The Industrial Green Game. 1997. Pp. 132–147

Washington, DC: National Academy Press.

Improving Environmental Performance Through Effective Measurement

BRIAN L. STEELMAN, JAMES HALL, C. PETER NAISH, AND ANTONIO MAZZARIELLO

In general, business in the 1970s was strongly driven by concerns about quality. In the 1980s, price and innovation were major drivers along with quality. In the 1990s, these driving forces are still in place; however, companies' environmental performance has emerged as a major factor that can affect short- and long-term business success. Environmental compliance audits are but one small measure of a company's overall environmental performance. An effective set of performance measurement tools is required to develop information for company managers and other stakeholders. Development of well-defined and effective measurement tools for environmental performance is still in its infancy, with only a small number of companies having made significant progress to date.

Improvements in environmental performance1 do not occur abruptly. Success requires a permanent commitment to environmental leadership, including but not limited to the following elements: an overall philosophy and corporate culture established and demonstrated by senior management; acceptance of and commitment to the overall philosophy, governing principles, and policies by all employees; clear standards of performance and operating procedures; technologies and technical resources qualified to meet challenges in a competitively advantageous manner; well-educated and well-trained staff at all levels; and systems to measure and evaluate current performance, identify areas for continuous improvement, and incorporate these into new performance standards and goals.

Improving environmental performance requires successful implementation of all of the above-described leadership elements. However, a system to measure and evaluate environmental performance is certainly a key element and one that companies have been struggling with over the past several years.

ENVIRONMENTAL PERFORMANCE EVALUATION2: OVERVIEW

Compliance with applicable laws and regulations is a basic company (facility) operating requirement that must be achieved through line management and confirmed by audits. In the environmental area, there is never a lack of data. However unless those data are translated into useful information, they are nothing but a huge set of numbers useless for setting priorities or making decisions. The overriding goal for effective environmental performance measurement systems should not be on compliance; rather, it should be to gather information (not data) for use in identifying opportunities for continuous improvement. Herein lies the linkage between environmental measurement systems and any quality improvement process, which can be paraphrased as total quality environmental management (TQEM).

Most companies are just beginning to implement TQEM programs. Useful environmental performance measurements require several years of information because TQEM measures progress or continuous improvement rather than relying on absolute measures of quality (FitzGerald, 1993). Most companies are still developing and testing their environmental measurement systems. However, there have been several recent conferences on the subject, and companies are beginning to share their experiences.

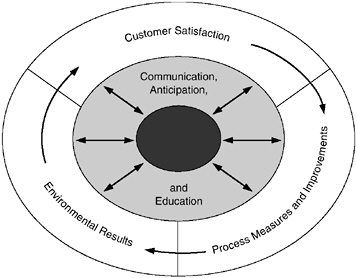

The first step in developing an effective measurement system is to identify the information needed. By using TQM principles, this must be derived from the requirements of the customers, both internal and external. Wells et al. (1993) propose that effective environmental measurement systems collect information from three interrelated perspectives: process measures and improvements, environmental results, and customer satisfaction (Figure 1).

FIGURE 1 Customer requirements drive environmental measurement. SOURCE: Wells et al., 1993.

Process measures and improvements assess the effectiveness of existing management systems to meet not only current requirements but also anticipate future requirements; this information is typically collected through the audit process. Environmental results evaluate the effectiveness of programs on incremental improvement; this information is typically generated through self-reporting by facilities. Customer satisfaction measurements assess whether changes or improvements are valued by stakeholders. It is important to recognize that corporations have many stakeholders, including the general public, stockholders, employees, senior management, regulatory authorities, raw materials suppliers, and purchasers of products. Although it may be quite straightforward to understand the direct requirements of several of these stakeholders (e.g., current compliance requirements of regulatory authorities or a challenge from senior management to reduce waste by a certain percentage per year), obtaining information from other customers can be more challenging, as illustrated later in this paper by Ciba-Geigy (Ciba) efforts to measure the environmental satisfaction of its customers.

No single measurement will accurately reflect a company's overall environmental performance. A properly selected set of measures, used as a system, is required to provide the types of information necessary for decisions and action plans. Table 1 lists a number of measures, what they measure, as well as their general advantages and disadvantages.

Although the toxic release inventory (TRI) system has been valuable in raising the environmental consciousness of U.S. corporations, some of its measurement protocols do not reflect actual releases to the environment. For example, a facility whose wastewater contains highly biodegradable materials will not have a "measured" release if it has an on-site treatment plant but would show a release according to TRI if the wastewater is piped to a publicly owned treatment works. For these two cases, there is no difference as to what is actually released to the environment, but one is measured as a release whereas the other is not.

Most of the systems listed in Table 1 do not consider efficient use of raw materials, most notably raw water usage. Although the supply of usable water is generally not yet critically limiting, reduced availability of this resource is becoming apparent, and attention to this issue is appropriate to prevent it from becoming a significant problem. Also, most of the systems listed in Table 1 do not recognize the domino effects of addressing environmental issues. For example, hydrochlorofluorocarbons (HCFC) substitutes for chloroflurocarbons require more energy to achieve the same results, producing secondary emissions of greenhouse gases (e.g., carbon dioxide). An alternative chloroflurocarbon substitute (ammonia) has good energy efficiency but higher toxicity and would require enhanced safety considerations.

STRATEGIC ENVIRONMENTAL AUDITING

The term "audit" is often misused in that it is used to refer to ordinary controls or inspections that are an integral part of any manager's or supervisor's

TABLE 1 Measures of Environmental Performance

|

Measures |

What It Measures |

Advantages |

Disadvantages |

|

Permit Compliance |

Compliance with applicable permits expressed as exceeding permit limits. |

An essential measure—customers will look first to your compliance with permits |

Taken alone, a narrow measure indicating that you are doing only what is required. |

|

Toxic Release Inventory (TRI) Chemical Releases |

Over 300 chemicals subject to release annual reporting requirements under SARAa Section 313. |

Information on releases is widely available to the public; an effective way to communicate performance. |

Does not cover all important chemicals or industries; focuses on release volume without accounting for differences in toxicity. |

|

33/50 Chemicals |

A subset of 17 of the TRI chemicals identified by the Environmental Protection Agency as priority candidates for voluntary reductions in releases by industry. |

A more refined list of chemicals than TRI; companies participating in the 33/50 program and meeting goals will receive public credit. |

Leaves out many important chemicals; not clear that a company not participating in the 33/50 program will receive special credit for these reductions. |

|

Clean Air Act Toxics |

189 chemicals listed in the Clean Air Act as air toxics subject to maximum achievable control technology (MACT) standards. |

MACT standards will be extremely costly to meet. By reducing or eliminating releases, you avoid very high future costs. |

Taken alone, like TRI, not a full measure of environmental performance; focuses only on air; creates risk of shifting problem from air to other media. |

|

Risk-Weighted Releases |

Toxic chemicals weighted by their relative toxicity. |

A more realistic depiction of health and environmental effects than unweighted releases. |

Toxicity data are frequently highly uncertain; risk-weighted approach has not been generally accepted by key customers—EPA, environmental groups. |

|

Waste per Unit of Production |

Percentage of production lost as waste; generally measured by weight. |

A very broadly applicable measure that incorporates efficiency in use of resources as well as contaminant releases to the environment. |

No priority established in term of type of wastes; absent other measures, creates an incentive to focus on high-volume, low-toxicity wastes. |

functions. The term should be reserved for systematic and objective evaluations that are carried out by experts who are independent of the function or location being audited. Corporate auditing, as conducted by Ciba, is a strategic management tool; it helps to ensure compliance with current legal and regulatory requirements to minimize future risks and liabilities through a proactive approach that focuses on anticipating future requirements. Also, Ciba's approach to auditing helps to increase operating efficiency, effectiveness, and quality because it not only addresses management and control systems, but also technical, organization, and personnel issues. In summary, auditing does not simply provide a picture of a location's compliance status, it identifies weaknesses and vulnerabilities regarding continued compliance, either with today's or anticipated standards.

For any large manufacturing company, it is neither possible nor appropriate to conduct meaningful annual audits of manufacturing facilities, even the major ones. A number of audit findings may require significant effort by the facility to resolve, and it is appropriate to provide at least 2 years between audits to allow progress to be made. Also, compliance is the line responsibility of each facility, and conducting audits too frequently would tend to shift accountability for compliance from the facility to the auditors.

In addition to the information from audits, Ciba senior management needed an annual, worldwide survey to provide meaningful information on safety, energy consumption, and environmental performance. This information was needed to help set annual and periodic priorities for initiatives to improve worldwide performance in these areas. Therefore, in 1990 Ciba introduced annual reports on safety, energy, and environmental performance (commonly known as SEEP reports) to obtain accountability of safety, energy conservation, and environmental protection performance; determine performance criteria for sites; serve as a management tool; and provide information for communicating corporate performance.

CIBA'S WORLDWIDE ENVIRONMENTAL MEASUREMENT SYSTEM

For many years, Ciba's worldwide production facilities provided environmental reports to their site, national (group company), and worldwide corporate managements. However, these reports were not always comparable because they were based on the information needs of local management and the legal requirements of individual countries. These reports were of interest to the worldwide corporate headquarters, but because of their varying formats, it was not possible to consolidate the reported data to gain information on worldwide corporate performance.

In 1990, a corporatewide standardized reporting system was established, known as the annual SEEP report. All major production sites are required to complete the report, whereas submission by other sites is at the discretion of the head of the group company. The number of sites submitting SEEP reports rose

from 64 in 1990 to 82 (from 17 countries) in 1992, covering all chemical production and major formulation works within Ciba and capturing annual information on greater than 90 percent of Ciba's worldwide emissions (Ciba-Geigy, 1993). The consolidated data from these reports form the basis of the corporate environmental report, which was issued for the first time in 1992. This document provides stakeholders with a report card on Ciba's environmental activities and accomplishments.

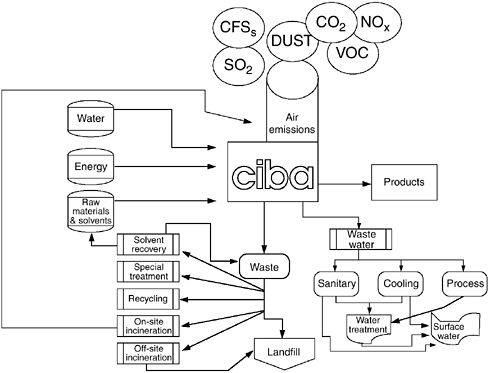

Information submitted in the annual SEEP reports falls into four categories: tabulated and charted data on safety, energy usage, and environmental protection; summaries of safety and environmental protection investment and operating costs; case studies of improved safety or environmental performance, and energy savings (and also examples of unsuccessful initiatives); and a report on any other matters of significance for safety, energy usage, or environmental protection. Table 2 summarizes and Figure 2 illustrates types of information requested under the SEEP program to measure environmental performance and energy consumption at a particular site.

SEEP has become an important management tool for Ciba, complementing the auditing program, training, and policy-making. It allows the company to measure safety, energy conservation, and environmental performance at the corporate as well as at the local level. As a result, priorities can be established;

FIGURE 2 Safety, energy, and environmental protection (SEEP) information categories related to environmental and energy performance.

TABLE 2 Safety, Energy, and Environmental Protection (SEEP) Information Categories Related to Environmental and Energy Performance

|

General Site Data |

Water Pollution Control |

Air Pollution Control |

|

• Volume of production in tons, units, square meters, etc. • Processes discontinued for safety or environmental reasons • Water inputs and uses (process, sanitary, cooling, etc.) • Effluent discharge (type and quantity) • Noise: cases of noncompliance with legal limits • Soil, ground water: cases of contamination • Audits or inspections by authorities, division, or group company |

• Location of sampling points • Effluent volumes • Effluent quality: COD/TOC, DOXa, and inorganic salts load regulatory values; number of excursions • Biodegradability • Other reportable substances or important waste water variables |

• Summary of emissions in tons (nonhalogenated and halogenated organics, carcinogens, organic and inorganic dusts and inorganic gases) • Emissions of individual critical substances • Chlorofluorocarbons purchased • Emissions of SO2, NOx, HCl, and CO2b from boiler houses and incinerators |

|

Solvent Usage (separated into halogenated and nonhalogenated categories) |

Waste Management |

Energy Management |

|

• Total input of solvent • Input of new solvent • Solvent recycled • Solvent sold • Solvent consumed as reagent • Waste solvent incinerated • Solvent losses |

• Type and quantity of waste • Waste treatment technique (recycling, incineration, landfill, special treatment) • Waste treatment facilities used |

• Energy sources, quantity consumed • Energy conversion, cogeneration, losses • Energy consumption breakdown by category • Comments of fuel quality, sulfur content, new technology |

|

Expenditures and Personnel for Environmental Protection |

Cases: Environmental Successes and Failures |

Highlights: Changes, Problems, and Developments |

|

• Capital investments • Operating costs • Personnel costs • Number of personnel |

• Prevention or reduction of water or air pollution • Avoidance or reduction of waste • Recovery, reuse, and recycling of wastes • Integrated pollution control measures • Reduction of process risks and major hazards • Progress in environmental technology • Energy conservation |

• Major problems and challenges • Legislation • Objectives • Organization and responsibilities • Technology • Monitoring and controls • Personnel awareness and training • Communications with the public and authorities • Recognition awards |

|

a COD/TOC = chemical oxygen demand/total oxygen demand; DOX = dissolved organic halogen; b SO2 = sulfur dioxide; NOx = nitrogen oxide; HCl, hydrochloric acid; CO2 = carbon dioxide. |

||

site-specific goals can be set; specific actions can be planned, approved, and implemented; and progress can be measured.

Ciba believes that site-specific goals are more effective in achieving results than are companywide, across-the-board targets that apply to all facilities. With this approach, priorities can be set according to the highest environmental needs or to maximize the environmental return from a given investment level. For instance, it would make little sense for Ciba to establish an internal company goal of an across-the-board 10-percent volatile organic compounds (VOC) emission reduction at all sites, when three manufacturing facilities account for about half of the corporation's worldwide emissions.

Each year, the quality of SEEP data inputs has improved. When sites first started reporting in 1990, the quality of the data was not always reliable, and many of the numbers reported represented estimates rather than measured values; increasingly, the reported values are based on actual measurements.

Although completion of the SEEP report requires a significant amount of time and effort by site personnel, Ciba's experience has been that it quickly gained broad support from facilities. The SEEP information allows site managers to critically review facility environmental performance, set concrete objectives, and monitor progress over time. In addition, the information is helping sites with their local and national external reporting.

When comparing data across the corporation, remember that fluctuations occur in the number of sites reporting. This has varied as more and more small sites submit reports for the first time or as sites are acquired or sold. Hence, data are not strictly comparable from year to year but nevertheless provide a clear and valid picture of trends.

A review of the SEEP information since its inception has shown many positive results and some that are disappointing (Ciba-Geigy, Ltd., 1993):

-

Between 1990 and 1992, Ciba's overall energy use increased by about 8 percent. The energy requirement was met by purchasing electricity from public utilities and primary fuels such as natural gas, oil, and coal to produce heat. These sources of energy were used directly in the buildings and processes, converted to steam for process heat, or converted to electricity in Ciba's own generators. Increased requirements for pollution control equipment and automation of processes and operations resulted in increased electricity usage of about 9 percent.

-

Between 1990 and 1992, Ciba's worldwide facilities continuously reduced overall emissions of sulfur dioxide by about 43 percent. These reductions were achieved by using more natural gas, which is sulfur free; by changing from heavy to light oil, which contains less sulfur; and by increasing the incineration of wastes in units with flue-gas cleaning to remove sulfur dioxide.

-

Between 1990 and 1992, Ciba's worldwide facilities reduced nitrogen

-

oxide emissions by about through complex technical measures such as catalytic conversion or using ''low-nitrogen oxide" burners. The process of replacing burners is ongoing.

-

Ciba's worldwide carbon dioxide emissions increased from 1990 to 1992 by about 8 percent, mainly due to increased on-site incineration of wastes to produce energy. The carbon dioxide emissions resulting from incineration of wastes in third-party facilities in the past were not counted as emissions from Ciba.

-

As a result of aggressive water conservation measures, Ciba has significantly reduced water use. Between 1991 and 1992, water usage decreased by about 6 percent. Much of this reduction was achieved by installing recirculating systems, which have the disadvantage of requiring additional energy for pumps and fans.

-

Like most of the chemical industry, Ciba's production processes frequently require large quantities of solvent. In most processes, the solvent does not react but acts as a medium to facilitate the chemical reaction of other constituents. At the end of the process, the solvent needs to be removed and recovered or disposed of. In 1992, SEEP consolidated solvent information indicated that more than 95 percent of Ciba's worldwide solvent requirements were met through recycling. Also, between 1991 and 1992, Ciba's emissions of organic vapors to the atmosphere from production operations decreased by 11 percent.

Another measure of performance in solvent usage is the amount of halogenated solvent used. Halogenated solvents are viewed as important because of their environmental persistence and potential to bioaccumulate. As a result, Ciba places high priority on replacing them with other solvents. In 1992, 78 percent of the solvent used in production was nonhalogenated. Also between 1991 and 1992, Ciba's emissions of halogenated organic vapors to the atmosphere from production operations decreased by about 10 percent.

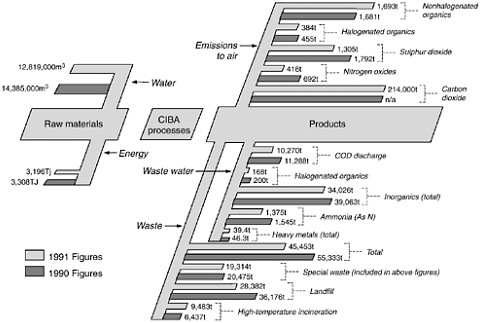

One of the most important aspects of an effective environmental measurement system is the collection of data that can be meaningfully interpreted. Figure 3, is an example of an emission statement prepared for major Ciba group company from the 1990 and 1991 SEEP data. It provides a good representation of all discharges to the air and water and the amounts of waste being added to landfills or destroyed (Rothweiler, 1994). This is an example of an effective management tool for evaluating accomplishments and prioritizing additional areas for improvement. For example, this figure shows that significant reductions in sulfur dioxide and nitrogen oxides emissions to the atmosphere have been made through the use of low-sulfur fuels and improved energy management technology. It is also clear that organic emissions need to be reduced, although substantial progress has been made in substituting nonhalogenated for halogenated organic compounds.

FIGURE 3 SEEP data from a Ciba company (example). t = ton; m3 = cubic meter; TJ = tera joules.

Analysis of the SEEP data in this way provides a picture of environmental achievements from a broad operational perspective and aids in setting further goals and performance standards. However, although a graphic such as Figure 3 is effective in summarizing accomplishments across the company, it is really analysis of trends in specific site data from year to year (either by using an analysis similar to that illustrated in Figure 3 or another method) that allows targeting of specific areas for improvement.

As mentioned previously, data associated with environmental performance measurement systems can be quite voluminous, especially for large, multinational corporations. Hence, in 1993, after 3 years of experience with implementing SEEP, Ciba automated and computerized the process. Also, Ciba recently retained an independent firm to access the SEEP program. The objectives of this independent assessment were to critically review and assess the process for collecting and analyzing the SEEP data from group companies and provide a validation assessment of the 1993 SEEP data for publication in the annual corporate environmental report.

Four years of experience with SEEP and the recent independent assessment reveal an important additional complexity for interpreting and using SEEP information as a management tool: Different measurements are required to assess environmental performance at different levels of facility operation. For example, measurement of wastewater releases from a production area to either on-site or

off-site treatment provides a measure of pollution -prevention performance. However, measurement of releases to the environment after treatment only provides information on the end-of-pipe result, without regard to the progress of production processes toward preventing pollution.

CIBA'S U.S. TEXTILE PRODUCTS CUSTOMER SATISFACTION SYSTEM

Ciba's U.S. Textile Products Division (Ciba-TPD) collects customer satisfaction data monthly. To ensure objective and valid data, the surveys are conducted by an independent, third-party marketing firm. The survey consists of three parts: relative-importance rankings of the attributes being measured, numerical rating of attributes on a scale of 1 to 10, and open-ended questions to solicit information on perceived strengths, weaknesses, and future areas for improvement.

The raw data are provided to Ciba-TPD and are managed through a confidential database. Segmented information is routinely extracted from the data according to bossiness segment, account size and activity level, the type of customer contact (production,technical,administrative, or executive), and other variables associated with the customer (such as region, sales volume, product mix, and salesperson).

Customer contacts are made across all areas of business, and the information collected addresses in excess of 80 percent of total sales as well as priority potential accounts. The customer survey solicits feedback in 14 specific areas: overall product quality, product performance, delivery service, laboratory service, field service, follow-up on requests and messages, routine customer service, special handling customer service, organization and communication, value, price, packaging, environmental responsiveness. General information is also solicited: What are Ciba's strengths? What are Ciba's weaknesses? What will it take for Ciba to become or to stay the preferred supplier in the future?

Specific feedback sought in the environmental areas includes:

-

Environmental assistance—How helpful is Ciba with assistance on product application (dyeing methods), product characteristics (material systems data sheets, ecology-toxicology data), environmental communication, environmental services?

-

Environmental responsiveness—How responsive is Ciba in assisting in waste minimization, regulatory compliance, product stewardship, and environmental marketing efforts?

-

Packaging—How well does Ciba's packaging meet the customer's requirements, and how does its durability, ease of use, and ease of recycling rate?

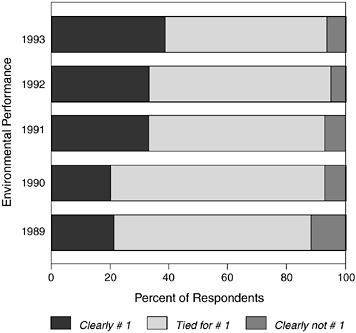

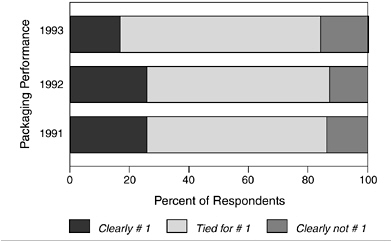

FIGURE 4 Environmental performance (Ciba-Textile Products Division vs. best competitor).

Figure 4 provides summary measurement data for the environmental assistance and responsiveness categories for the past 5 years. These results are measured relative to Ciba's best competitor. The overall environmental performance ratings by our customers for 1989–1990 indicate that a little more than 20 percent of Ciba's customers perceived the company to be clearly #1, 10 percent perceived Ciba to be clearly not #1, and the balance (slightly fewer than 70 percent) perceived Ciba to be tied for #1. During late 1990, Ciba-TPD began concerted efforts to improve their overall environmental performance, as perceived by their customers, and in 1993 40 percent of Ciba customers perceived Ciba to be clearly #1, or nearly double the 1989–1990 average results; fewer than 10 percent perceived to be, clearly not #1, a modest decrease from the 1989–1990 average results; and 50 percent perceived Ciba to be tied for #1.

These environmental performance numbers indicate that by 1993, more than 90 percent of the company's customers perceived Ciba-TPD to be #1 or tied for #1 with the company's best competitor, and major gains were made in comparison to best competitor since 1989–1990, as evidenced by the doubling of the company's clearly #1 ratings.

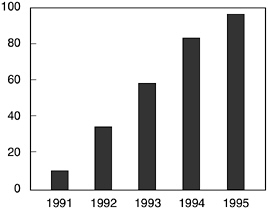

As described above, solicited feedback on packaging includes a number of attribute measures, one of which is environmental (i.e., ease of recycling). Figure 5 provides summary measurement data for packaging overall for the past 3 years. Although Ciba-TPD has invested significantly in improving its packaging during

FIGURE 5 Packaging performance (Ciba-Textile Products Division vs. best competitor).

this time, the data indicate that the company's overall position of being clearly #1 or tied for #1 has remained relatively stable (85 percent) whereas the company's position for clearly #1 appears to have slipped somewhat in 1993.

This information indicates a highly competitive marketplace, with significant attention being paid to this attribute by the company's competitors. In response, Ciba-TPD has established aggressive goals and implemented plans to further improve packaging. One example of the packaging goals pertains to the percentage of the packaging deemed to be environmentally friendly.3Figure 6 illustrates the past 3 years of performance in this area and shows the goals for 1994 and 1995. In summary, between 1991 and 1995, Ciba-TPD planned to go from 10 percent to 98 percent environmentally friendly packaging. By the end of 1993, a sixfold increase to 60 percent environmentally friendly packaging had already been achieved.

FIGURE 6 Environmentally friendly packaging, by year (Ciba-Textile Products Division).

SUMMARY

Since the first Earth day in the early 1970s the impact of businesses' environmental performance has been growing; by the 1990s, it had become a major driving force in determining long-term success. Positive environmental performance in industry requires leadership from the top and commitment throughout the company as well as allocation of significant human and financial resources. Because of limited resources, companies must be able to identify and select issues on which to act where their investments will yield the most cost-effective benefit. Such action can turn improving environmental performance from a perceived liability into a real competitive advantage.

Identification and prioritization of environmental issues requires effective measurement of environmental performance. Periodic compliance auditing should not be confused with environmental measurements. Generally, auditing is conducted by independent experts every several years, whereas environmental measurement data are self-reported by each facility at least annually. Implementation of an environmental measurements program is a long-term commitment. In concert with their goal to help identify and prioritize issues for action, such programs are intended to foster continuous improvement, which requires measurements to evaluate the results.

Development and use of environmental measurement systems is still in its infancy, and the systems continue to evolve rapidly. Because environmental issues are complex and often interrelated, effective environmental measurement systems can become quite complex, and initial implementation can appear to be an overwhelming task. However, initial implementation of a rather straightforward system, with a recognition that continuous upgrading and improvements will be necessary, is a manageable approach that will begin the process of continuous improvement of environmental performance.

NOTES

REFERENCES

Ciba-Geigy. 1993. Corporate Environmental Report 1992. Basle, Switzerland: Ciba-Geigy.

FitzGerald, C. 1993. Selecting measures for corporate environmental quality:Examples from TQEM companies. Pp. 15–23 in Measuring Environmental Performance. New York: Executive Enterprises Publications Co.

ISO/TC 207 Environmental Management Subcommittee #4. 1994. Environmental Performance Evaluation Framework Document on Definitions, Principles and Methodology. Final draft.

Rothweiler, W. 1994. Reviewing and monitoring environmental Management Handbook, B. Taylor, C. Hutchinson, S. Pollack, and R. Tapper (eds.), London: Pitman Publishing.

Wells, R.P., M.N Hochman, S.D. Hochman, and P.A. O'Connell. 1993. Measuring environmental success. Pp. 1–13 in Measuring Environmental Performance. New York:Executive Enterprises Publications Co.