2

Treatment Options for Aluminum Spent Nuclear Fuel

This chapter focuses on the first charge in the statement of task, ''an examination of the set of technologies chosen by the Department of Energy (DOE) and identification of other alternatives that DOE might consider" for treating aluminum spent fuel.1 To address this charge, this chapter provides a review of the options for treating aluminum spent fuel that were identified by DOE, as well as the methodologies used by DOE to rank these options and identify primary and backup technologies.

The main sources of information used in this assessment are the presentations received from DOE and contractor staff at the two information-gathering meetings (see Chapter 1 and Appendix B) and the following reports provided by DOE and Westinghouse Savannah River staff:

- Technical Strategy for the Treatment, Packaging, and Disposal of Aluminum-Based Spent Nuclear Fuel (Task Team, 1996), and

- Alternative Aluminum Spent Nuclear Fuel Treatment Technology Development Status Report (WSRC, 1997a).

The first part of this chapter provides a brief review of treatment alternatives and the methodologies used by DOE to select the primary and backup treatment options. The second part of the chapter provides an analysis of this work in response to the first charge of the statement of task.

|

1 |

As noted in Chapter 1, the term "aluminum spent fuel" refers to aluminum-clad or aluminum-matrix spent nuclear fuel from foreign and domestic research reactors, the subject of this report. |

Background

In 1995, the Office of Spent Fuel Management of DOE established a team of experts (the Research Reactor Spent Nuclear Fuel Task Team, hereafter referred to simply as the "Task Team") to help develop a technical strategy for treatment of aluminum spent fuel to put it into "road ready" form for disposal at a repository. The Task Team comprised ten core staff and seven technical support staff drawn from the DOE complex and associated organizations. These core and support staff had expertise in spent fuel behavior and treatment, fuel handling, nuclear criticality, regulation and licensing, waste-package design, and repository requirements.

The Task Team was asked to evaluate alternative treatment and packaging technologies that could be used in the place of conventional reprocessing2 to interim store and ultimately dispose of aluminum spent fuel in a safe and cost-effective manner (Task Team, 1996, p. 2). The team produced a report that evaluated various treatment technologies and recommended a strategy for selecting, developing, and implementing3 one or more treatment options by the year 2000. The Task Team report was an important input to the current study, and the chair of the Task Team, Mr. Jack DeVine of Polestar Applied Technology, Inc., provided a presentation of the Task Team's work at the second information-gathering session for this study.

As noted above, the focus of the Task Team's work was on technologies for treating aluminum spent fuel that could be used in the place of conventional reprocessing. Savannah River currently has two reprocessing facilities in operation (the F and H Canyons; see Figure 2.1)

|

2 |

Conventional reprocessing involves the dissolution of aluminum spent fuel in acid followed by the chemical recovery of uranium. The remaining liquid waste stream, which contains plutonium (if present in the spent fuel) and fission products, is stabilized by forming it into glass in a process known as vitrification. |

|

3 |

As noted in Chapter 1, DOE now defines implementation as "an authorized project underway (i.e., detailed design begun)" (WSRC, 1998). |

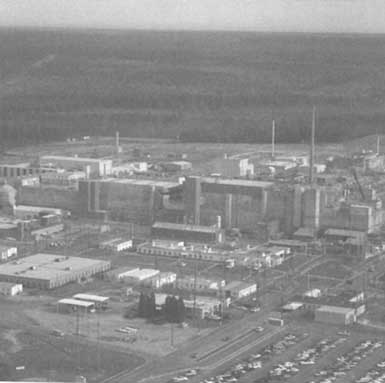

Figure 2.1

Oblique aerial view of the F Canyon chemical separations plant at Savannah River where spent fuel is separated into its constituent components, including uranium, fission products, and, if desired, plutonium. SOURCE: Savannah River Laboratory.

and a facility for making high-level waste glass (the Defense Waste Processing Facility, or DWPF) that are being used to reprocess fuel and targets from the production reactors at Savannah River. In principle, the Canyons also could be used to process the inventory of aluminum spent fuel from research reactors, which is small in comparison to the inventory of aluminum spent fuel from production reactors. In fact, some aluminum

spent fuel from research reactors has been (or will be) processed in the Canyons because it was either degraded, declad, or perceived to represent a higher risk than other parts of the inventory. The Task Team identified approximately 35 MTHM of fuel4 that potentially could be reprocessed for these reasons (Task Team, 1996, Table 5.2-1). This material includes damaged, failed, and sectioned fuels, particulate target materials, and depleted uranium blanket fuels.

The need to develop alternative treatment technologies for aluminum spent fuel was necessitated by DOE's policy to phase out reprocessing. The policy to phase-out reprocessing at DOE sites was announced by the Secretary of Energy in February 1992 (DOE, 1992a), based on recommendations from the Highly Enriched Uranium Task Force.5 The phase out of the reprocessing Canyons at Savannah River is now scheduled to occur at about 2002. Prior to phase out, those materials identified as "at risk," including some aluminum spent fuel from research reactors, will be reprocessed in the Canyons (Figure 2.2).

In addition, DOE is currently undertaking a review of the proliferation risks associated with the disposal of foreign research reactor fuel6 and is expected to issue a report in the second quarter of fiscal year

Figure 2.2

At-risk materials include spent fuel with damaged or degraded cladding as shown here, for example, by the corrosion pits on the cladding of a Materials and Test Reactor fuel element. The pits are about 1 cm in diameter. SOURCE: Savannah River Laboratory.

1998 (WSRC, 1998; see Chapter 5). According to Savannah River staff, this study also may address reprocessing of domestic research reactor fuel. Because the receipt of aluminum spent fuel currently is scheduled to continue for several decades beyond the scheduled operation of the Canyons at Savannah River, non-reprocessing treatment options for this spent fuel will have to be planned unless the present schedules are revised.

Treatment Technologies For Aluminum Spent Fuel

The Task Team evaluated 11 treatment technologies for aluminum spent fuel identified in the foreign research reactor spent fuel environmental impact statement (EIS; DOE, 1996c) and the DOE spent fuel technology integration plan (DOE, 1996b).7 The treatment technologies evaluated by the Task Team fell into one of three categories:

- Direct Disposal Technologies. These involve no processing of the spent fuel except for drying.8 After the fuel is dried, it would be placed in a disposable canister and stored until it could be shipped to a repository.

- Highly Enriched Uranium (HEU) Dilution Technologies. In these, the fuel is physically or chemically diluted with depleted uranium to reduce the concentration of uranium-235 (235U) to 20 percent or less by mass. Both criticality and proliferation risks are perceived by many to be lower for low-enriched uranium (LEU) than for HEU.

- Advanced Treatment Technologies. Here, the fuel is processed to produce other waste forms for repository disposal than is possible for either the direct disposal or the HEU dilution technologies and to reduce the volume of waste for disposal.

A brief review of the technologies considered by the Task Team is given below. Readers interested in obtaining more detailed descriptions should consult the Task Team report (Task Team, 1996).

Direct Disposal Technologies

Two treatment options were considered by the Task Team, direct disposal treatment9 and direct co-disposal treatment. A third treatment option, can-in-canister treatment, was eliminated during an initial screening step.10

Direct Disposal Treatment. The fuel assemblies are trimmed to remove nonfuel components (e.g., end fittings and grappling fixtures), dried, and loaded into canisters to meet the 235U mass limits imposed by transportation or repository criticality requirements (each canister could contain several fuel assemblies). Neutron poison inserts (e.g., borated steel) are added to the canisters as needed to reduce the criticality hazard or to allow increased fuel loading. According to the Task Team, approximately 1,100 canisters would be required to dispose of all of the aluminum spent fuel to be sent to the repository.

Direct Co-Disposal Treatment. The fuel assemblies are cropped as required, dried, and loaded into canisters that will fit into the center spaces of repository waste packages containing high-level waste glass logs produced in the DWPF. A conceptual design for the repository waste package is shown in Figure 2.3. The Task Team estimated that approximately 1,400 canisters would be required to dispose of all of the aluminum spent fuel to be sent to the repository.

Figure 2.3

Schematic illustration of a co-disposal package. The disposable canister that contains the aluminum spent fuel is packaged in a double barrier, corrosion-resistant container with five high-level waste glass logs. NOTE: HLW = high level waste; SNF = spent nuclear fuel.

SOURCE: Task Team (1996) Figure 1.3-1.

HEU Dilution Technologies

The Task Team also considered two dilution technologies: press and dilute treatment and melt and dilute treatment. A third option, chop and dilute treatment, was eliminated during an initial screening step.11

These treatment technologies have three major advantages over the direct disposal technologies: (1) the volume of waste and, hence, the number of waste packages are reduced, and (2) the perceived criticality potential may be lowered; and (3) the proliferation or security risk may be lowered.

Press and Dilute Treatment. The dried and sized aluminum spent fuel assemblies are physically pressed into sandwiches along with sheets of depleted uranium to produce dimensionally uniform packages with composite 235U enrichments of 20 percent or less by mass.12 Neutron poisons would be added if necessary to further reduce the criticality potential of the fuel. The sandwiches would then be loaded into canisters that will fit into the center space of a repository waste package containing high-level waste glass logs produced in the DWPF (e.g., Figure 2.3) in the same manner as proposed for direct co-disposal treatment. At a 20 percent composite 235U enrichment, about 400 canisters would be required to dispose of all of the aluminum spent fuel to be sent to the repository.

Melt and Dilute Treatment. The aluminum spent fuel is combined with depleted uranium and melted in a crucible to produce an alloy that has a 235U enrichment of 20 percent or less by mass. The material is solidified in a mold (the mold may be the crucible itself) and is loaded into canisters for co-disposal with the glass logs produced in the DWPF (e.g., Figure 2.3). At a 20 percent composite 235U enrichment, about 400 canisters would be required to dispose of all of the aluminum spent fuel to be sent to the repository.

|

|

consideration because the other dilution treatment options were similar in design and were deemed to be superior. |

Advanced Treatment Technologies

Five advanced treatment options were considered by the Task Team: (1) plasma arc treatment, glass material oxidation and dissolution treatment, dissolve and vitrify treatment, electrometallurgical treatment, and processing and co-disposal treatment. A sixth treatment option, chloride volatility treatment, was eliminated from further consideration during an initial screening step.13

Plasma Arc Treatment. For this treatment concept, spent fuel is combined with depleted uranium and melted in a plasma arc furnace at high temperature to produce a vitreous ceramic with a uranium enrichment of 20 percent or less by mass. The Task Team estimated that at a 20 percent composite 235U enrichment, about 400 canisters would be required to dispose of all of the aluminum spent fuel to be sent to the repository. These canisters could be co-disposed with the glass logs produced in the DWPF. This option is similar to melt and dilute treatment except that the melting takes places at a higher temperature, which allows the fuel to be oxidized to produce a ceramic waste form. The Task Team assumed that a borosilicate glass waste form also could be produced from the plasma arc waste products through a multi-step process, with the later steps occurring at more modest temperatures.

Glass Material Oxidation and Dissolution Treatment. The fuel is placed into a melter with depleted uranium, lead oxide is added to oxidize the metals, and a frit (essentially a powdered borosilicate glass) is added to make glass with a 235U enrichment of 20 percent or less by mass. The lead is recovered from the melt and reused. The Task Team estimated that

about 800 glass logs would be produced to dispose of all of the aluminum spent fuel to be sent to the repository. These logs would be co-disposed with the glass logs produced in the DWPF.

Dissolve and Vitrify Treatment. The fuel is dissolved in acid with enough depleted uranium to reduce the 235U concentration to 20 percent or less by mass. The solution is transferred to a vitrification plant where it is combined with frit to produce glass logs. The Task Team estimated that about 800 DWPF-size glass logs14 would be produced to dispose of all of the aluminum spent fuel to be sent to the repository. The logs would be co-disposed with the glass logs produced in the DWPF.

Electrometallurgical Treatment. The aluminum spent fuel is melted to produce a metal ingot. The ingot is then placed in an electrorefiner, and the aluminum, uranium, and fission products are separated. The fission products are oxidized and dissolved in glass to produce about 90 DWPF-size glass logs. The recovered uranium is remelted and combined with depleted uranium to produce an ingot with a 235U enrichment of 20 percent or less by mass, which could be used to make commercial fuel.15

Processing and Co-Disposal Treatment.16 The Task Team referred to this option as a ''reference technology" because the reprocessing component of this option has well-known cost and

performance characteristics and therefore could be used as a baseline against which the other options could be compared. The Task Team assumed that a portion of the aluminum spent fuel would be reprocessed in the Savannah River Canyons to recover the uranium, which subsequently would be diluted with depleted uranium to obtain a 235U enrichment of 20 percent or less by mass and sold for commercial purposes. The remaining liquid waste, which contains small amounts of plutonium and the fission products, would be fed into the DWPF to produce about 120 glass logs, which would be co-disposed in the repository. The portion of the spent fuel not treated by reprocessing (i.e., the portion of fuel received at Savannah River after the Canyons are shut down) would be subject to other treatments.

Evaluating the Treatment Alternatives

The Task Team used a combination of qualitative and quantitative methodologies to screen and rank the alternative treatment options. The objective of this exercise was to eliminate from further consideration those options that were less likely to be implemented successfully because of technical, cost, or scheduling difficulties. The Task Team used four ranking criteria based on the following requirements:

- The foreign research reactor spent fuel EIS (DOE, 1996c) establishes a target date of 2000 for implementation of an alternative technology for aluminum spent fuel. Thus, the treatment option must have a fair chance of being implemented by the year 2000.17

- The treatment technology must produce a waste form that is acceptable for disposal in a repository. Thus, the waste form must

- conform to waste acceptance criteria being developed for Yucca Mountain (see Chapter 3).

- The treatment technology must meet existing health, safety, and environmental requirements.

- The cost of developing the alternative technology must fit within expected DOE budgets. The Task Team determined that no more than about $500 million would be available for development over a five-year period.

The four ranking criteria used by the Task Team are (1) confidence in success, (2) cost, (3) technical suitability, and (4) timeliness. A brief description of these criteria is given in Table 2.1. The Task Team assigned a weighting factor to each of these screening criteria as shown in Table 2.1. A composite score for each treatment alternative was calculated by multiplying each weighting factor by a scaling factor between 1 and 10, which was assigned by expert judgment, and then summing the results. The results of the rankings are shown in Table 2.2. The overall scores ranged from 74 for direct co-disposal treatment to 23 for plasma arc treatment. The three most highly ranked alternatives were direct co-disposal treatment, melt and dilute treatment, and press and dilute treatment. No score was calculated by the Task Team for processing and co-disposal treatment, because, as noted previously, the team was directed to consider alternatives to conventional reprocessing.

The Task Team performed a simple sensitivity analysis to determine whether the relative rankings would change if any of the ranking criteria were eliminated from the analysis. To this end, the Task Team recalculated the rankings after removing from the analysis, one at a time, each of the four evaluation criteria shown in Table 2.1. The results of this analysis are shown in Table 2.3. The Task Team observed that the rankings did not change significantly by removing any one of the criteria, suggesting that the overall results were not dominated by any single assumption, criterion, or evaluation.

Table 2.1 Screening Criteria and Weighting Factors Used by the Task Team to Evaluate Treatment Options

|

Evaluation Category |

Screening Criteria |

Weighting Factor |

Scaling Factor |

|

Confidence in success—evaluators' confidence that the technology can meet technical performance requirements at predictable cost and schedule |

Technology development must be reasonably complete by 2000 |

30 |

1-10 scale reflecting evaluators' judgment of the likelihood of success for each candidate treatment option, a higher likelihood of success yields a higher score |

|

Cost—projected total implementation costs |

Costs must be less than $500 million for the first 5 years |

30 |

1-10 scale; higher-cost options receive lower scores |

|

Technical suitability—technical merits of each technology |

Final waste form must meet 20 anticipated repository waste acceptance criteria, and technology must meet environmental, health, and safety requirements |

20 |

1-10 scale reflecting evaluators' judgment, a higher suitability yields a higher score |

|

Timeliness-projected time to implement technology |

|

20 |

1-10 scale, with the highest score(10) assigned to any technology projected to be in place and operating by 2001 |

|

SOURCE: Task Team (1996), Table 4.4-1. |

|||

TABLE 2.2 Results of the Task Team Evaluation of Treatment Options for Aluminum Spent Fuel

|

|

|||||

|

|

Confidence in Success (30%) |

Cost (30%) |

Technical Suitability (20%) |

Timeliness (20%) |

Overall Scoreb |

|

Treatment Option |

|||||

|

Direct co-disposal |

6 |

10 |

5 |

8 |

74 |

|

Melt and dilute |

6 |

8 |

7 |

6 |

66 |

|

Press and dilute (20%)c |

6 |

7 |

7 |

6 |

63 |

|

Press and dilute (2%)d |

7 |

5 |

6 |

6 |

62 |

|

Direct disposal |

5 |

7 |

4 |

8 |

60 |

|

Electrometallurgical |

3 |

5 |

8 |

3 |

46 |

|

Dissolve and vitrify |

4 |

1 |

7 |

1 |

31 |

|

GMODSe |

1 |

2 |

7 |

1 |

25 |

|

Plasma arc |

1 |

2 |

6 |

1 |

23 |

|

a The scaling factors range from 1 to 10 for each criterion, where 1 is least suitable and 10 is most suitable. b The overall score was calculated by multiplying each of the scaling factors by the weights shown in Table 2.1, summing the results, and multiplying by 100. The range of possible scores is 10 to 100, where 100 is the most suitable treatment option of those considered. Although the score is quantitative, it is based on qualitative evaluations by the Task Team. c Dilution to 20% 235U by mass. d Dilution to 2% 235U by mass. e Glass material oxidation and dissolution. SOURCE: Task Team (1996), Table 4.4-2. |

|||||

Task Team Recommendations

The Task Team noted that although all of the technologies it considered were potentially capable of converting aluminum spent fuel into an acceptable waste form for disposal, no single technology appeared to be optimal for all fuel types or sufficiently mature to be relied on to the exclusion of others.18 Therefore, the Task Team recommended that DOE continue to examine and develop several treatment options to maintain flexibility and increase the overall likelihood of success.

The Task Team recommended direct co-disposal treatment as the primary treatment option, with melt and dilute treatment as a "parallel" option. The task team noted that direct co-disposal treatment "is the simplest of the technology options evaluated, and seems technically achievable in all respects, at moderate cost and on a timetable consistent with DOE's needs" (Task Team, 1996, p. 68). However, the Task Team recognized that the acceptability of HEU in the repository was a major uncertainty for the success of direct co-disposal treatment, and noted that the waste form produced by melt and dilute treatment was potentially more acceptable and probably more easily licensed.

The Task Team also recommended electrometallurgical treatment, which was the highest-scoring advanced treatment technology (Table 2.2), as a backup option, because the technology is fundamentally different from the others and thus offers some protection against unforeseen technical or licensing problems. The Task Team also noted that the borosilicate glass waste form, the product of this treatment option, is "very robust and highly likely to meet the regulatory requirements . . ." (Task Team, 1996, p. 68).

Finally, the Task Team recommended that DOE focus its development funds on direct co-disposal treatment and melt and dilute

TABLE 2.3 Results of Sensitivity Study to Determine Significance of Various Evaluation Criteria in Table 2.1

|

|

Sensitivity Case Rankingsa |

||||

|

Technology |

Base |

Case 1 |

Case 2 |

Case 3 |

Case 4 |

|

Direct disposal |

5 |

3 |

5 |

3 |

|

|

Direct co-disposal |

1 |

1 |

2 |

1 |

1 |

|

Press and dilute (20%) |

3 |

3 |

3 |

4 |

3 |

|

Press and dilute (2%) |

4 |

5 |

1 |

5 |

4 |

|

Melt and dilute |

2 |

2 |

3 |

2 |

2 |

|

Plasma arc |

9 |

8 |

9 |

8 |

9 |

|

GMODSb |

8 |

7 |

8 |

8 |

8 |

|

Dissolve and vitrify |

7 |

9 |

7 |

7 |

7 |

|

Electrometallurgical |

6 |

6 |

6 |

6 |

6 |

|

a Rankings range from 1 to 9, with a lower number indicating a higher ranking. b Glass material oxidation and dissolution. NOTE: Base case: Rankings with all screening criteria (Table 2.1) included; Case 1 = confidence in success excluded; Case 2 = cost excluded; Case 3 = technical suitability excluded; Case 4 = timeliness excluded. SOURCE: DOE Task Team (1996) Table 4.4-3. |

|||||

treatment, and that it follow the work being done elsewhere (at Argonne National Laboratory) on electrometallurgical treatment.

Response to First Charge in Statement of Task

The first charge of the statement of task involves an examination of the set of technologies chosen by DOE for treatment of aluminum spent fuel and to the identification of other alternatives that DOE might

consider. As noted previously in this chapter, the Task Team selected direct co-disposal treatment and melt and dilute treatment as the primary treatment options and electrometallurgical treatment as the backup treatment option. Most of the comments in this section are addressed to these alternatives, but the chapter will conclude with comments on other treatment options that DOE should consider.

The first charge is addressed through a discussion in this section of the following four questions:

- Were a reasonably complete set of treatment alternatives identified by DOE?

- Was the methodology used to screen and rank the treatment alternatives technically sound, and did it lead to the selection of appropriate primary and backup treatment options?

- Are the primary and backup treatment options likely to work as described and produce acceptable waste forms?

- What other treatment options should DOE consider?

-

Several of the consultants provided comments that were helpful in responding to these questions, most notably Joseph Byrd, Robert Dillon, Harry Harmon, and Paul Shewmon. Their reports are provided in Appendix D.

The answer to the first question—were a reasonably complete set of treatment options identified?—is a qualified "yes." The Task Team used a somewhat ad hoc approach to identify the set of alternative treatment options in that it relied on the knowledge of Task Team members, two DOE documents (DOE, 1996b, c), and a solicitation to DOE laboratories to identify alternative treatment options. There was no effort made to perform a systematic search for treatment technologies in use in other countries or industries that might be applied to aluminum spent fuel. Nevertheless, the Task Team appears to have succeeded in identifying a reasonably complete set of alternatives, and neither the Principal Investigator (P.I.) nor the consultants invited to the second

information-gathering meeting were able to identify other treatment options that should have been considered by the Task Team. Additionally, a query by the P.I. to International Atomic Energy Agency staff did not uncover any other known treatment options.

The affirmative answer to this question is qualified for two reasons. First, the Task Team may incorrectly have eliminated chloride volatility treatment during the initial screening stage. The reason given for eliminating this treatment option that "no experimental work has been completed" (Task Team, 1996, p. 32). In fact, considerable experimental work on chloride volatility was completed between 1950 and 1965 at Argonne National Laboratory (e.g., Jonke, 1965). Although the primary fuel investigated was zirconium based, there were pilot-scale runs on aluminum fuel assemblies and some experimental runs on irradiated fuel. The P.I. did not attempt to determine whether this treatment option would have ranked above the other advanced treatment alternatives had it been evaluated further by the Task Team, but the reason for eliminating it seems to have been based on a lack of awareness of the earlier work.

Second, the Task Team did not consider options for treating the depleted uranium spent fuel, which comprises about 40 percent of the inventory of aluminum spent fuel expected to be received at Savannah River. 19 As noted earlier in this chapter, the Task Team identified this fuel as a candidate for reprocessing because the fuel is declad and is comprised of uranium metal that may not be suitable for disposal in the repository. If reprocessing is not possible for policy reasons (see Chapter 5), then there is no obvious treatment and disposition pathway for this fuel.

The answer to the second question—was the methodology used to screen and rank the treatment alternatives technically sound and did it lead to the selection of appropriate primary and backup treatment options?—also is a qualified "yes." The Task Team developed sufficient

technical information and understanding about the treatment alternatives to make reasonable assessments and comparisons of likely performance. Information did not exist, however, to enable the Task Team to determine whether some of the advanced treatment options such as glass material oxidation and dissolution treatment and plasma arc treatment could be made to work in remote handling environments, but this uncertainty appears to have been at least partially reflected in the lower scores and rankings (Table 2.2) for these options.

The Task Team appears to have developed the technical requirements for the alternative options in general terms, but neither the team nor other parts of DOE have developed a complete set of process requirements that would allow an adequate assessment of the options to be made. The most significant set of incomplete process requirements involves repository waste acceptance criteria, which are discussed in more detail in Chapter 3. Most significantly, the acceptability of HEU for disposal in the repository is uncertain, primarily because of criticality and proliferation concerns. If this fuel is not acceptable for disposal, then direct co-disposal treatment should not be selected. The responsibility for establishing repository requirements lies with DOE's Office of Civilian Radioactive Waste Management, not with DOE-Savannah River, and this divided responsibility makes it very difficult to develop an efficient and cost-effective program. Nevertheless, until such requirements are known, implementation of appropriate treatment alternatives cannot proceed without significant financial and schedule risks.

The technical approach used by the Task Team to evaluate and rank the alternative treatment options was appropriate, given their degree of technical maturity and the amount and quality of available data, and the ranking methodology was adequate for screening purposes. The Task Team was consistent in its application of the ranking methodology to the various treatment options, although the various treatment alternatives were at different stages of maturity (e.g., the direct co-disposal treatment technology is more mature than the plasma arc treatment technology) and

therefore had different amounts of information available on which to base screening assessments.

Although the Task Team used a quantitative methodology to rank treatment options, the methodology relied to a very great extent on expert judgment of the Task Team members in assigning scaling factors to each of the four evaluation criteria (Table 2.1). Thus, the results are only as good as the judgments being made, a fact noted by the Task Team in its report. Although the P.I. was not personally acquainted with all of the Task Team members before undertaking this project, he has reviewed their backgrounds and believes that team members have the appropriate mix of expertise and experience.

The output of the ranking methodology appears to be consistent with what one would expect. The technologies that scored most highly on the four evaluation criteria tended to be technically mature and relatively simple to implement. As a consequence, estimated development costs were lower for the primary treatment options, and the likelihood of timely implementation was correspondingly higher.

The third question posed above—are the primary and backup treatment options likely to work as described and produce acceptable waste forms?—has two parts: (1) Are the primary and backup treatment options likely to work as described? and (2) Are the primary and backup treatment options likely to produce acceptable waste forms? The answer to the second part of the question is deferred to the next chapter, and the P.I. will focus only on the first part in the following discussion.

Direct co-disposal treatment is technically simple and straightforward to implement. The technologies for drying the fuel, placing it in a container, and sealing the container are readily available and likely can be adapted to this application with little additional development work. Although the composition of the co-disposal container has not yet been determined by DOE, the briefings received at the second information-gathering meeting indicate that it probably will be an austenitic stainless steel. In an atmosphere of dried air at room temperature, the aluminum fuel will form a protective oxide layer, and

very little reaction of the waste form with the atmosphere or the stainless steel container for decades of interim storage would be expected.20

Melt and dilute treatment is more demanding technically than direct co-disposal treatment and will require a more significant infrastructure, including hot cell space, a melter, and an off-gas treatment system. The radioactive fuel must be melted at temperatures up to about 1000 °C, which will result in the release of gaseous fission products such as krypton and at least partial release of volatile elements such as cesium and iodine. These non-gaseous volatiles must be recovered by an offgas system and recycled into the waste stream or otherwise disposed of. To the P.I.'s knowledge, melt and dilute treatment has not been applied to any other type of spent nuclear fuel. However, all of the technologies needed to make this system function successfully have been used in other applications, and it should be a relatively straightforward exercise to bring them together for aluminum spent fuel treatment. For example, melting and casting technologies have been used for several decades to manufacture unirradiated aluminum fuel elements and irradiated uranium alloy fuel elements, and commercially available furnaces and ancillary processing equipment can be modified for remote operation. Similarly, offgas systems are in use in several other applications and have even been utilized successfully to capture fission products from the pyrometallurgical processing of the highly radioactive spent fuel from the Experimental Breeder Reactor (ANL, 1963; see Figure 2.4). Although such systems cannot be used directly for aluminum spent fuel treatment, they should be readily adaptable for treating aluminum spent fuel, much of which has been in storage for more than a decade and has lost to decay much of its gaseous radionuclide inventory.

Melt and dilute treatment is worth pursuing despite the additional development and infrastructure requirements because it allows more control over waste form composition and performance characteristics. For example, the waste form can be designed for criticality safety without the

|

20 |

See the report of consultant Paul Shewmon in Appendix D. |

use of neutron poisons. Additionally, this treatment option would reduce significantly the need for spent fuel characterization and the number of canisters to be interim stored and eventually shipped to the repository.21

There is not enough information at present about any of the advanced treatment technologies to select a backup option. In particular, not enough is known at present about electrometallurgical treatment, which was selected as the backup option by the Task Team, to determine whether it will work as described, and additional development work will have to be done to determine the feasibility of applying this treatment technology to aluminum spent fuel.22 The uranium removal process has been demonstrated successfully on uranium metal-based spent nuclear fuel, but the electrorefining step for removal of aluminum requires further development and testing. In addition, more work must be done to demonstrate that all of the waste streams from this process either can be recycled or will be acceptable for disposal in a repository. These questions are currently being addressed by staff at Argonne National Laboratory. If they are successful and the product uranium is almost free of fission products, the process could face the same proliferation concerns as conventional reprocessing.

The answer to the last question—are there other treatment options DOE should consider?—is ''yes." DOE should have given more careful

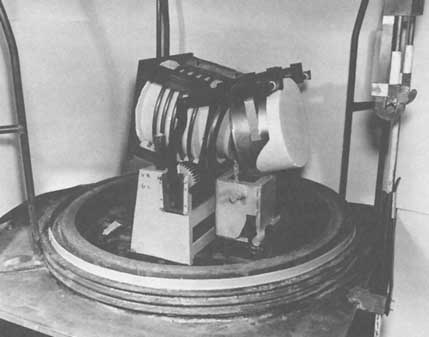

Figure 2.4 (A)

A view inside a hot cell at Argonne West showing two remotely operated furnaces for melting highly radioactive fuel. Each furnace (see Figure 2.4B) is covered by a bell jar offgas system (cylindrical metal can) that is lowered over the furnace during melting to capture the gaseous fission products. SOURCE: Argonne National Laboratory.

Figure 2.4 (B)

Closeup photo of one of the furnaces that demonstrates the process for casting a 10 kilogram ingot of highly radioactive fuel. The insulated crucible is heated by an induction coil shown here in the pouring position. The photo shows actual in-cell equipment but the pouring is simulated because of photographic problems with high radiation fields. After casting, the ingot was fabricated into fuel elements for return to the reactor. These furnaces were operated for five years in the mid-1960s as part of the pyrometallurgical fuel cycle used to recycle HEU fuel from the Experimental Breeder Reactor II. SOURCE: Argonne National Laboratory.

consideration to conventional reprocessing of aluminum spent fuel. 23,24 There appear to be several technical advantages to this option over the others considered by the Task Team. Conventional reprocessing has been demonstrated to work for aluminum spent fuel from production reactors, the costs and risks are well known, the necessary facilities (the Canyons and the DWPF) are currently in operation at Savannah River, and the waste form (borosilicate glass) is assumed to be acceptable for disposal in a repository.

As discussed in more detail in Chapter 5, conventional reprocessing of even a portion of the aluminum spent fuel could significantly reduce the overall costs of treating the total aluminum spent fuel inventory by alleviating the need for additional spent fuel storage space at Savannah River and eliminating the problems with odd-sized fuel elements that may be difficult to process by other methods. There is still some uncertainty about whether the Canyons will be available after 2002 for reprocessing, and future developments in DOE proliferation policy25 may preclude the use of the conventional reprocessing option except in some special cases (e.g., disposal of damaged spent fuel elements; see Chapter 5 for a fuller discussion of this issue).

It is recommended that DOE-Savannah River undertake a common-basis cost and performance comparison of the two primary treatment alternatives (direct co-disposal and melt and dilute treatment) and conventional reprocessing as part of its process for evaluating and selecting a treatment option.

|

23 |

These comments are directed at DOE generally and not to the Task Team, because the Task Team was specifically directed by DOE to look at alternatives to conventional reprocessing. |

|

24 |

See also the comments of consultant Harry Harmon in Appendix D. |

|

25 |

As noted previously, DOE is expected to release a study on the proliferation implications of conventional reprocessing of aluminum spent fuel from foreign research reactors in the second quarter of FY 98. |