The Industrial Green Game. 1997. Pp. 117–123.

Washington, D.C: National Academy Press.

The Industrial Symbiosis at Kalundborg, Denmark

HENNING GRANN

The concept of sustainable development is being widely referred to by politicians, industrialists, and the press. Although there is agreement in principle about the meaning of this concept, there are many and differing opinions as to what it means in practice and how the concept should be translated into specific actions.

The industrial symbiosis project at Kalundborg, Denmark (100 kilometers west of Copenhagen, population of approximately 15,000), is a model of environmental sustainability. It provides a vision of what is possible. The project has attracted a good deal of international attention, notably by the European Community, and been awarded several environmental prizes.

The symbiosis project, however, is not the result of a careful environmental planning process. It is rather the result of a gradual cooperative evolution of four neighboring industries and the Kalundborg municipality. Although begun by chance, the project has now developed into a high level of environmental consciousness in which the participants are constantly exploring new avenues of environmental cooperation.

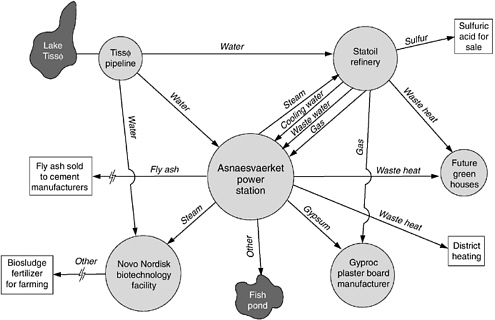

What is industrial symbiosis? In short, it is a process whereby a waste product in one industry is turned into a resource for use in one or more other industries. It is the essence of a well-functioning ecosystem. The Kalundborg experience shows that cooperation among different industries in the use of waste increases the viability of the industries. At the same time, the demands from society for resource conservation and environmental protection are met.

Four industrial facilities—a power plant, an oil refinery, a plaster-board manufacturing plant, and a biotechnology production facility—and the local municipality participate in the Kalundborg symbiosis.

-

The power plant, Denmark's largest, is owned by Asnæsværket. It is coal fired, has a capacity of 1,500 megawatts (mW), and employs about 600 people.

-

The oil refinery, Denmark's largest, is owned by Statoil. The refinery has a capacity of about 3 million tons per year (tons/yr) and is being expanded to a capacity of 5 million tons/yr. It employs about 250 people.

-

The plaster-board manufacturing plant, owned by Gyproc a.s., produces about 14 million square meters per year of plaster-board for the building industry. It employs about 175 people.

-

The biotechnology facility is owned by Novo Nordisk. The company produces about 45 percent of the world market of insulin and about 50 percent of the world market of enzymes. In addition, the company produces substantial quantities of growth hormones and other pharmaceutical products. Novo Nordisk operates in several countries, but the Kalundborg plant, with 1,100 employees, is the company's largest production site.

-

The Kalundborg municipality controls the distribution of water, electricity, and district heating in the Kalundborg city area.

DEVELOPMENT OF THE SYMBIOSIS

The symbiosis—or cooperative use of waste heat and materials—was not planned. The relationships that developed and are shown in Figure 1 evolved over a period of more than 20 years. A chronology of key events follows.

|

1959 |

The principal player, Asnæsværket, was started up. |

|

1961 |

Tidewater Oil Company commissioned the first oil refinery in Denmark, and a pipeline was constructed from Lake Tissø to provide water for its operation. (The refinery was taken over by Esso in 1963 and acquired by Statoil in 1987 along with Esso's Danish marketing facilities.) |

|

1972 |

Gyproc established a plaster-board manufacturing plant. A pipeline to supply excess refinery gas was constructed from the refinery to Gyproc facilities. |

|

1973 |

The Asnæsvæket power was expanded. To meet increased water demand, an agreement was reached with the refinery to build a connection to the Lake Tissø-Statoil pipeline. |

|

1976 |

Novo Nordisk started delivering biological sludge to neighboring farms by tank truck. |

|

1979 |

The power plant started supplying fly ash (until then a troublesome waste product) to cement manufacturers such as Aalborg Portland located in northern Denmark. |

|

1981 |

The Kalundborg municipality completed a district heating distribution |

|

|

network within the city of Kalundborg utilizing waste heat from the power plant. |

|

1982 |

Novo Nordisk and the Statoil refinery completed the construction of steam supply pipelines from the power plant. By purchasing process steam from the power plant, the companies were able to shut down inefficient steam boilers. |

|

1987 |

The Statoil refinery completed a pipeline to supply its effluent cooling water to the power plant for use as raw boiler feed water. |

|

1989 |

The power plant started to use the waste heat from its salt cooling water (+7-8°C) to produce trout and turbot at its local fish farm. |

|

1989 |

Novo Nordisk entered into an agreement with the Kalundborg municipality, the power plant, and the refinery to connect to the water supply grid from Lake Tissø to meet Novo's rising demand for cooling water. |

|

1990 |

The Statoil refinery completed the construction of a sulphur recovery plant. The elemental sulphur being recovered is being sold as a raw material to a sulfuric acid manufacturer located in Fredericia on the mainland of Yetland in Denmark. |

|

1991 |

The Statoil refinery commissioned the building of a pipeline to supply biologically treated refinery effluent water to the power plant for cleaning purposes and for fly-ash stabilization. |

|

1992 |

The Statoil refinery commissioned the building of a pipeline to supply refinery flare gas to the power plant as a supplementary fuel. |

|

1993 |

The power plant completed a stack flue gas desulfurization project. This process converts sulphur dioxide (SO2) flue gas to calcium sulphate (or gypsum) which is sold to the Gyproc plaster-board plant, where it replaces imported natural gypsum. The new raw material from the power plant has increased the quality of plaster-board that is manufactured. |

|

Future |

The construction of green houses, to be supplied with residual heat, is being considered by the power plant and the refinery. |

ACHIEVEMENTS OF THE SYMBIOSIS

The annual material and energy flows of the four industrial partners in the symbiosis are shown in Table 1. The reductions in resource consumption, emissions, and waste in this symbiotic relationship are shown in Table 2. The most significant achievements of the industrial symbiosis cooperation at Kalundborg are that:

-

there have been significant reductions in energy consumption and coal, oil, and water use;

TABLE 1 Annual Materials and Energy Flows of the Four Industrial Partners in the Kalundborg Symbiosis

|

Industrial Partner |

Production |

|

Emissions |

|

Resource Consumption |

|

|

Asnæsværket |

Electricity: |

300,000,000 kWh |

CO2: |

4,300,000 tons |

Water: |

400,000 m3 (treated) |

|

|

Process Steam: |

355,000 tons |

SO2: |

17,000 tons |

|

100,000 m3 (raw) |

|

|

District heating: |

700,000 GJ |

NOx: |

14,000 tons |

|

700,000 m3 (re-used) cooling water from Statoil |

|

|

Fly ash: |

170,000 tons |

|

|

|

500,000 m3 (re-used waste water from Statoil) |

|

|

Fish: |

200 tons |

|

|

Coal: |

1,600,000 tons |

|

|

Gympsum: |

80,000 tons |

|

|

Oil: |

25,000 tons |

|

|

|

|

|

|

Gas: |

5,000 tons (flare gas from Statoil) |

|

Statoil Refinery |

3,200,000 tons of a full range of fuel products |

SO2: |

1,000 tons |

Water: |

1,300,000 m3 (raw) |

|

|

|

|

|

NOx: |

200 tons |

|

50,000 m (treated) |

|

|

|

|

Waste Water: |

500,000 tons |

Steam: |

140,000 tons (from Asnæsværket |

|

|

|

|

Oil: |

1.8 tons |

|

189,000 tons (own waste heat) |

|

|

|

|

Phenol: |

0.02 tons |

Gas: |

80,000 tons |

|

|

|

|

Oily Waste:a |

300 tons |

Oil: |

8,000 tons |

|

|

|

|

|

|

Electric: |

75,000,000 kWh |

|

Gyproc |

14,000,000 m2 of plaster-board |

N/A |

|

Gypsum: |

80,000 tons (from Asnæsværket) |

|

|

|

|

|

|

|

|

33,000 tons (natural gypsum) |

|

|

|

|

|

|

|

8,000 tons (from recycling) |

|

|

|

|

|

|

Cardboard: |

7,000 tons |

|

|

|

|

|

|

Oil: |

3,300 tons |

|

|

|

|

|

|

Gas: |

4,100 tons |

|

|

|

|

|

|

Water: |

75,000 tons |

|

|

|

|

|

|

Electric: |

14,000,000 kWh |

|

Novo Nordisk |

Industrial enzymes |

|

Waste Water: |

900,000 m3 |

Water:1,400,000 m3 (treated) |

|

|

|

Insulin |

|

COD: |

4,700 tons |

|

300,000 m3 (raw) |

|

|

|

|

Nitrogen: |

310 tons |

|

|

|

|

|

|

Phosphorus: |

40 tons |

Steam: |

215,000 tons |

|

|

|

|

|

|

Electric: |

140,000,000 kWh |

|

kWH = kilowatt-hours; GJ = gigajoule; m2 = square meters; m3 = cubic meters a The oily waste is biologically degraded at Statoil's sludge treatment facilities. |

||||||

TABLE 2 Results of the Kalundborg Symbiosis

|

Sources of Reduction |

Total Reductions (tons/yr) |

|

Resources |

|

|

Oil |

19,000 |

|

Coal |

30,000 |

|

Water |

1,200,000 |

|

Emissions |

|

|

CO2 |

130,000 |

|

SO2 |

25,000 |

|

Waste |

|

|

Fly ash |

135,000 |

|

Sulfur |

2,800 |

|

Gypsum |

80,000 |

|

Nitrogen from biosludge |

800 |

|

Phosphorus from biosludge |

400 |

-

environmental impacts have been lessened through reductions in SO2 and CO2 emissions and improved quality of effluent water; and

-

traditional waste products such as fly ash, sulphur, biological sludge, and gypsum have been converted into raw materials for production.

The symbiosis has created a positive image of Kalundborg as a clean industrial city. Perhaps most significantly, there has been a gradual development of a systematic environmental "way of thinking" that may be applied to many other industrial settings and which may be used in planning new industrial complexes. The effective symbiosis at Kalundborg has a number of important characteristics (Box 1).

FUTURE DEVELOPMENTS

At Kalundborg, all future projects and/or process modifications will be considered for potential inclusion in the industrial symbiosis network. A number of interesting ideas have been identified for further study. In the meantime, the Kalundborg experience offers a practical model to examine ways to minimize the environmental impact from existing and new industrial complexes.

Traditionally, increase in industrial activity implies an almost linear increase in the load on the environment. The industrial symbiosis concept suggests that this need not necessarily be so. Indeed, under this model, increased industrial

|

BOX 1 Characteristics of Kalundborg Symbiosis

|