9

MATERIALS AND STRUCTURES

INTRODUCTION

At various stages in the evolution of aeronautics, one of the foundation disciplines—aerodynamics, propulsion, control, or structures—has been either the obstacle to progress or the conduit to major improvements. They all, therefore, constitute "enabling technologies." In the sense, however, that no airfoil will develop full lift if its surface cannot maintain shape and smoothness under the pressures it is designed to generate; that no engine will function if its components cannot withstand fuel combustion temperatures and rotation loads; and that no control system can cause aircraft attitude changes if its linkages will not carry the forces that create hinge moments—in that sense, structures and the materials used to build them are first among the enabling, foundation aeronautical technologies. Providing a safe and durable structure is a matter of fundamental importance, because a functional failure of structural components usually has catastrophic results. This chapter discusses the committee's findings and recommendations regarding future materials and structures technology. The boxed material summarizes the primary recommendations that appear throughout the chapter, with specific recommendations given in order of priority, and the benefits that can be gained through research and technology development efforts aimed at advanced structures and materials.

Beyond being an enabling technology, development of the structures of airframes and engines continues to be a key element in determining the economic success of aircraft. Structural weight is the single largest item in the empty weight of an aircraft and is, therefore, a major factor in the original acquisition and operating cost and in establishing operational performance. One pound added to structural weight requires additional wing area to lift it (all other flight variables being held constant), additional thrust to overcome the associated incremental drag, and additional fuel to provide the same range. All these additions result in further increases in structure. This vicious circle converges, in typical aircraft designs, to gross weight increases from 2 to 10 times the 1-pound empty weight increase that began the cycle.

The trend in aeronautical structures from all-metal construction to composite airframes, which began about 25 years ago, has reached the point at which specialized military aircraft, fighters, and vertical takeoff and landing (VTOL) aircraft, now have composite structures

|

Recommendations General NASA's structures and materials program should emphasize continuing fundamental research to achieve both evolutionary and revolutionary advances in materials and structures, as well as focused technology programs in materials and structures to address specific aircraft system requirements. This should include:

Specific

|

constituting from 40 to 60 percent of the airframe weight (AV-8B and V-22, respectively.) Commercial transports use advanced composites in essential secondary structures such as flaps and control surfaces and in some primary structure such as vertical fins.

The advantages of composite materials, as exemplified by their greater strength and stiffness per unit weight, superior fatigue and corrosion resistance for many applications, and potential for lower manufacturing costs through reduced part counts and tooling expenses, make their wide application to U.S. aircraft designs a compelling need. However, the slow rate at which they are being adopted is evidence that their design, analysis, manufacturing, inspection, and repair methodologies are all in a developing state.

|

Benefits of Research and Technology Development in Structures and Materials

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aircraft structural design, analysis, manufacturing and validation testing tasks have become more complex, regardless of the materials used, as knowledge is gained in the flight sciences, the variety of material forms and manufacturing processes is expanded, and aircraft performance requirements are increased. A greatly expanded design data base of applied loads is now available for more complete and thorough definition of critical design conditions, thanks to the expanding use of computational fluid dynamics (CFD), advanced wind tunnel testing techniques, and increasingly comprehensive aeroelastic and structural dynamic analysis computer codes. Similarly, computer-aided design tools make it easier and quicker to consider a much greater variety of alternative structural designs. The use of high-speed, large-memory computers permits, in turn, more detailed internal structural loads analysis for each of the many loading conditions and design alternatives, with fine grid analysis determining more precise load paths, stress distributions, and load deflection characteristics for subsequent aeroelastic analysis.

Expansion of structural synthesis, analysis, and testing capabilities and the widening options available are making the choice of materials for both the airframe and the engine one that is intrinsically woven into the structural concept, detailed part design, and manufacturing process selection. A fundamental aspect, of course, is knowledge of the physical properties of these materials. Characteristics such as static tensile strength, compression and shear strength, stiffness, fatigue resistance, fracture toughness, and resistance to corrosion or other environmental conditions, can all be important in the design.

Each of these aspects must be considered and dealt with concurrently if modern structural designs for aircraft are to approach optimum configurations and, thereby, success in international

commercial competition. Thus, a successful airframe and engine structural design/manufacturing team will cover a spectrum of sub disciplines, consisting of

-

advanced alloy metallurgists; constituent materials specialists with expertise in fibers, organic, metal, and ceramic matrices, and interfacial coatings;

-

continuum, ply and laminate micromechanics specialists with expertise in ply property determination from constituent properties and interfacial failure mechanisms;

-

continuum, ply, and laminate macromechanics specialists with expertise in elastoplastic behavior, and strength, stiffness, fatigue, and environmental behavior based on averaged properties;

-

designers of structural members, components, and joints who are capable of predicting load paths, stress concentrations, and deflections and are knowledgeable about joining techniques;

-

manufacturing specialists capable of choosing the optimum "raw material" form (sheet metal, dry filament, prepreg, tape, or woven broad goods); fabrication process (forging, superplastic forming, braiding, winding, tape or fabric laying, or resin transfer molding); and tooling concepts;

-

quality assurance specialists, expert in the choice of nondestructive evaluation (NDE) and other testing methodologies; and

-

repair specialists, dealing with operational damage in the field and "depot level" or "overhaul facility" operations using extensive facilities.

It is most important to note that current and future materials and structures aspects of aeronautical systems, both airframes and engines, require a new level of collaboration among all of these specialists. It will probably be necessary for each specialist to become more conversant with the fields in which the others work and, from the earliest stages of design, for all of these specialists to work together in ways that are unprecedented in the aircraft industry.

To summarize, the compelling reason to apply composites and other advanced materials to the structural design of the advanced aircraft envisioned in this report is to achieve the lightest weight and most effective structure possible. This includes a highly reliable structure that requires minimum maintenance and is durable under all applicable environmental influences. U.S. industry must achieve these capabilities if it is to maintain a preeminent position in the world's commercial aircraft sales and operations.

This chapter outlines the key areas of research needed and the approaches that research programs should use. Among the attributes mentioned earlier, low structural weight fraction, long life, and low costs are the principal drivers for the airframe structures of future aircraft systems described in this report. For propulsion systems, higher specific strength and ability to withstand higher temperatures are the principal drivers. These objectives, in turn, require advances in materials, structural design concepts, life prediction methodologies, and fabrication technologies. The scope of the National Aeronautics and Space Administration (NASA) structures and materials program should emphasize

-

continuing fundamental research to achieve both evolutionary and revolutionary advances in materials and structures; and

-

focused technology programs in materials and structures to address specific aircraft system requirements (e.g., subsonic fixed and rotary wing, and supersonic transport aircraft).

FUNDAMENTAL, BROADLY APPLICABLE RESEARCH

Applied research in structures and materials is virtually always required at some level in developing a new type of advanced aircraft. Such applied research, specific to vehicle classes discussed in other parts of this report, is dealt with in subsequent sections of this chapter. In addition, however, there is a continuing and essential need for long-term, fundamental materials and structures research of a generic nature. An appropriate program of this kind should be guided by needs that arise in the development of generic aircraft types; it also should, by its results, change the direction of generic aircraft developments. Thus, an appropriate fundamental program of materials and structures research should seek to provide both evolutionary and revolutionary advances in materials and structures, which will be required to sustain a leadership role in both airframe and propulsion technologies. Specific areas of fundamental research that should be considered for emphasis are outlined below.

Materials and Processes

Metallics

Metallic alloys continue to be used for more than 75 percent of most airframe and propulsion systems by weight. They constitute relatively mature and reasonably well-understood classes of materials ranging from aluminum alloys for airframe structures to nickel alloys for hot sections of turbine engines. Continued research into metallics is strongly recommended, emphasizing tailoring of alloy systems to provide significant advances in such traditional areas as weight reduction and environmental resistance. Aluminum-lithium (Al-Li) alloy systems, for example, promise evolutionary benefits in higher stiffness and lower density, with no reduction in structural life. Continued research efforts are required, however, to ensure that Al-Li alloys will be endowed with the balanced strength, corrosion resistance, and toughness properties necessary for cost-effective airframe structural applications. Powder metallurgy technology is another area in which continued research efforts are warranted. Aluminum powder and rapid solidification techniques offer a wider range of chemical composition and processing options, which in turn promise alloys of improved strength, toughness, and corrosion resistance, compared to ingot metallurgy processes. Powder metallurgy also has the potential of producing aluminum base alloys with capabilities to 900ºF that could make them competitive with more costly materials, such as titanium, in both airframe and engine applications. Improved titanium alloys also have great potential. Alloys capable of superplastic forming continue to promise both economic fabrication of parts with complex curvature or integral stiffeners and weight savings

through reduction of stress concentrations where there would otherwise be mechanical fasteners. Research is needed to increase allowable strain rates and, thereby, part output; to reduce cavitation flaws; and to broaden the classes of superplastically formable alloys available to structural designers. Beyond more conventional metallic systems, research efforts in ordered alloys of the TiA1, Fe3A1, and Ni3A1 types should be substantially increased. Emphasis should be on increasing fundamental understanding of the structure-property relations in these systems and on alloy additions to enhance strength and toughness. Both airframe and propulsion systems could benefit substantially from the high strength-to-weight potential of these more unusual alloy systems.

Composite Materials

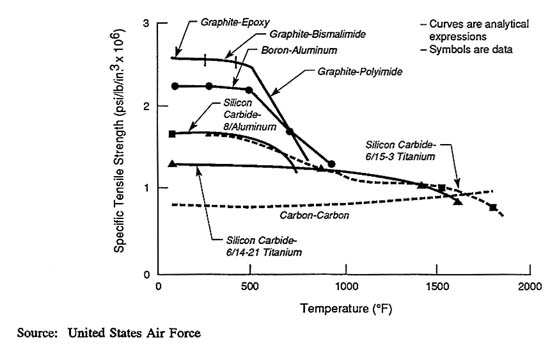

Significant research investments are required to develop the full potential of composite materials for both airframe and engine applications. This class of materials is, in general, very large; it includes polymer matrix, metal matrix, and ceramic matrix composites (CMCs), as well as continuous and discontinuous fibers. Various combinations offer differing advantages, depending, for example, on the thermal environment (Figure 9-1). Fibers can be entirely of one constituent material or used in combination. Some of the more traditional potential advantages of these materials are, by now, well understood. They include higher specific (relative to material mass density) strength, and stiffness, and better fatigue and fracture resistance compared to metallic alloys. Hybrid materials such as those having combinations of glass and graphite reinforcements show significant improvement in tensile fracture properties versus solely graphite-reinforced laminates. This is especially important for application to fuselage structure for penetration damage containment. Damage tolerance of these materials—particularly hybrids—is not as well understood and is an area of high potential payoff.

Polymer matrix composites research appropriately deals with both the constituent materials and the way they are combined to form composites. It should emphasize tougher matrix resins for use up to 700ºF as well as novel forms of thermosets, thermoplastic, and crystalline polymers with improved processing characteristics and properties. Improvements in carbon fiber reinforcements for polymer matrix composites are expected to continue, based on the efforts of various suppliers; government research programs in this area are not likely to be required. Understanding of the fiber matrix interface characteristics required for tougher composites, however, needs to be improved, as does knowledge of how to apply textile technology, such as stitching and weaving, successfully to improve interlaminar strength. It should be recognized that a polymer matrix structure will require appropriate adhesives, sealants, and finishes.

Metal matrix composites (MMC), with either continuous or discontinuous reinforcement, have significant potential for use in both airframe and propulsion systems, particularly when operating temperatures fall in the range of 225–2000°F. Research by NASA emphasizing composites with discontinuous reinforcements is recommended, based on the belief that such materials are likely to simplify fabrication. Both aluminum and titanium matrix composites with silicon carbide type reinforcements (particulate, fiber, ribbon), for example,

FIGURE 9-1 Tensile strength per unit mass as a function of operating temperature for several composite materials.

warrant substantial continuing research and development. Technology expansion of MMCs should be directed toward tailored matrix chemistry/fiber properties for achieving consistency in high-strength/high-stiffness properties, along with practical levels of ductility, toughness, and cost. Fabrication technology, particularly for tailored structures, should be emphasized to fully exploit the advantages of MMCs and prevent cost from becoming an insurmountable barrier. Hybrid systems involving metal sheets interleaved with various types of reinforcements also show promise as structural materials.

CMCs constitute one of the highest-risk research opportunities in the materials and structures discipline. However, the magnitude of the potential benefits from these materials for higher-temperature applications, such as uncooled turbine engine components, justifies major research efforts. Both ceramic matrix and ceramic fiber technologies need to be pursued, along with an emphasis on improving fabrication technology. Achieving reproducibility in fiber quality, matrix features, and composite behavior is essential before these promising materials can be considered to have reached a state of technology readiness. It appears that ceramic materials of the silicon nitride and silicon carbide families should receive the greatest attention.

Structural Analysis and Design

NASA's research efforts in structural analysis and design should focus on improving stress and deflection analysis methods; establishing proven structural dynamics and aeroelastic analyses; developing improved life prediction techniques and damage-tolerant design concepts; formulating proven methodologies for optimizing structural designs, including tailored composites; and exploiting adaptive or ''smart structures'' concepts. Structures researchers will have to play a stronger leadership role in working with materials researchers, both in defining priorities among material properties improvements and in adapting advanced materials to innovative structural concepts. The nation's materials and structures research program should have components considering how to cause structural, dynamics, materials, control systems, and manufacturing engineers to join in simultaneous consideration of structural, materials, and fabrication technology developments at the earliest design stages. Such "concurrent engineering" seems essential to achieving the successful application of advanced materials to aircraft structures in the time period of interest in this study.

Improved structural analysis methods capable of exploiting the computational power that will be available in the near future should be a high-priority objective of structural design research. A necessary adjunct of this is development of tools to reduce the cycle time for generating structural analysis models sufficiently that such analyses for both strength and stiffness can accompany the earliest structure design concepts considered by designers. Automated finite element mesh refinement and remeshing capabilities, which readily identify areas of high stress concentration and high strain gradients and allow crack propagation characteristics to be predicted should be developed and incorporated to the point of being standard features of structural analysis.

Formalized structural optimization techniques must become a standard computational tool for design purposes. Such techniques should also allow for choice among multiple static and dynamic analysis options (e.g., transfer matrix, finite element, and boundary integral methods) in unified procedures that ensure the balance between efficiency and accuracy at various design stages, which is requisite for application of these analyses to realistic designs. Integrated analysis techniques that couple structural, thermal, dynamic, aeroelastic, and control technologies are required to truly optimize a design. Experience with optimization methods to date indicates that the state of these procedures requires fundamental research and that successful application can establish major competitive advantage in the marketplace.

Factors such as broader ranges of flight conditions and larger applications of high-temperature structures will require methods for design and analysis that account for temporal and spatial variations in loading and operating conditions, material states, and variations of materials themselves throughout the structure. NASA should pursue research to improve life prediction methods and damage-tolerant designs, closely linked to the understanding of individual material properties; to their compatibility in combination, particularly at structural joints; and to NDE techniques. Structures research should take a strong lead in integrating these technical areas to achieve more efficient designs. Life prediction systems must include multiple failure mode assessments of complex, multiaxially

loaded/reinforced composite structures, by recognizing both time dependence and the need for damage tolerance. Ultimately, a probabilistic approach will be required with regard to operational loads, routine damage in service, and material properties in the delivered structure, to maximize the potential of many of the advanced materials. Stochastic analysis methods should also receive greater attention to account for more complex operational aspects of advanced aircraft systems.

Whereas the more revolutionary concepts should be taken to the proof-of-concept stage in laboratory research, composite material developments per se have outdistanced current abilities to routinely design and manufacture useful parts from them. It is important to emphasize that the research itself should often involve close and interdependent teaming of materials researchers, fabrication technologists, and structural designers. Such teamwork is increasingly necessary for cost-effective application.

Fabrication

Resin Matrix Composites

Composite materials and structures fabrication techniques constitute a major area of uncertainty for the aircraft of the future. The form of the precured material, the manner in which it is put together to form the desired component, its "cure," and means of assembly into the final structure all are involved. Plate or shell-like components with polymeric resin matrices tend to be "laid up" from tape or fabric that may have been preimpregnated with resin or, in the case of thermosets, have had the resin applied "wet." Relatively thin-walled cylindrical components are frequently wound, using continuous filaments or braids. Components with roughly equal three dimensionality are candidates for woven preforms of fiber that may later be injected with resins in a liquid state. Cures may be effected for thermosetting resins under high temperature and pressure (i.e., with ''vacuum bagging" or in an autoclave with metal molds). For thermoplastic resins, both temperatures high enough to make them flow and molds are necessary in some instances; hot gas torches and filament winding are sufficient in others. The compatibility of desired fiber/matrix volume fraction, resin viscosity, preform density limitations, and fiber wet ability are principal problems of the kind that injection cures encounter.

Whereas fabrication techniques are relatively stable in metal aircraft manufacture, there is less certainty as to the techniques for manufacture of composites. Certain technical concerns and high manufacturing cost remain overriding factors inhibiting the wider use of composites in aircraft structures, especially in cost-sensitive commercial applications. These are the principal reasons, along with design conservatism, why the potential for large weight savings and other benefits of using composites have not been realized except on a very limited basis. Applications where weight savings, fatigue life, and corrosion resistance override cost considerations have been limited VTOL and combat aircraft.

Essential to the realization of reduced manufacturing costs with composite structures is a reduction in labor costs sufficient to offset higher materials costs. This can best be

accomplished for airframes by taking advantage of the unique properties of composites to drastically reduce the number of individual parts and, thus, greatly simplify assembly processes. To minimize part count in basic fuselage and lifting surfaces, it is necessary to achieve wide spacing between stiffening members or to provide skins with integral stiffeners, or both. Reducing the parts count makes the use of sandwich skin construction attractive, relative to conventional skin-stringer construction, whether metal or composites are being used.

Sandwich construction provides the capability of carrying pressure loads and the stiffness to stabilize shear panels of large dimensions, which is necessary if wide spacing of substructural members is to be achieved. The possibility of curing composite skins simultaneously with bonding skins to the sandwich core gives composite sandwich structures one manufacturing advantage over metal sandwich construction. Reduced susceptibility to corrosion when moisture invades core voids offer another. Significant weight and cost reductions were achieved by using composite sandwich construction in the Airbus A330/A340 rudder. Weight was reduced by 20 percent and cost by 10 percent, compared with the metal design it replaced. Stabilizer, elevators, flaps, and spoilers are also of composite sandwich construction on the latest Airbus models. These are large structures; the A310/A300 carbon fiber vertical fin is 25 feet high and 25 feet wide at the base.

The Boeing Model 360 research helicopter demonstrated a large cost reduction over equivalent metal semimonocoque construction by using sandwich composite structure and wide spacing of stiffening members. Frames were placed only where major loads entered the structure, resulting in frame spacings up to 6 feet. Four longerons, with strength for limit load factor with one missing, resulted in 6-foot spacing between longitudinal bending members. Skins were Kevlar®/epoxy; the honeycomb core was NOMEX®; and the frames and longerons were largely graphite/epoxy composite. Shop man-hours to fabricate and assemble this structure were one-half as much as usual, and tooling costs were less than one-tenth those of equivalent metal structures. The simplicity of the structure produced an 86 percent reduction in the number of parts and a 93 percent reduction in the number of fasteners.

Boeing helicopter operational experience with composite honeycomb rotor blade structures on U.S. Army aircraft has been excellent. The mean time to unscheduled removal to depot was increased from 800 flight hours with metal rotor blades to 10,000 hours with composite blades. The metal blades had aluminum honeycomb structure aft of the spar, and the composite blades had NOMEX® honeycomb in the same application. Despite concern with sealing against water entry, no blade removals were associated with water entry to the NOMEX® honeycomb. Experience has also been excellent with Kevlar/NOMEX® honeycomb structure on the 1,000-gallon external fuel tanks used on Model 234 Chinooks, which have been operating in the North Sea oil fields for many years.

This background of good experience accumulated by Boeing Helicopters and others with composite honeycomb sandwich structures is still apparently unable to overcome resistance to its widespread use on the part of a large segment of the industry. Additional fundamental research and technology development is needed to broaden the data base and further increase confidence levels. Because finding an effective means to seal sandwich panels has been a particular challenge and concern, an evaluation of existing edge and surface sealing methods

used on aircraft honeycomb structures and of additional sealing methods is necessary to identify and substantiate the best sealing method for any application.

Although sandwich skins appear to have the greatest potential for reducing part count and, hence, manufacturing costs, considerable attention should be given to integrally stiffened composite structures. The term "integrally stiffened" requires definition. Simply bonding two precured parts clearly does not produce an integrally stiffened structure. Cocuring skin and frames that have been filament wound in the same operation, for example, would produce a structure that is integrally stiffened. The viewpoint taken in this report is that as long as cure of one of the components being joined to another occurs simultaneously with the joining, the part is integrally stiffened. It is not unusual to do this with uncured skins and either a cured or a partially cured ("B-stage") substructure.

Experience to date has shown that design and tooling for integrally stiffened skin panels should provide for adjustment in the position of the substructure to be attached to skins, to account for tolerances of fit-up between skin panels and frames and stiffeners, for fuselages, and for ribs and spars for wings. Uniformity of the inside surface, with tooling on the outer surface, cannot be counted on to provide good surface-to-surface conformity and, in the case of precured substructures, clamp-up stresses can cause cracking of the substructure matrix around fasteners. The tool concept developed for the Airbus fin by the German firm MBB bonds precured ribs by cocuring rib shear ties to the skins. Adjustment normal to the surface of the position of skin surfaces, with rib height, prevents prestressing at assembly. A system of aluminum blocks between skins, stringer flanges and webs, and rib shear ties provides cure pressure by thermal expansion of the aluminum. Large, integrally cocured panels are, in general, desirable to reduce the number of parts and, hence, assembly costs. However, large stiff parts present fit-up problems if close tolerances are not maintained. Much effort is needed to understand and better control the warping of large, complex parts during cure. Also, more robust joining procedures are needed.

Automated lamina placement for buildup of fuselage skins will significantly reduce costs, compared to hand lay-up, whether it be in tape or tow form. Means of doing this most cost-effectively need to be investigated. A V-22 Osprey tiltrotor aircraft fuselage after body was manufactured by using automatic tow placement and tape J-stringers. This method of manufacture substantially reduced manufacturing hours and provided excellent strength. All test panel failures were within the scatterband of the original, hand lay-up fabric design. Failures were instantaneous, as in the case of the fabric design. They exhibited some disbonding, which was not present in the fabric test panels, but carried equal loads before failure. Similar advantages appear in lifting surface manufacture. For instance, a "number one" composite helicopter rotor blade required approximately 15 man-hours per pound with hand lay-up. With automated lay-up, they were produced in less than 1 man-hour per pound. This is much lower than the number of man-hours expended for metal parts. With the exception of very large structures, such as the 747 fuselage constant section, 3–4 man-hours per pound after hundreds of units is typical. Thus, it appears that with proper design, remarkable cost reductions can be realized in composite part production by introducing automation to replace hand lay-up.

In summary, NASA should undertake fundamental research and technology development for composite materials and structures, including a comprehensive investigation of the issues associated with design for manufacturing that results in reduction in parts count. This is the key to reducing the cost of composite structures and, in turn, the key to broader realization of the weight and other benefits promised by composites. Use of the unique anisotropic characteristics of composites to produce the most efficient structures should be emphasized by using sandwich-stiffened skins, skins with integral stiffeners, and widely spaced additional stiffening elements. Manufacturing technology programs conducted for composite structures by both the Air Force and NASA have proved to be of great benefit to our national competitive position.

Metal and Ceramic Matrix Composites

Metal matrix composites are, as might be expected, formed under various combinations of high temperature and pressure, and ceramic matrix composites, such as carbon-carbon, by infiltration processes such as chemical vapor deposition in a vacuum. Although more experience exists with MMCs than CMCs, both are in their infancy with regard to large-scale application.

In general, the fabrication options available are also variably susceptible to automation, most are energy intensive, and those with fine dimensional tolerances require precise molds.

Fabrication Summary

To date the assembly of primary structures by composites has been accomplished with mechanical connections—for the most part, rivets or bolts. Uncertainty regarding the integrity of bond lines made outside of cocuring facilities has mitigated against bonded joints. This is also true for bonded joints in metal structures, particularly when the extended useful lives of commercial aircraft are considered.

From these considerations, it is apparent that structural design with composites is influenced to a far greater extent by fabrication technologies and materials choices than is the classical design of metal airframe structures. Superplastic forming of metallic parts is considered nonclassical in this context and raises its own challenges. Composite application to engine structure may be at least as integrated a matter as it is with airframes, but composite applications to engines until now have not been extensive enough to provide indicators. Research in these areas, however, should be a continuing part of NASA's base program.

Test Methods

From the wide spectrum of materials and structures tests that exist, three areas have high priority for increased research emphasis: fundamental test information, nondestructive evaluation techniques, and material lifetime properties. First, fundamental test information is needed from which materials constitutive relationships can be developed that lead to reliable structural models of failure mechanisms. Experimental methods must be devised

to provide such data with the objectives of predicting responses to all pertinent types of loadings and states, and the total lifetimes for the structural components of interest. This class of design problem is particularly important for high-temperature applications. Materials researchers should emphasize the multiaxial, coupled nature of most materials applications to aeronautical structures and ensure that test methods for materials characterization can be performed under conditions corresponding to actual operation of the structural component. This capability does not usually exist but would be a valuable asset in the development of advanced aircraft and engines.

Second, NDE is an area of great need and promise. Many NDE techniques are available that will detect flaws and other imperfections with various degrees of accuracy and reliability. Although sensitivity and reliability of crack detection need an order-of-magnitude improvement, both NDE and the damage tolerance of materials and their applications must be advanced before efficient damage-tolerant design concepts can become routine for airframes and the critical rotating parts of turbine engines.

Integration of NDE into the structural concept/design/fabrication processes and automation of the NDE process also require greater attention. Advanced design concepts are being actively pursued that permit in situ and real-time damage assessment through the use of embedded sensor/processor technology. This approach, combined with highly damage-tolerant structures, could provide a means of assessing structural integrity over the lifetime of the component, with attendant improvement in safety and operating economics. Technology for complete automation of the NDE process over a broad spectrum of applications should be a priority research goal. This includes sensors, sensor placement tailored to the structure, and automated scanning and interpretation of results.

Third, composite materials represent new challenges not previously encountered in life prediction systems. For example, the thermal expansion incompatibilities between fiber and matrix can often be limiting in composite applications. Long-term exposure effects in composite materials are virtually unknown for the advanced systems being designed, particularly in the high-temperature regime. Testing techniques that are realistic and allow the projection of long-term effects must still be developed. Standardization of test techniques unique to composite construction should continue to be pursued. This will be especially important as new failure theories are developed consistent with the way composite materials behave.

Smart Structures

Adaptive structures is a relatively recent concept that offers potentially important benefits in aircraft design. If, for example, a wing or wing section can be made to adapt its shape to maximize aerodynamic performance or minimize load regardless of flight regime, this could be a significant advantage—particularly if it were to reduce the number of moving parts. This technology began, in one sense, with the so-called control-configured vehicle concept and has grown to include compliant materials and structures combined with embedded sensor/processor/actuator systems. NASA should play a major role in developing adaptive or smart structure concepts. This research should include variable blended wing-fuselage-engine

inlet concepts, smart landing gears, active flutter suppression/load alleviation systems, and health-monitoring and field inspection procedures.

Durability

Airframe durability is a systems issue focusing on economic factors. It encompasses longevity, which concerns safety and structural capability to carry load after repeated operations. Aspects contributing to durability are design characteristics leading to ease of maintenance, damage monitoring and inspection, repairability, and ultimately airframe retirement. NASA should aggressively investigate better methods to improve structural life. The program should be composed of three parts: the determination of loads and resultant damage, including accelerated aging tests for all classes of materials; analysis techniques to assess the findings of such determinations quantitatively; and effective repair techniques to restore structural integrity when mandated. Programs dealing with aircraft structural integrity, fleet structural management, and aircraft life cycle management and operation are important contributors in this regard, but technology advances are needed in each of these three parts of life management programs.

The same basic philosophy in life management programs is common to metallic and composite structures, but the technology advances required are different for structures composed of these two classes of materials.

Metals

Events in recent years have brought the issue of aircraft longevity, and thus durability, to public consciousness, and the government has made safety evaluations of aging aircraft a national priority. In the current metallic aircraft fleet, particular concerns are disbonds in fuselage splice joints, fatigue cracks in riveted splice joints, and airframe corrosion. Research is needed to increase the reliability and efficiency of NDE techniques, such as ultrasound and phased array imaging.

Although fracture mechanics technology has existed for years, continued advances in understanding and capability are needed, including the ability to analyze the stress field in, and resultant fracture of, structures with multiple-site damage. This requires an understanding of various crack geometries. In addition, probabilistic structural analysis methods need to be extended to cases in which damage is present to assess residual load-carrying capabilities and lifetimes of damaged aircraft structures.

Repair techniques for metallic aircraft structures are well developed, but techniques to decrease the costs of such repairs are desirable.

Composites

The use of composite materials in aircraft is relatively limited, especially in civilian applications, so the base of experience with longevity and durability is limited as well.

However, the use of composites is increasing—particularly in the Airbus 320 and Boeing 777—and so it is vital that more attention be given to issues of longevity and durability in composite aircraft structures. NASA should lead a coordinated national program to address longevity and durability issues for composite structures.

Nondestructive inspection techniques for laminated composite structures are not well developed in comparison to those for metallic structures. The fact that much of the damage in composite materials occurs below the surface of the structure and can, therefore, not be detected by visual methods hampers nondestructive inspection. This contrasts directly with metallic structures in which most damage can be seen. Furthermore, composite materials exhibit a number of damage modes, all of which may not be detectable if NDE is limited to one technique. An effort to develop quantitative methods for nondestructive evaluation of composite structures is clearly needed. Without this first step, assessing the residual life of such structures will not be possible.

Whereas fracture mechanics is well understood and useful for assessing damage in metallic structures, such a capability does not exist for composite structures. The multiplicity of damage modes possible in composites does not allow a single-analysis methodology to assess the effect of various possible damage states. The development of an area known as "damage mechanics" shows promise, but it is currently limited to an assessment of the stress/strain field and not a prediction of residual load-carrying capability and lifetime. The lack of a general understanding of the failure mechanisms in composite materials and structures inhibits making progress in the latter. It is clear that this understanding must first be established before progress can be made in predicting the effects of damage on residual capability.

Repair techniques for aircraft primary structures made of composite materials have been developed but are oriented mainly toward military aircraft. No similar capability exists for civilian aircraft. Furthermore, costs of repair may be the key limiting factor, including basic materials and labor costs and those needed to develop the infrastructure to handle composite repairs. A concentrated program to establish repair procedures ranging from on-site repairs, which are temporary in nature, to depot-level repairs, which are considered permanent, is necessary. Although the knowledge of the criticality of certain damage is important in assessing the need for repair, such knowledge is not necessary to develop repair techniques. Thus, such programs can proceed immediately.

Life management programs generally involve discrete inspection time intervals as determined from various analysis techniques and design philosophies. The ultimate goal of such programs should be the continuous monitoring of structures for applied loads and damage growth and associated evaluation of residual load-carrying capability. Recent technology advances indicate that this may be possible by embedding strain sensors in the structure and monitoring these throughout the use of the aircraft. The concept is particularly applicable to composite structures, because the necessary network of sensors can be embedded during the manufacturing process. Such an approach is not as straightforward, if it is possible at all, with metallic structures.

Programs in the military sector have addressed the area of "self-diagnostic structures," that is, structures that assess their own health. However, no such programs exist for civilian

applications. Numerous issues must be addressed such as the basic capability of the embedded sensors (e.g., optical fibers, piezoelastic materials, memory materials), the network of sensors and information carriers necessary, embedding techniques, and on-line analysis and assessment capabilities. However, this area holds great promise for increasing the ability of aircraft operators to assess the health of aircraft and thereby improve operational safety while decreasing maintenance costs associated with currently expensive inspection techniques such as teardown.

FOCUSED TECHNOLOGY ADDRESSING SUBSONIC TRANSPORT AIRCRAFT

Materials and structures technology needs for subsonic commercial transport aircraft are outlined in this section. Emphasis is given to commercial transport aircraft, because technology benefits there offer substantially greater payoffs.

Technology advances in materials and structures applicable to commercial transport are, for the most part, transferable to other subsonic aircraft systems. However, it is important to recognize certain unique aspects of commercial transport service operations and customer relations in dealing with the application of advanced materials and structures to that class of aircraft. Flight operations per aircraft average roughly 3,000 hours annually and close to 60 hours per week. Commercial transport aircraft can be in revenue service well beyond 20 years, and the manufacturer must be concerned about safe operation. Thus, the financial risks undertaken by private companies when they introduce advanced materials and structures into commercial transport aircraft go beyond liability for passenger safety—as important as those ramifications are—and can involve structural maintenance, modification, and repair of fleets worldwide.

Airframe

Lower structural weight fraction and lower costs are high-payoff aspects of advanced subsonic airframe structures. Fiber-reinforced polymer matrix composites offer the greatest potential for meeting this need. Currently, polymer matrix composite (PMC) materials have advanced to the point of wide use for fairings and doors, and limited applications in empennage and control surfaces on transport aircraft.

Although much of the basic technology is at hand to produce a commercial transport aircraft with a large percentage of composites in the primary structure, there are three significant areas of concern. First, the current cost of producing composite structures is on the order of two to three times that of comparable metal designs; second, durability, maintenance, and repair present a number of uncertainties that could appreciably affect operating cost. Finally, facilities such as large autoclaves and inspection equipment currently used to produce large composite parts and assemblies require major capital expenditures.

Cost-effective application of composite materials as a technology program must include advances in materials and structural concepts that are integrated into fabrication methods. Structural concepts that minimize part count and can be automated are essential to achieving an economically competitive airframe. Replacing skin-stringer construction with sandwich skin

panels would seem to have been a natural evolution for commercial aircraft, whether fabricated by using metal or composites. Environmental factors, however, have been determinative in choosing between skin and stringer versus sandwich construction in metal. Corrosion associated with water trapped in sandwich core spaces has been seen as an insurmountable problem. PMCs tend to vitiate this objection to sandwich construction. Further, cocuring of skin and stringer composite construction results in parts count reduction. Thus, both sandwich skins and skins with integral stiffeners promise manufacturing cost reductions with the use of composites.

The approach employed is likely to depend on the application. Sandwich skin panels for fuselages have many attractive advantages. Wings will most likely have integrally stiffened composite skins as has been done with the A-6, AV-8B, and V-22 airplanes, because of the high load intensity and stiffness needed in most wing structures. These result in skins that are too thick to be good candidates for sandwich construction. In addition, many airplane wings use every bit of available internal wing volume to store fuel. These aircraft with wet wings are not required by crashworthiness criteria to use elastomeric tank liners, as many VTOL aircraft are. In wet-wing applications of sandwich skins, there is concern about fuel seepage into core voids, certainly more concern than one has about the small amount of water in other structural components. Also of concern with wet wings is the loss of available volume for fuel due to the thickness of sandwich skins, because space for fuel is at a premium in all aircraft.

An important technological development for the future of composite structures, whether sandwich panels or integrally stiffened skin panels, is the incorporation of crack stoppers. Hybrid composite construction does promise the means to do this, with bundles of highstrain-allowable fibers interspersed at intervals among the high-modulus fibers that provide the bulk of structural properties. In addition, these structural concepts will have to meet damage tolerance and long-life requirements typical of transport aircraft. The current NASA effort in advanced composites technology (ACT) is making excellent progress toward developing the technology base for composite primary structures. Extension of the ACT program to verify large structural components, including cost-effective fabrication as well as structural performance, is essential to bring this technology to a state of readiness for commercial application.

In addition to research supporting composite airframe structure technology development, research is needed in selected areas for metallic airframe structures. These include improved structural integrity and life prediction methodology to account for the fact that the economic life of current aircraft is being extended into the future. NASA's current Aircraft Structural Integrity program is an ongoing program that addresses this need.

Improvements in engine noise for commercial high-subsonic transport aircraft have reached the point, thanks largely to higher bypass ratios and duct absorption systems, at which noise generated by the airframe is an important consideration. Cavity resonances are suspected in, for example, landing gear wells before retraction in takeoffs, and after extension in landings, as sources of pervasive, low-frequency sound.

Propulsion System

The commercial fleet today is made up primarily of high-bypass ratio, turbofan-powered aircraft, whereas the next generation of commercial aircraft will be powered by advanced ducted engines characterized by very high bypass ratios. The following generation is likely to include aircraft propelled by unducted prop fans, with large-radius propeller-like blades having high and radially varying sweep, thin sections, and high solidity. Goals for all of these future products include significant decreases in fuel consumption, significant reductions in engine weight, and reduction in the airlines' operating costs for these engines and their propulsive adjuncts.

Key technologies for achieving these goals include improved materials and innovative structural concepts; both need to be addressed. Better metals, new families of engineered materials, and techniques for achieving aeroelastic stability and vibration reduction, including smart structures, all have sufficient promise to demand attention.

There will be an ongoing need for the evolutionary development of conventional metals for the particular requirements of gas turbine engine applications. In parallel, however, efforts must be directed to creating innovative, even more lightweight and efficient structures, through new design concepts that exploit the unique characteristics proposed by those engineered materials currently being studied for use in the year 2000 and beyond.

The longevity requirements of commercial products will typically be 15,000 hours for cold-section parts and 20,000 hours for hot-section parts. Engine efficiency improvements will require compressor exit temperatures higher than 1300°F and maximum turbine temperatures (uncooled) of more than 3000°F. These form the basis for advanced materials goals.

The families of materials to be considered for engine applications, in the general order of increasing temperature environment, are PMCs, aluminum MMCs, advanced titanium alloys, titanium MMCs, superalloys, titanium and nickel aluminides, intermetallic matrix composites (IMCs), and CMCs. NASA's program should emphasize PMCs, MMCs, the aluminides, and CMC-type materials. Specific materials and structures needs are identified by component in the following sections.

Rotating Systems

Fans

Future fan sections will require lightweight fan blade materials, rugged enough to survive damage by foreign objects and erosive elements. Historically, titanium has been the major compressor material in advanced subsonic aircraft. Ducted fan blade diameters are increasing, due to increasing requirements for thrust and propulsive efficiency. Such blades are shroudless and swept for aerodynamic efficiency. The continuing challenge is to design blades that deliver improved performance, whether composite or hollow titanium whose construction is capable of withstanding the loading associated with bird impact. Robust manufacturing processes must be developed for these new blades, with recognition of the structural and aerodynamic requirements. In-service inspectability and repairability are also issues of importance.

Aeroelasticity considerations in fan blade design continue to pace the technology. Flutter-free blades, both ducted and unducted, depend on developing advanced computational analytical design systems, probably utilizing unsteady CFD techniques. Current aeroelastics technology leads to first-stage blades with lower aspect ratios than desirable based on weight goals. Improved understanding of both flutter and resonance stress problems is required to achieve higher aspect ratio blade designs and reduced weight. Improved resonance stress prediction capability is also needed for such advanced designs. NASA/industry cooperative efforts are essential in improving the technology of fan design. In addition to cooperating in the development of analytical tools, government test facilities will be required to generate benchmark test data for substantiating and calibrating these new tools.

Compressors

The cycle selected for advanced engine designs will depend on the temperature level permitted at the exit of the high-pressure compressor. Higher allowable temperatures result in higher cycle pressure ratios and associated improvements in core thermal efficiency.

As with the fan section, titanium has, in recent years, become the major compressor material. Lightweight, higher-temperature materials hold the key to increasing compressor exit temperatures. Disks and/or drums make up a major portion of high-pressure compressor weight. MMC disks should provide the improved temperature capability desired. Managing the cost to manufacture these disks will be crucial; ensuring long-term reliability will be essential (through damage tolerance and adequate creep resistance); and providing efficient joining techniques, which allow the rotor to be built up from many individual pieces, will be necessary. Joining technology for these applications is not currently receiving adequate attention.

Reinforcing compressor disks with composites provides a good example of how new concepts can exploit the properties of composites. The stress field in a disk varies considerably from the bore inner diameter to the outer rim area that retains the blades, due to the effects of centrifugal loads and radial thermal gradients. The bore of the disk is primarily stressed in the circumferential, or ''hoop,'' direction. Orienting fibers in the circumferential direction in the bore would be an efficient use of such materials. This approach will produce a thinner disk bore with a faster thermal response characteristic, thereby reducing the critical bore-to-rim transient thermal gradient and associated stresses.

Several materials are available for compressor blades. Conventional nickel-based superalloys (probably cast, to keep cost low) and titanium MMCs are two promising choices. The challenge is to find usable techniques for attaching these blades to the advanced material disks. Advanced joining techniques should be exploited to eliminate conventional but inefficient dovetail attachments and to exploit more fully the capabilities of advanced blade and disk materials.

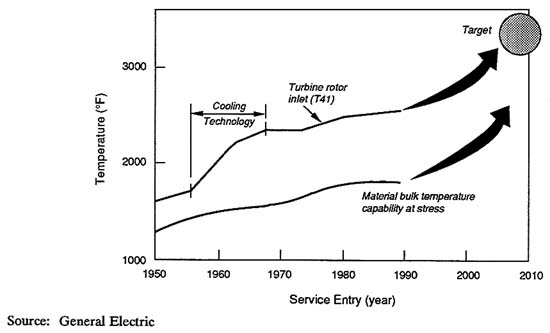

Turbines

Since turbine-powered aircraft entered commercial service, temperature capability at the turbine inlet has been increasing steadily. In the 1960s, advanced cooling technology permitted a significant increase in the allowable operating temperature. This trend to higher temperatures has been paced by increases in bulk material temperature capability increases. To make further significant increases in overall temperature capability, even greater increases in bulk material temperature capability must occur. It is expected that CMCs will provide that necessary increase. CMCs in airfoils, disks, and engine cases should allow turbines to be operated at increased temperature without the inefficiencies associated with cooling.

The progressive substitution of ceramics and CMCs for metals in the hot section of aircraft engines could begin late in the 1990s and continue for the next few decades. To bring this about, it will be necessary to create a technology base to improve ceramic and CMC material reliability and producibility, while developing the concomitant design methodologies and life prediction systems. Building this base will require efforts to understand the relationships among materials, their processing, microstructure, and properties. It will include applying this understanding to developing design tools to deal with materials with reduced ductility compared to today's experience. Other areas of concern include improving oxidation resistance, ensuring compatibility of the fiber/matrix interface, and developing CMC fabrication technology. It is important to note that CMC development has the potential to be one of the highest-payoff materials programs for advanced engine systems.

As in compressor applications, additional turbine structural challenges include developing new design concepts that capitalize on the unique properties of composite materials. Here, too, conventional blade attachment "firtrees" must be replaced with mechanical schemes that exploit the directionality of engineered material systems. These advanced concepts will likely be revolutionary rather than evolutionary. Integrating the disciplines of material sciences, mechanics, structural, design, and manufacturing process development will be essential to the success of this enabling technology.

Shafts and Bearings

Advanced engine core sizes will continue to get smaller. The challenges resulting from this trend involve higher rotor speeds, smaller disk bores, restrictions on maximum low-pressure shaft diameters, and very high-speed bearings. This will require flexible high-speed shafts, which in turn will drive the need for active control of rotating system response to minimize damaging loadings on the engine structures themselves and the aircraft structures to which the engines are attached. Higher bypass fans will operate at lower speeds and may need to be coupled to the low-pressure turbine through a gearbox. This suggests an increased oil supply for cooling the gearbox and an enhanced cooler design.

Advanced technology engines will probably incorporate magnetic bearings instead of rolling contact bearings for the performance (5 percent) and weight improvements (10–15 percent) possible through their use. New systems will also incorporate electric starters/generators

on the high-speed rotor and feature all-electric accessories. Advantages of magnetic bearings and all-electric accessory systems include elimination of the oil system, elimination of the tower shaft and gearbox, simplified packaging of engine external components, reduced friction losses, higher rotational speeds, active shaft damping, and higher bearing operating temperatures. Figure 9-2 shows the expectations for increased temperature capability of bearing

FIGURE 9-2 Expected temperature capability of turbine engine bearing systems as a function of service entry year.

systems as the level of technology increases. The majority of the basic technologies for applying magnetic bearings are currently being developed; however, miniaturization of digital electronics will be required to bring this technology to commercial application. In addition, magnetic wiring installation with sufficient temperature capability must be developed.

Nonrotating Components

Engine Cases

Application of composite materials to engine static structures will be highly dependent on the ability to design and manufacture these complex structural shapes and to provide means for determining their remaining life after years of use. Fan exit frames, for example, incorporate large-diameter rings interconnected by aerodynamically shaped struts that, in turn, are attached to inner rings forming the flow path for exit of the engine fan stream. This is yet another example in which effectively integrating structural design efforts with both

manufacturing process development and the development of maintenance procedures will be crucial to the successful incorporation of composites. The materials being developed for rotating structures in the compressor and turbine sections of the engine are very likely to be applicable to major cases as well. However, for maximum benefit in case applications, the details of the design and the orientation of fibers may well require specialized development.

Inlets and Nacelles

Because inlets and nacelles have increasingly large diameters, the need to reduce weight is the primary driver for the structural designer. They clearly must be made of composites if advanced engine weight goals are to be achieved. Their temperature requirements are modest, so that polymer matrix composites can be applied. The major challenge will be to develop the materials and structural concepts that will be cost-competitive. The need to incorporate noise suppression treatment in these structures will continue in the future. In-service inspection and repair techniques must be developed concurrently with component development.

In addition to the environmental aspects of noise reduction, techniques must be developed for dealing with the acoustic loads produced in inlet and exhaust structures. Improved methods for predicting load generation and structural response in acoustic environments should be explored. Materials with high specific damping, capable of functioning at moderate and high temperatures, are required to ensure inlet and exhaust structure durability and reduce noise transmission.

Acoustics

Community action barriers to the needed growth of the airline transport system are likely to be based primarily on the environmental noise generated by large, subsonic commercial transport aircraft in the vicinity of airports. Of major importance is the availability to manufacturers of the acoustical information needed to make appropriate design choices, and the methodologies and data bases required to substantiate predicted levels to the regulatory authorities and to the communities affected. It is equally important, on the other hand, that appropriate noise information, including subjective response surveys, be available from unbiased authority to help ensure that evolving noise regulations are established on sound technical and environmental bases can be met with practical configurations and without incurring unacceptable costs.

Both external and internal noises are matters of concern with unducted, so-called ultrahigh bypass fan propulsion systems. To a first approximation, the thrust generated, blade radius, helical tip speed, blade area, and number of blades determine the sound pressure levels generated. Airfoil thickness, sweep, interaction with the airframe-induced flow field and blade phasing can make lesser differences; flight paths and counter rotating arrangements, either of which can cause blade vortex intersections, can result in greater changes in noise levels.

FOCUSED TECHNOLOGY ADDRESSING SUPERSONIC TRANSPORT AIRCRAFT

Materials and structures technology needs for supersonic aircraft are outlined in this section. They generally follow the technology requirements defined in the studies being conducted for the NASA High-Speed Civil Transport (HSCT) program. The HSCT is a high-performance aircraft in which weight is a key factor. Thus, technologies that reduce weight are important technical drivers.

Airframe

For the HSCT airframe structure, specific material requirements are dependent on cruise Mach number, which could range from 1.8 to 2.4. At higher Mach numbers, materials with a 300–350°F temperature capability are required.

Neither the higher dynamic pressures nor the higher temperatures associated with a speed of Mach 2.4 give rise to important design considerations that are new in the aircraft design field. Although considerably above current subsonic requirements, these temperatures and speeds are in the range of currently designed military aircraft. They do, however, involve design criteria not dealt with in previous large U.S. commercial transport aircraft structures. These include the possibility of panel flutter, large temperature gradients across airframe structures during acceleration and deceleration, and very thin wing sections. An economic objective of the HSCT program is to achieve an airframe weight reduction of up to approximately 30 percent relative to Concorde-generation designs. The importance of achieving this weight reduction cannot be overemphasized. Not only are operating economics directly affected, but current runway/taxiway infrastructure limits are estimated to be 900,000 pounds, and each pound of empty weight added in the design stage grows to several times that in takeoff gross weight.

Although the drive for a low structural weight fraction places PMC materials in the lead role, advanced titanium is competitive in compression applications. High-temperature aluminum may also play a role in certain applications because of the relatively low cost. Titanium alloys are available that would meet all technical requirements, but considerable effort must be expended in research and development to further improve their engineering properties and reduce fabrication costs. These advances could lead to their widespread use. Thus, the materials technology program required to meet HSCT requirements should focus on PMC, advanced titanium alloys, and the development of cost-efficient design concepts for titanium and hybrid laminates.

Currently, there are no proven PMC materials or aluminum alloys capable of 60,000 hours of service in an airframe structural environment at temperatures in the 225–375°F range. Because it is usually necessary to demonstrate twice the expected lifetime, the materials requirement for HSCT will be difficult to meet. Some seven to eight years of testing is required just to validate the 60,000-hour life capability of a material under HSCT airframe thermal and mechanical loads and real-time temperature conditions. The development of accelerated testing procedures and modeling techniques for thermal, thermal-mechanical, and environmental degradation mechanisms is vital to developing and characterizing new materials. Materials

development testing and validation for this service environment should be a high priority in the technology program. Some specific recommendations are outlined in the following sections dealing with each class of materials.

Polymer Matrix Composites Technology

PMC technology development should include high-temperature thermosetting and thermoplastic matrix resins. Significant improvements in both processibility and high-temperature stability are required for the HSCT mission. Most likely, a major breakthrough in resin technology will be required to achieve the combined technical performance with the ease of fabrication necessary to produce cost-effective airframe structures.

As in the case of subsonic transport aircraft, cost-effective application of PMCs for HSCT will require an integration of material advances and structural concepts into cost-effective fabrication methods. Structural concepts that minimize parts count and can be automated are essential. The most demanding aspect of an HSCT regarding airframe structure is the fuselage. The use of sandwich construction is desirable, because it is very efficient and provides good heat insulation for the cabin area. Pressurized fuselage concepts that preclude cabin decompression are essential for an HSCT that cruises above 40,000 feet. Special wing configurations are likely in an advanced HSCT to minimize sonic boom footprints and provide laminar flow control. These needs will also require innovative solutions by the structures community.

In addition to the materials and structures developments noted above, substantial efforts will be required to verify combined advances in materials and structural concepts. This activity is likely to include many subscale tests leading eventually to near full-scale testing.

Aluminum Alloys

Current ingot metallurgy aluminum alloys are limited to 200–225°F. Increasing the temperature capability of these alloys another 100°F to meet the higher HSCT requirements is difficult. However, recent advances in powder metallurgy aluminum alloys show excellent potential for achieving the higher-temperature capability. This approach is more costly than ingot metallurgy alloys, but should be pursued together with advanced ingot metallurgy approaches. Microalloying and particulate reinforcement are promising approaches to make ingot aluminum alloys satisfactory for certain HSCT applications.

A successful, economically competitive structural design will involve a combination of materials in the airframe. The higher speeds will place greater emphasis on achieving compatibility among components with different thermal coefficients of expansion. There is a large difference between the thermal coefficients of expansion of composite materials and those of metal components. Unless proper design concepts are developed, these differences could result in significant internal stresses as the temperature environment changes for major structural components.

Materials and structures research and development effort in support of the HSCT needs to be directed toward

-

developing basic composite and metallic materials that can operate in the range of 225–375°F, have durability and toughness properties that can resist degradation in the operational environment for 20 years, and can be reliably produced at minimum cost;

-

establishing design concepts that save significant weight relative to current metal structures and can be economically fabricated; and

-

verifying materials developments, design concepts, and fabrication technology by producing large-scale components that can be subjected to laboratory or, preferably, full-scale service testing.

The present NASA program embodies many characteristics needed to achieve these goals, but the major emphasis to date has been on subsonic aircraft requirements. Much of technology development involving new structural concepts is applicable to both subsonic and supersonic designs, but the research program should be balanced to ensure that materials and manufacturing process development will include those compatible with the more extreme requirements of the HSCT.

Propulsion System

Most of the advances noted in the subsonic aircraft section for rotating components (compressors and turbines) are also required for the HSCT. In addition, special developments in the inlet, combustor, and exhaust nozzle are required for the HSCT. They are described in the following sections.

Combustors

The exit temperature of the high-pressure compressor and the combustor associated with supersonic cruise translate to an HSCT mission in which 80 percent of operations are at maximum temperature. Current subsonic commercial aircraft typically fly at maximum temperature for less than 10 percent of the total mission time. Operating at extremely high temperatures over such a long portion of the flight reinforces the need to develop high-temperature materials for the HSCT combustor. Additionally, the materials system selected for combustors must have good high-cycle fatigue resistance to withstand significant acoustic and vibratory loads.

In other respects, combustor materials needs for HSCT are similar to those of advanced subsonic commercial transport applications. In either case, it is essential that the engines satisfy low nitrogen oxide (NOx) requirements. Advanced combustors can be expected to have (1) decreased liner cooling flow or no cooling at all, (2) staged combustors, and (3) turbine inlet temperatures of at least 3000°F.

CMCs capable of operating to 3000°F are likely candidate materials for the combustor. CMCs offer the high-temperature performance of monolithic ceramics with improved toughness and reliability. For CMCs in which the matrix modulus is high relative to the fiber

reinforcement, material toughness is likely to be dominated by the fiber/matrix interface and its characteristics.

High-conductivity, high-strength silicon carbide and silicon nitride composite systems have the potential to meet current projected combustor material requirements. Improvements in silicon carbide fiber capability are needed to increase high-temperature strength retention and composite structure creep resistance. Materials processing is a critical part of advanced CMC development, and it must be addressed concurrently with combustor materials selection and evolution of the design. Processing approaches could vary considerably, depending on the matrix, fiber, coating, and material form (such as weave) selected for the combustor.

In addition to materials with higher-temperature capability, structural concepts must be developed that avoid high thermally induced strains at points of attachment. Advanced aerothermal and structural computational codes are likely to be needed to achieve optimized designs, and appropriate testing is required to prove the feasibility of advanced combustor configurations.

Nozzles

A key technology area for many jet aircraft types, but for the HSCT in particular, is the design and manufacture of the exhaust nozzle. This component must be lightweight, designed for high propulsive efficiency, and include sonic treatment for noise control. Alternative nozzle designs being considered for the HSCT all represent a significant percentage of the installed propulsion system weight. By their nature, these low-noise exhaust nozzles are large, mechanically complex structures running at elevated temperature, with large gas flows and pressure gradients.

Development of a practical nozzle configuration is highly dependent on the simultaneous development of advanced, high-strength materials and associated structural concepts that exploit the use of composites. They must perform uncooled to the maximum extent possible to avoid performance losses associated with cooling large surface area liners. In addition to meeting challenging temperature and strength requirements, the materials selected must allow fabrication into the large, complex shapes currently being studied. The materials systems being considered currently have low ductility in general and, thus, may be difficult to fabricate.

Advanced nozzles are likely to be produced from several different materials. A very wide range of maximum temperatures and a wide range of specific strength requirements will be encountered, depending on which part of the nozzle is considered. No single material system is likely to have superior properties in comparison to others over this entire strength-temperature range. Carbon-carbon composites have high specific strength and stiffness and adequate temperature capability, but exhibit poor oxidation resistance uncoated. It will be necessary to develop an effective coating that prevents oxidation before further exploitation of this otherwise highly capable material is possible.

CMCs will probably be employed in the part of the nozzle exposed to gas path exhaust temperatures. IMCs will make up many other parts of the structure. This is an enabling technology for the HSCT. The materials development done in support of this nozzle will have

high payoff for other sections of advanced subsonic engines, once feasibility has been established.

FOCUSED TECHNOLOGY ADDRESSING SHORT-HAUL AIRCRAFT

Short-haul aircraft are thought of in three subcategories: commuter aircraft, rotorcraft, and general aviation (GA) aircraft. The associated propulsion systems in the 2000–2020 time frame have no substantial materials and structures problems that differ from those of other subsonic aircraft. Accordingly, this section refers solely to airframe aspects of short-haul aircraft.

Commuter Aircraft

Commuter aircraft, rotorcraft, and GA airplanes are included in the short-haul category. Commuter aircraft range in size from 19-passenger turboprops to 65-passenger turboprops and 107-passenger jets. Although more are in service, today only two commuter types are being manufactured in the United States, the 19-passenger Beech 1900 and the Fairchild Metro. All others are of foreign design and manufacture.

Low-weight composite and/or superplastically formed metallic airframe structures, with costs substantially below those of aluminum structures, could provide a competitive edge, helping U.S. manufacturers to compete in the short-haul market. The need for structural research to achieve these low-cost structures is common to the activities identified for all subsonic aircraft fuselage and wing structures. Aside from a general trend toward greater simplicity, and more lightly loaded structures as aircraft become smaller, there are no unique structural issues specific to commuter aircraft.

Rotorcraft

Civilian use of rotorcraft consists primarily of helicopters, although tiltrotor aircraft are under development and proposed commercial versions show promise for the commuter market. Structural research aimed at low-cost, low-weight composite fuselage structures will benefit the rotorcraft industry greatly. However, unlike commuter aircraft, rotorcraft involve a number of unique structural issues that impede development and successful application to commercial operations.

Vibration and Noise Reduction