2

Surface Platform Technology

OVERVIEW OF FUTURE SURFACE PLATFORM TECHNOLOGY

Within the next three decades the U.S. Navy must be able to produce surface combatants capable of conducting all types of naval missions with minimal crews and with stealth levels that allow combat operations to be conducted with the lowest possible risk. The characteristics of 21st-century naval platforms will be influenced by three primary factors: (1) resources allocated for defense, (2) technology, and (3) evolving threats. These are not independent variables. By leveraging commercially available technology with focused development targeted on the unique needs of the Navy and Marine Corps, the Department of the Navy can create an effective and affordable military capability. Some investment is required, however, in order to pursue the available opportunities that emerging technologies afford. Failure to allocate resources to develop new platform technologies will mean continuation of the status quo into the future.

It is anticipated that the technologies described in this report, such as advanced hull forms, integrated electric power and propulsion systems, stealth, and automation, will be applicable to all surface platforms envisioned for the early part of the 21st century. The panel anticipates the following platform types:

-

The aircraft carrier of this era will continue to fulfill the missions of deterrence and sustainable strike combat power. A significant reduction in manning1 level with concomitant life-cycle cost reductions will be made to both ship

-

and airwing. Engineering plants could include high-power-density nuclear power plants with integrated electric power and propulsion systems. Steam catapults may have given way to lighter, less manpower-intensive systems (candidate systems include electromagnetic and internal combustion catapults). The carrier could be configured to handle conventional takeoff and landing, short takeoff and vertical landing, vertical takeoff and landing, and pilotless aircraft. It will have a complete mission planning capability for all weapon systems (joint weapons) and may be capable of controlling one or more arsenal ships.

-

The surface warfare combatant will be a rugged, survivable, highly automated, low-signature platform with an efficient hull form and electric drive. The ship will be minimally manned and will have the capability to deliver ordnance against air, surface, and subsurface targets (the linear descendant of the Fletcher). It will have a mission planning capability and an ability to guide either surface- or air-launched weapons. It will be capable of operating independently and in conjunction with one or more arsenal ship types and aircraft carrier battle groups. Some surface ships will have guns and missiles for naval surface fire support, as well as antiaircraft warfare, antisubmarine warfare, and theater missile defense mission capabilities.

-

A new ship type, the arsenal ship, will project any and all of the vertical launch system (VLS) weapons of the 21st century. It will support all mission areas for which there is a VLS weapon. The weapon system of this ship type will be controlled remotely from another ship, a land station, or a control aircraft. Primary ship defense of this type will derive from low signatures in all areas: radar, acoustic, magnetic, infrared (IR), and visible.

-

Amphibious platforms will be configured to support littoral warfare. It is envisioned that two classes will dominate: (1) a large ship similar to today's aircapable ships carrying advanced amphibious assault vehicles, landing craft air cushioned, rotary wing aircraft, and VLS for protection, strike, and remote launch; and (2) a smaller, dedicated platform to support Marine Corps concepts such as Sea Dragon.

The following are the technology focus areas for major efforts with respect to surface platforms:

-

Minimal manning through automation,

-

Integrated electric power and propulsion systems,

-

Signature reduction,

-

Modular design,

-

Environmental control,

-

Aircraft catapults, and

-

Indigenous self-defense.

TECHNOLOGY FOCUS AREAS

Minimal Manning Through Automation

Objective

In addressing affordability while maintaining functionality, achieving minimal manning is the most significant factor in driving down ship system life-cycle costs. Not only must normal watch standing, machinery monitoring, and maintenance be accomplished with lower numbers of personnel, but so also must casualty and damage control for survivability. The logistics operations for maintaining ships at sea are essential efforts that can profit from a more automated ship through the greater availability of timely information about the ship's systems. Automation can support these reductions while ensuring adequate performance. Even in the case of damage control, the capabilities that automation provides, especially in new designs, offer strong encouragement that truly automated, low-manpower ships are practical. As a result, ships and their systems can be operated and fought remotely.

Enabling Technology: Automation and Control

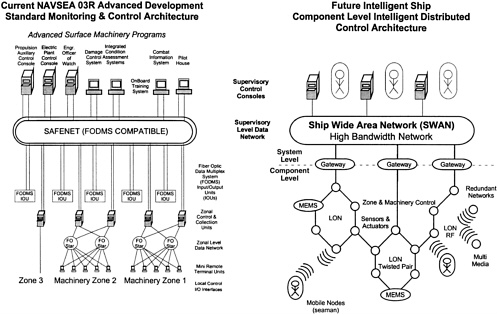

The purpose of automation is to provide access to information and control at all desired levels and points in a ship. By and large, present Navy automation programs address issues from the command level down, relying on traditional local area network (LAN) protocols and the use of technology developed to support the management and manipulation of high-level information systems. Current approaches toward machinery automation and automated damage control seek to better sense and collect information. This information is generally routed to central stations where evaluation and response functions reside. True distributed intelligent sensing, reasoning, and response are not yet available. At the tactical systems level, the concept of distributed intelligent control with modular software and the use of standard interface structures is being adopted. The reliance on relatively disparate proprietary approaches is giving way to systems that employ commercially available hardware and software with standard interfaces and open architectures. At the tactical and system monitoring levels, these LAN-based, modular, open architecture systems offer much in the way of improved reliability, reduced cost, and upgrade capability. The LAN-based approach loses its effectiveness at the component level, however, where the pernode hardware and software costs become excessive and the complexity of developing software embedded in a relatively few computers running a LAN protocol becomes unmanageable. The reason is simply that the nature of the functions and communications at the component level differs considerably from what is often required at the tactical level.

Truly distributed control systems have long been a dream that has evaded realization because of the high costs of addressing large, complex systems down to the component level. Recently, a powerful set of tools and components in the form of an open architecture, local operating network (LON) have emerged from the commercial sector to provide a control bus environment at the component level. With the emergence of a fully exploited control bus, component-level intelligent distributed control systems (CLIDCS) can provide sensing, thinking, and acting with full access to information and control at any level in the control system hierarchy. This results in increased flexibility, survivability, and cost-effectiveness over other approaches. CLIDCS consists of a cost-effective, commercial off-the-shelf (COTS), open architecture system including communications processors, transceivers, microcontrollers, and open network protocols that permit each sensor and actuator device in a ship's system to connect directly to any other node through a peer-to-peer communications network, while avoiding the essentially point-to-point networks common to other approaches. This arrangement provides local intelligence through the use of embedded microprocessors at each node (every important electromechanical device) in the system, the ability of each intelligent node to communicate directly to any other node on the control network as required, and as a result, transparent access to information and control at the component level or any other desired level. Software changes can be made at individual nodes, thus avoiding disruptive changes common to monolithic software architectures. Depending on the application, a node may manage one or several system sensor and actuator signals.

If this emerging technology can be identified, developed, demonstrated, and implemented in a timely fashion, CLIDCS will be the essential enabler of increased performance and reduced life-cycle costs through minimal manning. At a minimum, the use of this approach should dramatically reduce control system wiring as the point-to-point technique common to previous-generation control systems is replaced by the serial linked array of nodes that communicate using a protocol optimized for short, high-reliability command-type messages. Interoperable protocols allow future upgrades without major system upheavals. Beyond this, with intelligence residing at each node, sensing, computation, and actuator functionality may be distributed as desired throughout the system. Information can be available transparently throughout the network, thus providing a virtual information fabric for the system. Current costs (on the order of $200 for microcontrollers, communications protocol, and transceivers per node) are kept low through the use of high-volume, commercially available technology designed specifically for control. Control from, and communications with, higher levels of command can be provided through gateways between the CLIDCS system and the higher control levels. The proposed CLIDCS approach thus complements current and proposed Navy shipboard automation systems at higher levels (e.g., the Standard Machinery Control System). The result could be a common, open control architecture that will be both scalable and interoperable to

support applications across platform types as well as to accommodate future system growth. Figure 2.1 shows a schematic representation of the Navy's current design of the Advanced Development Standard Monitoring and Control Architecture and a conceptual design of a CLIDCS system.

Although CLIDCS is a new approach for ship automation, a broad and rapidly growing market of factory, building, and transportation system applications currently exists. Furthermore, systems of this type and of comparable complexity are currently used in operating autonomous unmanned undersea vehicles developed and operated with Navy funding.

Benefits

Machinery Control

Future Navy ships will be minimally manned. Highly automated ships will be achievable only if affordable intelligence is present wherever the combination of sensing, computation, actuation, and communications (functions currently performed by sailors) is required. Such automation will make it possible to have a ship's functions carried out with little more than the direct commands of its relatively smaller crew. Ship systems will function in the background to provide support for the crew or to provide ship system response directed by the crew. Maintenance problems with ship equipment will be detected through intelligent condition-based monitoring in time to provide maintenance by special traveling at-sea teams with timely logistical and technical support either at sea or from shore. Equipment redundancy and durability will support the automation approach. Ship crews will likely do much less routine machinery maintenance and repair than is the case today.

Minimal ship crews will permit a reduction in hotel requirements. As a consequence, ships will be designed with more attention to their offensive missions and survivability, while attention given to the crew will be focused more on providing greater functionality, survivability, and comfort than are currently possible.

Damage Control

Ship survivability can be enhanced through the use of integrated intelligent sensing and action systems for rapidly and automatically detecting, characterizing, and controlling fire, flooding, and structural damage. Future ships may be relatively uninhabited, thus permitting focused design efforts aimed toward achieving heightened ship self-protection, including the inerting of spaces, secure compartmentalization, self-healing structural boundaries, and self-sealing fire and flooding control or information networks. Enhanced functionality could be made available either in anticipation of a developing threat or as a result of a

damage event. Relative to today, ships' crews can be much less personally involved in confronting ship damage control emergencies because the ship will be designed to limit damage inherently and to react automatically to damage threats as they occur. Ships' crews would be protected in secure facilities from which they are able to continue combat operations while assessing and managing overall ship conditions.

Potential Impact for the Future Navy

Dependable, cost-effective CLIDCS will transition maintenance, evaluation, and damage control from manual to automated and intelligent, from people doing tasks to people commanding and monitoring tasks, imbuing systems with the ability to sense, reason, act, reconfigure, and share information and status. The impact on the future Navy will include the following:

-

Minimal manning capabilities with enhanced inherent readiness and survivability;

-

Modular, interoperable ship system design for adaptability of next-generation technology;

-

Automated, conditioned-based monitoring and maintenance;

-

Greater integration of at-sea systems with logistical support;

-

Significant improvements in damage characterization and control; and

-

Greater damage containment and control through enhanced compartmentalization, modularity, and system interoperability.

The state of the rapidly developing CLIDCS technology and its availability in the commercial marketplace are such that a great deal can be accomplished in terms of ship automation.

Integrated Electric Power and Propulsion System

Objective

The objective is to capitalize on advances in permanent magnet material technology and in power electronics that are making alternatives available for power generation and distribution for ship propulsion, weapons, and auxiliary systems. Practical demonstration at sea of electric drive with an integrated power system is required in order to develop the mature technology that could be delivered to the fleet. While directed energy weapons tied to integrated power systems require further development, many integrated electric power and propulsion system technologies are ready for at-sea demonstrations in the near term. Such demonstrations should clarify any outstanding issues associated with utilizing

these advances. The Navy could then reap the advantages of improved performance with improved affordability.

Enabling Technology

The combination of advanced permanent magnet materials and power electronics enables affordable, high-performance, electric drive ship propulsion with a fully integrated power system. The integrated power system includes power generation (for both propulsion and ship service applications), zonal electric power distribution, power conversion within each ship module for servicing user equipment, and total system monitoring and control.

In the area of permanent magnet material, neodymium iron boron has higher field strength and lower costs than samarium cobalt, the previous permanent magnet material of choice. Widespread use of these magnets in commercial applications is providing the business base to drive down magnet costs.

Insulated gate bipolar transistors (IGBTs) are gaining widespread commercial use today in power electronic applications. Power converters using IGBTs offer advantages in size, weight, noise signatures, complexity, and affordability relative to conventional power conversion technology. Further advances in power electronics are promised by metal oxide semiconductor-controlled thyristor (MCT) technology. With the reductions in size, weight, complexity, and cost promised by MCTs, a revolution in electronics dubbed "power electronic building blocks" (PEBBs) is promised. PEBBs can be thought of as the integrated circuit of power electronics. A PEBB converts source power into that required by the load and provides programmable system control of the load as well. PEBBs can be useful in such diverse applications as motor controllers, power supplies, bus transfer switches, circuit breakers, actuators, adjustable speed drives, and power inverters or converters. Commercial interest in these applications can be expected to provide the business base and unit volume necessary to drive down costs.

Benefits

These technologies promise benefits in the areas of affordability, arrangement flexibility, power density, increased ship payload, and quieting.

Affordability

Commercial use of these technologies obviously drives down the cost of the elements that comprise the whole. Beyond this, commonality of propulsion motor modules across widespread ship applications offers significant opportunity for cost savings. This commonality would be achieved by producing motor modules in bulk (relative to today's highly individualized propulsion plants) for marine propulsion applications. A single motor module might power a commercial

ship, whereas two such modules might power a surface combatant of moderate size. Multiple motor modules per shaft might power a large combatant. In each case, a standard motor module would be the basic propulsion plant building block, with both commercial and naval applications helping broaden the business base to gain the benefits of production in volume.

Propulsion motors can be powered by electricity generated through any number of power sources. Gas turbine generators, diesel generators, steam plants, or any other viable source of electricity can power the electric drive motors. This compatibility further encourages the use of common motor modules for any number of marine applications, commercial as well as naval. With the integrated power system generating both propulsive and ship service power, the design option exists to maximize the ability to drop generators off the line at less than full load speeds to optimize fuel efficiency.

Also contributing to overall ship affordability are the arrangement flexibility, power density, increased payload, and quieting.

Arrangement Flexibility

With electric drive, the prime mover is not tied to the shaft line. This allows ship designers to better balance competing demands for space in the ship's hull. For instance, if a gas turbine prime mover is used in a mechanical drive plant, significant space within the ship's hull must be dedicated to getting air to, and exhaust gases from, the turbines, which are low in the ship, tied into the propulsion shafts. With electric drive, the designer can trade stability and volume concerns and optimize a design that locates the gas turbine generators near the ship's topside to minimize the impact of the intake and exhaust systems.

Power Density

With the permanent magnet motor approach, electric drive can convert a given amount of power while requiring far less weight than a geared mechanical drive system. To further this advantage, the same power generation source that provides electricity to the electric drive motor(s) can provide ship service electricity. Even with redundant power sources for reliability, the advantage lies with electric drive, because redundant ship service and redundant propulsion power systems would become one set of redundant integrated power systems.

Increased Payload

The combination of the power density and arrangement flexibility attributes of electric drive translates into increased payload availability (or conversely, smaller overall ship size for a given payload) for all types of ships.

Quieting

The inherent quietness of solid-state electronics offers cost advantages over conventional power conversion hardware because the need for additional noise control measures is minimized.

Directed energy weapons technology has not yet reached the level of maturity achieved with electric drive and integrated power system technologies, but directed energy weapons and integrated power systems are naturally compatible.

Signature Reduction

General

The increasing general emphasis on the reduction of all naval surface platform signatures (acoustic, radar, magnetic, infrared, and on low observability) is a direct result of the increased performance and lethality of the threat and the move of the Navy into the littorals. The strong emphasis being placed on reduction of the radar cross section of the naval platform is a direct result of the significantly increased performance of the cruise missile and the capabilities of new generation search radars. It can be expected that by 2035 the detection and classification capability of weapons will have advanced significantly beyond what is available today.

Improved weapon seekers across the spectrum of platform signatures will stress the capability of both active and passive defenses. It has long been recognized that decreasing the total signature of a platform decreases the enemy's weapon sensor effectiveness and shrinks the enemy's battle space. For the defender, reduced signature buys space and time.

Senior U.S. Navy policy-makers and program managers recognize the importance of signature control and are now establishing ambitious, specific, and quantitative signature goals for platforms and their individual components.

A few fundamental overarching technologies could further the realization of these ambitious signature goals. Pursuing these technologies could result in future naval platforms that are significantly more survivable. The technologies are as follows:

-

Composite materials,

-

Magnetic signature reduction,

-

Drag reduction, and

-

Alternative hull forms.

These fundamental technologies and the benefits that will accrue in reducing the signatures and increasing the survivability of future naval platforms are described below. It was the judgment of the panel that these technologies hold the greatest

promise for reducing the overall signature of surface ships. Other technologies, such as those that could reduce infrared (IR) emissions or those that could reduce the acoustic wake formed by cavitating propellers, could also be important but are not discussed in detail here.

Composite Materials and Surface Ship Structure

Objective

A significant reduction in the radar signature of future naval platforms can be enabled by the replacement of steel and/or aluminum with affordable, fire-tolerant, composite material for topside and hull structure.

Enabling Technologies

The use of composites in surface ships' structure enables embedding of antennas and sensors; introduction of special paints, coatings, and various absorbers; introduction of various unique material properties; layering of different materials; tuning of transmission windows in the composite for optimum performance of sensors and emitters; and specific shaping. This can result in a radar signature significantly lower than that of a conventional metal structure.

Current technical challenges preventing the introduction of composite materials into the next generation of naval surface platforms are fire tolerance, toxicity, and electromagnetic interference (EMI) and electromagnetic pulse (EMP) resistance. Additional technical challenges that most likely can be addressed within the current level of effort and funding during the next decade include bonding, grounding, and joining methods; resin and core material development; producibility; strength, weight, and cost parity with aluminum and/or steel; maintenance requirements; and ballistic protection.

The research and development goals of the aircraft industry and other commercial industries are not sufficiently aligned with the goals of the military shipbuilding industry to be relied on to solve the technical challenges peculiar to surface combatants. Commercial industry is not focused on EMI-EMP resistance and significant structural applications for a military environment. In the near and midterm, it is unlikely that the cost-effective application of composite material to topside structure on a surface combatant will result in a significant weight savings compared to aluminum. Weight and cost reductions can be expected to follow the development and initial application of fire-tolerant composite materials for surface combatant ships.

There are several Navy-sponsored advanced technology demonstrations (ATDs) under way that will result in the introduction of composite materials in surface combatant topside applications in a limited manner. These include the advanced enclosed mast-sensor, the multifunction electromagnetic radiation system,

and the low-observable stack. These ATDs are critical components of the overall effort to introduce composite materials into surface warships in a wholesale manner. Within the current level of effort and funding, however, a solution to fire tolerance, conflagration or flammability, toxicity, combustibility, thermal resistance, and EMI-EMP technical challenges will not be developed in time to allow the application of composites into the next surface combatant program. A focused effort indigenous to the U.S. Navy surface ship community will be required to address the fire tolerance and EMI-EMP technical challenges associated with the application of composites as a primary structural material in naval surface platforms.

Benefits

Utilization of composite material as topside, including deckhouse, stack and mast, and hull structure, in naval surface platforms will enable a reduction in platform signature several magnitudes greater than currently possible for a surface combatant with the traditional steel and/or aluminum material as its primary structure.

Composite materials will enable multifunctional sensors and emitters to be embedded and conformal. Composite materials will also enable specific geometric shaping, treatment, and reflection or absorption characteristics of exposed structure; downsizing or elimination of the mast(s); integration with other topside components such as low-observable intakes or uptakes; and fully enclosed small craft handling equipment, hangars, speakers, lights, and doors. The aggregate result of these changes would be a significant reduction in the radar cross section of a future naval surface platform.

Magnetic Signature Reduction

As the 21st century evolves, U.S. Navy platforms will be increasingly engaged in operations in the littoral—areas close to land and choke points. Potential adversaries can be expected to take advantage of opportunities afforded by the use of cheap and effective mines in the context of littoral warfare.

Bottom mines, both new mines and those left over from past conflicts, often utilize magnetic sensing as their primary sensor technology. Therefore, if Navy platforms (future and existing) can reduce their magnetic signatures significantly, the threat to ships operating in the littoral can be greatly reduced.

Objective

Dramatically reduce the magnetic signature of surface combatants.

Enabling Technology

An appropriate technology may be intelligent, adaptive closed-loop magnetic degaussing. The degaussing system should permit real-time internal monitoring of a platform's magnetic signature for any latitude, any course change, and any combination of internal operating machinery.

Benefits

If significant magnetic signature reduction can be achieved, ships so protected will be considerably less vulnerable to most of the world's existing mine inventory. Moreover, in an effort to engage a ship with a low signature successfully, the adversary can be expected to increase mine sensitivity, which will make mines significantly easier to sweep. Tactically, this should enable U.S. naval forces to operate more effectively in the vicinity of mined areas, particularly those inherent in ''brown water" and littoral warfare.

Advanced Hull Forms

Objective

Apply advanced hull form shaping above and below the waterline to provide signature reduction and, where possible, also obtain measurable improvements in seakeeping, speed, and endurance. These improvements along with signature reduction can directly improve the militarily important areas of mission effectiveness, survivability, affordability, and operational availability. Table 2.1 shows the interrelationship between performance and military attributes.

Enabling Technologies

Ongoing naval technology programs in signature reduction offer the opportunity to apply novel hull forms to surface ship platforms in the near term. Advanced materials and computational fluid dynamics (CFD) simulations are among the technologies that can facilitate development of advanced hull forms. Additionally, advances in the understanding and application of concepts such as the hydrofoil small waterplane area ship, wave piercing hull forms, and the small waterplane area twin hull concept offer the potential for major improvements in surface ship configurations.

Benefits

Mission Effectiveness. Signature reduction means that the ship design can be more focused on the offensive mission. Optimized hull shaping both above and

TABLE 2.1 Advanced Hull Form Benefit Matrix

|

|

Performance Attributes |

|||

|

Military Attributes |

Signature Reduction |

Seakeeping |

Speed |

Endurance |

|

Mission effectiveness |

X |

X |

X |

X |

|

Survivability |

X |

X |

X |

|

|

Affordability |

X |

X |

||

|

Operational availability |

X |

X |

X |

|

below the waterline can be used to decrease the potential for detection by opposing forces and increase the potential for avoiding a direct hit if the ship is detected.

Seakeeping improvement delays degradation in mission performance, both hardware and human. Having the ability to put ordnance on target in inclement weather provides significant advantages from the warfighting perspective. The ability to develop hull forms capable of sustained operations at high speed in heavy seas would yield tremendous tactical benefits, and the peak performance of any crew is enhanced if the adverse effects of roll and pitch can be minimized.

Speed enables access to more littoral engagements and cooperative operations and also provides potential advantages relative to the element of surprise. Furthermore, speed allows for coverage of a greater global area with fewer assets.

Survivability. Signature reduction lowers the detection probability. Hull form shaping both above and below the surface can be used to reduce acoustic, wake, and radar signatures dramatically. In addition to reduced detectability, reductions in signature make it more difficult for others to target even when the ship has been detected.

Improved seakeeping generally promotes safety in extreme weather and has the additional advantage of allowing a full range of operations over a wider range of ship speeds. The ability to launch weapons in heavy weather is an obvious offensive advantage, and having the ability to do so for defensive purposes clearly increases the potential for survival against enemy attack from the air or from submarines. The seakeeping characteristics of a ship can be altered drastically through hull form shaping. Modern computer technology, coupled with advanced CFD algorithms, makes the assessment of hull form optimization possible. Hull forms capable of reasonably high speeds can be developed that minimize the downside impacts of high fuel consumption, poor seakeeping, large wake signatures, or the application of sophisticated systems historically associated with surface effect ships.

Affordability. Flat panels associated with improved radar signature have the compounding advantage of reduced construction costs. Standard shapes allow increased utilization of automated processes. The shape of the hull can have a significant positive effect on maintenance costs as a result of improved corrosion resistance.

Through hull shaping, drag of the body through the water can be reduced in comparison with conventional monohulls. This can lead to both acquisition and life-cycle cost savings associated with the propulsion system and fuel use. Over the life of the ship, even a small reduction in fuel consumption can translate into many millions of dollars in savings for a class of ships. Reduction in drag may be directly associated with reduced powering requirements, which could result in a smaller power plant for a given size ship. Smaller propulsion plants have the inherent benefit of being less costly to procure, and a smaller propulsion plant may provide flexibility in arrangements that benefit other attributes as well.

Operational Availability. Increased speed, seakeeping, and endurance all serve to increase the time available for operations.

Flow Control

Objective

To reduce wake and acoustic signatures while simultaneously reducing vehicle drag and hence power required, or fuel consumed, for a given speed.

Enabling Technologies

Boundary layer control, transition and turbulence control via electromagnetic force application, and other active drag reduction techniques have the potential to enable a significant improvement in drag for both surface and undersea vessels, but the phenomenology is not well understood and, in some cases, not consistently repeatable (in the case of electromagnetic turbulence control, for example). These represent higher-risk, longer-term approaches. Integrated hull/propulsion design, shaping, circulation control, and intelligent vortex generators and strakes are examples of flow control technologies currently under active investigation, but are anticipated to have a more limited (although more certain) payoff. In many cases, the individual efforts may be used in some combination to provide an integrated system design or configuration improvement.

Several technical approaches have been identified to reduce hull drag through reduction of turbulent skin friction: introduction of foreign substances, geometrical modification, controlled suction, electromagnetic force control, and synergism. Polymers and other additives have already been developed, and some of them are available commercially, but additional research is required into methods

for introducing polymers into the boundary layer and for recovering and recycling the additives, thus reducing the space, weight, and cost impact of flow control additives. Additional work on geometrical modifications, such as riblets, large eddy breakup devices, vortex control devices, and convex surfaces may prove fruitful, but examining combinations of these and others (i.e., synergism) may offer the best potential in this area. Another technique, known to work in principal, is microbubble drag reduction, but the challenge of keeping the bubbles below the surface may be insurmountable. This is also an example of an approach that is embryonic in nature and that should be explored at a modest level.

The application of selective boundary-layer suction and other active flow control measures via interactive control loops may show promise in reducing skin friction. Recent developments in the control of chaotic systems and in microfabrication technology provide opportunities for practical implementation of the required large arrays of inexpensive, programmable sensor or actuator chips (microelectromechanical systems or devices) embedded on the surface. These technologies, and the potential systems they may enable, are applicable to surface vessels, submarines, and aircraft.

It appears that the work thus far on boundary layer control using the controlled application of electromagnetic forces has some promise at relatively low Reynolds numbers. The practicality of this approach requires further study.

Benefits

Flow control offers the potential to reduce acoustic and wake signatures, while at the same time reducing drag. Clearly this area merits continued investigation and research since there exist significant potential benefits if the technological challenges can be overcome.

Modular Design

Objective

Future system architectures enable concepts of modular design to be reconsidered in order to achieve both flexibility in upgrading existing combat systems or in installing new systems over the life of a naval ship and a significant reduction in building time and cost.

Enabling Technology

The architecture of future technologies such as CLIDCS, integrated power systems, open architecture networked combat systems, PEBBs, and multifunctional antennas warrants and enables addressing modularity in ship design and construction. Modularity and standardization in future ship design can be extrapolated

FIGURE 2.2 Danish Navy's Standard Flex 300 design. SOURCE: Jack Guilfoyle, Chris McKesson, Mark Oakes, Robert Scott, Steve Cohen, and Mark Hoggard, "Patrol Craft Requirements and Technology for the Next Century," p. 6-15 in Symposium on Naval Ship Design for Setting Course for the 21st Century, Society of Naval Architects and Marine Engineers, Jersey City, N.J.

from a program in modularity and standards started in the early 1980s, called the Ship Systems Engineering Standards Program. The concept was to develop interface standards that would permit a wide variety of systems through the easy interchange of modules anytime in the service life of the ship. Standards were developed for the then current vertical launch system, but the program was terminated before additional standards for electronics and machinery were developed.

A limiting factor is the current hard-wiring of systems that are customized for the particular sensors, consoles, computers, and launchers of a specific weapon system. Networking technology will enable the designer to replace the hardwired system with data buses and standard interfaces that will carry all of the information used by the combat system. These are similar in principle to electric power cables in that power cabling is not predicated on the details of the equipment served. Thus, as long as the data bus has sufficient capacity and standardized interfaces, changes in combat system units should not require rewiring. Moreover, with an open architecture data bus system, important combat system or combat system role changes may be easily implemented as technology advances. If all computers and consoles have access to all data in the combat system, then any one computer or console can be defined to perform any required role. Alternatively, multiple functions, including those outside the combat system, can be monitored or controlled by a single computer and/or console.

The data bus concept can be further extended. Currently, it is usual to distinguish between combat systems and systems such as propulsion, steering,

and damage control. The Navy is beginning to apply data buses to the latter functions. It is conceivable that the boundary between combat and ship systems will become blurred and that a common bus will serve all functions, as well as integrated power systems.

Some years ago the Royal Danish Navy could not replace all of the types of ships it was then operating. Yet it could not abandon roles such as prehostilities surveillance, mine laying, missile attack, torpedo attack, and mine countermeasures. The technologies of data buses and general-purpose computers suggested a solution. A 300-ton corvette, StanFlex 300, shown in Figure 2.2, was designed with containerized weapons and in some cases sensors. Each could plug into the combat system data bus, which also ran through the ship's combat information center (CIC). Each CIC computer and console had its role defined entirely by software, so that it could shift roles easily. In theory, StanFlex 300 can change all of its combat system in 24 hours or less simply by replacing containers and software.

Blohm and Voss (B&V) has been containerizing weapons and other ship components for a number of years. The flexibility of its corvette and frigate designs accommodates the desires of several navies for different combat systems. In 1991, B&V delivered its first frigate with a data bus replacing conventional point-to-point wiring for weapon and electronic systems. This ship was constructed in 32 months. B&V claims that modularization reduced the time from contract award to commissioning from about 72 to 48 months. Attendant with this decreased construction time, however, is an increase in the quantity of connections at the module interfaces and in the complexity of the ship's service systems (air conditioning plants, fire pumps, and so forth) and the ship's structure.

Benefit

Experience to date indicates that designing for flexibility through modularity not only facilitates making changes during the service life of a ship, but also could make ships easier and less costly to construct.

Environmental Control

Objective

To comply with increasing restrictions placed on ship discharge by the international community (e.g., MARPOL Annex V2), U.S. maritime organizations are actively seeking to develop technological solutions for the treatment of shipboard

waste. The difficulties in implementing waste treatment systems on board existing military ships have to do with the volume of waste generated during long military missions. Future shipboard waste treatment systems could consist of an array of separate systems for specific classes of waste, or there could be a single, large-scale waste treatment system that potentially would handle nearly all types of waste streams generated on board naval vessels. The Navy's objective is to develop and field systems that properly treat shipboard waste without hampering a vessel's fundamental military mission, whether during peacetime or war, and minimize this impact on the limited space and power available on board.

Some of the more recent enabling technologies that may be applied here are described below. Other more mature technologies (e.g., plastics processors, pulpers or shredders, and liquid filtration systems) are currently at the implementation stage and are not discussed further.

Enabling Technologies

Supercritical Water Oxidation

Supercritical water oxidation (SCWO) for the destruction of concentrated liquids is a process by which oxidation of waste species takes place in H2O at very high temperatures and pressures, well beyond the critical point. With residence times of the order of seconds to minutes, SCWO can produce very high destruction rates in a relatively clean, easy-to-control system. Yet it is highly energy intensive, whereas available systems tend to be large, heavy, and relatively expensive.

Advanced Shipboard Incineration Systems

On-board incineration could be an attractive waste alternative from a technological point of view. In addition to providing a significant reduction in waste volume, it is often possible to recover a substantial amount of energy (heat) and material (e.g., acids) through incineration. Nevertheless, as a result of public opposition to the notion of incineration systems, only a small fraction (<5 percent) of combustible waste has historically been treated by incineration on land and the technology has received mixed support in Navy circles. The fact that the few existing on-board incineration systems are extremely old (1940s technology) and inefficient does not help improve this perception.

Shipboard incineration systems could take the form of comprehensive waste treatment systems, such as fixed hearth-refractory box or rotary kiln, which are capable of incinerating a wide variety of solid or liquid waste. Alternately, specialized incineration systems could be used on board to treat specific waste streams, such as sewage concentrate, oily waste, and/or food and paper slurries. Advanced incineration systems based on aerospace propulsion devices, some of which are

being examined through Navy ship environmental R&D program studies, have demonstrated extremely high destruction rates compared with conventional incinerators and should be examined further for future implementation. Thermal insulation and shielding noise control, as well as operator training and expertise, are essential issues for the development of on-board incineration systems.

Plasma Arc Pyrolysis

Plasma arc pyrolysis is an ultrahigh-temperature process that can be used very effectively to destroy both hazardous and nonhazardous wastes in the absence of oxygen. In this process, a direct-current (dc) power source is required to form an electrically discharged plasma arc, which can attain temperatures as high as 15,000°C. Solid waste as well as liquids and slurries can be fed into the arc jet or into the molten slag formed by the plasma arc, whose temperature can exceed 2,000°C. The high temperatures attained in the plasma and molten slag are very effective in destroying waste, yet the combustible gas product usually is burned in an afterburner, and as such, the system can be classified officially by the Environmental Protection Agency as an incinerator, with its associated negative political connotations.

Plasma arc pyrolysis has many potential advantages for waste treatment in general. The slag formed after waste pyrolysis is inert and of relatively low volume; it can be extracted readily from the system. There is also little or no ash discharge, and the gaseous discharge from the process can be passed easily through an afterburner and/or air pollution control equipment such as a venture scrubber. Certain disadvantages, however, may outweigh the advantages. Current plasma arc systems are very large and viewed by some as impractical, given the size constraints on Navy vessels, even on aircraft carriers. Further, a large dc power source is required to create the plasma (500 kW to 1 MW value), in addition to concerns about the IR and electromagnetic (EM) signature associated with the device. Finally, the buildup of slag on the liners of the pyrolysis chamber (usually from glass) can be excessive, requiring periodic removal, but liner replacement is common to most thermal destruction systems.

An alternative plasma-based system that may be suitable for shipboard waste treatment is the silent discharge or nonthermal plasma process. This process is based on the formation of free radicals in a nonequilibrium plasma that is created by electrical discharges from electrodes covered with a dielectric material. This approach can have advantages over thermal plasma systems because the nonthermal plasma component of the system is mostly silent, and waste is destroyed at ambient temperatures. Its power requirements are typically lower than those of thermal plasma systems for similar volumes of waste processed.

Benefits

There are a number of advanced waste treatment technologies that could be exploited, even in the near future, to solve shipboard waste management problems.

Since fuel for the ship's propulsion plant is already part of the existing shipboard system, waste treatment systems utilizing this same fuel for operation (e.g., incineration) may be integrated more easily into the ship. Highly energy-intensive devices such as the plasma arc pyrolysis system, however, could necessitate an external generator, introducing additional complexities to the ship system.

If one overall treatment technology for all waste classes is implemented on a ship, very reliable backup systems would be required. If significant "downtime" occurs for a single large system, whether due to routine maintenance or system upset, nearly every waste stream generated on board could be affected and would have to be stored, at least temporarily, until the problem was solved. Alternately, if multiple, diverse technologies are used, more complex failure pathways might occur, but they would be much less likely to affect all waste streams at once. This observation indicates that specialized treatment systems could work quite well within the system that makes up a military vessel and should be explored by the Navy.

Aircraft Catapults

Objective

Replace the steam catapult in order to gain flexibility in the choice of main propulsion plants and achieve significant savings in the space and weight of the catapult system.

Enabling Technology

Currently, research is being conducted on two alternative catapult systems: an electromagnetic system and one powered by an internal combustion engine. Such catapults must be compatible with the launch thrust requirements for current as well as potential new aircraft.

Benefit

The introduction of an alternative to the steam catapult on new aircraft carrier designs would eliminate the dependence of the catapult system on steam from the main power plant. This offers the following options to the platform designer:

TABLE 2.2 Surface Ship Technologies

|

|

Minimal Manning Through Automation |

Integrated Electric Power and Propulsion Systems |

Signature Reduction |

Modular Design |

Environmental Control |

Aircraft Catapults |

|

Platforms |

||||||

|

Carrier |

X |

X |

X |

X |

X |

X |

|

Surface warfare combatant |

X |

X |

X |

X |

X |

|

|

Arsenal ship |

X |

X |

X |

X |

X |

|

|

Amphibious ships |

X |

X |

X |

X |

X |

|

|

Major improvements |

||||||

|

Reduced life-cycle costs |

X |

X |

|

X |

X |

X |

|

Reduced development time |

X |

X |

X |

|||

|

Reduced logistic support |

X |

X |

||||

|

Increased range |

X |

X |

||||

|

Increased survivability |

X |

X |

X |

|||

|

Increased effectiveness |

X |

X |

X |

X |

X |

|

-

A wider choice of main power plant (e.g., diesel, gas turbine, high-power-density nuclear), and

-

Elimination of the weight (approximately 440 tons in a large carrier) of the piping for the steam supply.

CONCLUSIONS AND RECOMMENDATIONS

Summary of Applications

Table 2.2 summarizes the applications of the foregoing technology thrusts, in terms both of the platforms that will benefit from these developments and breakthroughs and of major improvements in performance and affordability factors.

Payoff

Successful pursuit of these technologies offers the potential for a streamlined, affordable, and effective fleet of surface ships. The smaller crew sizes and increased automation will facilitate focusing ship operations on the primary military missions. The technologies discussed offer potentially unprecedented levels of platform commonality with attendant benefits in training, logistics, and reduced life-cycle cost. Integrated electric power and propulsion systems will provide great opportunity for advances in standardization.

Composite development will be a key part of signature reduction efforts, along with advanced hull forms and flow control. In addition, flow control, if successfully pursued, will offer many benefits from increased range for a given speed to smaller ships for a given endurance. Modular design will permit increased flexibility in fielding new weapons and other warfighting improvements as they emerge. The environmental effort has a long-term benefit for humanity as well as putting the Navy on a standard course. Finally, aircraft catapult work is needed to open new possibilities in the design of aircraft carriers. The Navy-Marine Corps team, by emphasizing certain thrusts, can make major strides toward creating a winning force for 2035 with only a modest impact on current programs.

Although all of the technologies recommended by the panel for application to surface platforms are worth pursuing, three recommendations stand out in terms of potential payoff (both near term and far term):

-

Automation to reduce manning will enable a significant realization of life-cycle cost savings.

-

Integrated electric power and propulsion systems offer improved power density, greater ship arrangement flexibility to maximize payload, and improved affordability.

-

Composite materials offer opportunities for heterogeneous fabrication that supports new possibilities for signature reduction.

Work should move forward in all three areas now. All offer clear opportunities in the relatively near term, as well as promise for increased benefits in the longer term as the development of resources and increased attention drive the technologies toward maturity.