Chairmen's Overview

ROBERT A. FROSCH AND MICHIYUKI UENOHARA

As traditional strategies of environmental protection reach the limits of effectiveness, new and complex challenges have emerged. This report on the March 1993 U.S.-Japan Workshop on Industrial Ecology responds to the need to seek new approaches for harnessing technology for economic and environmental benefit.

World population is larger than ever and continues to grow. The standard of living for many is better than ever. The quest to improve that standard while improving the lot of others continues. A growing economy necessary for development, however, will require more energy and materials. This in turn will result in wastes from production operations and consumer discards. As the economies of the world continue to grow, how can the environment be preserved, restored, and managed?

Today, after several decades of research and experience, we recognize that it is insufficient to treat the symptoms of dirty rivers, urban smog, hazardous waste sites, or litter, although these problems must be addressed. The larger problem is linked to the effects of global economic growth and population increase on the global environment. The rate and scale of these effects have brought new concerns—concerns about the rate of natural resource use and the ability of supporting biological, physical, and chemical systems to assimilate the materials and heat emitted from economic activities.

The June 1992 United Nations Conference on Environment and Development (UNCED) in Rio de Janeiro, Brazil, addressed these concerns in an agenda for national and global actions of great breadth and complexity based on the concept of sustainable development. The agenda focuses on preventing pollution, improving the quality of life, and finding ways to ensure that the needs and aspirations of future generations are not compromised by economic growth decisions made today. The strategies for preventing pollution include improving efficiency and productivity through frugal use of energy and materials, substituting environmentally detrimental materials with ones that are less so, as well as recycling and reusing products at the end of their lives. These steps are viewed as prudent and beneficial measures to take regardless of uncertainties about the environmental consequences of economic growth. The UNCED agenda moves to augment direct regulations with market-based mechanisms that tax pollutants or disposal practices. Its purpose is to provide industry with incentives to reduce or eliminate certain materials and to manage waste differently.

Global action is needed to shift from crisis management strategies to improving the economic and environmental efficiency of linked industrial and consumer activities. Under the UNCED agenda, waste is considered as “material out of place” and an indicator of inefficiencies undermining the profitability of companies and the competitiveness of nations. Environmental goals of nations are stated in terms of creating the incentives for actions to be taken upstream (or early) in manufacturing processes so that waste is not created in the first place. The rationale for such actions is that reducing waste not only protects the public but also increases efficiency. To move to an incentive structure, it is necessary to formulate policies that deal with the “three media ” (air, water, and land) comprehensively and to stop treating them separately for bureaucratic reasons.

Industrial ecology, the subject of the March workshop convened and hosted by the National Academy of Engineering, provides a systems approach to environmental issues. The workshop was not intended to reach a consensus among the participants or to formulate recommendations for public policy. Instead the workshop discussions yielded interesting insights and observations about industrial ecology as a framework for assessing the technological status and the immediate, short-, and long-range strategies being promoted to incorporate environmental factors in innovating technologies, formulating policies, and developing management strategies. This report, which builds on earlier efforts by the Academy, including Technology and Environment (Ausubel and Sladovich, 1989), Energy: Production, Consumption, and Consequences (Helm, 1990), and The Greening of Industrial Ecosystems (Allenby and Richards, 1994), contains summaries of workshop presentations and discussions. This chapter reflects the observations of the workshop cochairmen.

FROM AN INDUSTRIAL ECOLOGY PERSPECTIVE

Industrial ecology provides an integrated systems approach to managing the environmental effects of using energy, materials, and capital in industrial ecosystems. To optimize resource use (and to minimize waste flows back to the environment), managers need a better understanding of the metabolism (use and transformation) of materials and energy in industrial ecosystems, better information about potential waste sources and uses, and improved mechanisms (markets, incentives, and regulatory structures) that encourage systems optimization of materials and energy use.

In any system, boundary definitions are critical. Industrial ecology uses the biological ecosystem as an analogue. In this context, industrial activities, unit processes, and industries are considered as interacting systems instead of isolated components in the system. Industrial ecology systems, therefore, can be defined in many ways—by material flow (e.g., wood), by a specific product (e.g., corrugated cardboard), by industry sector (e.g. pulp and paper), or by a geographical area of human activity (e.g. timber-producing area). For example, the ecology of platinum-group metals can be characterized by tracking their flow through various fabrication and manufacturing processes, the products in which they are embedded, and their fates in recycling and disposal (Frosch and Gallopoulos, 1989). The ecology of simple articles (pencils) and complex products (airplanes) can be traced in two ways. The first is to track the flow of materials and energy used in making, using, recycling, and disposing of them. This is similar to characterizing their environmental life cycle. The second is to include the actors—raw material suppliers or component manufacturers; delivery, maintenance, and collection systems; waste handlers; recyclers; and consumers—involved in the complicated production and consumption activities. In the second, complex spatial and temporal webs of human production and consumption activities of individual materials can be traced through several different industrial ecosystems. A more accurate picture of a product's ecosystem emerges by linking materials, energy, and actors involved in each industrial ecosystem. Each industrial sector (and each company) may be characterized as playing a role in several industrial ecosystems. In turn each industrial sector (such as mining or agriculture) would also have its own ecology. Finally, the global network of industrial activities may be characterized as a single interrelated, complex industrial ecology web.

This systems approach leads to thinking about using different industries, plants, and processes that operate in concert as a network to minimize the total amount of industrial waste that needs to be disposed of or is lost in process. This builds on an old practice of certain industries that continues today. The chemical and steel scrap recycling industries provide examples of industrial systems and processes that have long used the waste of one process as feedstock for another. The use of cement kilns as sinks for waste from other industrial sectors is another way of reducing waste from an industrial ecology perspective. In both the United States and Japan waste materials burned in cement kilns provide a source of energy, and displace the need for fuel. In addition, some materials can replace raw materials used to make cement. The Japanese cement industry, for example, makes different types of cement by incorporating waste material from other industries (mining, oil refining, sugar manufacturing) and postconsumer discards (tires, wire covering, paint, oil, etc.) (Akimoto, Chapter 4). When waste output from one industry is used in another, the waste is used as a resource in the receiving industry. This effectively reduces the overall waste generated within an industrial ecosystem. If waste is not used in the cement kilns, for example, it may end up at a disposal site, adding to the waste load on the environment. As long as cement kilns and other heat recovery units operate within established environmental, health, and safety standards, they serve a vital role in minimizing waste.

There are several factors, however, that impede the creation of waste redistribution systems within industrial ecosystems. First, lack of information and communication about waste (such as what is available, where it may be used, and what is needed) can hinder development of

links that reroute waste to new uses. Second, markets for waste by-products are needed to provide the incentive for their recovery. Seventy-five percent of a typical automobile, by weight, is recycled in the absence of mandated recycling. The recycling is driven by markets for the recovered materials. Third, laws and regulations can inadvertently prevent optimization of material used in industrial ecosystems. For example, the legal classification of a waste as hazardous restricts what may be done with it, how it may be transported, and how it may be handled. Such restriction occurs even when the waste material is equivalent to an industrial or hazardous chemical that is sold on the open market.

Waste distribution is but one of several issues that need to be understood by regulators, industry, and the public. Intergenerational equity questions, the rising conflict between the changing environmental management structures and current legal structures, and the question of complex or conflicting environmental trade-offs are additional challenges to be faced in moving toward restructuring the industrial ecosystem (Allenby, Chapter 2).

INDUSTRIAL ECOSYSTEMS LINKED TO NATURAL ECOSYSTEMS

The global industrial ecosystem, the result of human economic activities, is a component of the more complex, finite, global natural ecosystem. The natural ecosystem serves as the source of materials and energy for global economic activities. It also serves as a sink for discards from the economy. As a sink it absorbs, assimilates, and transforms the waste from human activities. Only partial reduction of environmental loads on the natural ecosystem can be achieved by changing production and consumption practices to minimize waste. “Zero” waste goals will not be met overnight. Nor is it clear that such goals are thermodynamically feasible given dissipative loss of material and heat. In addition, waste reduction goals depend on changing consumer behavior. Environmental benefits can be gained by improving the efficiency of using material and energy in production and consumption activities, but efforts are also needed to restore and improve the assimilative capacity of the environment.

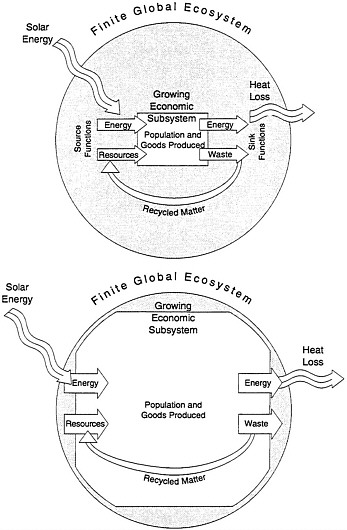

Figure 1 shows the effect of the growing global industrial ecosystem on the finite natural global ecosystem. A growing population will place greater demands on the environment. Industrial countries face the challenge of minimizing the environmental degradation to below sustainable levels. This will allow developing countries to advance and developed nations to maintain living standards in environmentally sustainable ways (Uenohara, Chapter 2).

FIGURE 1 The finite global ecosystem relative to the growing economic subsystem. SOURCE: Goodland (1991).

Broadly this means that renewable resources should not be extracted at rates greater than their regeneration rates. Nonrenewable resource use should not exceed the rate at which substitutes are developed and used. Emission rates of pollutants should not exceed the assimilative capacity of the environment.

With proper economic and social incentives in place, reserves of natural resources can be extended by advanced technologies that save energy and materials, and recycle and reuse products and materials. The current flow is from extraction to production, use, and disposal. Recycling and reuse can reverse this flow. Since industrial ecology is a component of the complex global natural system, industrial processes can control energy and materials flows within the economy. Industrial society must be highly efficient in using the environmental capacity it extracts from the Earth and must increase the Earth's environmental capacity as well (Akimoto, Chapter 2).

TECHNOLOGY IS CRITICAL

Technological advance can play a critical role in transforming industrial ecosystems. While technological advance is sometimes referred to as an evolution, human artifacts such as technology do not evolve. They are pushed in different directions by the decisions of inventor, manufacturers, marketers, and users, people who have economic, social, and cultural as well as practical reasons to remake technology in ways that serve them best. As environmental concerns grow, environmental considerations will increasingly be integrated into technological innovation.

If environmental impacts are to be minimized, it will be necessary to reduce environmental degradation associated with each unit of resource used. This can be achieved by harnessing technology to control, reduce, and prevent pollution, as well as to improve the efficiency and productivity of industrial systems. In the United States and Japan, technology has been critical to meeting the twin goals of economic growth and environmental improvement, as is illustrated in the energy sector.

With limited natural resources and high energy prices, Japan initiated in the early 1970s several R&D programs to identify, develop, and market energy-efficient technologies as well as technologies to substitute unlimited energy sources (such as coal and nuclear) for limited energy resources (such as oil). In the last 20 years, energy consumption in manufacturing has decreased while industrial production has stayed stable or has increased. The growth of the Japanese economy despite sharp energy constraints is attributed to the substitution of technology for energy (Watanabe, Chapter 3).

The practices of the Tokyo Electric Power Company (TEPCO), the largest of nine utilities in Japan, accounting for approximately one-third of the nation's electric power, illustrate the effects of Japan's technology substitution strategy. TEPCO reduced carbon dioxide (CO2) emissions by 18 percent in the last decade by improving thermal efficiencies and shifting from fossil fuels to nuclear power. Furthermore, TEPCO plans to use energy resources that do not generate CO2. As a result, TEPCO has no coal power plants; its power plants are driven by natural gas, oil, nuclear, or water power (Mitsui, Chapter 3). The shift to nuclear power, however, is being slowed by public opposition.

In the United States the electric industry is being restructured by market-driven technological innovations. The efficiency and cost advantages of large central stations are being challenged by technological advances of power cycles. Over the next few years, U.S. utilities plan to spend about 25 percent more on transmission and distribution upgrades than on new generating capacity. The substitution of electronic controls circumvents barriers inherent in traditional mechanical switching devices. This technical shift promises to change the structure of the industry and improve services that utilities can provide their customers (Yeager, Chapter 3).

Technological innovation has also fueled dramatic changes in the type and use of materials in the twentieth century. Advances in materials technology during this period have contributed to environmentally beneficial economic growth. New processing technologies, more sophisticated materials, and improved product design have resulted in more efficient use of materials. This trend suggests that economic growth need not be accompanied by increased resource use (Eyring, Chapter 4).

The application of new materials, however, does lead to complex environmental trade-offs. Superconducting materials offer the potential for greater efficiencies but are made of hazardous materials. Energy-efficient light bulbs use mercury, a toxic substance. The benefits resulting from newer technologies have to be balanced against the cost of potential environmental effects. The complexity of options facing society is likely to grow.

Advances in materials technology show how the substitution of new materials can replace bulkier material, improve efficiencies, and substitute for less environmentally preferable alternatives (Eyring, Chapter 4). Pollution control technology used in power plants, as well as the role of fuel switching (from coal to oil, natural gas, and nuclear power) to reduce carbon dioxide emissions, illustrates the use of technology to increase the assimilative capacity of the environment (Mitsui, Chapter 3). Technological advances can also change the nature of business, as is evident in the use of electronic switching to transmit and distribute electricity (Yeager, Chapter 3) or in Japan's use of advances in communications and computer technology to connect company operations directly to the customer (Uenohara, Chapter 6). In this futuristic scenario of the ecofactory, customers would specify product functions, including environmental considerations. These specifications would be negotiated with design and manufacturing teams. Environmental considerations could be integrated into the products and network needed for product stewardship. The linking of computers and communication technology also offers opportunities for management of materials within industrial ecosystems. In product design, materials would be selected to meet product function, manufacturability and environmental considerations. In addition, the new information technologies would allow products to be encoded with recycling information. Recyclers could locate their facilities near

the point of sale and could be informed of the materials used in the product. When the product is returned for recycling, the facility would have the information needed for effective recovery and redistribution of product parts. The potential use of existing and new technologies for environmental benefit is extensive.

INDUSTRY AND MATERIAL FLOW

As the primary producer of the goods and services that fuel the economy, industry is in a pivotal position to control the flow of materials and energy. In this position, industry plays a critical role as an agent of environmental improvement. Industry has traditionally responded to environmental demands by complying with regulations, controlling emissions from plants, and managing waste disposal. As society focuses on the environmental fate of obsolete products, the implications of product stewardship are growing in importance. Product recycling and reuse and life cycle approaches are emerging industry practices.

Flow rates of materials in the economy can be lowered by more efficient use. Materials in the economy are disposed of as waste, recycled, reused, or lost dissipatively. Waste disposal is increasingly regulated and recycling mandates are growing. In the United States, individual states and the federal government are turning to recycling to manage solid waste—bottles, newspapers, yard waste. Japan's Recycling Law (Yumoto, Chapter 6) goes further in promoting recycling of appliances and durable goods.

Recycling, however, has long been an integral part of several industries. Steel scrap recycling, for example, is as old as the industry itself. Similarly, in both the United States and Japan, approximately 75 percent by weight of a discarded car is recycled through well-developed infrastructures (Labana, Marumo, Chapter 6). Markets for the recovered parts and materials have been instrumental in developing these recycling loops and will be critical as newer recycling mandates prompt companies to design their products for recyclability.

Canon, for example, has initiated a recycling program for its electrophotographic cartridges as part of the company's global operation and in response to the growing recycling demand. To do this the firm is tailoring recycling infrastructures around the globe to support its efforts (Maki, Chapter 6). This formidable task has included developing programs to encourage user participation, initiating and implementing cartridge collection programs, building recycling facilities, and developing appropriate recycling processes. The first trial program was initiated in May 1991. To date, the program is unprofitable, but the process of creating a recycling infrastructure from scratch has been an invaluable learning experience that Canon believes will be profitable as markets emerge for the recycled parts and material.

As companies take greater responsibilities for their products, environmental life cycle assessment (LCA) is emerging as a method of measuring all possible sources of environmental impacts associated with a product or process. The environmental impacts of a product throughout its life cycle result from direct emissions from a plant as well as “indirect” pollution generated in all activities associated with transporting, using, recycling, and disposing of a product (Denison, Chapter 5). By means of LCA it is theoretically possible to identify all indirect environmental impacts. To do so practically, however, requires a huge data collection effort and extensive analysis. Because the importance and severity of environmental concerns depend on factors that vary geographically and change over time, the results of LCA analysis usually cannot be generalized. Furthermore, LCA results differ widely depending on the analysts carrying out the study, the assumptions made, and the resources devoted to the effort. This is not unique. Many analytical methodologies are difficult, and empirical methods involve tailoring analysis to available data for practical application.

Despite serious questions about the results and implications of LCA analysis, the life cycle approach (as opposed to assessment) offers promising opportunities in product development. Design for Environment (DFE)— a structured technical method using a hierarchy of preferable environmental actions—is an example of ways in which the life cycle approach of considering environmental impacts of a product can be evaluated and altered during the design stage (Allenby, Chapter 5).

INDUSTRY-GOVERNMENT COLLABORATION

Direct regulations and economic incentives influence the actions taken by industry. Direct regulations have been effective in improving environmental conditions in both the United States and Japan by encouraging the adoption of pollution control technologies. In addressing complex multimedia environmental problems, the challenge is to find a mix of regulations and economic incentives that promote the necessary actions. There is also a need for greater collaboration between government and industry to accommodate the increasing complexity of the environmental issues and changes in the global economic climate in which firms operate.

Governments greatly influence the climate in which industry operates and can therefore thwart or encourage

actions companies take. In Japan, where industry and government work closely together, industrial policies that have built Japanese industry have also been central to forwarding environmental initiatives. For example, Japan's policy decision to shift to a knowledge-intensive industrial structure in the 1970s resulted in placing a lesser burden on the environment (Watanabe, Chapter 3). Japan's energy and environmental policies have also been instrumental in improving Japan's environment. Many of these gains have resulted from the adoption of pollution control and energy-efficient technologies. The Japanese Recycling Law and Ecofactory initiative (Yumoto Chapter 6) illustrate continued efforts by Japan's government and industry to work together to meet national environmental goals and to develop technologies to meet environmental mandates in external markets.

In the United States, environmental gains can be attributed to development and adoption of best available technologies (Lindsey, Chapter 2). In other areas, market forces rather than industrial policies have led industry to adopt other technologies (energy, production, process) that have had indirect environmental benefits.

Environmental rules in the United States have been crafted and implemented in a confrontational atmosphere between government and industry. This is in contrast to the more consensus-building, collaborative approach Japan has taken. The various policies adopted by national governments differ in many respects (Szekely, Chapter 7) and have both advantages and disadvantages. However, as environmental issues have become more complex and global, there are signs of greater collaboration in the United States between government and industry. Recently, the U.S. Environmental Protection Agency (EPA) and Amoco Corporation collaborated on a two-year pollution prevention project at Amoco's refinery in Yorktown, Virginia. The objectives of the project were to measure the emissions from the facility, evaluate options to reduce the emissions, and examine factors that encourage or discourage pollution prevention initiatives (Solomon, 1993). Similarly, a collaborative effort among the EPA, the U.S. trucking industry, and the U.S. oil industry has resulted in a reduction of sulfur in diesel fuel. The effort began in 1988 when the oil industry and the manufacturers of diesel engines submitted a joint proposal for meeting new environmental standards with low-sulfur fuel and modifications to diesel engines. This collaborative effort has led to a program in which diesel-fueled vehicles will shortly begin using fuel that contains 90 percent less sulfur (Salpukas, 1993).

CONCLUDING REMARKS

Despite differences between the two countries (Takeda, Chapter 7), technology has driven advances in economic growth and environmental protection in both Japan and the United States. Technological innovation will continue to be critical to meeting these goals. On the environmental front, the systems approach of industrial ecology can play an important part. Examples from this workshop illustrate that both the United States and Japan are exploring ways to use the framework of industrial ecology to develop practical solutions to several industrial environmental issues.

Two areas lend themselves to cooperative efforts:

-

Studying and comparing the flows of materials and energy through specific industrial sectors.

-

Finding cross-industry linkages for the uses of wastes (and embedded energy), such as the use of primary industry processes for processing “waste” from secondary or manufacturing industries.

Existing mechanisms of exchange between the two countries should be used to encourage further effort in these areas.

Furthermore, both manufacturers and consumers must change their habits and attitudes. Government regulations must become more flexible and focus on economic incentives for sustainable manufacturing. The concepts of systems optimization and industrial ecology must be taught more widely in traditional educational systems and understood more widely by public officials, industry leaders, and the media.

The overall goal of improving efficiencies of industrial systems and extending the assimilative capacity of natural ecosystems is both environmentally desirable and necessary to make current industrial ecosystems more environmentally sustainable. Technological innovation is a necessary but insufficient means to that end.

REFERENCES

Allenby, B. R. , and D. J. Richards , eds. 1994 . The Greening of Industrial Ecosystems . Washington, D.C. : National Academy Press .

Ausubel, J. H. , and H. E. Sladovich , eds. 1989 . Technology and Environment . Washington, D.C. : National Academy Press .

Frosch, R. A. , and N. Gallopoulos . 1989 . Strategies for manufacturing . Scientific American 261(3) : 144–152 .

Helm, J. L. , ed. 1990 . Energy: Production, Consumption, and Consequences . Washington, D.C. : National Academy Press .

Salpukas, A. 1993 . Unique joint effort is seeking to reduce sulfur and diesel fuel . New York Times, 26 September .

Solomon, C. 1993 . What really pollutes? Study of refinery proves an eye opener . Wall Street Journal, 29 March .