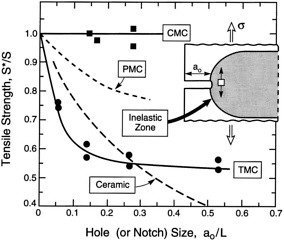

FIGURE 3 The relative notch sensitivities of various composite systems. The inset shows the inelastic zone that dictates the stress redistribution occurring around the notch. The notch length ao is normalized by L, the inelastic zone length that develops upon localization of the failure process on the notch plane.

conjunction with elastic analysis. Often, such conservatism discounts the advantage of the composite relative to competing monolithic materials. The limitations of this design strategy are ameliorated by the stable nature of the damage. That is, delamination and shear cracks invariably arrest as the stresses redistribute upon cracking, such that some load-carrying capacity is retained [31]. These noncatastrophic modes provide a crucial thermostructural “safety factor.”

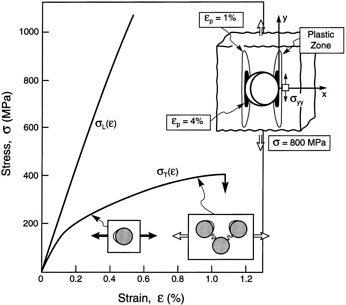

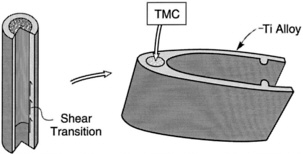

A different anisotropy issue arises in TMCs [17]. These materials have moderate transverse strength and toughness, as well as sufficient ductility to facilitate stress redistribution (Figure 4). But design flexibility is still limited, because TMCs only have structural benefit when unidirectional reinforcements are embedded in monolithic Ti alloys [18,32]. The designs are configured in such a way that the loads enter the TMC through the monolith with minimal transverse stresses [32-34] (Figure 5). However, many potential applications are excluded by this constraint.

MANUFACTURING CHALLENGES

Manufacturing problems and associated costs often dominate implementation strategies. Simple process and cost models highlight the key issues. A straightforward expression for the cost per component, designated $, is

where $m is the raw material price per component. The summation is over all manufacturing steps. The throughput τs is the ratio of the number of components passing through the manufacturing process, Ns, divided by the cycle time ts. The cost-rate $oR includes power usage, capital and replacement costs, labor costs, and so on,

FIGURE 4 The anisotropic stress-strain behavior of TMCs. The inset indicates the plastic zone that develops around a hole at 800 MPa. The contours indicate the plastic strain levels.

FIGURE 5 A schematic of a TMC within a bonded monolith that transmits the stress into the TMC with minimal transverse loads.

Here, ![]() is the average power used in a cycle, and ϕu its cost (in $ per kilowatt hour). Cc is the equipment price, tL the depreciation period, and Ce the cost of tooling, heating elements, and other parts that must be replaced with periodicity, te: ∆t is that portion of the cycle time that requires labor, ϕL (in $ per hour). The goal is to reduce $oR and increase τs such that $ approaches $m. For most hightemperature components, this goal is not realized, because of manufacturing complexity and the small

is the average power used in a cycle, and ϕu its cost (in $ per kilowatt hour). Cc is the equipment price, tL the depreciation period, and Ce the cost of tooling, heating elements, and other parts that must be replaced with periodicity, te: ∆t is that portion of the cycle time that requires labor, ϕL (in $ per hour). The goal is to reduce $oR and increase τs such that $ approaches $m. For most hightemperature components, this goal is not realized, because of manufacturing complexity and the small