Jim Gray, Headquarters Air Force Materiel Command/Engineering Directorate, Executive Officer. Personal communication to the committee, April 11, 2011.

FIGURE 2-4

Product engineering: problem statement and gaps. SOURCE: Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. “Expeditionary Logistics for the 21st Century (eLog21).” Presentation to the committee, January 17, 2011.

are non-standard processes and ultimately “the results are reduced availability and increased cost.” During the committee’s tours of the ALCs and discussions with selected personnel at Wright-Patterson Air Force Base, the non-standard approaches were highlighted. Ultimately, the lack of a single, disciplined process by which the Air Force determines its maintenance actions puts its engineering efforts into a reactive posture, which is particularly troubling given the aging fleet the Air Force must operate now and into the future.15

Finding 2-3. The Air Force has neither a single collaborative, engineering process nor a standard process for types of aircraft to determine the appropriate

______________

15 During the study, committee members with extensive experience in sustaining civil aviation systems cited the increased efficiency of operations and effectiveness of problem resolution as a direct result of having a single collaborative, engineering methodology. In addition, committee members from the manufacturing sector, with experience in both civil and military equipment, noted the effectiveness of the Federal Aviation Administration-enforced methodology in assuring timely fleet alerts and modifications, in contrast to a less collaborative approach currently used by the Air Force.

tasks, procedures, and frequency of maintenance actions to operate and sustain its operational systems.

Finding 2-4. The Air Force does not aggressively pursue standardized engineering programs that could improve the maintenance programs for the aircraft, accelerate process improvements, and increase aircraft availability across the service.

Recommendation 2-3. The Air Force should select and deploy either a single (preferred) or standard (by type of aircraft) collaborative engineering methodology to determine the processes, procedures, tasks, and frequency of maintenance actions.

Comprehensive Approach to Gathering and Analyzing Data

Over the past four decades, the DoD and Air Force focus has shifted with regard to the basic concept used to describe how the services will gather and use data to orchestrate the sustainment processes. Although the Air Force has varied in its engineering approach to sustainment, and more specifically in its maintenance, processes, and procedures, it has developed a well-designed series of data gathering and documentation endeavors to allow for a more predictive approach in some of its more critical subsystems. For example, the Aircraft Structural Integrity Program (ASIP), the PACER CENTURY effort on early F100-PW-100 engines, and the Joint Oil Analysis Program were all designed to provide current data on the condition of an aircraft’s structural integrity, potential maintenance needs or failure of aircraft engines, or the potential failure of oil wetted systems in engines, respectively. However, there are shortcomings; for example, not all procured aircraft are equipped with a full ASIP capability. Data are captured on approximately one of six aircraft, and the condition of the remainder of the fleet is determined by extrapolations and like-mission scenarios.

Because the above endeavors showed some success and because better data automation and information management systems, such as the Core Automated Maintenance System (CAMS)/Reliability Maintenance Information System (REMIS), were implemented in the 1980s and early 1990s, the Air Force became better able to understand some aspects of a selected fleet’s condition. Over time the Air Force developed new capabilities based on not only the theoretical aspects from tabletop RCM and FMECA studies but also actual data. These new capabilities were more scientifically predictive and were known as Condition-Based Maintenance (CBM).16 The CBM concept, combined with better data efforts, enabled

______________

16 Chapter 5 contains additional discussion on CBM.

the Air Force to see its way to other new concepts such as Autonomic Logistics Information Systems. From automated and enhanced data collection, the sustainment community will realize a growth in opportunities to better understand and determine appropriate maintenance actions and consequently to greatly improve the effectiveness and efficiency of its enterprise. Unfortunately, these opportunities have not been capitalized on, and it will be some time before breakthrough efforts are fielded. Until then, the results will continue to be “best possible estimate engineering” from the best available data. Although the data have not improved substantially over the past few years, the DoD continues to espouse programs that demand even more data.

Currently, the DoD encourages the sustainment community to move toward a CBM+ concept that, similar to CBM, takes advantage of increasingly available technologies in the form of embedded sensors, mission scenarios, and external events, which can help to reduce maintenance actions to only those necessary to prevent a system, subsystem, or part failure. In theory, such a concept makes sense, but only when accompanied by rigorous, engineering-based analyses of the criticality of potential failures. The analysis must consider the consequences of predicting a failure and taking preventative maintenance actions versus performing maintenance actions after a failure occurs. Furthermore, CBM+ requires an investment to develop the specific technology for the specific platform and then install the capability across the fleet.

As outlined above, the processes used to determine appropriate maintenance and sustainment actions are engineering-based, have evolved over the past four decades, and are fully integrated in the commercial aviation world. However, the Air Force has not been able to apply the latest techniques to the legacy aircraft. In an environment of increasing sustainment costs, as discussed in Chapter 3, the Air Force’s inability to advance to a data-based engineering solution for sustainment activities is of particular concern.

Current Governance Structure for Air Force Sustainment

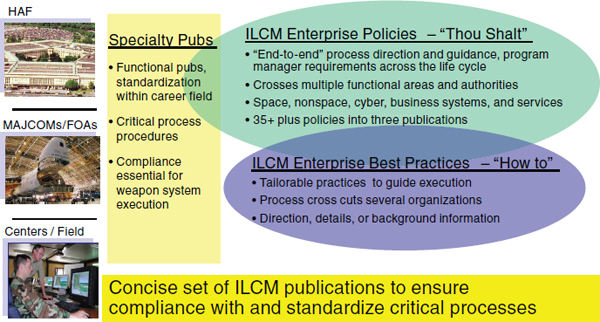

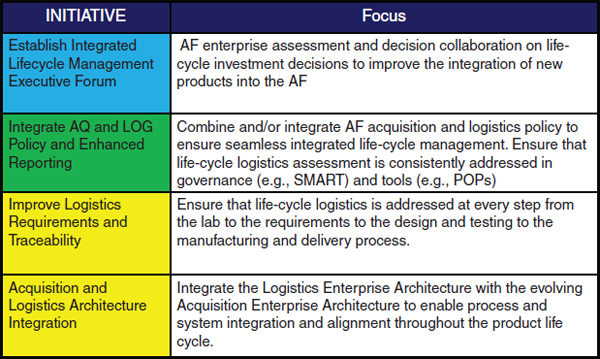

The governance of the sustainment enterprise is complex and involves many organizations, all of which have vested interests in the processes, procedures, and outcomes. The centerpiece of the sustainment strategy is founded on the concept of an Integrated Life-Cycle Management (ILCM) enterprise. Laudably, the Air Force acquisition and sustainment communities are working together and embrace the concept shown in Figure 2-5.17

______________

17 Blaise J. Durante, Deputy Assistant Secretary for Acquisition Integration, Office of the Assistant Secretary of the Air Force for Acquisition. “Budgeting Considerations Relating to Sustainment.” Presentation to the committee, October 20, 2010.

FIGURE 2-5

The concept behind the Integrated Life-Cycle Management (ILCM) enterprise. SOURCE: Blaise J. Durante, Deputy Assistant Secretary for Acquisition Integration, Office of the Assistant Secretary of the Air Force for Acquisition. “Budgeting Considerations Related to Sustainment.” Presentation to the committee, October 21, 2010.

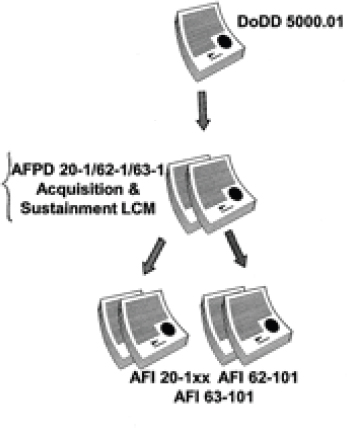

The integrated life-cycle concept is being codified by a single Air Force Instruction (AFI) 63-101. To properly define this effort, the Air Force has begun the process of combining into a single document the various functional directives previously designed to control the governance and policies of the various communities contributing to the sustainment processes. The introduction to this document states:

This instruction must be used in conjunction with Air Force Instruction (AFI) 10-601, Capabilities-Based Requirements Development, AFI 99-103, Capabilities Based Test and Evaluation, AFI 63-1201, Life Cycle Systems Engineering, and AFI 20-101, Logistics Strategic Planning Procedures, to provide an integrated framework for the implementation of ILCM.18

Figure 2-6 shows the Air Force product support on ILCM. AFI 63-101 clearly states the need to integrate the efforts of the various functional elements that contribute to the ILCM enterprise. As the above quote shows, ILCM encompasses requirements, test, systems engineering, and sustainment, and, by its very framework, acquisition. The ILCM enterprise’s primary mission is to provide seamless

______________

18 USAF. 2009. Acquisition and Sustainment Life Cycle Management. April 8. Available at http://www.e-publishing.af.mil/shared/media/epubs/AFI63-101.pdf. Accessed August 18, 2011.

FIGURE 2-6

Product support. SOURCE: Major General Judith A. Fedder, Director of Logistics, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters United States Air Force. “AF Sustainment Study—Product Support, Material Management, Transportation.” Presentation to the committee, February 14, 2011.

governance, policy, transparency, and integration of all aspects of weapon system acquisition and sustainment. Figure 2-7 demonstrates the effort to consolidate the various policies into one that is applicable to all communities. No longer will one community be able to assert that what is in another community’s instructions does not apply to its respective effort. This is a very positive step; however, many remaining issues affect the sustainment process.

Despite the challenges presented by the statutes, policies, and processes and the ever-evolving and never-settling engineering and data efforts described above, the senior members of the Air Force sustainment community understand their plight and are working to improve the sustainment enterprise. To this end, over the past several years, sustainment professionals have developed an overarching strategy called Expeditionary Logistics for the 21st Century (eLog21)—a compendium of governance, policies, processes and information that will be used for enterprise optimization. See Figure 2-1, which depicts the comprehensive nature of the eLog21 strategy. Its far-reaching goals will demand greater cooperation and integration

FIGURE 2-7

Ongoing effort to consolidate the various policies. SOURCE: Colonel Kurt Hall, Deputy Director, Engineering and Technical Management Directorate, Headquarters Air Force Materiel Command, Wright-Patterson Air Force Base. “AFMC/EN Brief to the Air Force Studies Board.” Presentation to the committee, December 8, 2010.

across the Air Force requirements, acquisition, engineering, and sustainment communities than in the past.

In addition, the Air Force’s effort will have to fully permeate from the headquarters level to the execution levels. As shown in Figure 2-8, the eLog21 strategy is transformational and will require an extraordinary amount of procedural governance and discipline to achieve the envisioned integration of effort.

The details in Figure 2-9 clearly show that the each of the initiatives listed on the left has ample, detailed process flow information that will drive toward execution and completion. Other important initiatives have similarly detailed information charts.

With the ILCM instruction and the eLog21 initiative ongoing, Headquarters Air Force has established an Integrated Life Cycle Management Executive Forum, co-chaired by the Assistant Secretary of the Air Force for Acquisition (SAF/AQ) and the Assistant Secretary of the Air Force for Installations, Environment and Logistics (SAF/IE). Interestingly, depending on where a system is in its lifecycle, either SAF/ AQ or SAF/IE has “51%” of the vote with regard to management and resource allocation decisions. This co-chair approach will go a long way to ensuring that

FIGURE 2-8

eLog21 Campaign plan. SOURCE: Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. “Expeditionary Logistics for the 21st Century (eLog21).” Presentation to the committee, January 17, 2011.

FIGURE 2-9

Product support initiatives. SOURCE: Grover L. Dunn, Director of Transformation, Deputy Chief of Staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force. “Expeditionary Logistics for the 21st Century (eLog21).” Presentation to the committee, January 17, 2011.

sustainment considerations are made a more important part of the development process for a new weapon system, which is clearly mandated in DoD Instruction 5000.02 and strongly recommended in the 2009 DoD Weapon System Acquisition Reform Product Support Assessment report.

Often during the course of the study, the opinion arose that the sustainment concept and strategy should be moved to much earlier in the acquisition process, that is, brought forward to the Milestone “A” Defense Acquisition Board decision. In fact, the DoD acquisition directive states the same, and the ILCM Executive Forum will help the Air Force ensure compliance with the directive. Furthermore, the DoD Weapon System Acquisition Reform Product Support Assessment and the LMI Future Capability of DoD Depot Maintenance reports comment on the state of acquisition and sustainment decisions and make recommendations for tighter controls and earlier sustainment considerations in the acquisition process, including making sustainment considerations a Milestone A exit criteria.19,20 Under the eLog21 umbrella, the sustainment community works the Logistics Requirements Traceability initiative, which maps gaps and entry points to insert sustainment considerations into the early stages of the acquisition effort. This is another major step forward to ensuring that sustainment is considered as early as Milestone A in the acquisition process. The Executive Forum represents a significant advancement in governance, and the Air Force is to be commended for establishing this group. However, the committee found no factual evidence that the Air Force has a designated commander with responsibility for looking well beyond the year of execution to demand decision making that will leave the future Air Force in compliance with the earlier described statutes, regulations, and policies and with appropriately balanced and standardized long-term execution of the Air Force’s sustainment directives. Clearly, the responsibility for developing Air Force policy rests with the Secretary of the Air Force. AFI 63-101 states that the Assistant Secretary of the Air Force for Installations, Environment and Logistics (SAF/IE) will:21

Provide strategic logistics oversight for life cycle support; develop strategic level logistics, installations, and environmental policy for life cycle support; and provide vertical and horizontal integration of ILCM policies to provide for standardization and compliance

______________

19 DoD. 2009. DoD Weapon System Acquisition Reform Product Support Assessment. November. Washington, D.C.: Office of the Under Secretary of Defense for Acquisition, Technology, and Logistics. Available at https://dap.dau.mil/career/log/blogs/archive/2010/01/28/implementation-ofdod-weapon-system-acquisition-reform-product-support-assessment-psa-recommendations.aspx. Accessed November 22, 2010.

20 LMI. 2011. Future Capability of DoD Maintenance Depots. LG901M2. February. Mc:ean, Virginia: LMI, p. v. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=394b31e6-4adc47ca-a6f5-21547f0751fa. Accessed February 20, 2011.

21 USAF. 2009. Acquisition and Sustainment Life Cycle Management. April 8. Available at http://www.e-publishing.af.mil/shared/media/epubs/AFI63-101.pdf. Accessed August 18, 2011.

mechanisms across the Enterprise. Ensure functional policies as requested are communicated to the field. (p. 29)

Somewhat paradoxically, the same instruction states that the Headquarters Air Force/Directorate of Logistics will:

Develop policy and issue AF implementation guidance for logistics support capabilities to ensure weapon system readiness for the user consistent with statutes, executive orders, and DOD issuances. Ensure functional policies as requested are communicated to the field. (p. 31)

The SAE authority for acquisition programs will not change, and the Assistant Secretary of the Air Force/Acquisition (SAF/AQ) is clearly the policy maker and executor for acquisition programs. AFI 63-101 also states that the SAF/AQ will

Serve as the Service Acquisition Executive (SAE) as delegated for non-space AF programs and execute responsibilities as the senior corporate operating official for non-space acquisition. Execute SAE responsibilities outlined in the DOD 5000-series for execution of non-space AF acquisitions. For purposes of defining SAE responsibilities, this includes lifecycle acquisition of non-space systems and services processes from pre-Milestone A to weapon system retirement. This includes research, development, test, evaluation, production, and delivery of new systems, or significant modifications to existing systems. Management responsibility flows directly, without intervention, from the SAE and Milestone Decision Authority to the Program Executive Officers (PEOs) to the System Program Managers (SPMs). (p. 24)

Interestingly, these excerpts from the policy document do not use the terms sustainment or product support, but it is promising that they do use the term life cycle. Furthermore, the policy does not designate a single individual or commander as the sustainment or product support lead with responsibility for looking across the entire acquisition and sustainment enterprise (operational commands, in addition to the AFMC and the Defense Logistics Agency) and with authority for conducting future critical planning efforts, developing the execution details, standardizing engineering tools, and developing the sustainment equivalent of “operational tactics, techniques, and procedure.” To ensure that AFI 63-101 is adhered to, the well thought out principles and processes of eLog21 are executed, and the significance of sustainment responsibilities are well represented, the Air Force should designate a field organization and commander as responsible for long-term sustainment planning and progression as well as for year of execution decision making. Without such a designation, the governance structure necessary to implement the lofty goals of eLog21 will drift, sustainment results in the out years will continue to be sub-optimized, and the Air Force will likely not achieve

the eLog21 objectives, perceived sustainment goals, or the efficiencies mandated by fiscal year 2012 efficiency considerations.

Ironically, there is a need for some flexibility in the military environment. Therefore, as the committee discussed the issues associated with a senior sustainment commander, it recognized that there must be room for adjustments across the diverse operations. The committee believes that the sustainment enterprise would best work with strong centralized policy, procedures, and practices determined by the SAF/AQ, AF/A4/7, and the sustainment commander. When these are in place with the appropriate metrics, decentralized execution should be allowed to occur and performance reflected in the metrics.

Finding 2-5. The Air Force’s eLog21 is an impressive umbrella effort encompassing multiple logistics transformation initiatives designed to help move the Air Force sustainment and acquisition communities toward an ILCM construct.

Finding 2-6. The SAF/IE, SAF/AQ, and AF/A4/7 effort to consolidate the key Air Force policy directives (AFPDs) dealing with acquisition and sustainment into a single AFPD is an important and positive step toward creating an ILCM culture in the Air Force. However, the Air Force has not yet completely developed the top-to-bottom governance structure, policies, and procedures necessary to achieve the ILCM objectives across the acquisition and sustainment enterprise.

Finding 2-7. It is not clear who has been designated as the sustainment process and product owner with authority to develop processes, advocate for enterprise sustainment interests, and assure balance in planning and execution of sustainment resources.

Recommendation 2-4. The Air Force should consider formally designating a senior commander, such as the AFMC, as the commander of the entire sustainment process, from concept phase through system retirement, with the responsibility to advise SAF/IE, SAF/AQ, and AF/A4/7 on policy and then train, organize, equip, plan, and execute the Air Force’s ILCM processes.

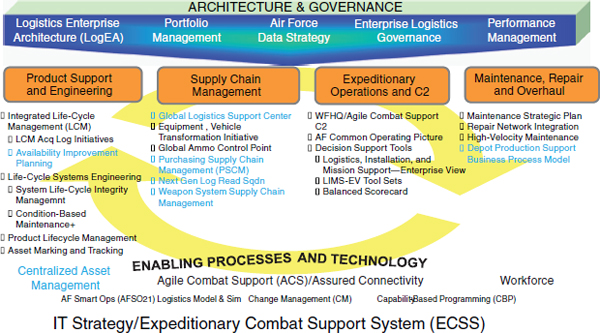

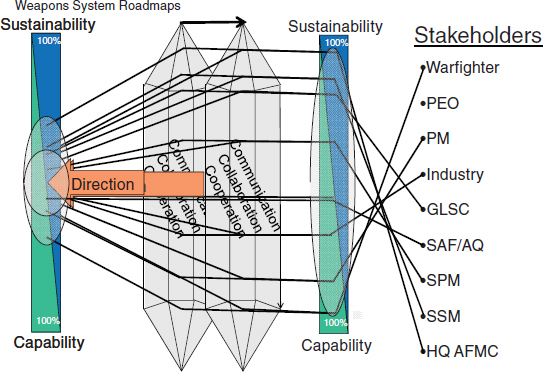

Current Air Force Organization Complexities for Collaboration

Throughout the study, the question “Who is in charge of sustainment?” was repeatedly posed. As Figure 2-10 shows, there are numerous stakeholders in the Air Force sustainment enterprise. The organization is too complex for just a single program, let alone multiple programs. In fact, the organizational structure is so

FIGURE 2-10

Focus the enterprise. GLSC, (Air Force) Global Logistics Support Center; HQ AFMC, Headquarters Air Force Materiel Command; PEO, Program Executive Office; PM, Program Manager; SAF/AQ, Assistant Secretary of the Air Force (Acquisition); SPM, System Program Manager; SSM, System Support Manager or System Sustainment Manager. SOURCE: Brigadier General Arnold W. Bunch, Jr., Director and Program Executive Officer for the Fighters and Bombers Directorate, Aeronautical Systems Center, Wright-Patterson Air Force Base. “ASC/WW (Fighter/Bomber PEO).” Presentation to the committee, December 8, 2011.

complex that collaboration, although essential, is unlikely to achieve repeatable successes. An accredited sustainment commander would be able to ensure appropriate streamlining and trans-organization coordination with significantly more effective results.

Outcome-based Metrics

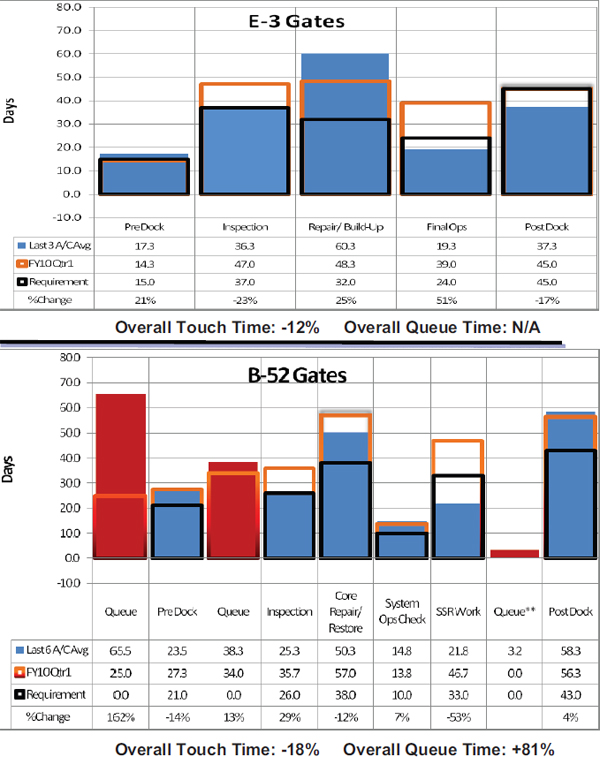

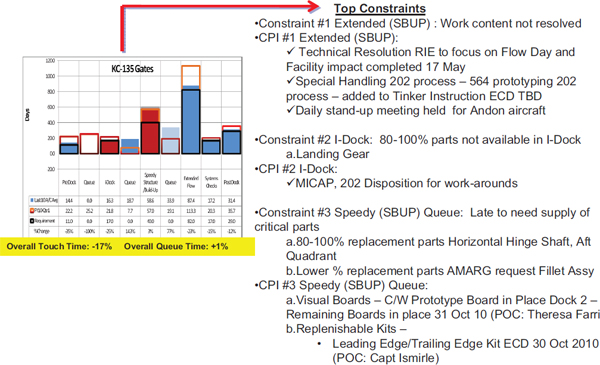

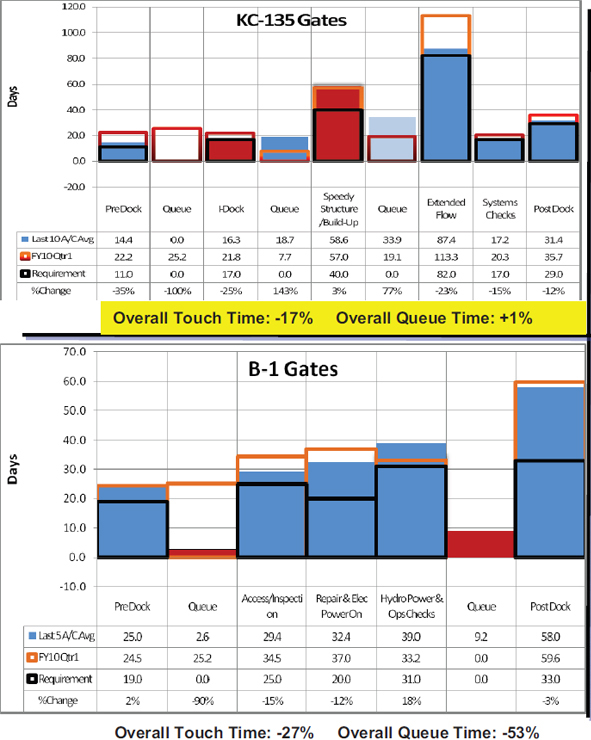

At this stage in the chapter, five of the six criteria for an effective sustainment effort have been discussed. The logical remaining element is metrics for measuring and reporting on how the system and the processes are working. At the beginning of the chapter, the committee explained that the Air Force does not appear to have specified an overarching, outcome-based, measurable goal for the sustainment process. The committee did observe, however, the use of metrics across the sustainment enterprise. In fact, many very good metrics report on the various processes, and many focus on outcomes. Figures 2-11 and 2-12 illustrate the tracking of aircraft depot maintenance at Oklahoma City Air Logistics Center (OC-ALC). Figure

FIGURE 2-11

The performance of a detailed top-level metric against an expected standard and an outcome-based expectation. SOURCE: Major General Bruce A. Litchfield, Commander, 76th Maintenance Wing, Oklahoma City Air Logistics Center, Tinker Air Force Base. “76 MXW Production Machine.” Presentation to the committee, January 11, 2011.

2-11 represents the performance of a detailed top-level metric against an expected standard and an outcome-based expectation. Figure 2-12 represents a “drill down” and analysis of the KC-135 product line covered in Figure 2-11.

As the committee studied these many metrics, it repeatedly asked if they build toward an overall assessment of the Air Force sustainment enterprise. In the end, the committee concluded that the metrics are well employed at the lower echelons of the organization, but they do not contribute to an overall assessment of the Air Force sustainment enterprise.

Finding 2-8. The Air Force sustainment enterprise employs extensive metrics to assess processes and performance, but these metrics do not build to an overall assessment of the Air Force sustainment enterprise.

Recommendation 2-5. The Air Force should develop and implement weapon system-level metrics that set AA levels and the cost of providing that availability, as well as identify who is responsible for attaining both. Furthermore, these measures should be at a level that reflects sustained implementation of process improvement initiatives, such as cost-reduction incentives and not just increasing sustainment costs driven by aircraft aging.

PAST, PRESENT, AND POTENTIAL FUTURE

STRATEGIES FOR AIR FORCE SUSTAINMENT

The committee gave serious consideration to all aspects of the term “strategies” with respect to Air Force sustainment and determined that the strategies are interwoven and are the results—different from outcomes—of the statutes, regulations, and policies. From extensive interactions with Air Force officials, it became apparent that the strategies the Air Force either has in place, or desires to achieve, are designed to cope with the previously discussed statutes and policy constraints. For example, eLog21 is a strategy to shape processes and focus Air Force sustainment efforts on sustainment concepts and on producing a positive enterprise outcome (AA and cost) for the Air Force. Yet, the concept of how to gain an enterprise outcome for the direct support of weapon systems is a key part of the strategy equation. According to briefs from SAF/AQ, SAF/IE, AF/A4/7 and presentations from AFMC, enterprise weapon system support strategies are presently undefined and over the past 15 years have been program versus enterprise driven. These sustainment strategies range from total contractor support, to hybrid support from contractor and organic sources, to total government support. During these same discussions, it was noted how costly contractor support concepts are, but, at the same time, references were made to the positive outcome of the contractor support

concepts. Strategies were examined from the perspective of how the Air Force got to this state and what have been the true results.

As a part of its acquisition reform strategies in the early to mid-1990s, the DoD consciously selected operational systems to be entirely sustained (at least above the organizational level of support) by the commercial/contractor world. The Air Force already had been successful in sustaining some of its operational systems through Contractor Logistics Support (CLS), such as most of Air Education and Training Command’s training aircraft, most of the operational support aircraft (of which there are at least 25 different types),22 and the KC-10 tanker. Therefore, the Air Force initiated transitions of more systems to contactors, such as the C-17 under a Total System Performance Requirement (TSPR) contract followed by a CLS arrangement, or the mature F-117 system to a Total System Support Requirement (TSSR), which usually resulted in superior performance plus or minus the quality of the initial statement of work, defined metrics, and clear incentives. Missing from the equation was a balance between performance and cost: Although performance was generally considered excellent, the data were often owned by OEMs, and therefore future competitions were limited at best, and the cost factor appeared, to many individuals, to be expensive.

As these sustainment methodologies were designed and implemented, they fell neatly into line with the overall and emerging DoD preferred sustainment strategy known as Performance Based Logistics (PBL).

The poster child of this latter approach (and by policy, DoD’s preferred sustainment concept) is called Performance Based Logistics, more commonly referred to by its acronym PBL. PBL was and is transformative. Jacques Gansler, Under Secretary of Defense for Acquisition, Technology, and Logistics, from 1997 to 2001 described the context of what needed transforming at that time: …to reverse this trend—with current short-term needs consuming an ever-increasing “share of the pie” at the expense of longer-term military capability—will be extremely difficult. I have called this situation a “death spiral;” and, in fact we will come to that…if we do not act decisively, now. It will require significant cultural change, a sense of urgency, and difficult program funding decisions. The result may be that we will have to put some sacred cows out to pasture—not just keep trying to milk them.23

It seems as though these findings are as true today as they were then.

As it turned over the sustainment of many of its systems to contractors, and in keeping with the general PBL philosophy, the Air Force moved to an outcome-

______________

22 Please see Tinker Air Force Base’s Force Development Division, Oklahoma City Air Logistics Center website. Available at http://www.tinker-af.org/. Accessed May 4, 2011.

23 DoD. 2009. DoD Weapon System Acquisition Reform Product Support Assessment. November. Washington, D.C.: Office of the Under Secretary of Defense for Acquisition, Technology and Logistics, p. 8. Available at https://dap.dau.mil/career/log/blogs/archive/2010/01/28/implementation-ofdod-weapon-system-acquisition-reform-product-support-assessment-psa-recommendations.aspx. Accessed November 22, 2010.

based concept. In doing so, the Air Force did not always stipulate the needs for individual contractors to use data gathering and analysis systems that would be compatible with Air Force systems, for specific engineering processes to continually review the fleet status, and for altering maintenance and sustainment processes, as well as the Technical Orders. The Air Force did not always have a contract for access to second- and third-level of engineering and manufacturing data and the details necessary to understand the materiel management and/or maintenance management status with regard to contractor-sustained operational systems. Having the proper data is essential to determining a contractor and Air Force blended work-sharing approach.

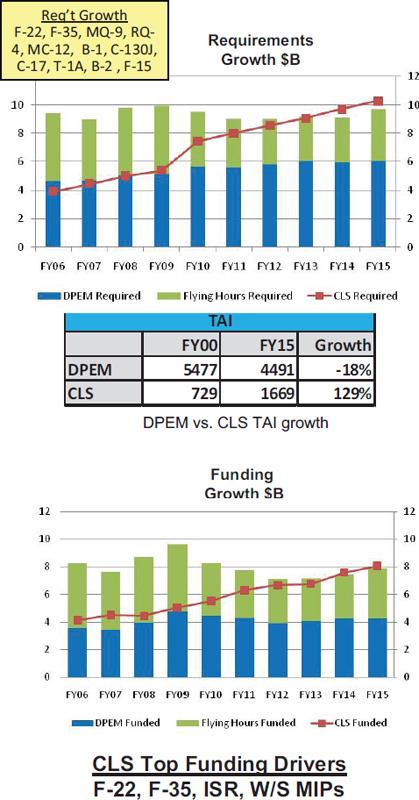

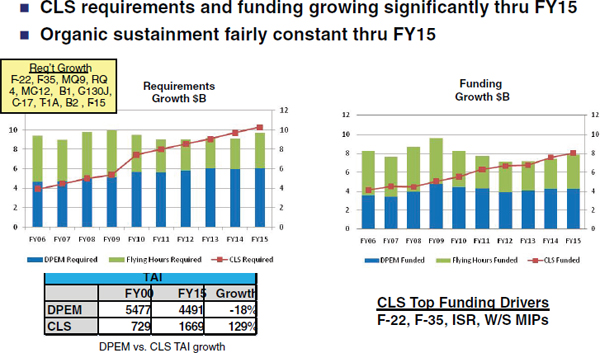

As time went on, and as the Air Force altered the statements of work to fine tune/reduce the costs of operating the systems, it found re-competitions to be very challenging—if not impossible—because it did not have command of the data used by the incumbent (often OEMs) to sustain the systems. This effort to transition to different contractors or to bring maintenance efforts under organic support has suffered several fits and starts during the past 10 years. As shown in Figure 2-13, the Air Force is reaching the conclusion that contractor support arrangements are prohibitively expensive.24 This is one perspective, but the committee has observed a different perspective.

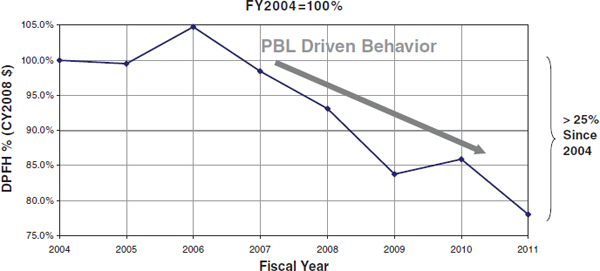

Although the resources did not exist to extensively examine the cost versus effectiveness trade-offs, the available data indicated that the true challenge is in ensuring that comparisons of effectiveness and efficiency are objective. For example, the data presented in Figure 2-14, adjusted as noted, indicate that compared to other organically supported and contractor-supported platforms, the C-17 offers tremendous performance.25

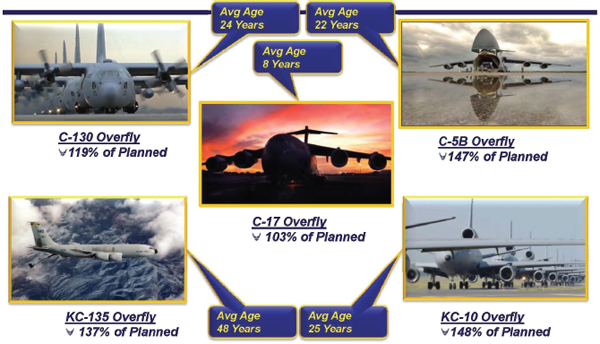

Figure 2-15 depicts the performance of the C-17 in terms of reductions in cost per flying hour. These reductions were due to several factors, including more aircraft and more flying hours to cover fixed costs and changes in contract structure and performance standards. Although these data elements are important and accurate, a true measure of performance also must account for the platform’s effectiveness. Figure 2-16 illustrates the demand on this high-value aircraft system as well as all Air Mobility Command aircraft.

The C-17 is the workhorse of the air mobility fleet and is in constant demand. Of course, the Air Force has finite resources, but concerns about sustainment costs must be weighed against what is being delivered in terms of capability. Further-

______________

24 Deborah K. Tune, Principal Deputy Assistant Secretary of the Air Force for Installations, Environment and Logistics, Office of the Assistant Secretary of the Air Force for Installations, Environment and Logistics. “Air Force Studies Board Sustainment Study: Developing the Right Product Support Concepts for the Future.” Presentation to the committee, October 10, 2011.

25 The “assumptions” for the costs associated with Figure 2-15 are much different from the assumptions made with Figure 3-6.

FIGURE 2-13

Organic versus contract sustainment. SOURCE: Debra K. Tune, Principal Deputy Assistant Secretary of the Air Force for Installations, Environment and Logistics, Office of the Assistant Secretary of the Air Force for Installations, Environment and Logistics. “Developing the Right Product Support Concepts for the Future.” Presentation to the committee, October 20, 2010.

FIGURE 2-14

Change in weapon system cost from FY2004 to FY2009. SOURCE: Mark Angelo, Director, C-17 GSP Operations and Site Lead, The Boeing Company; Robert Tomilowitz, Executive Director, Supply Chain Management and Support Equipment, The Boeing Company; and Richard (Skip) Whittington, Senior Manager, C-17 GSP Business Development, Boeing Defense, Space & Security. “C-17 Globemaster III Sustainment Partnership.” Presentation to the committee, January 18, 2011. Personal communication with the committee by the C-17 program office personnel who confirmed the accuracy of the data. Personal communication by the committee with Gustavo Urzua, The Boeing Company, who acknowledged that the data source was the Air Force total ownership cost database.

more, the 2009 DoD Weapon System Acquisition Reform Product Support Assessment analyzed partnering strategies and stated:

While there are a range of indicators resulting from the maturity assessments and root-cause analysis, the weapon system data analysis clearly shows that performance-based (outcome-based) product support strategies, particularly when coupled with government-industry partnering approaches, have consistently delivered improved materiel readiness across numerous weapon system applications over the past decade. Cost benefits are more difficult to assess; as cited in several GAO [Government Accountability Office] reports, many outcome-based support strategies have claimed cost reductions and cost avoidance, but DoD financial systems lack the visibility and fidelity to validate these benefits consistent with audit standards. In summary, performance-based product support strategies consis-

FIGURE 2-15

C-17 Global Sustainment Partnership (GSP): Dollars per flight hour (DPFH) reductions FY2004-FY2011. SOURCE: Mark Angelo, Director, C-17 GSP Operations & Site Lead, The Boeing Company; Robert Tomilowitz, Executive Director, Supply Chain Management and Support Equipment, The Boeing Company; and Richard (Skip) Whittington, Senior Manager, C-17 GSP Business Development, Boeing Defense, Space & Security. “C-17 Globemaster III Sustainment Partnership.” Presentation to the committee, January 18, 2011.

FIGURE 2-16

Demand on mobility fleet FY2002-FY2009. SOURCE: Timothy Thomas, Deputy Chief, Maintenance Division, Headquarters Air Mobility Command. “AMC/A4 Perspective.” Presentation to the committee, October 21, 2010.

tently deliver improved materiel readiness, but assessing the true cost of both traditional (transactional) and performance-based strategies is difficult, if not impossible, given current financial systems.26

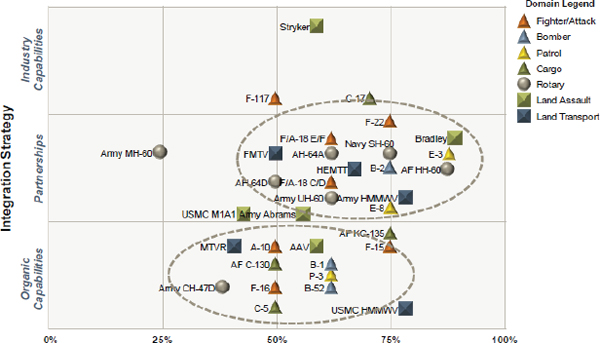

Additionally, as Figure 2-17 shows, strong performance factors are derived from partnering relationships. Cost is always a factor, but the partnerships must capitalize on each of the partners’ strengths and deliver an outcome to the warfighter that is both highly effective and efficient. In striving to deliver effectiveness and efficiency, the DoD and Air Force must consider external factors that affect sustainment strategies, largely the legislative provisions of Title 10 of the U.S. Code. At the same time, 10 U.S.C. § 2474 offers significant relief by allowing the Air Force to establish partnering relationships between maintenance depots and contractors in the form of Centers of Industrial and Technical Excellence. Although this provision has existed since November 1997,27 only 1 percent of the Air Force’s depot maintenance work is conducted by public-private partnerships.28 The intent of the Congress in passing this legislation was to allow Centers of Industrial Technologies and Excellence—Air Force depot maintenance facilities, in this case—to partner with industry and share work in the government facilities where both could gain work and the government facilities could gain technology enhancements to allow them to take on future work. The workload is taken out of the 50/50 calculations.

______________

26 DoD. 2009. DoD Weapon System Acquisition Reform Product Support Assessment. November. Washington, D.C.: Office of the Under Secretary of Defense for Acquisition, Technology and Logistics, p. 11. Available at https://dap.dau.mil/career/log/blogs/archive/2010/01/28/implementation-ofdod-weapon-system-acquisition-reform-product-support-assessment-psa-recommendations.aspx. Accessed November 22, 2010.

27 Quoting, in part, 10 USC § 2474 entitled “Centers of Industrial and Technical Excellence: Designation: Public-Private Partnerships” and enacted November 18, 1997, by Public Law 105-58: “(1) The Secretary concerned, or the Secretary of Defense in the case of a Defense Agency, shall designate each depot-level activity of the military departments and the Defense Agencies (other than facilities approved for closure or major realignment under the Defense Base Closure and Realignment Act of 1990 (part A of title XXIX of Public Law 101-510; 10 U.S.C. 2687 note)) as a Center of Industrial and Technical Excellence in the recognized core competencies of the designee. (2) The Secretary of Defense shall establish a policy to encourage the Secretary of each military department and the head of each Defense Agency to reengineer industrial processes and adopt best-business practices at their Centers of Industrial and Technical Excellence in connection with their core competency requirements, so as to serve as recognized leaders in their core competencies throughout the Department of Defense and in the national technology and industrial base (as defined in section 2500(1) of this title [10 USCS § 2500(1)]). For additional information, see http://www.law.cornell.edu/uscode/html/uscode10/usc_sec_10_00002474----000-.html. Accessed July 19, 2011.

28 LMI. 2011. Future Capability of DoD Maintenance Depots. LG901M2. February. McLean, Virginia: LMI, pp. 4-15. Available at http://armedservices.house.gov/index.cfm/files/serve?File_id=394b31e6-4adc-47ca-a6f5-21547f0751fa. Accessed February 20, 2011.

FIGURE 2-17

Partnering strategies produce higher sustained readiness improvement. Notes: 1. Sustained Readiness Improvement is the number of years over the span of 1999 through 2007 where a weapon system saw no decline in availability or saw a decline of lesser magnitude than the domain average. 2. F-22, FMTV, MTVR, and Stryker data do not span from 1999 through 2007 due to their newness. 3. USAF C-130 APU contract awarded to Honeywell in August 2007. Not enough time has occurred yet to include it as a partnership for this evaluation. SOURCE: DoD. 2009. DoD Weapon System Acquisition Reform Product Support Assessment. November. Washington, D.C.: Office of the Under Secretary of Defense for Acquisition, Technology and Logistics. Available at https://dap.dau.mil/career/log/blogs/archive/2010/01/28/implementation-of-dod-weapon-system-acquisition-reform-product-support-assessment-psa-recommendations.aspx. Accessed November 22, 2010.

Finding 2-9. The Air Force has used a variety of sustainment practices for new weapon systems and major modifications on older weapon systems without due consideration of their impacts on the sustainment enterprise. This has resulted in a wide diversity of sustainment practices and difficulty in tracking and understanding true sustainment costs.

Recommendation 2-6. The Air Force should develop and direct a sustainment execution model for weapon systems and major weapon systems modifications that balances the needs of the individual weapon system with the performance goals and cost constraints of the overall sustainment enterprise.

A BENCHMARK: PROCESSES AND POLICIES OF

THE NAVAL AVIATION ENTERPRISE

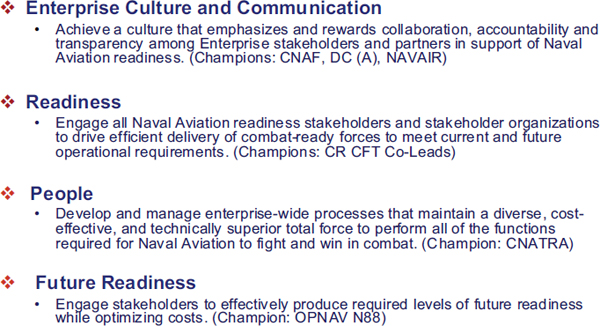

There are, indeed, wide differences in organization, size, and culture between the United States Navy (USN) and the Air Force aviation communities.29 The committee elected to examine how the Navy conducts sustainment operations. The committee did so briefly, not knowing what it would find, but recognizing that benchmarking—good or bad—affects thought processes. The Navy faced challenges in the late 1990s and early 2000s much like those faced by the Air Force today—in terms of readiness, support, and understanding and controlling costs. As a result, the Navy initiated a complete review of, and revision to, its approach to aviation readiness and sustainment. Simply put, the Navy focused on strategic outcomes—readiness and cost—or, in other words, “Be ready, control consumption.”

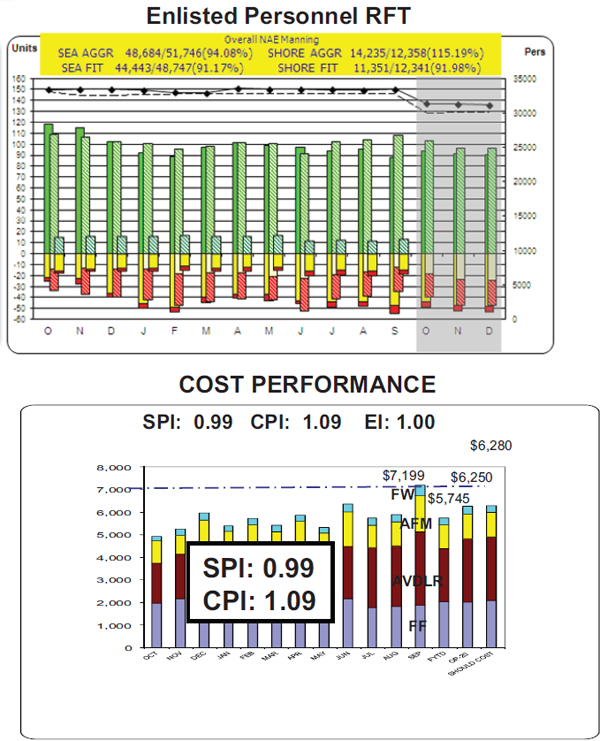

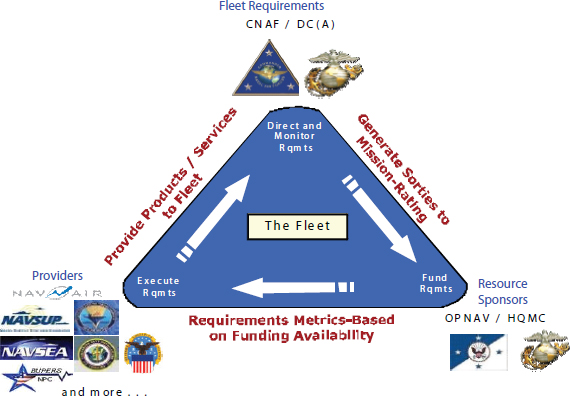

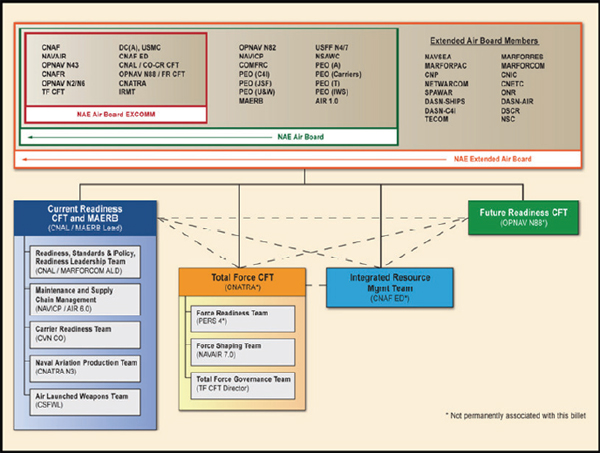

This review was necessitated by the observation of the Chief of Naval Operations that principal performance indicators for the aviation community were consumption oriented and had no value in measuring readiness.30 In addition, only limited performance indicators existed to provide Navy leadership with information about the cost-effectiveness of existing actions to provide readiness, establish outcome-based budget requirements, and manage operational results. In essence, readiness was not adequately, or appropriately, defined or measured in terms of its contribution, performance, and cost, relative to the Navy’s goals.31 As a result of the review, Naval Aviation was aligned into the Naval Aviation Enterprise (NAE). The NAE represents a behavior model focused on the warfighter as the Single Process Owner (SPO), with Navy resource and provider organizations in subordinate roles.32Figures 2-18 and 2-19 provide graphic portrayals of the NAE.

At the apex of the pyramid is the operational commander or supported commander who sets the tempo for the overall operation and is in fact the NAE commander. The many providers who support the commander are on the left-hand leg. The resource sponsors, who provide the resources to conduct operations, are on the right-hand leg. Interestingly, although the acquisition arm is under the Naval Air Systems command and is a force supporter, the maintenance depots and

______________

29 Appendix C, Navy Enterprise Transformation, provides additional details on the naval Aviation Enterprise.

30 USN. 2007. Navy Enterprise Transformation: Working for the Greater Good, pp. 3-6. May. Available at http://www.thomasgroup.com/getdoc/7c79c3c9-8603-4908-ad89-0ebb0e10a67f/NavyEnterprise-Transformation.aspx.

31 Ibid.

32 A similar positive relationship is discussed in Chapter 6 on page 6-29 where the triad of the FAA + OEM + Operator is established in the commercial aviation sector to achieve what the Navy implemented in the NAE. More specifically, the arrangement brings together the key elements of operating a fleet, including sustainment, to achieve an enterprise solution.

FIGURE 2-18

Strategic objectives of the Naval Aviation Enterprise (NAE). SOURCE: Captain Mike Kelly, Commander, Naval Air Forces (CNAF), Force Material, Maintenance and Readiness. “COMNAVAIR.” Presentation to the committee, January 17, 2011.

FIGURE 2-19

NAE’s enterprise framework. SOURCE: Captain Mike Kelly, Commander, Naval Air Forces (CNAF)1, Force Material, Maintenance and Readiness. “COMNAVAIR.” Presentation to the committee, January 17, 2011.

operational-level maintainers directly report to the commander of the Naval Air Forces even though they are providers.33

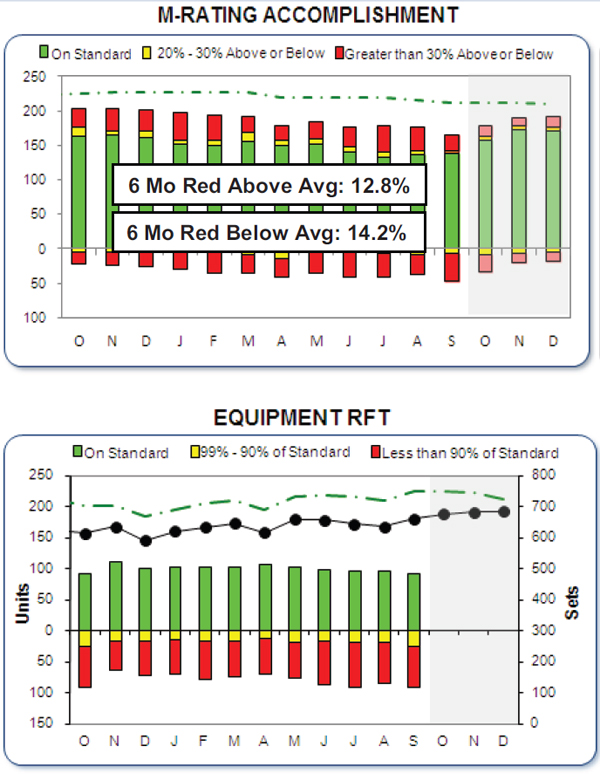

The NAE’s focus shifted from consumption (accumulation of flight time, carrier landings, and experience) to metrics (Single Fleet Driven Metric, or SFDM), reflecting the state of the fleet relative to goals established collectively by the fleet and senior military and government leadership. The organizational alignment and commitment to common metrics served to eliminate the “stovepipe” orientation common to many functionally driven organizations and focused all Naval Aviation assets on a holistic approach to readiness as shown in Figure 2-20.

As an example, a critical element involved a change to the relationship between the fleet, i.e., the operators, and the maintenance providers. Wing commodores became the principals for their aircraft types and were expected to assume responsibility for readiness, with maintenance providers subordinated to that effort.

Demonstratively representative statements of the NAE’s objective and organizational and philosophical approach are found in the minutes of the executive committee’s May 2010 meeting:

“Every time we do this meeting, we find that there is continuing relevance and there is a continuing reason for the Naval Aviation Enterprise,” said Vice Adm. Thomas J. Kilcline, Jr., commander, Naval Air Forces. “The NAE is maturing, and every year over the last six years, we have taken a really good hard look at what we are doing and how we can improve. This year, as in the past, we questioned the assumptions that underline what we do and why we do it.”

“The NAE is relevant, if not more relevant today, in championing the processes that deliver a warfighting capability. The purpose of this meeting is to bring together a core group of leaders that have an impact on naval aviation,” said James Beebe, executive director for Commander, Naval Air Forces. “It is all about communication and understanding the equities that we all have in supporting naval aviation requirements.”34

The NAE is to provide a leadership/management alignment that assures all functions related to the warfighting capability of Naval Aviation are focused on the warfighter’s missions (as demonstrated in Figure 2-21). The concept includes corporate tools and methodologies to integrate financial considerations and measurements into the operational process as a means to address fiscal and budgeting realities. A plan approved by a Board of Directors (BOD), consisting of the most senior leaders of the functional activities, exists for each functional alignment and identifies, prioritizes, aligns, and synchronizes investment efforts for the various entities. Gaps in capabilities relative to need are addressed with action plans. Prior-

______________

33 USN. 2007. Navy Enterprise Transformation: Working for the Greater Good, pp. 3-6. May. Available at http://www.thomasgroup.com/getdoc/7c79c3c9-8603-4908-ad89-0ebb0e10a67f/NavyEnterprise-Transformation.aspx.

34 Available at http://www.navy.mil/search/display.asp?story_id=53356. Accessed May 1, 2011.

FIGURE 2-21

Today’s NAE. SOURCE: Captain Mike Kelly, Commander, Naval Air Forces (CNAF), Force Material, Maintenance and Readiness. “COMNAVAIR.” Presentation to the committee, January 17, 2011.

ity and resource differences between functional units that cannot be resolved by the NAE are resolved by the BOD for the NAE.

Readiness is addressed in terms of operational goals established by the most senior leadership consistent with strategic and tactical doctrine. Sustainment is addressed through the NAE triad alignment that focuses the efforts of the Technology Developer (ONR/NRL/NRE) and the Material Developer (NAVAIR) on the needs of the Combat Developer (CNAF/OPNAV/CFFC) to optimize maintenance processes and support equipment and to provide a holistic approach to meeting required operational standards. The same model aligns personnel recruitment and training with operational needs. The focus is on meeting established operational objectives, or exceeding those objectives within fixed cost budgets, and management constraints are exerted to prevent doing more than is necessary to surpass those goals for which variable costs are involved. Evidence of the process’ success includes the ability of the NAE to meet operational objectives with a surplus of manpower, financial, material, flying, and other resources that have been eliminated

or returned for disposition to senior leadership. The NAE established the behavior model, organization, and processes to35

- Provide clear definition, organization, and planning process to achieve the Single Fleet Driven Metrics for readiness and sustainment.

- Provide a holistic methodology for organizational and functional alignment under appropriate warfighter commands, as Single Process Owners, to focus all asset efforts on the objectives established by the NAE.

- Provide fiscal/budgetary awareness relative to operational objectives within all aviation commands to aid in preventing unnecessary variable cost expenditures for unneeded readiness or sustainment capability and provide improved readiness at reduced cost.

- Provide a methodology for governance and continuous planning to address action plans to achieve current and future operational readiness, sustainment, and fiscal objectives in a process of continuous improvement.

- Provide SFDM as Key Performance Indicators for transparency within the entire Naval Aviation community relative to readiness performance.

Finding 2-10. Although the Air Force structure and program management mechanisms are designed differently, the NAE approach provides an interesting governance model and foci for the Air Force to consider as it executes its eLog21 strategy and deliberates on how to sustain its overall force.

CONCLUDING THOUGHTS

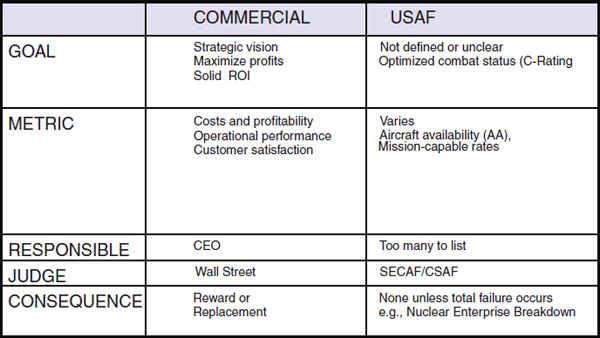

Foremost, the lack of clearly defined sustainment goals affects the entire Air Force. The Air Force can quickly develop a solution to this situation and then refine it over the longer term. The Air Force would be well served by assigning a sustainment commander with stature to work with the operational commands as well as the SAF/AQ, SAF/IE, and AF/A4/7 to develop and vet policy. This commander could then dynamically shape long-term sustainment planning, be accountable for achieving the sustainment goals, and oversee execution of the Title 10 U.S.C. provisions and day-to-day support of the fleet. From the outset of the study, the committee compared the Air Force sustainment model to general operations of large commercial firms. As stated earlier, it is imperative to determine who is in charge and what are the roles and consequences of their being in charge. Figure 2-22 notionally provides a side-by-side comparison of commercial business operations and accountability to what is considered to be the Air Force model.

______________

35 Vice Admiral Walter Massenburg (United States Navy, retired), Senior Director, Mission Assurance Business Execution, Raytheon Company. “Enterprise Behavior—Fundamental Changes in the Government Business Model.” Presentation presented to the committee, January 18, 2011.

FIGURE 2-22

Notional model depicting Air Force and commercial approaches to aircraft sustainment.

Any system in an organization the size of the Air Force is extraordinarily complex. Based on its interactions with numerous Air Force officials, the committee is confident that the officials understand what they are doing and the importance of their duties to the nation. At the same time, they expressed a general frustration with an inability to control their work processes and achieve positive results.