1

Overview

ADVANCED MANUFACTURING technology, because its strategic application results in important competitive advantages, including higher quality, greater responsiveness to consumer demands, and greater flexibility of capital investment, is emerging as a major corporate advantage in world trade. Development and deployment of advanced manufacturing technology will be affected by a host of factors, including capital, markets, tax and trade policy, corporate management, and skills.

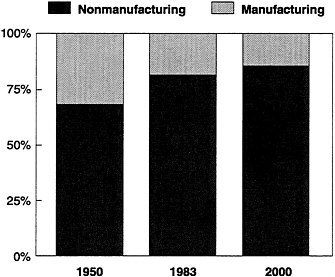

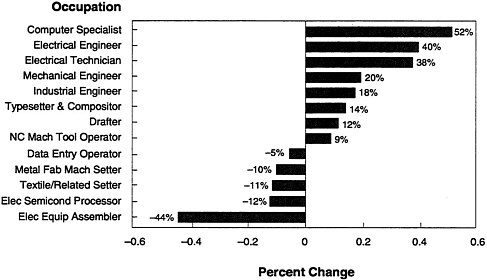

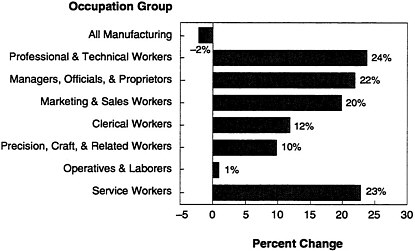

In a world that has come to expect zero defects and high reliability, manufacturing1 will move from a craft to a science, thereby requiring a much smaller work force that possesses multidisciplinary skills of a high order. Figure 1-1, Figure 1-2 to Figure 1-3 show this projected decline in manufacturing employment to the year 2000. In Figure 1-1, manufacturing employment is shown to decline by almost 20 percent between 1950 and 2000. In Figure 1-2, employment in more highly skilled occupations (i.e., computer specialists, electrical engineers, etc.) shows an increase from 9 to 52 percent between 1988 and 2000, while less highly skilled job categories (i.e., machine tool operators) showed a 5- to 44-percent decline. And in Figure 1-3, manufacturing is shown to be the only occupational group to show declining employment, in contrast to groups such as professional and technical workers, which shows a 24-percent projected increase between 1988 and 2000. The new skills that this smaller work force will need are dictated by three characteristics of advanced manufacturing technology:

FIGURE 1-1 Employment by industry sector, 1950, 1983, and 2000. Source: W. B. Johnston and A.H. Packer. 1987. Workforce 2000: Work and workers for the 21st century. Hudson Institute. 51-73.

FIGURE 1-2 Projected employment changes, 1988-2000. Source: Projections of occupational employment, 1988-2000. 1989. G. Silvestri and J. Lukasiewicz. Monthly Labor Review (112:11): 42-65.

FIGURE 1-3 Projected manufacturing employment changes, 1988-2000. Source: Projections of occupational employment, 1988-2000. Source: G. Silvestri and J. Lukasiewicz. 1989. Monthly Labor Review (112:11):42-65.

-

its integration of information and materials handling and processing, which are separate in traditional automation;

-

its reliance on higher levels of human and machine intelligence rather than on the skill of operators; and

-

its placement of the production process largely under the control of computer programs into which product and process specifications are fed as computer instructions.

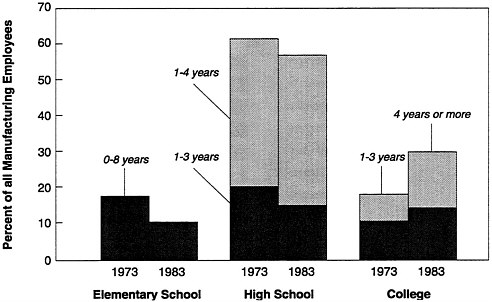

Firms that use advanced manufacturing technology will thus be distinguished less by their manufacturing processes than by the integrated systems that drive those processes. Creative use of the technology will yield greater competitive advantage. That is, the benefits of advanced manufacturing technology will depend more heavily on the people who develop the systems that determine the range and types of products that can be produced and resolve the contingencies that arise in production, than on the hardware that is likely to be available to any company that can pay for it. Figure 1-4 shows for the period 1973 to 1983 the educational attainment in manufacturing as a percentage of all manufacturing employees.

The nature of the new skills required is perhaps best understood in terms of the changes that will accompany the development and deployment of advanced manufacturing technologies. Tight integration of information and materials processing (see Chapter 5)

FIGURE 1-4 Educational attainment in manufacturing, 1973 and 1983. Source: Projections of occupational employment, 1988-2000. Source: G. Silvestri and J. Lukasiewicz. 1989. Monthly Labor Review (112:11):42-65.

will extend from choice of product, to design, to materials transformation and/or product assembly, and, finally, to marketing and distribution. Scheduling and resource allocation will be integrally linked to, and occur simultaneously with, planning in both the extremely short term (e.g., product time to market) and very long term (e.g., technology development and/or acquisition). Intelligent manufacturing control (see Chapter 2) will provide a means of controlling and recording continuous information about what is happening on the factory floor, and means of reporting the information on which operators and managers rely to make decisions. Control will be exerted primarily at the level of the work cell, will require significant intercell coordination, and will involve skills that have both human and machine components. Decision making in this context will require an understanding of logical relationships and statistical correlation and involve teamwork among peers. A growing portfolio of products and processes, machines and operators, and external forces will provide multiple windows for viewing problems, creating a concomitant demand for broader experience.

Time-to-market pressures that attend advanced manufacturing technology will drive organizations to compress their organizational hierarchy —become flatter—in order to push more responsibility down

to the factory floor. Operators, for example, will be called on to perform tasks that formerly were divided among several workers with different job classifications (e.g., machine setup and adjustment and quality monitoring, as well as operation). To maintain production while performing the frequent adjustments that are required by complex, integrated manufacturing systems, operators will have to be able to analyze problems and implement solutions, often in the form of computer programming. Operators will increasingly control production rather than be controlled by it.

The growing importance of manufacturing skills is best seen in light of the significance of advanced manufacturing technology. Product and process specifications that exist as computer instructions are highly transportable. Such transportability, together with the flexibility inherent in advanced manufacturing technology, creates a context in which a product can be produced anywhere, at home or abroad, by anyone with the requisite hardware. This situation renders production capacity a commodity.

The Japanese metalworking industry, using advanced manufacturing technology, has demonstrated remarkable increases in productivity: fivefold reductions in labor, reductions by half in the number of machines required, increases in machine utilization of more than 20 percent, delivery performances of 100 percent over three months, unscheduled system downtimes of 2 percent, and quality problems at the level of 0.006 percent (see Table 1-1 and Table 1-2). Advanced manufacturing technology makes traditional

TABLE 1-1 Comparison of Flexible Manufacturing Systems Studied in the United States and Japan

|

Manufacturing Systems Variables |

United States |

Japan |

|

System development time (years) |

2.5 to 3 |

1.25 to 1.75 |

|

Number of machines per system |

7 |

6 |

|

Types of parts produced per system |

10 |

93 |

|

Annual volume per part |

1,727 |

258 |

|

Number of parts produced per day |

88 |

120 |

|

Number of new parts introduced per year |

1 |

22 |

|

Number of systems with untended operations |

0 |

18 |

|

Utilization rate *(two shifts) |

52% |

84% |

|

Average metal-cutting time per day (hours) |

8.3 |

20.2 |

|

* Ratio of actual metal-cutting time to time available for metal cutting. SOURCE: R. Jaikumar. Post-industrial manufacturing. 1986. HarvardBusiness Review, Vol. 64. |

||

TABLE 1-2 Human Resource Requirements for Metal-Cutting Operations to Make the Same Number of Identical Parts

|

Conventional Systems |

Flexible Manufacturing Systems |

||

|

Operation |

United States |

Japan |

Japan |

|

Engineering |

34 |

18 |

16 |

|

Manufacturing overhead |

64 |

22 |

5 |

|

Fabrication |

52 |

28 |

6 |

|

Assembly |

44 |

32 |

16 |

|

Total workers |

194 |

100 |

43 |

|

NOTE: At the time of this study, no U.S. machine tool producer had a flexible manufacturing system on line. SOURCE: R. Jaikumar. Post-industrial manufacturing. 1986. HarvardBusiness Review, Vol. 64. |

|||

modes of production obsolete. Firms that hope to compete in the world market have no choice but to adopt it and learn to use it to their greatest advantage.

A 1988 Department of Defense report2 found serious, if irregular, indications of decline in sectors of the industrial base that are critical to continued U.S. leadership in advanced technologies and, by extension, to national security. The report finds particularly devastating the erosion of production technologies and equipment in vitally important sectors such as machine tools and electronics manufacturing equipment (see Table 1-3 and Table 1-4). Noting

TABLE 1-3 Top 10 Merchant Integrated Circuit Makers

|

Rank |

1976 |

1986 |

1996 |

|

1. |

Texas Instruments |

NEC |

IBM |

|

2. |

Fairchild |

Texas Instruments |

NEC |

|

3. |

Signetics |

Fujitsu |

Fujitsu |

|

4. |

National |

Hitachi |

Hitachi |

|

5. |

Intel |

Motorola |

Toshiba |

|

6. |

Motorola |

Toshiba |

Texas Instruments |

|

7. |

NEC |

Philips |

Matsushita |

|

8. |

GI |

National |

Mitsubishi |

|

9. |

RCA |

Intel |

Samsung |

|

10. |

Rockwell |

Matsushita |

Seimens |

|

SOURCE: Microelectronic Engineering at RIT: Manpower for Tomorrow's Technology. |

|||

TABLE 1-4 Percentage of the World Semiconductor Market

|

Year |

United States |

Japan |

Total (in billions of dollars) |

|

1980 |

60% |

27% |

$10 |

|

1988 |

36% |

53% |

$46 |

|

2000 |

? |

? |

$200 |

|

SOURCE: Semiconductor Industry Association. |

|||

that these are but the leading edge of scores of other technologies in which other nations are developing advanced manufacturing technologies for advanced products, the report suggests that U.S. industry cannot hope to compete in the world market with only technological equivalence. Nor can it expect to develop advanced technology without concurrently developing a work force that is competent to use it.

CHANGING GROUND RULES OF MANUFACTURING COMPETITIVENESS

Product quality, responsiveness to customers, process control and flexibility, and development and maintenance of an organizational skill base capable of spurring constant improvement have become the determinants of global manufacturing competitiveness. Manufacturers must adapt in order to succeed in these circumstances.

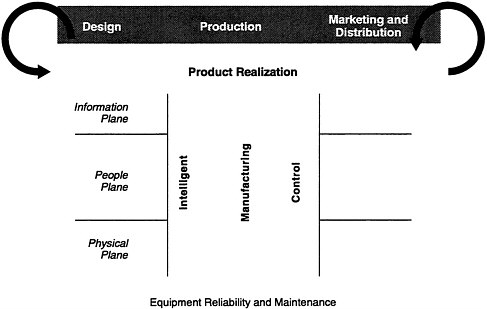

This report examines five critical areas in which such adaptation must be pursued. First, to improve equipment reliability, decrease cycle times, and achieve the greater precision dictated by demands for higher quality, manufacturing will have to adopt and further develop intelligent manufacturing control. Second, manufacturing must maximize the productivity of its capital investments through improved equipment reliability and maintenance practices. Third, manufacturing must enhance product characteristics —for instance, by using advanced engineered materials to reduce weight, broaden service temperature capabilities, impart multifunctionality, or improve life cycle performance. Fourth, to speed time to market, manufacturing must employ product realization techniques and adopt organizational changes that foster effective use of these techniques. Finally, creation of the new work force —highly adaptable and possessing multidisciplinary skills of a high order—that is critical to the application of these techniques and technologies will necessitate a focus on manufacturing skills improvement.

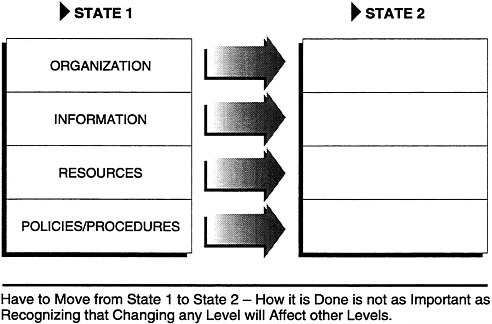

Effective management of modern enterprises is characterized by a high degree of interfunctional integration and coordination at a variety of levels. In short, it requires a systems view. The new learning organization is depicted in Figure 1-5. A competitive environment imposes a continuing need for an organization to move from the present state to a more competitive state. The catalyst of change may occur at any level, but a successful transition cannot be made unless the ramifications of change are assessed and accommodated at all levels.

Advanced manufacturing technology will seldom yield the anticipated flexibility and/or productivity in an organization unless corresponding changes are made in the organization itself and in its information systems and resources. Basic changes must be made in the processes, organization, and attitudes that are common in engineering and management. In engineering, manufacturers must strive to improve interaction among design engineers, production engineers, and marketers. Managers need to reevaluate common management practices and tools, such as accounting methods, investment criteria, inter- and intrafirm cooperation, and relationships with customers, to ensure that all the firm's resources, including manufacturing, constantly are driven to improvement.3

FIGURE 1-5 The new learning organization.

Implementation of advanced manufacturing technology has a pervasive effect on engineering, management, and the whole manufacturing environment. Advanced manufacturing technology has made information and materials processing effectively one entity. Management's responsibility for directing the flow of information is diminishing as information about manufacturing efficiency and capability is increasingly captured at the factory level. Teams working in the factory can use this information to solve problems and achieve superior process capability. The vast amounts of data collected by advanced manufacturing technology enable workers to supplement experience and trial-and-error problem-solving approaches with scientific method—for example, by performing experiments and building and refining models of production. Increasingly, learning is becoming the focus of the manufacturing plant.

The rest of this overview examines conditions antecedent to establishing a research agenda for manufacturing—specifically, a three-pronged theoretical basis for manufacturing and barriers to competitiveness —and suggests steps for changing. The research agenda is developed in the subsequent chapters.

A THREE-PRONGED THEORETICAL BASIS

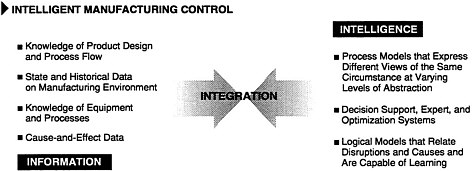

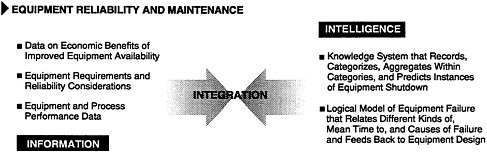

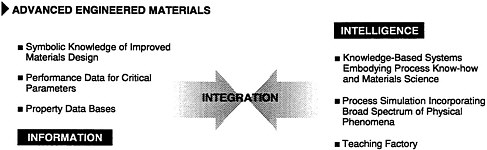

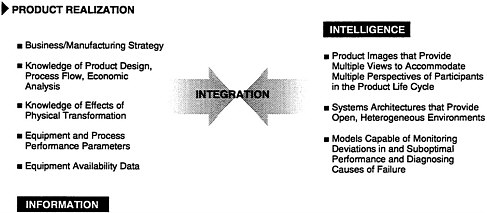

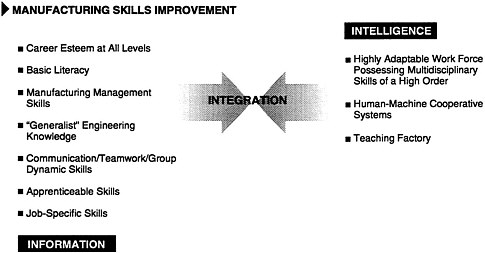

The changes that attend the development and deployment of advanced manufacturing technology involve the availability of information and the integration of that information with business functions to achieve various kinds of intelligence. Figure 1-6, Figure 1-7, Figure 1-8, Figure 1-9 through Figure 1-10 illustrate, for each of the topics covered in subsequent chapters, representative forms of organizational intelligence that can be realized from integration of domain-specific information.

FIGURE 1-6 Organizational intelligence realized from integration of domain-specific information: Intelligent manufacturing control.

FIGURE 1-7 Organizational intelligence realized from integration of domain-specific information: Equipment reliability and maintenance.

FIGURE 1-8 Organizational intelligence realized from integration of domain-specific information: Advanced engineered materials.

FIGURE 1-9 Organizational intelligence realized from integration of domain-specific information: Product realization.

FIGURE 1-10 Organizational intelligence realized from integration of domain-specific information: Manufacturing skills improvement.

Information

Advanced manufacturing technology facilitates the collection of enormous amounts of data. The controlling computer in a computer-integrated manufacturing system records every finite state in manufacturing operations as a series of snapshots. Computers can record hundreds of thousands of these states every second; they can examine one state, control its activity by some defined procedure, and then move on to the next state. The ability of a computer to observe a phenomenon in one state and use that observation to control an activity in the next is the essence of intelligent manufacturing control (IMC).

Many computer-controlled snapshots must be aggregated to provide a picture of a time period that is sufficiently long to be useful to managers. Aggregated snapshots permit managers to compare the current state of a system to the expected state and to relate events to corrective actions. The large volume of data that such systems collect necessitates additional programming to identify and store only dynamic information that typically is part of an investigative problem-solving activity.

The enormous quantities of data include a variety of types of information. At the raw materials end are property data bases, performance data for critical parameters, and information on safety, environmental, economic, and educational factors. Equipment data range from information about what constitutes reliability

and maintenance, to scheduled and actual equipment and process performance data, to data that illustrate the benefits of improved reliability and performance. Data relevant to IMC include state and historical data on the manufacturing environment as well as cause and effect data. The product realization process (PRP) relies on information on products and processes, control of equipment, and the effects of physical transformations of materials, as well as on the organization of production work, market and production problems, and variations in practice in different industries and national settings.

Integration

Information must be integrated into manufacturing operations at two levels: across process control and improvement, and across functions. Consider the integration at the raw materials end. Functional integration occurs, for example, when symbolic knowledge of improved materials design is integrated with process planning. The need to integrate measurement and control of critical process parameters with data on the performance of advanced engineered materials is addressed by IMC. Other types of integration relevant to IMC include machine and process flows in the factory, and human knowledge and machine intelligence.

With respect to reliability and performance data collected on the factory floor, integration is needed between (1) equipment user and supplier, (2) equipment requirements and reliability considerations, and (3) equipment reliability and cost accounting.

Product realization relies on integration of design and manufacturing to support parallel product development, of business logistics (to include supplier and codesigner), and of IMC with design and production. On the organizational side, the PRP relies on integration of (1) knowledge of the viability of alternative concepts, accurate evaluation of costs (e.g., equipment reliability and maintenance), market-imposed constraints, and opportunities afforded by technological change, and (2) the conception and implementation of new manufacturing technologies. (Figure 1-11 illustrates the integration of product realization, IMC, and equipment reliability and maintenance.)

Intelligence

Information is incorporated into business functions to gain a better understanding of the manufacturing process and its ele-

FIGURE 1-11 Integration across functional areas.

ments. The benefits of incorporating raw materials information include, for example, process simulations that incorporate extensive physical parameters and expert systems that embody both processing knowledge and materials science. Incorporation of equipment reliability and maintenance (ERM) data yields both knowledge systems that record, categorize, aggregate within categories, and predict instances of equipment shutdown; and logical models of equipment failure that relate different kinds of, mean time to, and causes of failure and uses this information in equipment design. Incorporation of the vast stores of data gathered by IMC systems facilitates the development of process models that express different views of the same circumstance at varying levels of abstraction; decision support, expert, and optimization systems; and logical models that relate disruptions to causes and are capable of learning. Pairing such developments with product realization yields product images that accommodate the multiple perspectives in the product life cycle; system architectures that provide open, heterogeneous environments; models capable of monitoring performance deviations and suboptimal performance and of diagnosing causes of failure; systems that encourage and foster nontraditional thinking; and organizational ability and incentives to be open to change.

BARRIERS TO COMPETITIVENESS

This section addresses four significant barriers to U.S. manufacturing competitiveness: inflexible organizations, inadequate technology, inappropriate performance measures, and a general lack of appreciation for the importance of manufacturing. The first three barriers may be changed from within. Industry, however, contributes to the fourth barrier by failing to provide financial and psychological incentives that might promote careers in manufacturing.

Inflexible Organizations

Manufacturing behavior in the future will continue to be driven by market as well as nonmarket factors. Market factors are those defined by technological opportunity, business strategy, and the competitive environment, and they interact to determine the investments a firm must emphasize to maintain a chosen competitive advantage. Trends in manufacturing competition and technological possibilities, for example, are driving firms to emphasize production flexibility in order to maximize their responsiveness to customers without sacrificing cost competitiveness. Nonmarket factors are outside forces such as national security, demographics, urban congestion, the regulatory regime, and social concerns over the integrity of the environment that force particular types of investments and technological developments. Nonmarket factors force firms to explore nontraditional approaches to organization and to reevaluate conventional product and process technologies. Standard approaches to solving the varied and conflicting problems that arise as a result of both market and nonmarket factors often are inadequate or completely ineffective. New manufacturing solutions, unconstrained by existing infrastructures, technologies, modes of business, or investment, are needed.

Inadequate Technology Base

The technology base of U.S. manufacturing has many types of problems, ranging from quality control to evaluation. A fundamental deficiency is the lack of standards—for design and test, for measurement and evaluation, for data communications, and for operator–equipment interfaces. Standards also are essential to the development of dynamic knowledge bases that are capable of adapting to change. Lacking as well is an information architecture that integrates hu-

man and machine intelligence to yield knowledge acquisition techniques that can support rapid start-up. Ultimately, these knowledge bases must give rise to a dynamic model that encompasses design, manufacturing, and management. Also needed is sensor integration, which will be a key ingredient of the dynamic model. Sensor integration is essential for developing reliable process models that represent the physical characteristics, structure, processing, manufacturing, performance, and cost of advanced engineered materials. And, finally, predictor maps are needed to achieve a better understanding of the interdependence of these considerations.

Such modeling and integration will rely on the development of a host of high-performance tools, including design compilers and synthesizers, rapid imaging devices, and selection analysis systems based on artificial intelligence and expert systems.

Because of the increasing importance of advanced manufacturing technology to international competitiveness, strong consideration also must be given to improving the U.S. technology skill base. This base includes both operators capable of learning to interact with intelligent equipment and managers capable of making informed decisions about acquiring and deploying such equipment.

Inappropriate Performance Measures

Much of the apparent weakness of U.S. manufacturing is attributed to reliance on inappropriate financial measures to evaluate manufacturing efficiency and corporate performance. Devised in the nineteenth century, and still the basis of the entire manufacturing infrastructure, these measures have failed to keep up with the major changes in the nation 's manufacturing systems. Management analyst Peter Drucker cites four examples: (1) cost accounting systems assume that blue-collar labor accounts for 80 percent of all manufacturing costs (excluding raw materials), even though 8 to 12 percent is rapidly becoming the standard; (2) the benefits of changing a process or system are measured primarily in terms of labor cost savings (rather than in optimization of equipment utilization); (3) since only costs of production are measured, nonproduction costs, such as machine downtime or defective products, are ignored; and (4) because the factory is considered an isolated entity, only cost savings realized in the factory are significant— process changes that might increase service quality or product acceptance in the market are ignored.4

Alternative measures, and creative ways of substituting them for financial measures, are badly needed. In particular, measures

are needed to assess the skills and levels of performance of an enterprise 's employees, the relative effectiveness of its technology, the value of knowledge gained through continual refinement of its products and processes, its use and conservation of time, and concepts such as the impact of speeded cycle times or flexibility. Unfortunately, little is known about how to quantify, represent, use, and report these criteria, even though they will increasingly determine manufacturing competitiveness.

Lack of Career Esteem

The image of manufacturing as a career has not evolved at the same rate as the manufacturing environment. Despite the advanced manufacturing technology that requires operators with high-level, multidisciplinary skills, manufacturing retains a sweatshop image, characterized by dirty work in noisy environs. Manufacturing receives little promotion from career guidance counselors and the generally low esteem in which manufacturing is held is reinforced by companies' recruitment policies, which often rank manufacturing engineers below design engineers.

Even if this image problem were to be solved, manufacturing will still face a very real, and growing, shortage of qualified people. The current applicant pool from U.S. schools is largely unqualified for highly skilled, professional manufacturing jobs. The state of education in the United States is exemplified by The Economist's report of a sample group of 20-year-olds, of which 60 percent could not add a lunch bill or read a road map,5 and by one employer's experience of soliciting 15,000 applicants to find a pool of 800 who could pass an elementary entrance examination.6

The qualifications of manufacturing management also come into question. Among Japanese users of advanced manufacturing technology, most managers have been trained as engineers. Most U.S. manufacturing managers have graduated from programs that stress financial management and have spent little or no time on the shop floor.

STEPS FOR CHANGING

The barriers to manufacturing competitiveness recounted above are not insurmountable. To use the enormous amount of information that is available to achieve integration and intelligence in the factory, however, it will be necessary (1) to restructure the organization to support learning and experimentation in the factory (the

notion of the factory as laboratory), and (2) to develop new methods of performance measurement and process/life-cycle costing that will enable management to evaluate problems, process improvements, resource utilization, and production management in economic terms. Some industries are already moving forward on these fronts.

The approach to process control costing can be changed fundamentally by focusing on the cause of process or product variance and attempting to capture all of the associated economic consequences. The costing system would view the production process as running exactly as expected unless disrupted by an event, would recognize such events, identify the effects of each event on the entire production process, and report this information to management. The power of this approach lies in the ability to identify events and their economic consequences simultaneously. To relate an event to performance measures and, subsequently, to make an economic decision to control a process requires:

-

the ability to translate the event and the performance measure into monetary terms,

-

a scientific model that relates production parameters to process parameters,

-

an economic model that relates resource utilization to process capacity,

-

knowledge of all the controllable parameters and constraints on production,

-

a time scale for every controllable feedback and feed-forward loop, and

-

knowledge of the relationship between a set of controllables and a set of resources.

As an example of costing events, contingencies, and process improvements, consider machine downtime. It is first necessary to determine for the machine a value per unit of time. This shadow cost of capacity can be obtained through a variety of methods related to capacity utilization. A production monitoring system provides information about all machine shutdowns (e.g., causes, durations). These events are classified by category and aggregated within categories. Given the opportunity cost of downtime, it is possible to calculate the benefit of reducing or eliminating each category of downtime. The example can be taken a step further, to the development of a logical model of machine failure that relates different kinds of failure, mean times between failure, and causes of failure. As information is gathered about production

processes, one can begin to assess the impact of different causes of machine failure. The model needed for process control costing is precisely the model needed to control a process. A process control costing system adds to this model the economic value and economic cost of reducing or eliminating the different causes of failure. The benefit realized equals the time saved multiplied by the opportunity cost of that time. The cost is the cost of the resources—in terms of new procedures, maintenance, new sensors or tools, and personnel —required to make a given change.

FINDINGS OF THE PANELS

Each of the five critical areas of manufacturing examined in this report is covered in a separate chapter. Summaries, including research needs, are provided below.

Intelligent Manufacturing Control

Chapter 2 examines the tight coupling of sensor technologies and software systems that manifests machine intelligence when some degree of synergy with a human interface is achieved. A framework is established for thinking about IMC in terms of domains of control that correlate with a compressed organizational hierarchy and levels of feedback time. Research efforts should be aimed at (1) developing technique-oriented communication standards; (2) refining sensor technology in data integration, pattern recognition, and actionable models; (3) building knowledge bases of design, manufacturing, and management intelligence that can adapt to changing knowledge and organizational structures; (4) creating a dynamic model of manufacturing; (5) identifying ways to use the human–machine interface to facilitate learning in an integrated environment; and (6) redefining methods to accommodate holistic research in a production environment (i.e., the factory as laboratory).

Equipment Reliability and Maintenance

ERM, covered in Chapter 3, includes both manufacturing equipment and the technical, operational, and management activities required to sustain the performance of such equipment throughout its working life. ERM has the potential to affect three key elements of manufacturing competitiveness: quality, cost, and product lead time. Several cases illustrate effective applications of ERM

programs, both in the United States and abroad. The limited penetration of such programs in this country is attributed in large measure to manufacturing managers' lack of awareness of the economic benefits of improved equipment availability. Technological problems that are associated with the implementation of ERM programs are considered to be more easily solved than are people problems.

Advanced Engineered Materials

Chapter 4 focuses on manufacturing involving advanced engineered materials (AEMs). Barriers to optimization outside the normal scope of manufacturing science and engineering are considered, as are future needs and directions. Challenges to the integration of AEMs into manufacturing operations include (1) both the need to integrate processing methods into the design and development of new materials from the beginning and the need to instill awareness of and sensitivity to materials' properties into process design paradigms; and (2) deficiencies in process simulation and modeling, knowledge-based systems applications, sensor applications, and technical cost modeling. Research should focus on needs in the areas of materials science and engineering, expanded and revised educational programs and objectives, and methods for better integrating materials-specific issues in manufacturing paradigms.

Product Realization Process

Product realization is both a consequence of and a response to pressures of time-based competition. The product realization process (PRP), discussed in Chapter 5, has both technological and organizational components. Technological enablers are needed to support the development of a universal product image that will be in sync with the views of the many participants in the product life cycle. Existing information architectures will not support the development of such images. Development of a universal product image also will rely on and engender a need for alternative organizational structures. Tomorrow's business organization is expected to resemble less a hierarchy than a peer network configured for mutual benefit. Research in this area should be directed at defining, identifying specific instances of, and developing intelligent images; identifying and establishing the requisite connections among these images; and devising an organizational structure in which these concepts can be made operational.

Manufacturing Skills Improvement

Effective deployment of advanced manufacturing technology, as pointed out in Chapter 6, relies on a host of skills that U.S. schools are neither cultivating nor preparing students to acquire. The first need is basic literacy. Then, beyond primary and secondary education, is a need for general engineering knowledge and the development of communication, team, and group dynamics skills. In the workplace, greater concentration is needed on the cultivation of apprenticeable and job-specific skills. Finally, the public must be made more aware of the importance of manufacturing to the national economy, starting with the development of career guidance materials for all levels of the educational system. The new manufacturing work force, destined to function increasingly as a component of human–machine cooperative systems, must be highly adaptable and possess multidisciplinary skills of a high order.

Implicit in the research topics identified in each chapter is a need for fundamental change in both methods and kinds of search. The typical laboratory experiment is concerned with observing a piece of a system, e.g., the signal-to-noise ratio is artificially high, and many of the variables are controlled. The notion of control, taken for granted in the laboratory, is itself the object of experimentation in the factory. In a production environment, it is necessary to study an enormous amount of information, including production histories, for a variety of integrated processes. The performance of an integrated production system can only be evaluated by observing the system as a whole in the factory.

The factory as laboratory is the new research imperative. It implies new ways of doing research, new forms of collaboration across functions and engineering disciplines, and cooperation between academic scientists and industrial practitioners. Therefore, development of an architecture for learning is critical. How to sponsor and promote the needed new forms of research is a fundamental question that must be addressed.

VISION

If the research proposed in this report is undertaken and proves fruitful, if manufacturing learns from and adopts the fruits of that research, if manufacturing gains well-deserved esteem, and if the nation proves equal to the task of redirecting and reinvigorating its educational system, manufacturing might achieve the vision summarized here.

Next-generation manufacturing will add more value during fabrication by placing greater emphasis on tailoring the specific properties of materials to specific uses. Highly specialized processing of metals, ceramics, and polymers stacked in interpenetrating layers will yield radical improvements in materials' strength and toughness and greatly reduce weight. Techniques for producing semiconductor materials at lower temperatures will dramatically reduce defects in devices of extremely small geometry. The design of next-generation manufacturing equipment will occur along with the design of the processes that will use this equipment and will draw on extensive bodies of performance data and user experience. Recognizing the productivity gains that can be realized from improved equipment availability, manufacturing managers will implement extensive programs of predictive maintenance. Maintenance will be performed by equipment operators, interacting synergistically with intelligent control systems capable of predicting and, in some instances, preventing or automatically remedying, equipment and control systems failures.

Intelligent control will extend throughout the manufacturing system. Autonomous control systems that achieve synergy between human and machine will exploit human powers of perception, pattern recognition, and problem solving in conjunction with machine capacity for manipulating vast amounts of quantitative data to learn from each situation encountered and decision made. The plant will become a locus of learning; linkages among individual intelligent controllers will support a systemwide view of the interrelationships among unit operations in the manufacturing cycle, facilitating the timely sharing of important process revisions, quality information, and overall system objectives.

Product realization techniques will increasingly substitute the content of a burgeoning knowledge base for traditional material inputs to the manufacturing process. The reduction of product and process specifications and manufacturing capabilities to intelligent images, capable of interacting with one another, will permit entire product life cycles to be simulated to evaluate trade-offs before producing a prototype. Indeed, prototypes will increasingly become the first units of production rather than preproduction models. Emphasis on maximizing capacity utilization and minimizing investment will shift production to a largely subcontracted function. Firms, radically restructured internally, will use advanced communications technologies to manage external relationships in a constantly shifting pattern, often cooperating and competing on different contracts at the same time. Global information sys-

tems will enable electronic virtual enterprises to access and coordinate the localized design and manufacturing capabilities of village industries all over the world. Nations' competitive positions will be determined by their positions in the world information market, which in turn will be determined by investment in the information infrastructure. World boundaries will be determined less by national affiliation than by class affinity for information categories.

Production will increasingly be handled by highly skilled professionals functioning as components of human–machine cooperative systems, and integrally linked with management functions in a compressed (“flat ”) organizational hierarchy that is characterized by peer-to-peer relationships. Manufacturing careers will be highly regarded and avidly pursued by well-educated youth who have been familiar with manufacturing enterprise since elementary school. Colleges will turn out Renaissance engineers and business schools managers who understand technology and the workings of their plants as well as the composition of their balance sheets. Job-specific skills will be imparted through nationally coordinated vocational and apprenticeship programs and satellite distribution networks.

Manufacturing will be regarded as a national asset, to be protected, cherished, and nurtured. Esteem for manufacturing will rise to the level of its technology.

NOTES

1. Manufacturing in this report is understood to be the processing of raw material inputs and the assembly, mixing, or other coalescence of outputs into high-quality, low-cost, salable products. The contrasting use of “manufacturing” in Chapter 6, Manufacturing Skills Improvement, is not a definition but a very important image issue. It reflects a perception of the definition that is increasingly at variance with the reality of manufacturing that employs advanced technologies. Qualifying this perception is very important to building career esteem.

2. Under Secretary of Defense (Acquisition). 1988. Bolstering Defense Industrial Competitiveness. Report to the Secretary of Defense. 1-2, 6-10.

3. Hayes, R. H. and Jaikumar, R. Manufacturing's crisis: New technologies, obsolete organizations. Harvard Business Review (September-October): 77-85.

4. Drucker, P. F. 1990. The emerging theory of manufacturing. Harvard Business Review (May-June): 94-102.

5. Gone fishing. 1990. The Economist. 314 (January 6): 61-62.

6. Richards, B. 1990. Wanting workers. Wall Street Journal Reports: Education (supplement) (February 9) R10.