3

Program Strategies

The progress and accomplishments of the DOE/ORNL intermetallic alloy development programs have demonstrated how breakthroughs in exploratory and basic research can be developed into commercially promising technologies. This chapter describes the lessons from the ONRL program and their influence on the overall OIT program strategy and commercial applications. The experience from the ORNL intermetallics alloy program can provide guidelines to OIT on how to effect the transition of their research program to the industry-led IOF (Industries of the Future) strategy.

IDENTIFYING AND PRIORITIZING PROJECTS

Until 1995, research and development management of the overall OIT program was driven by a “technology push” strategy. This approach led to documentable technological successes—the development of new materials, properties, and processes—but their commercial impact was more difficult to document. In 1995, OIT's program management strategy was revised to reflect a new commitment to increasing and documenting the commercial impact of OIT programs, provided they still met the overall goals of improving energy efficiency and reducing adverse environmental impact. OIT's research and development management strategy was changed from a "technology push" strategy to a "market pull" strategy. However, two key issues still had to be resolved:

-

Which markets should be served?

-

Who, within these markets, should do the "pulling"?

To answer the first question, OIT ranked industries according to their level of energy consumption and waste production. Seven industries—steel, forest products, glass, metal casting, aluminum, chemicals, and petroleum refining—were found to consume more than 80 percent of the energy and to produce more than 90 percent of the hazardous waste products generated in the manufacturing sector of the economy. These seven industries, designated IOF, became the focus of OIT's programs. OIT's research projects are now selected and prioritized to meet the business and technological needs of the IOF.

In the past, technologists and research and development directors from the targeted industries were asked to provide direction for OIT research. In the IOF strategy, the desire to develop industry commitments to research partnerships has led OIT to seek additional guidance on research priorities. Although the industry technical staff still provides a significant voice in setting industry priorities, OIT industry groups also derive input and support from the chief executive level for direction in the form of consensus-based, industry-wide "vision documents" that will ultimately lead to technology-development plans or "road maps." With OIT's assistance, the IOF industries have developed, or are developing, these vision documents.

Throughout the ORNL intermetallic alloy development program, interaction with industrial participants has been critical to identifying the needs and priorities for developing alloys and processes. Interactions with industry have provided ORNL with a focus on optimizing alloy compositions and developing process technologies to meet industrial needs (see Chapter 2). The experience of the ORNL intermetallic alloy development program in using industrial guidance to establish program goals and objectives may be of use to OIT in implementing the IOF strategy.

ORNL is in the process of assessing their program strategies and research projects with respect to IOF industry needs. For example, an analysis of the needs of the pulp and paper industry vis a vis the AIM program goals and ORNL projects has recently been completed (Angelini, 1995). The analysis was based on the industry vision document for the forest products industry (AF&PA, 1994) and on industry workshops with technologists to identify ways that ORNL and the AIM program could address those needs. The intermetallic alloy program would benefit from similar analyses of other industry visions. Examples of potential applications include expanding the use of Ni3Al for hot metalworking (dies, fixtures, furnace components), developing nickel and iron aluminides for processing equipment used in high temperature and corrosive environments in the chemical and refining industries, and using Ni3Al in transfer and processing rolls for the steel and paper industries.

BALANCING INDUSTRY-FOCUSED AND CROSSCUTTING PROGRAMS

Relying exclusively on market pull to define research and development objectives has certain inherent drawbacks. Federally initiated, crosscutting research programs involving technologies that could potentially benefit many industries, but are not the primary concern of any one industry, are not likely to elicit much interest in a market pull strategy. For example, it would be erroneous to assume that a program like the intermetallic alloy development program, which began as an exploratory research project and progressed through the efforts of various DOE program offices and diverse industrial participants, would receive industry support if it had been proposed within the OIT IOF strategy. The panel believes that there is no simple, self-reinforcing mechanism whereby a market pull strategy can be used to identify promising crosscutting programs. Instead, the panel recommends that OIT adopt the following approach:

-

Decide, with input from the IOF communities, on an appropriate percentage of overall research and development to be devoted to exploratory research and crosscutting technologies, i.e., develop a consensus that a percentage of research and development funds should be designated for the development of crosscutting technologies.

-

Based on analyses of the various IOF road maps, identify common (or related needs) and define and select a list of recommended exploratory research and crosscutting technologies for development. For example, identify potential applications that would benefit from the development of process technologies and the optimization of a particular alloy or alloy family.

-

Review these recommendations with the IOF working groups and solicit support and feedback for exploratory and crosscutting projects.

METRICS FOR SELECTING AND PRIORITIZING PROJECTS

Every method of measuring the efficacy of research and development programs has proponents and detractors, and none is universally or even widely accepted. One method, developed for evaluating materials processing innovations, recommends criteria based on (1) potential cost-effectiveness, (2) potential for exploiting new materials technologies, (3) commercial impact, (4) environmental compatibility, and (5) broad applicability (NRC, 1995). The panel recommends consideration of the following metrics, which are compatible with DOE and OIT organizational objectives, as a basis for comparing and selecting programs for the OIT IOF program:

-

potential for energy conservation

-

potential for waste reduction

-

consistency with IOF business objectives and technology road maps

-

commercial potential/market value

-

potential crosscutting benefits for multiple applications in more than one industrial sector

The best metrics for measuring OIT's efficacy are likely to be some of the same measures used internally by the IOF. Research and development managers from these industries should be asked to describe their approaches to setting research and development priorities and to measuring research and development effectiveness. However, "profit-based" metrics used in industry (e.g., return on investment) may not be appropriate for measuring the efficacy of government-funded, long-term research. IOF guidance should be sought to ensure that the program is relevant, but the panel suggests that short-term (i.e., one to three years) commercial potential should not be the primary "compass" that directs the selection of OIT programs.

COMMERCIALIZATION

Usually the word "commercialization" implies one of two possibilities. Either the embodiment of a technology must be sold in a way that is both profitable and sustainable, without corporate or government subsidies, or it must be incorporated into a component or system that is similarly sold. In short, to be considered a "commercial" product, normal transactions in the market involving its manufacture and sale must result in someone earning money.

Advanced materials, such as Ni3Al, are generally developed to meet perceived performance goals set by the user (e.g., high strength and oxidation resistance at elevated temperatures). However, barriers to commercialization may arise if costs, manufacturing processing requirements, and adequate supplier base are not taken into account during the development process. The developers must recognize that alternative materials and solutions may exist, perhaps with lower initial costs. Industries will generally seek the lowest cost alternative compatible with their existing manufacturing knowledge and facilities. Commercialization of Ni3Al alloys has been relatively slow because there are alternatives to intermetallics for all potential applications. The alternatives now in use may not have the properties (oxidation and carburization resistance, mechanical properties) that nickel aluminides can deliver, but they are well known, perform adequately, are reliable, and usually have lower initial costs.

To replace an established material with an alternate, factors other than performance must also be considered. These include:

-

cost and supply of raw materials

-

production capability of suppliers and manufacturers

-

cost of materials, fabrication processes, and tooling and facilities

-

environmental considerations, including the disposition of wastes

-

demonstrated material reliability

-

supplier infrastructure

-

risk and consequences of material failure

Meeting OIT's commercialization objectives requires early and ongoing interaction with industry/users to ensure that the real hurdles and motivations for acceptance are understood. In addition, developing advanced materials for commercial applications generally requires substantial technology development, especially processing technology. These criteria are part of the ORNL commercialization strategy. For example, ORNL work on nickel aluminide is focused on castability, weldability, formability, scale-up, and mechanical properties, all of which address industrial needs. Work by the ORNL Metals Processing Lab and their technical support of industrial product development have been very important. The AIM program strategy, the IOF focus, the Metals-Processing Laboratory User Center, and changes in the licensing strategy have established a framework for developing technologies that can be commercially successful.

However, commercializing new technologies is a difficult and risky proposition, even for corporations that specialize in, and depend upon, commercialization. Established materials and manufacturing companies worldwide have long lists of failed efforts to commercialize new technologies. In fact, failures greatly outnumber successes. Consequently, in many ways it is unrealistic for ORNL to measure the efficacy of a particular research and development program against the metric of commercialization.

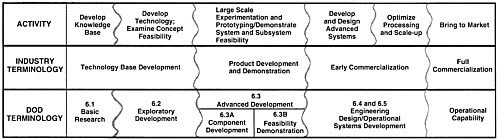

There is no standard way to commercialize new technologies, but there are stages in the commercialization process (NRC, 1993). These stages, shown schematically in Figure 3-1, include the following:

-

technology development (research and development)

-

product development and demonstration, including trials with selected "key" customers

-

early commercialization, including optimization of manufacturing processes and scale-up

-

full commercialization to bring the product to market, including market research, developing promotional materials and marketing strategies, and training sales personnel

At every stage of commercialization, the proponents of a new technology must solicit, defend, and secure corporate commitment and funds before advancing to the next step. For new materials technologies, the process generally takes years, often more than a decade, to complete (NRC, 1993).

As part of the federal research and development establishment, it is not possible for OIT to participate fully and actively in the commercialization process, especially in the later stages when the product is brought to market. The technologies developed by OIT must be commercialized by industry. Given the low success rate of the commercialization process, it is difficult to recommend ways to significantly increase the probability of successful commercialization. However, the following actions will improve the probability of production applications of technologies developed under OIT research and development auspices:

-

Involve key industrial participants representing suppliers, producers, and users of a material or process technology.

-

Avoid making license arrangements that require unrealistic technology development for commercialization (i.e., do not license too early), that unnecessarily restrict application of the technology, or that grant broad field-of-use exclusivity.

-

Support projects with potential suppliers and users of the technology to demonstrate and debut the technology.

-

Provide a mechanism for the orderly termination of (1) projects that have progressed to the final stage of commercialization (market introduction) or (2) projects that do not have sufficient industrial interest to support demonstration, process development, and scale-up efforts.

-

Publicize the technical accomplishments of the program at trade meetings (for instance, the Metallurgical Society, Society of Automotive Engineers, Society of Plastics Engineers, ASM International, and the American Chemical Society). Use these meetings as opportunities for making contacts and establishing networks with technical and business people who may be interested in the technology.

-

Establish networks that include not just technical experts, but also sales, marketing, and senior management personnel.

-

Expose OIT and laboratory technical personnel to basic business principles associated with commercialization, including cost estimation, value analysis, and market research.

-

Recognize that technology development is only a very small link, albeit an important one, in the commercialization chain.

REFERENCES

AF&PA. 1994. Agenda 2020: A Technology Vision and Research Agenda for America's Forest, Wood, and Paper Industry. Washington, DC: American Forest and Paper Association.

Angelini, Peter (compiler). 1995. Materials Needs and Opportunities in the Pulp and Paper Industry. ORNL/TM-12865. Oak Ridge, Tennessee: Oak Ridge National Laboratory.

National Research Council (NRC). 1995. Unit Manufacturing Processes: Issues and Opportunities in Research. Manufacturing Studies Board. Washington, D.C: National Academy Press.

National Research Council (NRC). 1993. Commercialization of New Materials for a Global Economy. National Materials Advisory Board. NMAB-465. Washington, D.C: National Academy Press.