2

Requirements Analysis

Using the results of the HSR Program to develop an HSCT is entirely the responsibility of industry. However, the technology being developed by the HSR Program will have value only to the extent that it is relevant to design requirements for an economically viable HSCT. This chapter examines the important links between HSR technology and HSCT requirements. In particular, the chapter examines expected HSCT market demand and the key performance parameters (i.e., aircraft speed, range, and payload) that impact market demand; international aspects of HSCT development; and the results of the QFD analysis the committee used to identify key HSCT design requirements.

MARKET DEMAND

The study statement of task calls for reviewing "existing studies of the likely demands for supersonic transports in light of the dependence of these demands on aircraft characteristics." Accordingly, the committee examined the methodology used in market demand studies, the basis for key assumptions (such as fuel costs), and the areas of risk inherent in those assumptions.

An important element of the vision statement (see Chapter 1) is development of the necessary technologies for an economically viable HSCT. Economic viability means that the aircraft can be operated profitably on enough routes that the airline industry will purchase enough units to make the program profitable for the airframe and engine manufacturers. The number of routes an airline can operate profitably with an HSCT is a function of aircraft performance, cost structure, and passenger demand.

Forecasting program size is industry's responsibility because industry will

be designing the actual aircraft and taking the financial risk of launching and building it. Nonetheless, these forecasts are also important to NASA and the HSR Program to ensure that funds allocated to the HSR Program are spent on technologies with an acceptable probability of commercial application and to ensure that technology development is focused on related risk areas, such as economic viability and environmental acceptability.

Forecasts of HSCT Program Size

Proponents and opponents of the HSR Program have generated vastly different estimates of program size for an HSCT. The long-term forecasting horizon creates significant uncertainty in the forecasts and contributes to differences among the estimates.

Industry has indicated that a minimum program size of approximately 300 to 500 units will be required for them to make a launch decision (MacKinnon and Bunin, 1996). The market forecasts produced by industry range from 925 aircraft (Metwally, 1996) to 1,270 aircraft (MacKinnon, 1996) through the year 2025. In other words, industry believes an economically viable market is likely to exist for an HSCT aircraft that meets the performance specifications of the TCA.

Industry forecasts are based on several assumptions that limit the number of routes considered eligible for HSCT travel. Eligible routes must allow HSCTs to provide significant time savings over subsonic flights. This occurs between city-pairs1 connected by long-haul routes, mostly over water. (Because of sonic boom, HSCTs will cruise subsonically over populated land masses.) In some cases, routes may be altered to avoid flying over land, but such diversions should be minimal. Eligible routes must also be forecast to have sufficient passenger demand to support daily flights. Refueling stops (called technical stops in the airline industry) are assumed on routes longer than the aircraft's range of 5,000 n.m.

Underlying these forecasts is the assumption that airlines will obtain a 20 percent yield premium on HSCTs compared to subsonic aircraft. (That is, passengers will be willing to pay 20 percent more for an airline ticket on a supersonic aircraft.) This premium is needed to cover the HSCT's higher operating costs per seat mile. Industry has spent approximately $1 million on market research, including in-flight surveys and focus group discussions regarding surcharges for tickets on a supersonic aircraft. This research indicates that both business and leisure travelers would accept surcharges of up to 20 percent (relative to actual, discounted fares in any given class) to realize the time savings associated with travel on a supersonic aircraft.

The committee has reviewed industry's market forecasts, and the assumptions used appear to be reasonable for the specified time horizon and consistent

with aviation industry practice. The committee did not find any credible market forecasts that contradicted industry's forecasts. However, there are several risks or uncertainties in these forecasts.

Reliability of Market Research. The reliability of market research supporting the surcharge that passengers are willing to pay is uncertain. Travelers and corporate travel departments have never had the option of supersonic flights at an affordable price, so it is difficult for them to estimate accurately what their consumption will be. Also, the results from in-flight surveys of passengers are of limited value because many passengers do not pay for their own tickets, particularly high-fare business travelers. Focus groups with business managers were also used to examine this issue, but the results are not statistically sound.

Airline Economics. The impact of HSCTs on subsonic aircraft economics and the resulting impact on total airline system profits are not fully understood nor do they seem to be accounted for in current market forecasts. If HSCTs are not able to command the expected surcharge, airlines may be reluctant to adopt HSCTs because they may deteriorate the economics of their route systems by adding costs without adding revenue. In other words, the same revenue would be spread across a more expensive asset base.

Subsonic International Flights From Inland Cities. HSCTs will be best suited for operation to and from coastal cities. HSCT forecasts for routes between coastal cities assume that a portion of traffic transfers from connecting flights from inland cities. However, the number of inland cities with international flights has increased in recent years. Inland airports, such as Dallas/Fort Worth and Chicago, have nonstop service to Europe, Asia, and South America. Passengers in these cities will have the choice of taking a subsonic nonstop flight or a subsonic connection to a supersonic flight. Available market research does not address consumers' preferences in this situation. Increasing the range of subsonic aircraft and improving in-flight communications and entertainment may reduce passengers' perceived "lost time" during subsonic travel and mitigate their willingness to pay premium fares for supersonic speed. Current forecasts do not seem to account accurately for this competition for passengers.

Technical Stops. Technical stops can be effectively used on some long-range routes that exceed HSCT range. Even with a technical stop, the projected time savings over a subsonic flight on a transpacific route exceeds four hours—or 30 to 50 percent of the elapsed time—depending on the route. Nonetheless, technical stops may not be competitive, especially on routes like Los Angeles to Sydney on which subsonic aircraft can make the trip nonstop. A technical stop increases costs and uncertainty. The technical stop is probably not on the shortest approved nonstop route, increasing the distance of the trip. The additional takeoff and landing incurs additional landing fees and requires additional fuel and ground staff. Weather or runway conditions, air traffic congestion, or maintenance problems identified during required ground inspections can all cause delays. Thus, technical

stops may be viewed as a disadvantage by both airlines and passengers, potentially reducing passenger demand on long-range HSCT routes.

Utilization. Market forecasts are based on average aircraft utilization (in terms of flight hours per day) on a few high profile routes. This may be a poor representation of the actual aircraft utilization that can be achieved for a large airline network. Lower utilization would seem to increase the number of required aircraft, but the relationship is not that simple. Lower utilization increases capital costs per seat mile, possibly reducing the number of routes an HSCT can serve profitably.

Scheduling. The method used to calculate the number of eligible routes ignores some operational and marketing constraints that affect schedules. Factors such as the availability of landing and takeoff slots, airport curfews, and marketable departure and arrival times have been analyzed only on an anecdotal basis for selected routes, not for a global airline network. These constraints may lower HSCT utilization to an unacceptable level on some routes now included in the list of profitable HSCT opportunities.

Resolving the above uncertainties will require additional studies of market demand. This will also allow the quality and reliability of market studies to keep pace with technological development. As investments by NASA and industry increase, continued market studies will confirm that the HSCT performance characteristics targeted by the HSR Program remain consistent with a viable market.

Finding 2-1. Industry forecasts of market demand indicate that an HSCT consistent with TCA performance specifications will have a market size large enough to be economically viable. The assumptions in these market forecasts appear to be reasonable, although not certain or risk free. Generalizations in the forecast assumptions may overstate the projected market size.

Recommendation 2-1. Industry should conduct further market research and simulations to reduce the uncertainties associated with current forecasts and to validate that performance specifications used by the HSR Program to guide technology development are consistent with the design of an economically viable HSCT.

Impact of Cruise Speed

The HSR vision statement specifies a cruise speed of Mach 2.4. The Concorde, designed in the 1960s, has a cruise speed of Mach 2.0. The block time (i.e., the time between leaving the gate at the departure airport and arriving at the gate of the destination airport) for a trip between Los Angeles and Tokyo with a Mach 2.4 aircraft is 35 to 45 minutes less than with a Mach 2.0 aircraft. On transatlantic routes, the difference is less noticeable: both Mach 2.0 and 2.4 aircraft can cross the Atlantic four times per day, and the difference in block times between New York and London is about 15 minutes.

TABLE 2-1 HSCT Schedule between New York City (NYC) and London Heathrow (LHR) (local times)

|

Mach 2.4 (Elapsed time: 3 hours, 18 minutes each way) |

|||

|

New York to London |

London to New York |

||

|

Depart NYC |

Arrive LHR |

Depart LHR |

Arrive NYC |

|

8:00 (Day 1) |

16:18 (Day 1) |

17:50 (Day 1) |

16:08 (Day 1) |

|

22:00 (Day 1) |

6:18 (Day 2) |

8:00 (Day 2) |

6:18 (Day 2) |

|

Mach 2.0 (Elapsed time: 3 hours, 40 minutes each way) |

|||

|

New York to London |

London to New York |

||

|

Depart NYC |

Arrive LHR |

Depart LHR |

Arrive NYC |

|

8:00 (Day 1) |

16:40 (Day 1) |

18:05 (Day 1) |

16:45 (Day 1) |

|

21:50 (Day 1) |

6:30 (Day 2) |

8:05 (Day 2) |

6:30 (Day 2) |

|

Source: MDA, 1995 |

|||

Both Mach 2.0 and Mach 2.4 allow for marketable arrival and departure times on transpacific and transatlantic routes (MDA, 1995). Tables 2-1 and 2-2 show schedules for a single aircraft on these routes at Mach 2.4 and Mach 2.0. Aircraft turn times (i.e., the time between aircraft arrival and departure that allows for unloading passengers, servicing the aircraft, and boarding new passengers) are assumed to be 90 minutes at each airport. This appears to be consistent with airline industry practice for an aircraft of this size and for routes of this length.

One of the key justifications for building a Mach 2.4 HSCT, instead of a technically less challenging Mach 2.0 HSCT, is to maximize HSCT productivity in terms of passenger miles per day.2 On the routes from the U.S. west coast to Japan, a Mach 2.4 aircraft can make four crossings in 24 hours, while a Mach 2.0 aircraft can make only three crossings. However, scheduling four crossings with a Mach 2.4 HSCT provides very little slack in the schedule to absorb delays caused by weather, congestion, or maintenance. Also, a fleet of Mach 2.0 HSCTs could be scheduled so that individual aircraft alternate between different routes, maximizing their utilization and providing a total number of seat miles that may not be significantly lower than the total number of seat miles provided by an equivalent fleet of Mach 2.4 HSCTs.

TABLE 2-2 HSCT Schedule between Tokyo (NRT) and Los Angeles (LAX) (local times)

|

Mach 2.4 (Elapsed time: 4 hours, 29 minutes each way) |

|||

|

Tokyo to Los Angeles |

Los Angeles to Tokyo |

||

|

Depart NRT |

Arrive LAX |

Depart LAX |

Arrive NRT |

|

9:00 (Day 2) |

21:29 (Day 1) |

23:00 (Day 1) |

19:29 (Day 2) |

|

21:00 (Day 2) |

9:29 (Day 2) |

11:00 (Day 2) |

6:29 (Day 3) |

|

Mach 2.0 (Elapsed time: 5 hours, 5 minutes each way) |

|||

|

Tokyo to Los Angeles |

Los Angeles to Tokyo |

||

|

Depart NRT |

Arrive LAX |

Depart LAX |

Arrive NRT |

|

9:00 (Day 2) |

22:05 (Day 1)a |

23:35 (Day 1) |

20:40 (Day 2) |

|

22:10 (Day 2) |

11:15 (Day 2) |

12:45 (Day 2) |

9:50 (Day 3)b |

|

a The aircraft crosses the international date line during the flight and arrives on the night of the, day before it left. b More than one Mach 2.0 aircraft would be required to fly this pattern because the first leg of the next cycle leaves Tokyo at 9:00, before the last leg is completed—illustrating that a Mach 2.0 aircraft can complete only three crossings in a 24-hour period. Source: MDA, 1995 |

|||

Finding 2-2. From an airline scheduling perspective, an HSCT with a cruise speed as low as Mach 2.0 is likely to have productivity similar to a Mach 2.4 HSCT, assuming similar maintenance and servicing requirements.

Impact of Design Range and Payload

Aircraft range and payload correlate in an adverse way: increasing payload decreases range and vice versa. Early in the design synthesis phase, trading off range and payload is the traditional approach used to understand and evaluate aircraft design sensitivities and margins. Recently, greater emphasis has been placed on economically robust design processes, which Dieter (1991) has defined as "the systematic approach to finding optimum values of design factors which result in economical designs with low variability" (emphasis added). This definition and approach seem particularly applicable to the development of an HSCT.

Most recent analyses of potential HSCT designs have targeted payloads from about 200 to 350 passengers and ranges from about 4,000 to 6,500 n.m. A sensitivity analysis by Mavris, Bandte, and Sebrage (1996) shows that increasing the number of passengers from 220 to 300 would substantially increase economic

performance, whereas increasing range from 5,000 to 6,500 n.m. would decrease economic performance, although not to the same degree.

A Japanese study (Mizuno et al., 1991) examined payloads of up to 400 passengers and concluded that the economic viability of a supersonic transport is not improved when the payload is increased beyond 300 passengers. As a result, that analysis focused on payloads of 200 to 300 passengers. The same study also focused on a design range up to 6,500 n.m., which would enable nonstop flights between Tokyo and New York.

The HSR Program has fixed payload and range at 300 passengers and 5,000 n.m., respectively. The nominal range of 5,000 n.m. was selected to allow a TCA-like HSCT to provide nonstop service between Los Angeles and Tokyo, based on typical assumptions for the weight of passengers and their baggage, winds aloft (which are quite low at HSCT cruise altitudes), etc. Developing a precise range estimate for the TCA is unnecessary. NASA and industry participants in the HSR Program currently work together to ensure that the technology developed in accordance with the TCA design is compatible with the separate industry designs for an HSCT. Ultimately, industry will define the range and payload of any HSCTs that are built, based on its assessments of up-to-date market analyses and technological maturity. For example, an HSCT could be designed with a smaller payload to increase range. However, for payloads of less than 250 passengers, economic viability is expected to be unsatisfactory despite the increase in range. An aircraft with longer range would be optimized for longer routes, but it would provide less-than-optimum economic performance on the larger number of routes serviceable by a 5,000 n.m. HSCT.

As illustrated by the range formula given in the aerodynamic design section of Chapter 4, either a 1 percent decrease in the lift-to-drag ratio (LID) during supersonic cruise or a 1 percent increase in specific fuel consumption would reduce range by I percent. Also, because fuel weight is slightly more than 40 percent of maximum takeoff weight (MTOW) (for the TCA), and because the structural weight fraction is approximately 20 percent of MTOW, the range formula predicts that a I percent increase in structural weight would cause about a 0.5 percent reduction in range. Alternatively, maintaining the same range despite a I percent decrease in L/D would require an increase in MTOW of 8,500 pounds (about I percent) above the TCA's estimated MTOW of 740,000 pounds.

Another factor that complicates discussions of range is reserve fuel requirements. The TCA design includes some reserve fuel for operational diversions in case of hazardous weather at the destination airport. However, the full impact of reserve fuel requirements has not been estimated. Reserve requirements for over-ocean engine failure and cabin depressurization, in particular, have not been examined, even though they could significantly reduce the effective range of a TCA-like HSCT.

The technological challenges faced by the HSR Program are similar in magnitude to the challenges faced by development programs for highly advanced

military aircraft, where experience indicates that the initial development effort does not enable new aircraft to achieve performance goals in every area. When shortfalls do occur, their impact must be managed through trade-offs with other parameters (where performance exceeds the design goal) to provide an acceptable level of overall system performance. With an HSCT, a shortfall in any of the key performance parameters (L/D, specific fuel consumption, range, structural weight fraction, or MTOW) would jeopardize overall economic viability unless one or more of the other parameters exceed their goals. And that seems unlikely because of the technical challenges that must be overcome to develop and manufacture an HSCT that meets the current goals of the HSR Program.

Finding 2-3. There is general agreement within industry and the HSR Program that a payload of about 300 passengers is required for an economically viable HSCT. A similar level of agreement does not exist regarding what design range (between 4,500 n.m. and 6,500 n.m.) will maximize economic viability.

Recommendation 2-2. The HSR Program should conduct further market research and economic simulations to capture the impact of payload and range on HSCT utilization and economics. These simulations should be based on a comprehensive analysis of specific city-pair routes rather than a top-down analysis.

Finding 2-4. Achieving the range, payload, and MTOW goals established by the HSR Program (i.e., 5,000 n.m., 300 passengers, and 740,000 pounds) depends on full attainment of goals for supersonic cruise L/D, specific fuel consumption, and structural weight fraction.

Recommendation 2-3. The HSR Program should establish design margins to allow for possible shortfalls in key performance parameters. The HSR Program should also establish a management system to make trade-offs among these parameters to maintain an acceptable level of overall system performance.

INTERNATIONAL CONSIDERATIONS

There is considerable interest around the world in developing a new, economically viable, supersonic commercial transport. In Europe, Aerospatiale, British Aerospace, and Deutsche Aerospace are working together to develop advanced technology for a supersonic commercial transport. Publicly presented concepts focus on a cruise speed of Mach 2.0, but the Europeans are also developing airframe materials for higher speeds.

The experience of the European community with certification and flight testing of the Concorde is an important advantage relative to U.S. industry. However, the Europeans do not yet have the propulsion or airframe technology needed for a Mach 2.4 transport, and developing an improved Mach 2.0 transport would still

require a major financial investment. Therefore, there seems to be little likelihood that the Europeans will be ready to initiate a new supersonic commercial transport soon.

Since 1987, the Japanese Ministry of International Trade and Industry has supported technical and market feasibility studies for a supersonic commercial transport. At the 1996 World Aviation Congress, the Japan Aircraft Development Corporation (JADC) released the results of a government-supported conceptual design study that reviewed specifications for a next-generation supersonic commercial transport (Takasu et al., 1996). This study examined cruise speeds from Mach 2.0 to 2.4 and ranges from 4,000 n.m. (the minimum range for transatlantic routes) to 6,000 n.m. (to accommodate a variety of transpacific routes). Payload was fixed at 300 passengers. Design concepts for engines for Mach 2.0, 2.2, and 2.4 were developed and applied to a supersonic-commercial-transport sizing and performance-prediction tool developed by JADC. MTOW for different configurations were surveyed to find the best combination of cruise speed and range, which were determined to be Mach 2.2 and 6,000 n.m., respectively.

The JADC study selected a mixed-flow turbo-fan engine similar to the baseline engine concept selected by the HSR Program (see Chapter 3). JADC estimated that MTOW could be minimized by using an engine bypass ratio of 0.7 to 1.0 for a Mach 2.0 aircraft, or 0.4 to 0.5 for Mach 2.4. (Lower bypass ratios are necessary to maximize specific fuel consumption at higher speeds. The bypass ratios used by an HSCT engine will probably be similar.)

It is interesting to note that JADC could not find a combination of wing planform (i.e., wing cross section) and engine thrust for a Mach 2.4, 6,000 n.m. aircraft that did not exceed a maximum takeoff distance of 11,000 feet.3 This indicates that additional enabling technologies are needed to reduce MTOW for a Mach 2.4, 6,000 n.m. design.

JADC recommended using the study results as the basis for market research that could optimize aircraft performance parameters in terms of economic viability. Future work planned by JADC includes flight tests using subscale models launched from a subsonic aircraft.

Elsewhere in the Pacific rim, China, South Korea, Taiwan, and Indonesia also have the potential to participate in development of a supersonic commercial transport. These countries have strong and growing economies, and they are interested in developing their aerospace industries. For example, Korean manufacturers already rank twenty-first in aerospace trade, and the Korean government has ambitions of reaching the top 10 by the year 2000.

Finding 2-5. Europe has the technical expertise to compete in developing a next-generation supersonic commercial transport. Japan and other Pacific rim countries

could contribute financially and, to a lesser extent, technically. Because of technical challenges and financial requirements, it seems unlikely that foreign interests will initiate a program to develop an economically viable supersonic commercial transport during the next 5 to 10 years. However, political factors could spur earlier action.

Recommendation 2-4. NASA should continue to track the development of supersonic commercial transport technology worldwide.

KEY PRODUCT AND PROCESS CHARACTERISTICS

Translating customer needs and objectives into key product and process characteristics (which then lead to design requirements) is essential for early product planning (including technology development). This is especially true for complex systems like an HSCT. The committee used the QFD (Quality Function Deployment) methodology for defining and prioritizing customer requirements and relating them to key design requirements. QFD is a way of making the ''voice of the customer'' heard throughout an organization.

Description of the QFD Matrix

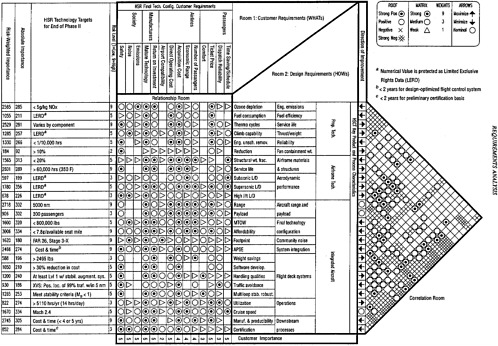

A QFD matrix is sometimes called a "house of quality" because of its house-shaped structure. The structure has various "rooms" as illustrated in the HSCT/HSR QFD product planning matrix (see Figure 2-1).

Customer Requirements and Importance

Customer requirements (the "whats") appear in the left side room (Room 1) of Figure 2-1. The committee established four categories of major customers for the HSR Program and, ultimately, for the HSCT that will incorporate the results of the HSR Program. The four customers are society, manufacturers, airlines, and passengers. Society's major requirements concern safety, noise, and emissions; major requirements of the manufacturers (primarily, the airframe and propulsion system manufacturers) are mature technology and return on investment; major airline requirements are airport compatibility, direct operating costs, acquisition cost, economic range, and payload (i.e., number of passengers); and major passenger requirements are comfort, ticket price, dispatch reliability, and time savings/schedule.

The column next to the customer requirements room is the customer importance room. The importance rating (1 through 5) is typically based on customer surveys. For this study, members of the committee provided this input, along with airline and FAA personnel who participated in study meetings. The committee rated the following areas as the highest priority customer requirements:

-

society: safety, noise, and emissions

-

manufacturers: mature technology and return on investment

-

airlines: direct operating costs

-

passengers: ticket price and time savings/schedule

Design Requirements

Design requirements are specified as key product and process characteristics (the "hows") in the upper center room (Room 2) of Figure 2-1. The key product and process characteristics are grouped into three major categories: propulsion technologies, airframe technologies, and integrated aircraft. (These categories correspond to Chapters 3, 4, and 5 of this report and roughly correspond to the organizational structure of the HSR Program.)

Wherever practical, the committee used characteristics in the QFD matrix that are also being tracked by the HSR Program. However, in some cases the characteristics used by the committee are at a higher level, as in the propulsion technologies category. More importantly, the committee has included additional characteristics. Many of these, such as certification, manufacturing, utilization, and affordability, are related to processes that can only be addressed by a combination of technologies.

QFD methodology requires selecting key product and process characteristics that can be quantitatively measured. Target values for each characteristic are located a row below Room 1 labeled "HSR Technology Targets, End of Phase II."

The committee included MTOW and affordability as characteristics of the final technology configuration because the committee believes that minimizing MTOW by itself is not sufficient to meet the program objective of developing technology that will lead to an economically viable HSCT. The committee endorses the view of the Boeing chief executive officer that "enabling technologies must be developed to permit the airplane to be built at affordable costs" (Condit, 1996).

Cost per available seat mile is a useful measure of affordability. The committee estimates that a cost of less than 7.8 cents per available seat mile would accommodate a fare surcharge of 20 to 30 percent relative to the fares for future subsonic transports.

Risk Levels

Immediately below Room 1 (the customer requirements room) of Figure 2-1, is a row labeled "Risk Level." The perceived risk level is a function of (1) the probability that the HSR Program will fail to reach the specified technology target value by the end of Phase II with a TRL (Technology Readiness Level) of 6 and (2) the impact that failure would have on the development of a successful HSCT. To indicate areas of high risk clearly, the committee used a nonlinear

TABLE 2-3 Risk-Weighting Factors

|

Perceived Level of Risk |

Risk-Weighting Factor |

|

low |

1 |

|

low-medium |

2 |

|

medium |

3 |

|

medium to high |

5 |

|

high |

9 |

weighting scale (see Table 2-3). This scale helped to illuminate high risk characteristics, such as environmental constraints, and to identify clearly the key product and process characteristics. The risk levels in Figure 2-1 are based on information provided by the HSR Program, as modified by the committee's assessment of current risk for each product and process characteristic.

Finding 2-6. The key product and process characteristics with the highest risk are engine emissions, engine service life, airframe service life, range, affordability, community noise, APSE (aero/propulsive/servo/elastic) phenomena,4 and manufacturability.5

Relationships

The center room, called the relationship room, shows the relationships between all the "whats" and "hows." To determine the strength of a relationship, the committee considered the impact that achieving a specific product or process characteristic would have on the customer's assessment of how well a specific customer requirement had been satisfied. One of three relationship symbols is used to define the strength of a relationship: a filled circle implies a strong relationship; an empty circle implies a medium relationship; and a triangle implies a weak relationship. No symbol appears if there is no relationship.

The triangular "roof" of the QFD matrix, called the correlation room, is used to identify correlations between pairs of product and process characteristics. A filled circle implies a strong positive correlation; an empty circle implies a weak positive correlation; an "X" implies a weak negative or adverse correlation; and an "XX" implies a strong negative or adverse correlation. If there is no correlation, the space is blank.

Negative correlations identify where trade-off decisions may be needed because of conflicts between individual product and process characteristics. In other

|

4 |

APSE phenomenon am associated with the highly interactive, dynamic nature of the HSCT airframe, propulsion, and flight control systems. See Chapter 5. |

|

5 |

These characteristics are listed in the order they appear in Figure 2-1. |

words, it may be possible to accomplish one product or process characteristic only at the expense of another. If a strong negative correlation cannot be eliminated, research may be needed to reduce the strength of the correlation.

The row directly below the roof indicates whether an increase or decrease in numerical value of each process or product characteristic would be beneficial. The information in this row is important for clarifying whether the correlations between the characteristics in the roof are positive (reinforcing) or negative (adverse). Three of the characteristics (range, payload, and cruise Mach number) have circles rather than arrows because the HSR Program has fixed these values.

The roof of Figure 2-1 illustrates the importance of the process characteristics (certification, manufacturing, utilization, and affordability). Most HSCT product characteristics have a strong relationship with one or more of the four process characteristics.

Finding 2-7. Most of the advanced technologies the HSR Program is developing to support an HSCT product launch decision are very process dependent, especially from the point of view of affordability.

Absolute and Risk-Weighted Importance

The "Absolute Importance" row near the bottom of the QFD matrix is used to record the calculated values indicating the importance of each product and process characteristic. The absolute importance of each characteristic is calculated as follows:

-

In the relationship room, a strong relationship (a filled circle) is assigned a numerical weight of 9, a medium relationship (empty circle) is assigned a numerical weight of 3, and a weak relationship (triangle) is assigned a numerical weight of 1.

-

The importance of each customer requirement (I through 5) is multiplied by the appropriate weighting factor (1, 3, or 9) in the relationship room (based on the strength of the relationship between the customer requirement and the key product and process characteristic of interest).

-

The results of steps I and 2 (for every customer requirement that has a relationship with the key product and process characteristic of interest) are then added.

The resulting levels of absolute importance do not reflect the risk levels for each key product and process characteristic. The "Risk-Weighted Importance" row corrects this. Risk-weighted importance is calculated by multiplying the absolute importance of each key product and process characteristic by its assigned risk level. The key product and process characteristics from Figure 2-1 are ranked according to risk-weighted importance in Table 2-4. The ranking based on absolute importance is also listed in Table 2-4.

TABLE 2-4 Key Product and Process Characteristics Ranked by Risk-Weighted Importance

|

Characteristic |

Risk-Weighted Importance Score |

Absolute Importance Ranking |

|

1. Affordability |

3006 |

2 |

|

2. Manufacturing and Producibility |

2745 |

6 |

|

3. Range |

2718 |

7 |

|

4. Airframe Service Life |

2601 |

9 |

|

5. Engine Emissions |

2565 |

10 |

|

6. Engine Service Life |

2529 |

12 |

|

7. APSE |

2466 |

13 |

|

8. Supersonic L/D |

1780 |

1 |

|

9. Cruise Speed |

1670 |

3 |

|

10. Community Noise |

1620 |

24 |

|

11. MTOW |

1600 |

4 |

|

12. Structural Weight Fractiona |

1565 |

5 |

|

13. Engine Reliability |

1330 |

15 |

|

14. Thrust/Weight Ratio |

1285 |

16 |

|

15. Multi-Loop Stability Robustness |

1265 |

17 |

|

16. Handling Qualities |

1200 |

18 |

|

17. Fuel Efficiency |

1055 |

20 |

|

18. Flight Deck System Software Development Cost |

1050 |

21 |

|

19. Traffic Avoidance |

930 |

25 |

|

20. Payload |

906 |

8 |

|

21. Certification |

852 |

11 |

|

22. Utilization |

822 |

14 |

|

23. High Lift L/D |

678 |

19 |

|

24. Subsonic L/D |

597 |

22 |

|

25. Flight Deck System Weight Savings |

588 |

23 |

|

26. Fan Containment Weight |

184 |

26 |

|

a Structural weight fraction is the ratio of the weight of the airframe structure to the total weight of the aircraft (MTOW). |

||

Results of the QFD Assessment

The scores in Table 2-4 indicate that risk-weighted importance divides key product and process characteristics into three groups of about the same size. In the most important group, affordability stands alone as the single most important characteristic. As shown in the "roof" of the QFD matrix, affordability is related to most other key product and process characteristics. Thus, even though some characteristics, such as certification and utilization, individually have low risk-weighted importance, their cumulative impact is reflected in the high importance of affordability. In the least important group, fan containment weight takes a distant last place in both absolute and risk-weighted importance.

Much of the information used to complete a QFD matrix is subjective, especially where there is little or no objective data available. For example, the committee

did not have the resources to conduct surveys of customer requirements. Nevertheless, the committee believes the results are generally valid and support the findings and recommendations that appear elsewhere in this report. Even so, the importance rankings should not be considered entirely objective.

In many cases, the results of the committee's QFD analysis are driven by the values assigned by the HSR Program to the top-level aircraft performance requirements: cruise speed of Mach 2.4, range of 5,000 n.m., and payload of 300 passengers. For example, a cruise speed of Mach 2.4 mandates the use of unproven materials for the airframe structure. With a lower cruise speed, using less risky materials would probably remove airframe service life from the most important group in Table 2-4.

A more sophisticated QFD analysis could be used to provide additional insights into product and process relationships. For example, a two-stage approach could be used. One QFD matrix could examine the relationship between (1) customer requirements and (2) propulsion and airframe design requirements. A second QFD matrix could use propulsion and airframe requirements as customer requirements and relate them to integrated aircraft design requirements (range, payload, MTOW, affordability, etc.). This two-stage analysis could provide a more accurate assessment of key product and process characteristics for the integrated aircraft.

Recommendation 2-5. The HSR Program's Integrated Planning Team should use the HSR/HSCT QFD planning matrix in Figure 2-1 to examine the complex interdisciplinary nature of the HSR Program and the trade-offs that may be required among design requirements.

Recommendation 2-6. The HSR Program should ensure that current and future efforts are properly focused on the most important, highest risk areas. The single most critical design requirement is affordability, and the HSR Program should adopt an affordability metric—such as average yield per available seat mile—that is more comprehensive than MTOW. The other areas of greatest importance, many of which are closely linked to affordability, are as follows:

-

airframe service life (durability)

-

dynamic interactions among the airframe, propulsion, and flight control systems (i.e., APSE effects)

-

engine emissions (ozone depletion)

-

engine service life

-

manufacturing and producibility

-

range

MARKET, TECHNOLOGY, AND FINANCIAL RISKS

Before making a product launch decision, industry must determine that the technological, market, and financial risks are acceptable. Technological risk is

the risk that efforts to develop new technologies will not yield anticipated results. A new technology may fail altogether, may not perform to specification, or may be too expensive to be profitable. Technological risk has traditionally been a relatively minor concern for commercial aircraft programs because they have drawn on proven military aircraft technologies. However, developing an HSCT will require many technological advances that have no parallel in military aircraft design. For example, there are no supersonic military transports; supersonic military aircraft do not have the long-range, supersonic cruise capability that will be essential for an HSCT.

Market risk is the risk that new aircraft will not sell as well as expected. The market success of an HSCT will depend upon its high productivity on relatively long, over-ocean flights. For a given seating capacity and utilization (flight hours per day), the supersonic speed of an HSCT produces higher productivity (passenger miles per day) than subsonic transports. The profitability of HSCTs will also depend upon the number of suitable routes, payload (seating capacity), fuel efficiency (at supersonic and subsonic speeds), acquisition costs, and operating costs. For example, the relatively low subsonic fuel efficiency and low seating capacity of the Concorde have contributed to its high cost per seat mile.

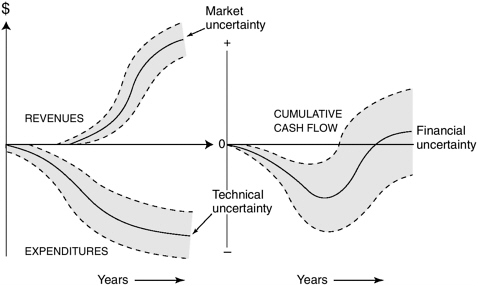

Financial risk is the risk of receiving an unsatisfactorily low return (or a loss) on investment. Both technological development and market trends will influence levels of return. Thus, financial risk captures the influence of both technological and market risk (see Figure 2-2). Because developing a new aircraft requires a large investment before sales generate any revenue, it can take 10 to 15 years to recover the initial investment, even for an aircraft that sells well (OTA, 1980).

FIGURE 2-2 Market, technology, and financial uncertainties. Source: OTA, 1980.

The HSR Program is focusing on research and development to overcome the technological challenges associated with a conceptual aircraft design (the TCA). Considerably higher costs are likely to result if industry decides to develop an operational HSCT. Industry would need to include full-scale manufacturing processes and the associated capital equipment costs. However, as illustrated in the roof of the HSR/HSCT QFD product planning matrix (Figure 2-1), there are strong negative (adverse) correlations between many of the propulsion and airframe product technologies and the integrated aircraft process technologies, such as manufacturing/producibility and certification. The resulting technological risk, together with market risk, make it quite unlikely that HSCT airframe and engine manufacturers will make a product launch decision in 2006, based on the deliverables the HSR Program plans to make available before the program terminates in 2002.

Finding 2-8. The strong negative (adverse) relationships among high-priority design requirements and the risks associated with these requirements (especially with regard to affordability) support the committee's recommendation for a substantial effort beyond the current Phase II.6

REFERENCES

Condit, P. 1996. 1996 Wright Brothers Lecture in Aeronautics. Presented to the American Institute of Aeronautics and Astronautics World Aviation Congress, Los Angeles, California, October 21–24, 1996.

Dieter, G.E. 1991. Engineering Design: A Materials and Processing Approach. New York: McGraw-Hill.

MacKinnon, M. 1996. HSCT Market Projections. Briefing presented to the Committee on High Speed Research, at the National Research Council, Washington, D.C., September 30, 1996.

MacKinnon, M., and B. Bunin. 1996. High Speed Civil Transport, Airframe Scale-Up and Manufacturability. Briefing presented to the Committee on High Speed Research, at the National Research Council, Washington, D.C., September 30, 1996.

Mavris, D.N., O. Bandte, and D.P. Schrage. 1996. Effect of Mission Requirements on the Economic Robustness of an HSCT Concept. Presented at the 18th Annual Conference of the Proceedings of the International Society of Parametric Analysts, Applications and Modeling Track, June 1996, Cannes, France.

MDA (McDonnell Douglas Aerospace). 1995. HSCT Economic and Operational Viability Assessment, September 29, 1995. Los Angeles, California: McDonnell Douglas Aerospace.

Metwally, M.1996. Personal communication from Munir Metwally, marketing manager, McDonnell Douglas Corporation, to Alan Angleman, September 26, 1996.

Mizuno, H., T. Ugai, S. Maekawa, and T. Takasin. 1991. Feasibility Study on Second Generation SST, AIAA Paper 91-3104. Presented at the American Institute of Aeronautics and Astronautics Aircraft Design Systems and Operations Meeting, September 23–25, 1991, Baltimore, Maryland. Available from: AIAA. Reston, Virginia.

OTA (Office of Technology Assessment). 1982, Impact of Advanced Air Transport Technology. Part 4, Financing and Program Alternatives for Advanced High-Speed Aircraft, Background Paper. Washington, D.C.:U.S. Government Printing Office.

Takasu, T., S. Maekawa, T. Ugai, and H. Mizuno. 1996. Preliminary Sizing of a Supersonic Commercial Transport Between Mach 2.0 and 2.4, AIAA Paper 96-5589. Presented at the American Institute of Aeronautics and Astronautics World Aviation Congress, October 21–24. 1996. Los Angeles, California. Available from: AIAA. Reston, Virginia.