Failures, Fantasies, and Feats in the Theoretical/Numerical Prediction of Ship Performance

L.Larsson,1,2 B.Regnström,2 L.Broberg,2 D.-Q.Li,1,3 C.-E.Janson2

(1Chalmers University of Technology, 2FLOWTECH International AB, 3SSPA Maritime Consulting AB, Sweden)

Abstract

The status of CFD in hydrodynamics is reviewed. After a brief historical survey a theoretical introduction is given to potential flow panel methods and methods based on the Reynolds-Averaged Navier-Stokes equations. Present capabilities are then discussed, and the attainable accuracy in the prediction of waves, wave resistance, local flow, viscous resistance and propeller effects is assessed. Prospects for improvements, based on present research in grid generation, free surface flows, turbulence modelling, propeller flows and full scale predictions are outlined. Finally, the exciting long term possibilities are presented and a number of conclusions drawn.

1. Background

The modern research in computational hydrodynamics is intimately linked to the development of the computer, and methods based on massive “number crunching” have replaced the more elegant, but less general, analytical methods developed during the first half of this century. One of the first representatives of the new approach is the Hess and Smith method (1), presented in 1962. For the first time it became possible to compute the 3-D potential flow around arbitrarily shaped bodies with an exact boundary condition applied on the hull surface. The method was later generalized to include lift, certainly important for aerodynamic flows, but of more hydrodynamic interest was the introduction of the free surface by Dawson in 1977 (2). Dawson’s method, although based on a linearization of the free surface boundary conditions, soon became an important tool in ship design, and it was the starting point for research at many organizations.

One of the main objectives of the research was to remove the free surface linearization and to introduce exact boundary conditions satisfied at the exact location of the wavy free surface. In a series of PhD projects at Chalmers University of Technology this route was followed, and in 1989 a paper was presented (Larsson, et al (3)), where the major results of the first three projects were presented. Recently, the fourth project was finished by Janson (4) and a robust non-linear method based on this research is now available in the commercial CFD package SHIPFLOW (5). A parallel development was carried out at MARIN, Holland, and in 1996 Raven (6) presented a non-linear method of a similar kind. In the opinion of the authors this development is now close to its limits. Raven’s and Janson’s theses work, based on all previous efforts in the same area, have led to methods which cannot be much improved under the potential flow approximation. To proceed further, viscosity has to be taken into account.

In the sixties the viscous flow research was directed towards 2-D boundary layer theory and by the end of the decade several methods for arbitrary pressure gradients were available. This research continued for 3-D methods during the seventies and an evaluation was made at a workshop organized by one of the authors in Gothenburg in 1980, see Larsson (7). Like in a previous workshop on wave resistance held in the Washington DC in 1979 a number of methods were applied to some well specified test cases and the differences were analysed in view of the differences in the

underlying theory. It turned out that most methods produced acceptable results for the major part of the boundary layer along the hull, while all failed completely near the stern. This prompted several groups to start research on less approximate methods based on the Reynolds-Averaged Navier-Stokes (RANS) equations. By the end of the eighties a number of RANS methods for ship flows had been developed and in a new Gothenburg workshop (Larsson et al (8)), a considerable improvement was noted in the capability to predict the stern flow. This improvement was verified at a new workshop organized by Kodama et al (9) in Tokyo in 1994, where, however, the most important breakthrough was the introduction of the free surface in the RANS methods. No less than 10 methods now featured this capability; a result of the research in several groups since the mid-eighties, as will be further discussed below.

There is no doubt that the most important developments to be expected in the future will be in the viscous flow area. With the increasing power of computers more advanced methods will become available, based either on the Large Eddy Simulation (LES) technique, where the large turbulent eddies are computed and only the smaller ones modelled, or on the DNS technique, where all eddies and scales are computed.

In the following, we will first give a brief theoretical introduction to potential flow panel methods and methods of the RANS type. This will be in Section 2. Thereafter, in Section 3 an assessment will be made of current CFD capabilities. Ongoing research and short term prospects for improvements will be addressed in Section 4, and in Section 5 a forecast will be made of the exciting long term possibilities. Finally, a number of conclusions will be drawn. The emphasis will be on resistance and powering, but some reference will be made to research in other areas of ship hydrodynamics as well.

2. Theory

In this Section a short theoretical introduction will be given, covering potential flow panel methods and Reynolds-Averaged Navier-Stokes methods. For obvious reasons the description has to be brief. This holds particularly for the RANS part, which will be further discussed in later Sections.

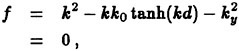

2.1 Potential Flow Panel Methods

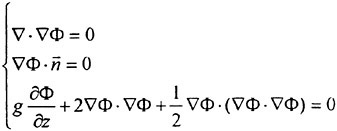

The flow is assumed steady, irrotational and incompressible. A Cartesian coordinate system is employed, where the origin is at the bow and at the undisturbed free surface level, x downstream, y to starboard and z upwards. U and q represent the undisturbed and disturbed velocities, respectively. Defining a velocity potential ![]() by

by

(1)

this potential will satisfy the Laplace equation

(2)

On the hull boundary the normal velocity is zero

(3)

and on the free surface boundary a similar relation holds. This kinematic condition may be written as

(4)

where h=h(x,y) is the equation for the wavy surface.

A dynamic free surface condition may be obtained from the continuity of stresses across the interface. In a potential flow, this condition degenerates to the simple statement that the pressure must be atmospheric at the surface, and without loss of generality this pressure may be set to zero. Neglecting surface tension and applying the Bernoulli equation the dynamic free surface boundary condition may be written

(5)

At infinity the velocity is undisturbed

(6)

g is the acceleration of gravity and R is the distance from the origin.

Finally, the radiation condition states that no below, this condition is enforced numerically. waves may be transmitted upstream. As explained

The free surface boundary conditions are nonlinear and they have to be applied at an initially unknown surface. This may be accomplished as follows. Assume that an approximate solution ![]() is known. Introduce small disturbances

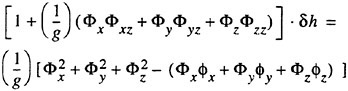

is known. Introduce small disturbances ![]() and δh and expand equations (4) and (5) in these quantities around the known solution. Delete terms of higher order. This yields, (see Janson (4))

and δh and expand equations (4) and (5) in these quantities around the known solution. Delete terms of higher order. This yields, (see Janson (4))

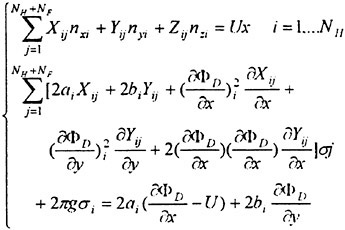

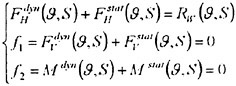

(7)

(8)

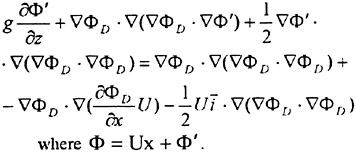

where ![]() has been replaced by

has been replaced by ![]() . In thin ship theory the known solution is taken as Φ=Ux, ho=0, i.e. the undisturbed flow and a flat free surface. Dawson used Φ=ΦDΜ, ho=0, where ΦDM stands for the double model solution. In SHIPFLOW (3), (4), (5),

. In thin ship theory the known solution is taken as Φ=Ux, ho=0, i.e. the undisturbed flow and a flat free surface. Dawson used Φ=ΦDΜ, ho=0, where ΦDM stands for the double model solution. In SHIPFLOW (3), (4), (5), ![]() and ho,n+1=hn, where n is the iteration number in an iterative sequence, which starts with the double model solution, as in Dawson’s method. When the process converges the neglected quantities in equations (7) and (8) go to zero and the position where the free surface boundary conditions are applied approaches the correct one. In the limit, the exact solution is thus obtained. Note that very non-linear effects, like spray and wave breaking cannot be predicted.

and ho,n+1=hn, where n is the iteration number in an iterative sequence, which starts with the double model solution, as in Dawson’s method. When the process converges the neglected quantities in equations (7) and (8) go to zero and the position where the free surface boundary conditions are applied approaches the correct one. In the limit, the exact solution is thus obtained. Note that very non-linear effects, like spray and wave breaking cannot be predicted.

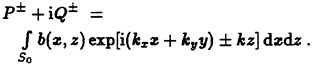

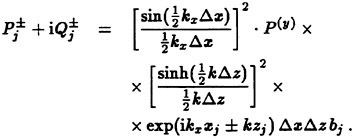

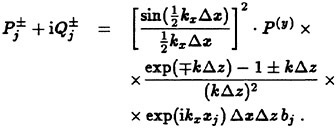

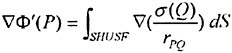

The problem posed by the field equation (2) and the boundary conditions (3), (6), (7) and (8) is solved by a boundary integral technique where sources are distributed on the hull and part of the free surface. Optionally, the free surface sources may be raised a certain distance above the surface (desingularisation, (4) (6)). The ![]() potential at any point due to the distribution of sources is

potential at any point due to the distribution of sources is

(9)

where σ is the source density, r is the distance from a point on the surface to the field point and S is the hull and free surface (covered part). Note that the sources satisfy both the field equation (2) and the infinity condition (6) for all σ. The solution thus has to be found from the three remaining boundary conditions (3), (7) and (8).

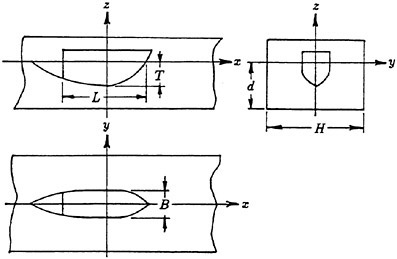

The problem is discretized by representing the hull and the (possibly raised) free surface by quadrilateral panels, each of which having an individual distribution of sources. In the SHIPFLOW code (3), (4), (5) two options exist: either the panels are assumed flat and the source strength constant on each panel (first order method), or the panels are parabolic with a linear variation in the source strength (second order method). In both cases the number of unknowns is equal to the number of panels. Since the boundary condition is applied at one point (the collocation point) on each panel the problem is closed.

A final free surface boundary condition is obtained by solving (8) for δh, differentiating this relation with respect to x and y and introducing all three quantities in (7). Second derivatives of the unknown potential ![]() will then appear and these may be handled in two principally different ways. Either (9) may be differentiated twice to give analytical expressions for the derivatives or first order derivatives in

will then appear and these may be handled in two principally different ways. Either (9) may be differentiated twice to give analytical expressions for the derivatives or first order derivatives in ![]() (i.e. velocities) may be differentiated numerically by finite differences on the free surface. The latter technique is Dawson’s approach, which has the advantage that the radiation condition is satisfied automatically (2). If the analytical approach is used the radiation condition has to be satisfied by an upstream shift of collocation points, see e.g. Jensen (10), for a discussion.

(i.e. velocities) may be differentiated numerically by finite differences on the free surface. The latter technique is Dawson’s approach, which has the advantage that the radiation condition is satisfied automatically (2). If the analytical approach is used the radiation condition has to be satisfied by an upstream shift of collocation points, see e.g. Jensen (10), for a discussion.

Upon introduction of the first and second derivatives of the potential in equation (3) and the combined free surface condition these become linear equations in the source strength (source strength at the collocation point in the second order approach). The system of equations is solved either directly by Gaussian elimination, or by an iterative technique. Note that the diagonal dominance of the matrix, known from aerodynamic methods, is lost in the block related to the free surface.

Having solved for the source strength, velocity components may be obtained from derivatives of (9). Pressures may then be computed using the Bernoulli equation. To obtain forces on the hull the pressure is integrated over the surface. In SHIPFLOW, this can be done in two ways: either by assuming the pressure to be constant on each panel and to act in the negative normal direction, or by using a second order technique, where the pressure varies linearly on each panel, the normal has a varying direction and the integration is carried out over the curved panel surface. It should be mentioned that lifting flows may be computed as well, by distributing dipoles on the lifting surfaces. For simplicity this feature has been omitted in the presentation above.

2.2 Viscous Flow

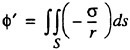

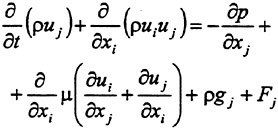

In Cartesian tensor notation the incompressible Reynolds-averaged Navier-Stokes equations may be written as follows

(10)

The continuity equation reads

(11)

Here, Ui represents the velocity components in the Cartesian coordinate system xi, Ρ is the pressure, ν the kin-

ematic viscosity, ρ the density and τij the Reynolds stresses.

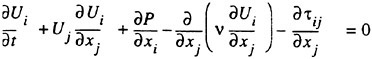

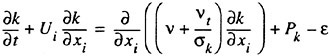

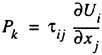

Although a number of turbulence models have been tested in the Chalmers/FLOWTECH group and elsewhere, as will be shown below, there are essentially only two models in practical use, the Baldwin-Lomax zero equation model (11) and the two equation k-ε model, where k is the turbulent kinetic energy and ε its rate of dissipation. Most methods today avoid the use of wall functions, and this calls for a special treatment of the ε-equation near the wall. A common choice is the two-layer model of Chen and Patel (12). The equations for k and ε read

(12)

(13)

where the production term Pk is defined as

(14)

and the eddy viscosity νt is obtained from

(15)

The constants are as follows

(16)

The most common boundary conditions for equations (10), (11), (12) and (13) are:

-

On the hull: Ui=k=0 (ε not needed)

-

Inflow, inner part, if there is an upstream boundary layer solution available: Ui, k and ε from the boundary layer solution

-

Inflow, outer part: Ui from potential flow solution, k and ε=small. If the calculations start in front of the hull: Ui undisturbed.

-

Outer edge: Ui from potential flow solution, or undisturbed. Sometimes symmetry conditions, k and ε=small or symmetry conditions.

-

Outflow: Most commonly Neumann condition for Ui, k and ε

-

Symmetry plane: Symmetry conditions for Ui, k and ε

-

Free surface: In most standard methods: symmetry conditions for Ui, k and ε. See section 4.2 for better free surface conditions.

A boundary condition for the pressure may be obtained either from the continuity equation or from one momentum equation.

To obtain an approximate solution to the equations, they are discretized in space and time and linearized. Numerous choices exist for solution algorithms and it is out of scope to review them here. The interested reader is referred to the proceedings of the two workshops (8), (9), where the numerical features of all participating methods are listed in detail. In general, an important capability in ship hydrodynamics is to be able to resolve thin boundary layers while taking large time steps to reach steady state, and this favours low order implicit time differencing. Spatial differencing is usually second order accurate with central differences for the diffusion term and some kind of upwind differencing for the advection term. Accuracy higher than second order has advantages, but is also less robust and more difficult to implement, especially when it comes to the boundary conditions.

3. Current capabilities

CFD is becoming an established tool in hydrodynamic design. Several methods are in routine use at shipyards, consultants and universities, and there exists a wealth of literature on various applications for different types of ships. For a review of methods and applications, see Larsson (13). In this Section an assessment will be made of the capabilities of established methods. Strong and weak points will be highlighted, and the need for the research presented in Section 4 will be explained. The discussion will address five important areas: wave pattern, wave resistance, wake/local flow, viscous resistance and propeller/hull interaction.

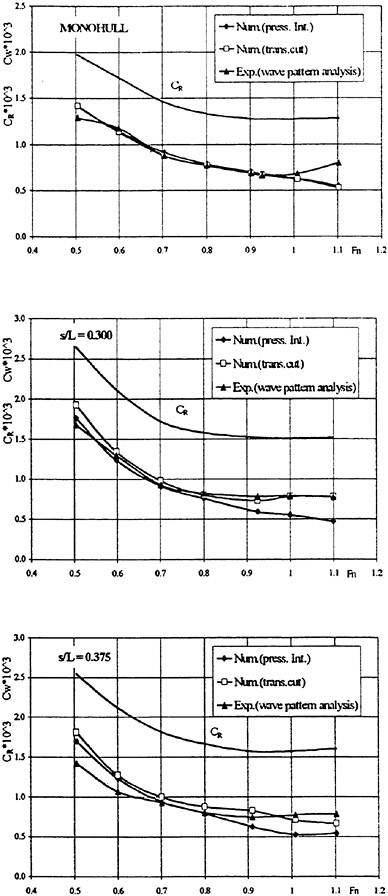

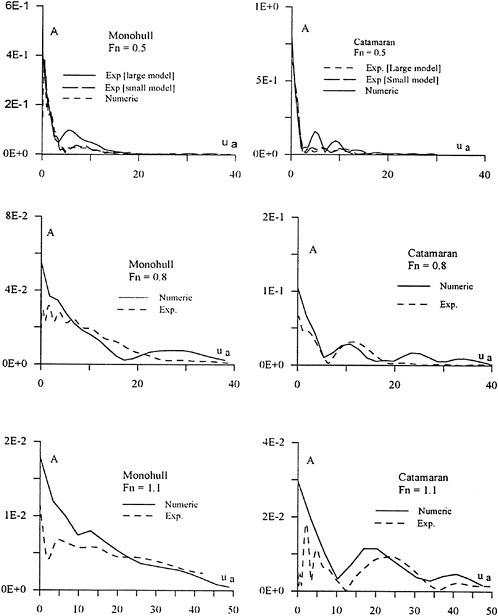

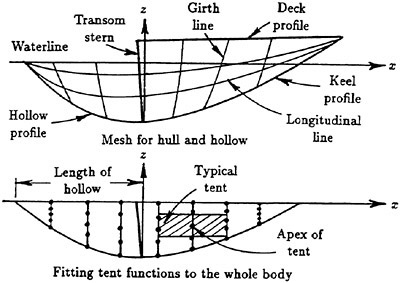

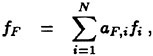

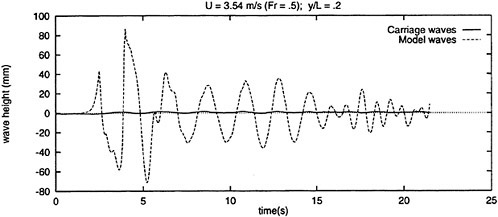

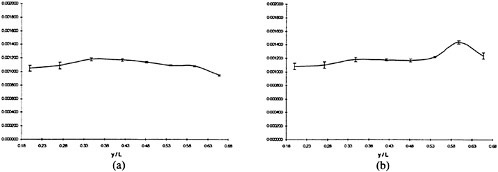

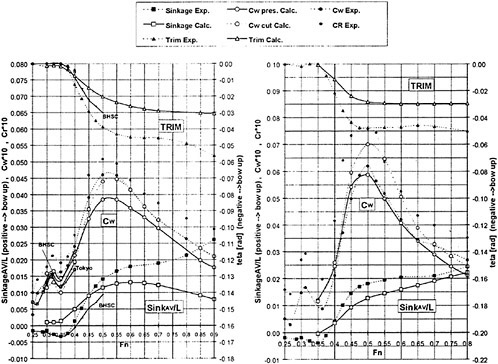

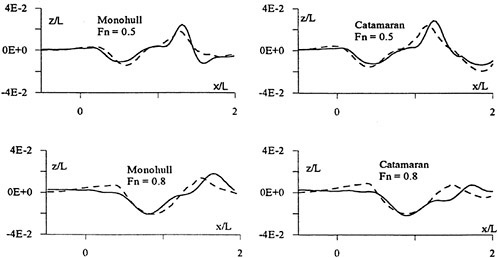

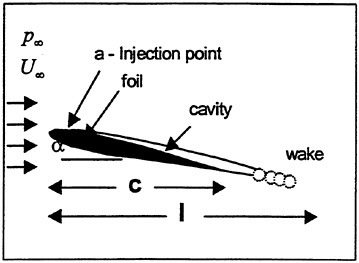

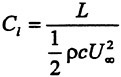

3.1 Wave pattern

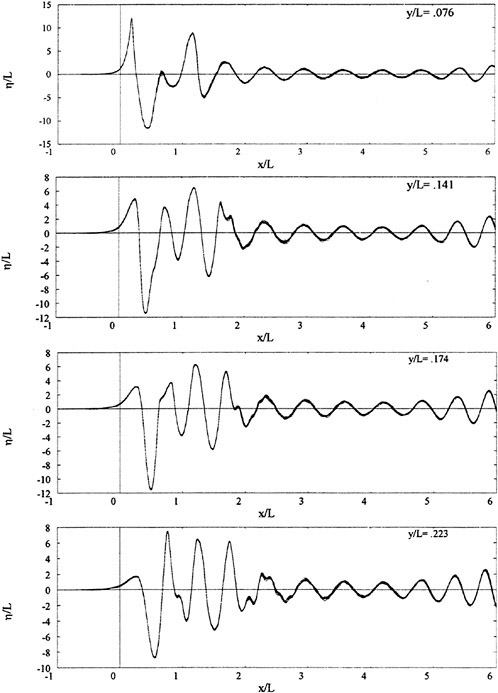

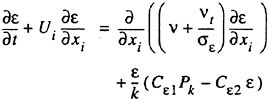

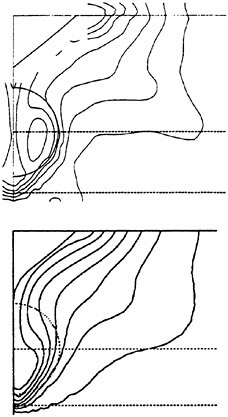

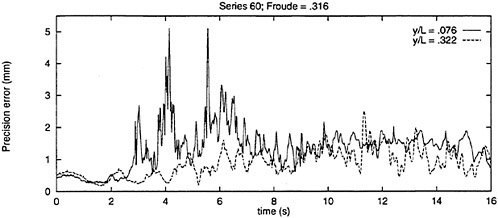

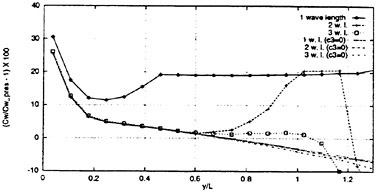

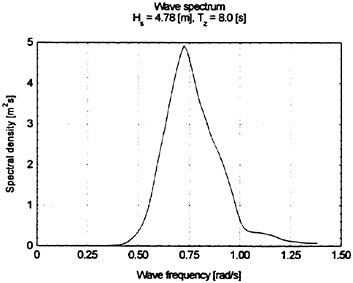

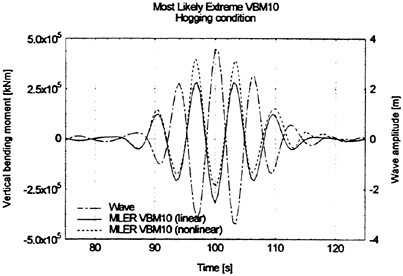

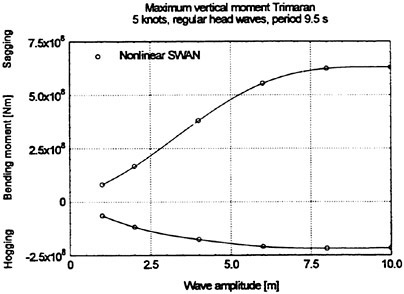

Figure 1 presents predicted potential flow waves from two different hulls, the slender Series 60, CB=0.60 hull and the very bluff Dyne tanker, designed as a test case at the 1990 Gothenburg workshop (8). Its block coefficient is 0.85. The Froude number for the slender hull is 0.316 and for the bluff one 0.165. Wave contours along two longitudinal cuts are shown for each hull. One cut is close to the hull and the other is further out. The bow is at x=0.0 and the stern at x=1.0. Both calculations and measurements are displayed. The number of panels used in the computation was 25

Figure 1. Wave cuts for two hulls (4)

Circles: measurement, Line: calculation

per wave length in the longitudinal direction on the surface for the Series 60 hull and 15 per wave length for the tanker. Laterally, 20 uniform panels were used for the slender hull and 15 stretched panels for the bluff one. The reason for the worse resolution of the tanker waves is the much smaller wave length, which calls for many more panels to achieve the same resolution. The number of panels followed the recommendations to the users of the SHIPFLOW code, considering available computer capacity, and the results were obtained with this software.

In general, the correspondence between calculations and measurements is quite good. For the Series 60 the wave peaks are slightly underpredicted along the hull, which indicates that the resolution is still not sufficient. Even though as many as 25 panels are used per wave length, systematic grid refinement studies (6) indicate that this is not enough to completely capture the peaks. For the cut closest to the hull an over prediction is noted in the wake. Most likely, this is caused by neglected viscous effects, i.e. the influence of the boundary layer/wake displacement effect.

The wave predictions for the tanker are surprisingly accurate, at least along the forebody, and no systematic under prediction of the peaks is noted. Considering the lower resolution this may seem to contradict the above discussion. However, most likely some breaking of the bow wave is present in this case which somewhat reduces the measured wave height. No such effects are of course considered in the calculation, so the very good correspondence may be attributed to a cancellation of (relatively small) errors. It is interesting to note what happens further aft on the hull, and particularly in the wake. The innermost cut exhibits an increasing over prediction of the wave peaks, and in the wake the predicted waves are several times larger than the measured ones. A much stronger effect of the neglected displacement effect is thus noted for this bluff hull. However, at the second cut there is practically no over prediction. Wave contours for this case show that this is due to the fact that the overpredicted stern waves have not reached the outermost cut at the end of the panelized free surface. This indicates that the waves from the rest of the hull are well predicted even at the downstream edge of the panelized surface.

The two hulls in the example represent extremes in hull bluffness and the good results of the predictions indicate that waves from the major part of the hull may be computed with good accuracy. This is utilized by ship designers in the optimization of ship forebodies and bulbs. By investigating the predicted wave pattern and wave profile, and comparing with the computed pressure distribution on the hull, experienced designers are guided in their optimization process. Good descrip-

tions of this technique are found in several papers from the Daewoo design team in Korea, see e.g. (14), and according to other users of the SHIPFLOW code, this approach is common also elsewhere. Undoubtedly, this is the best way of utilizing hydrodynamics CFD at present.

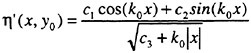

Great care is however recommended in the optimization of ship afterbodies using the above approach. As was seen in Figure 1, the real waves are modified at the stern due to viscous effects, not considered in a potential flow. When comparing two similar designs it may be tempting to assume that the ranking is unaffected by this effect, but this is not necessarily true, as was realized in a notable failure by two of the authors in the optimization of the Series 60 hull (15). Applying numerical shape optimization an optimized hull with significantly lower total resistance was developed. In later grid refinement studies this new shape was consistently better than the original hull. However, when the new hull was model tested, its resistance was slightly larger than for the original hull. A careful investigation of the possible reasons for this failure was carried out and it was found that the optimization caused a slight increase in bow wave height, while it minimized a stern wave, whose importance in reality was considerably smaller than in the computations. Further, there was a vertical shift of the boundary layer displacement thickness on the new hull, causing an increase in the wave resistance.

For high speed hulls the situation is different. If the hull has a submerged transom, the boundary layer grows much less than for a cruiser stern, where the girth length is reduced as the stern is approached and where the local convergence of streamlines may be very strong. There is thus a much smaller effect of the displacement thickness for transom stern hulls. This is, of course, provided the transom is dry. If the flow recirculates behind the transom, the problem cannot be handled by potential flow methods. Various proposals have been put forward for the boundary condition to apply at the transom edge, see (6) for review. In SHIPFLOW, the wave height at the upstream edge of each wake panel row is set equal to the transom draft at this position and this produces quite realistic waves, both behind the transom (the rooster tail wave) and laterally (5). There are thus much better prospects for optimizing the stern of a transom hull than of a displacement hull. An accurate prediction of the sinkage and trim is, however, quite important in this case, particularly at the lower range of Froude numbers for which the transom is dry. In this speed range the hydrostatic resistance, caused by the loss of hydrostatic pressure at the transom, is much larger than the hydrodynamic resistance and the former is proportional to the square of the transom draft. An interesting study of the effect of a trim change is presented in (13).

A problem attracting more and more interest is the wake wash of high speed ships. From the above discussion panel methods may appear to be a very suitable for this type of problem, but a difficulty is the large distances at which wave predictions are requested. Normally the interest is in far field waves several boat lengths away from the hull. Obviously, this is very difficult for a method that relies on a panelization of the free surface. Very limited stretching is permitted if the numerical damping of the waves is to be kept within acceptable limits. On the other hand, the non-linear free surface effects are limited to a region rather close to the hull, so predictions by a linear theory may be permitted outside this region. One possibility explored several years ago by Gadd (16) and Aanesland (17) is to match a near field method of the type described here with a far field method using Kelvin sources that automatically satisfy the linear Kelvin condition on the surface. This possibility does not seem to have been explored recently. A simple extension of the wavy surface outside the panelized region based on linear theory has been used by Hughes (18) and others.

The remedy for the stern wave problem in the case of displacement hulls is to abandon the potential flow approach and use viscous methods of the RANS type. As mentioned above, RANS methods with a free surface are becoming more and more common, but they are not at all as established as the panel methods. A major problem is resolution. Due to restrictions in computer capacity the free surface and the water layer just below the surface cannot be resolved well enough to avoid excessive damping, at least not for the low Froude number range. A more thorough discussion on free surface RANS methods will be given in Section 4.2.

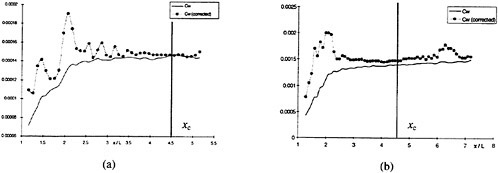

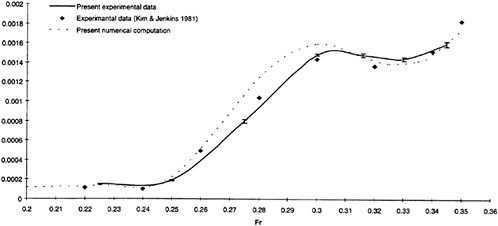

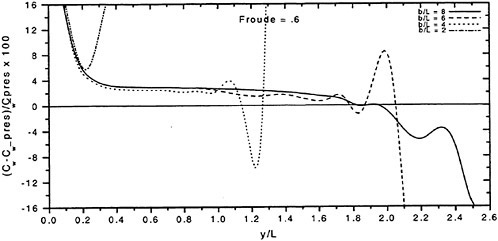

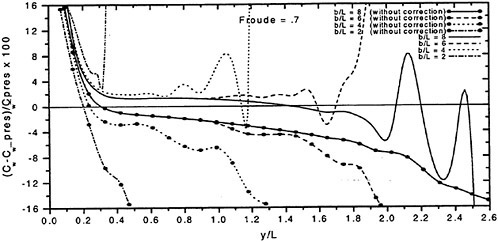

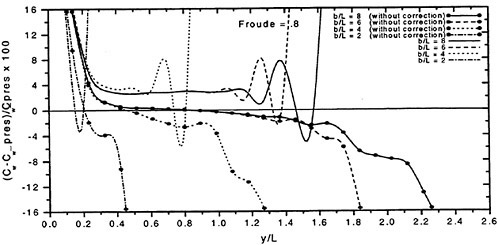

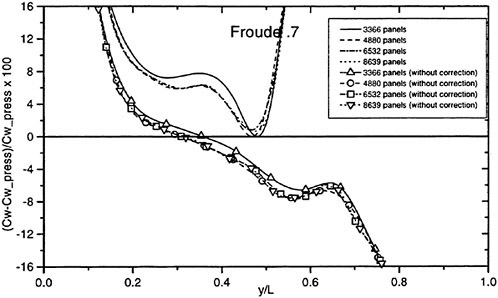

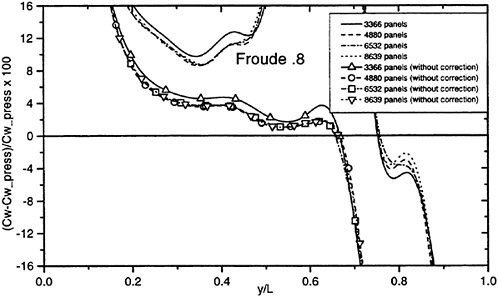

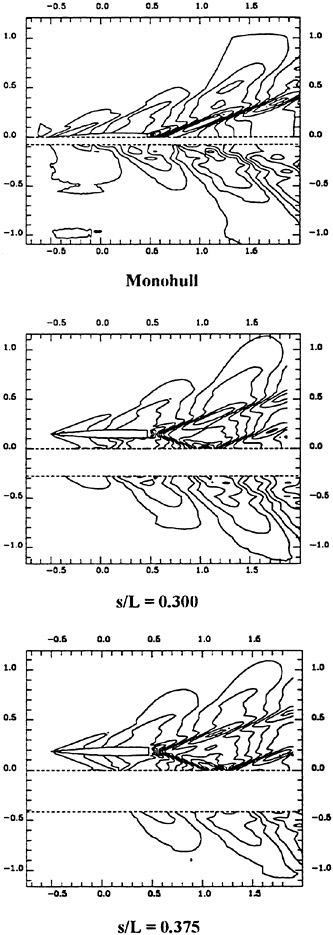

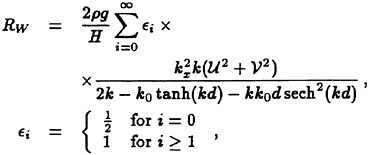

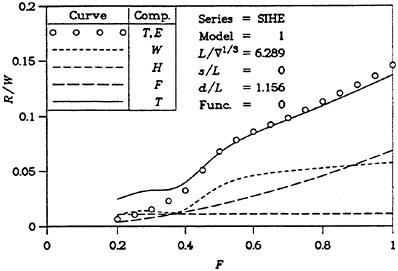

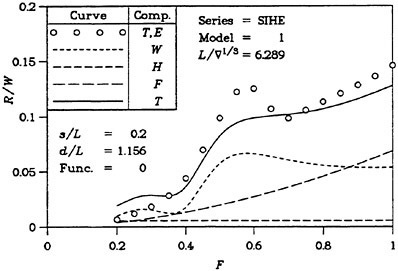

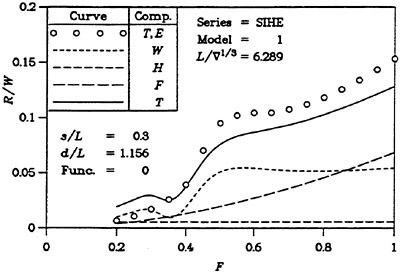

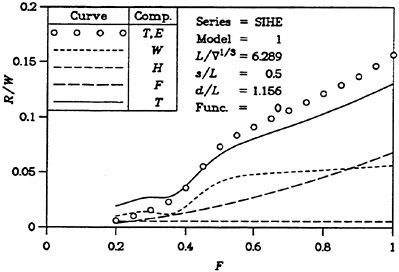

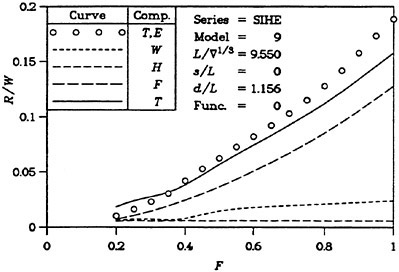

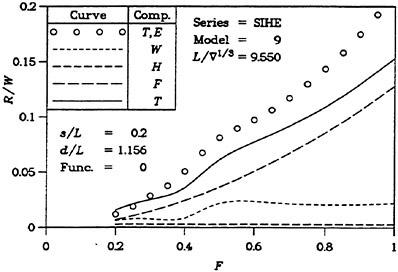

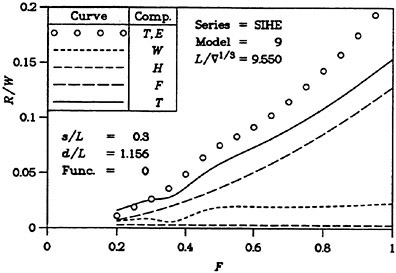

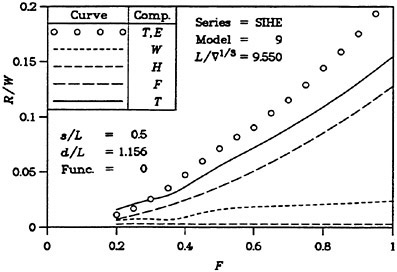

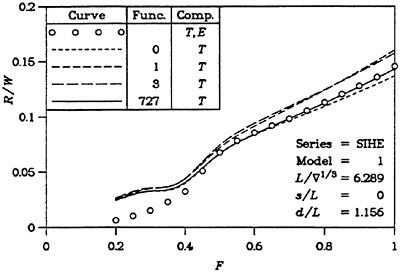

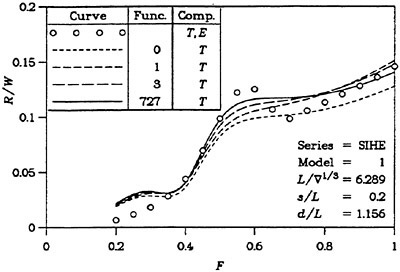

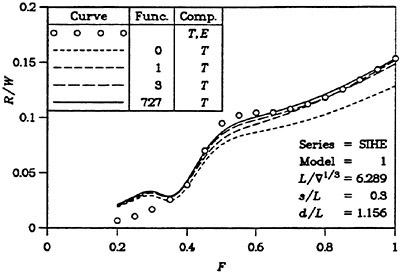

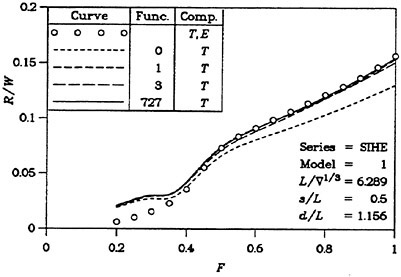

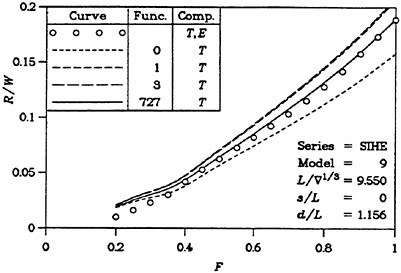

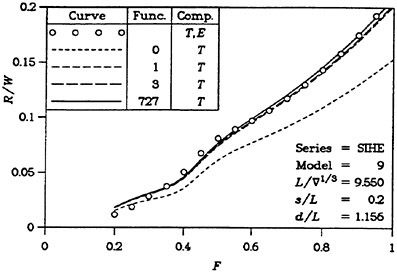

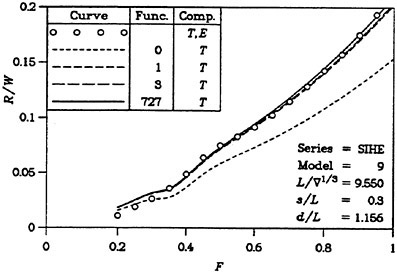

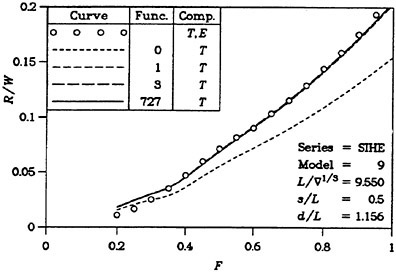

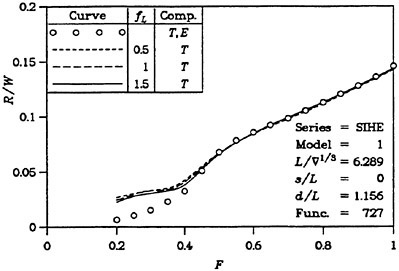

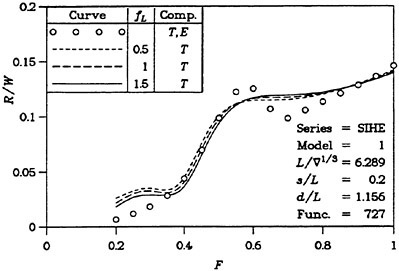

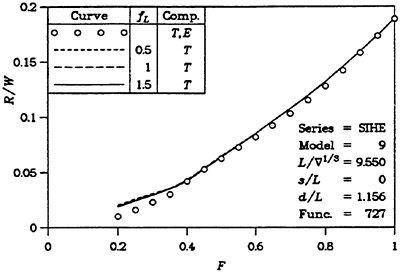

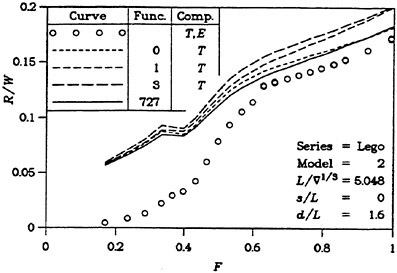

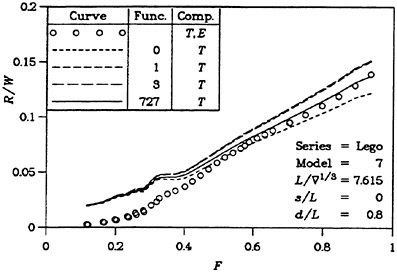

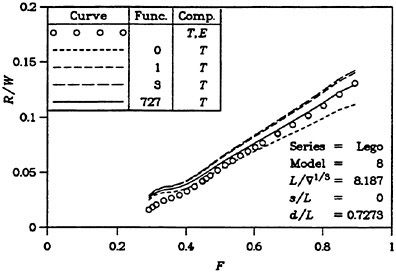

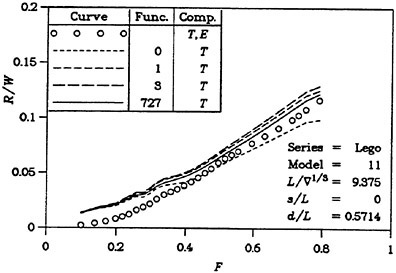

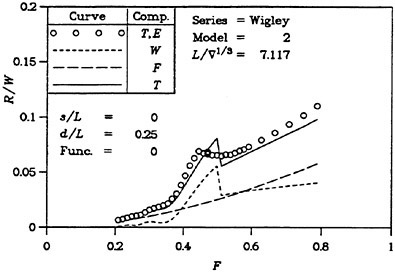

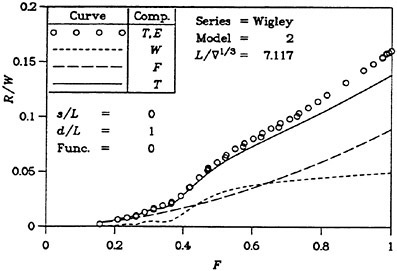

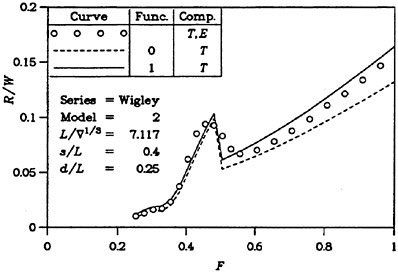

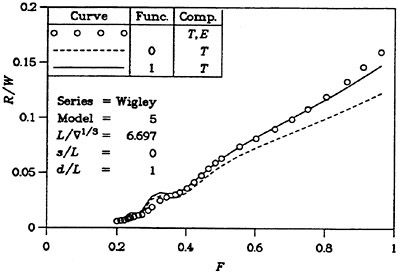

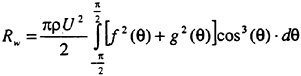

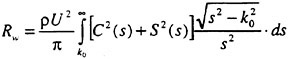

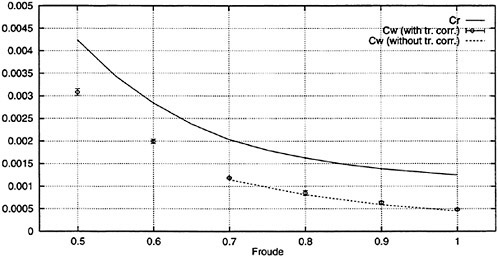

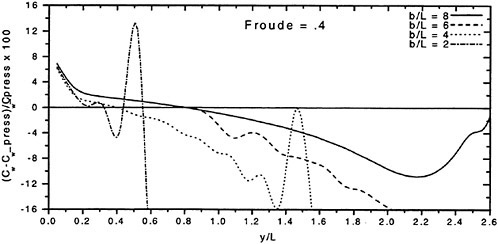

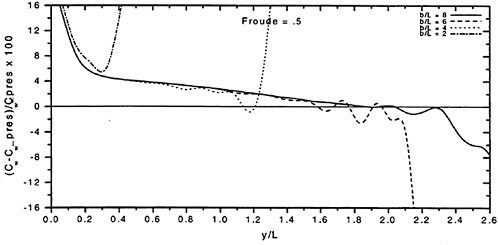

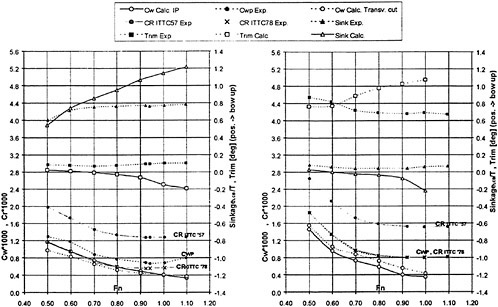

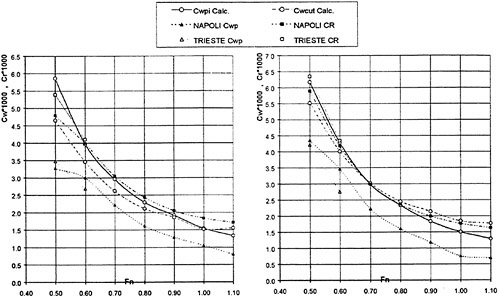

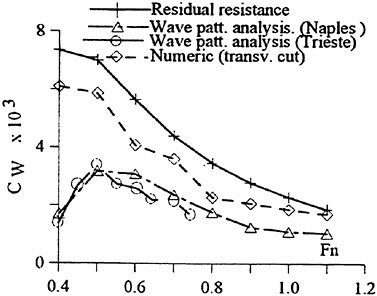

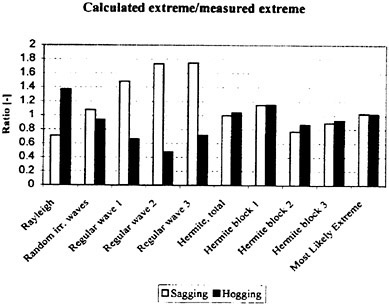

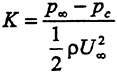

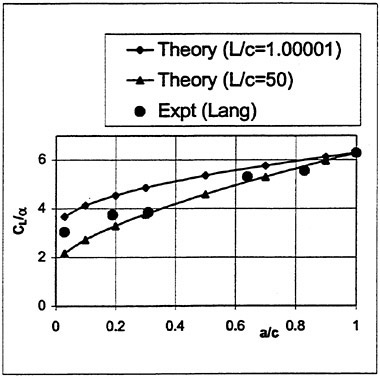

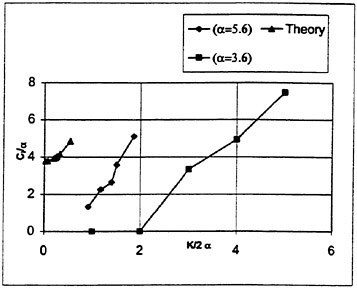

3.2 Wave resistance

The wave resistance is normally computed by adding the longitudinal components of the pressure forces on all panels. This means adding of the order of 1000 contributions of different signs, which almost cancel each other. For slow ships the sum may be of the same order as one of the larger contributions. The discretization error for such ships is thus often of the same order as the resistance. In a linear method the problem may be reduced by subtracting the resistance computed for a hull without a free surface, i.e. the so called double model case. According to d’Alemberts paradox the resistance for this case (without lift) is zero, so the computed resistance may be representative of the error associated with a given panelization. Unfortunately, this technique is much more difficult to apply in a non-

linear method, where the panels normally change in the iterative process. In SHIPFLOW this is entirely true and in principle all panels change in the iterative process, when the free surface converges to its final shape. Other methods, Jensen (19), use a given panelization on the hull, which extends through the free surface and integrate only over the (part of the) panels below the surface. Although the chances of using d’Alemberťs paradox are better for these methods the correction is still approximate due to the differences in the integration close to the water surface in the wave case and the double model case.

Better corrections for the discretization error can thus be devised for linear methods, but they are still inferior to the non-linear ones due to the linearization. As explained in Section 2, the linearization means two types of approximation: a neglect of the non-linear terms in the boundary conditions and a transfer of the conditions to the undisturbed free surface. Both contribute to inaccuracies. As shown by Raven (6) the approximation of the equations leads to a flow of energy through the surface. This may either increase or decrease the resistance. The erroneous location of the conditions normally leads to a reduction in resistance, since the positive contribution to the resistance from the bow wave above the undisturbed free surface is neglected, while a non-existing suction force below this surface is included. At the stern the effects are reversed, but normally much smaller. Very frequently, negative values of the wave resistance are found for linear methods and low Froude numbers.

There are thus several reasons why resistance calculations are inaccurate in the low speed range. A negative wave resistance is seldom found for non-linear methods, but the accuracy in the predicted resistance is still unacceptably low for slow ships, i.e. at least up to a Froude number of 0.20. In the intermediate speed range the prospects are better, since the wave resistance at these speeds is much larger than the discretization error. The most accurate calculations of the wave resistance are found for semi-planing hulls, from the Froude number where the flow clears the transom, around 0.35, up to about 1.0. Above this Froude number non-linear effects like spray, not accounted for, become too important.

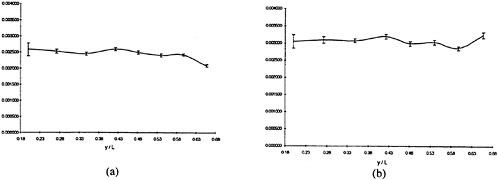

One way to improve the wave resistance prediction is to derive an empirical correction to the computed value. This may be accomplished by comparing large sets of measurements and calculations for a specific type of ships. At SSPA this technique is used for round bilge semi-planing hulls and the Technical University of Berlin (20) reports on successful corrections to slender cargo ships. It is very unlikely, however, that a similar correction can be found for slow ships.

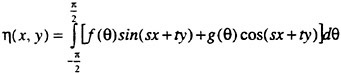

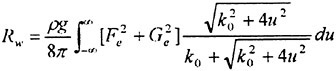

A more scientific way of improving the resistance prediction is to abandon the pressure integration technique and obtain the resistance from the computed waves. Since these are rather well predicted a more accurate resistance might be envisaged. Some attempts to follow this track have been made recently. A longitudinal cut method was tested by two Chalmers students in 1995 with promising results, and this idea was pursued by two of the authors in 1997 (15). More work is planned to optimize the technique, but there is no doubt that an improvement relative to the pressure integration technique is possible. A very interesting alternative is presently being investigated at MARIN (21), where a transverse cut technique is being developed. In principle, this technique is less approximate, since no truncation of the cut within the wave system needs to be done. While a transverse cut may cover the whole Kelvin wedge, a longitudinal cut must be truncated somewhere and analytically extended to infinity.

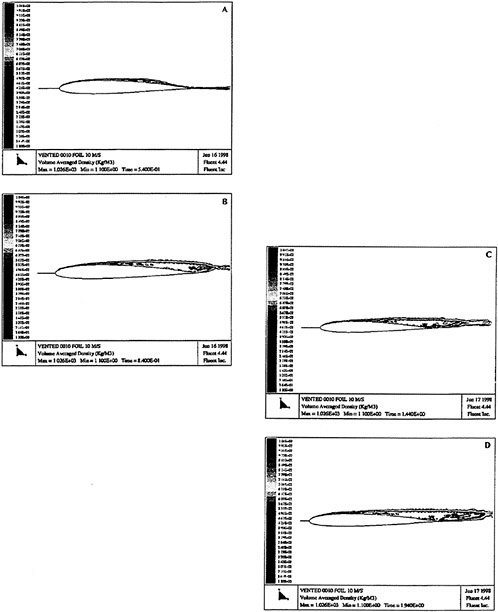

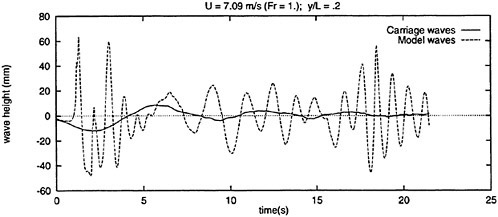

3.3 Wake/local flow

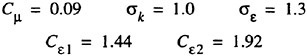

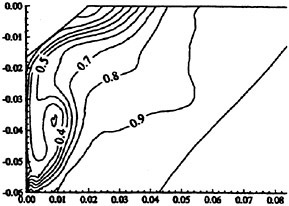

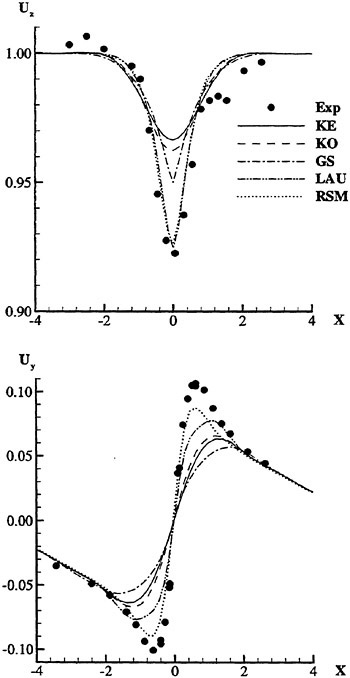

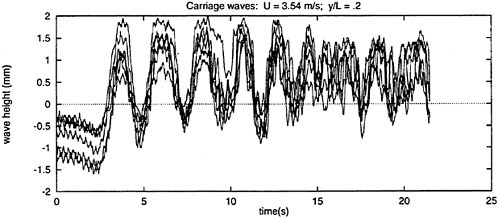

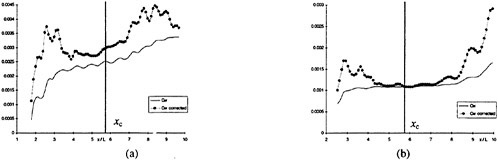

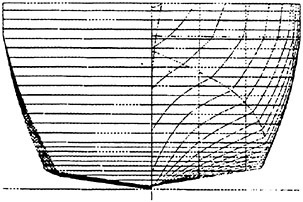

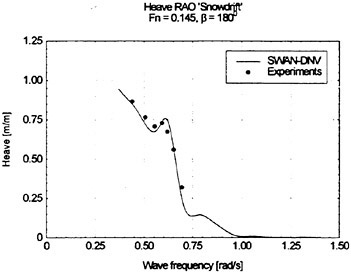

In Figure 2 a comparison is made between the predicted and measured wake contours of a very bluff hull, the Dyne tanker, designed for the 1990 workshop (8). The results are from the workshop, and are thus quite old, but they are still typical of most methods using standard turbulence models.

As can be seen in the figure, the contours in the propeller disk are not well predicted. While the computed contours are quite smooth, the measured ones exhibit an island and a quite pronounced “hook”. During the nineties much of the research in viscous flow CFD has been directed towards improving the ability to predict these features.

On closer inspection it turns out that the wake hooks, which are present for large classes of ships, are caused by the bilge vortices (one on each side), generated at the bilge and hitting the propeller plane inside the propeller disk. An accurate calculation of these vortices is thus important for the prediction of the hooks. This calls for a more advanced turbulence modelling than what was available in the early nineties. At the 1990 workshop the only models used were zero equation models of the Baldwin-Lomax type and the two equation k-ε model. The latter is still the most widely used one and is normally available in commercial RANS codes. Therefore, good wake contours cannot be expected using standard codes, at least for full ship forms. Very slender hulls, on the other hand, do not normally have pronounced bilge vortices, and quite accurate wake contours can be predicted, see for instance Zhang et al (22). It should be pointed out that, although the details of the contours are not well captured for the bluff hull, integrated quantities are better.

The radial variation of the circumferentially averaged wake, important for designing the pitch distribution, is thus better than the contours but not accurate enough for design purposes (23). The wake fraction, on the other hand, can normally be obtained with sufficient accuracy (22), (23), (24).

Figure 2. HSVA Tanker, wake contours in the propeller plane. Outermost contour: 0.9, interval: 0.1. Top: measurement. Bottom: calculations (8).

Since the wake contours in the propeller plane are insufficiently accurate, local viscous flow predictions may be questioned. Certainly, if predictions are requested as far aft as the propeller great care must be exercised when interpreting the results. However, local flow directions are often requested elsewhere, for the positioning of bilge keels, brackets and fins. Experience shows that such predictions are mostly sufficiently accurate for design purposes. As pointed out above, transom stern ships, have a relatively thin boundary layer even close to the stern, and bilge vortices are seldom a problem. For such hulls very good viscous flow predictions are possible, an important advantage, since these hulls often have brackets, whose direction can be optimized.

To improve the situation, more accurate turbulence models are required and several predictions have been reported where considerably improved results are demonstrated. This development will be discussed in Section 4.3.

3.4 Viscous resistance

The inability to compute the details of the wake flow certainly has some effect on the accuracy of the prediction also of the viscous resistance. However, the resistance is an integrated value, so just as in the case of the wake fraction, the details of the flow do not necessarily have to be very accurate to obtain a value of engineering interest. Therefore, existing RANS solvers should be capable of predicting the viscous resistance accurately enough for ranking purposes, provided certain conditions are satisfied. Where many methods fail is the grid quality. In particular, an accurate representation of the hull shape at the ends is important. Many grid generators produce a staircase-like hull shape at the stern contour, with very distorted numerical cells. Since this is an area of large importance for the resistance, both the erroneous direction of the normal to the hull surface and the inaccurate pressure contribute to an unrealistic pressure drag. For this to be computed accurately it is also important to have a sufficient number of grid points in the direction normal to the hull to resolve the pressure variation across the boundary layer. The frictional resistance, on the other hand, relies on an accurate prediction of the flow in the inner part of the boundary layer. The innermost points of the grid must thus satisfy given requirements for y+, be it a wall function method or a method using the no-slip condition. Grid dependence studies are certainly important in all CFD work, but especially in resistance prediction.

The viscous resistance was provided by eight methods at the 1994 workshop (9). Three were seriously in error and three predicted the resistance, as well as the split between the pressure and frictional contributions, quite well. There was no discernable advantage of the k-ε model as compared to the Baldwin-Lomax model and the methods were in most respects quite similar, so the different performance must be due to numerical details, most probably related to the grid. This conjecture is substantiated by the fact that careful grid refinement studies have been reported elsewhere for two of the three best methods, see Ju and Patel (25), and Ishikawa (26). In both papers successful rankings of hull afterbodies are reported. Streckwall (27) also reports on successful rankings and in a recent paper Masuda and Kasahara (24) present interesting calculations of the form factor for 20 hulls using the NICE code (28). The latter introduce a correlation between the predicted and measured form factors, and using this correlation, the error in the predicted values are within 2% for 18 out of the 20 hulls. As mentioned above, this is an good way of increasing the engineering value of CFD. It should be mentioned that a similar correlation was developed for the wake fraction.

3.5 Propeller/hull interaction

Already in 1977 Schetz and Favin proposed an actuator disk approach to introduce propeller effects in RANS methods. By applying body forces to the numerical cells in the propeller disk the flow may be accelerated in the same way as by a propeller with an infinite number of blades, producing the same thrust and torque. This approach was further refined and improved by Stern and his co-workers in Iowa (29), and in the Chalmers group by Zhang (22). More recently the method has been applied to design problems at the University of Athens (30). A somewhat simpler approach is to apply a pressure jump in the propeller disk, see Streckwall (27).

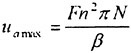

An actuator disk is now included in the SHIPFLOW code, where the body forces are computed by a lifting line propeller analysis method, run interactively with the RANS solver. Using the velocity computed in each numerical cell within the propeller disk, the lifting line program computes the circulation and thereby also the axial and tangential body forces, which are returned to the flow solver in an iterative process. Strong under relaxation is required to introduce the body forces, but the iterations are included in the normal pressure/ velocity iterations, so the computer effort is not much increased Since the code can be run with a propeller only, corresponding to an open water test, the propulsive factors can be computed.

Although the actuator disk has been available in SHIPFLOW for a couple of years it does not seem to have been much used. It is therefore difficult to assess the accuracy of the computed propulsive factors. Zhang’s own calculations (22), as well as more recent work in a Master’s thesis indicate that the thrust deduction can be obtained with good accuracy even for high speed hulls, where a large part of the thrust deduction comes from trim changes. The effective wake and the relative rotative efficiency also seem to be reasonable. The actuator disk approach should be further evaluated and used by the designers. It seems to be a useful tool for power prediction (of course with the limitations of the resistance calculation). For more accurate predictions of blade flows and pressure fluctuations the more advanced methods presented in Section 4.4 will be required.

4. Present research

As explained above, the most advanced potential flow methods have now reached a state where the major obstacle for further improvement is the inherent neglect of viscosity, and the efforts to fine tune available methods have been covered already in Section 3. Therefore, the present section will only cover research in the RANS area. The work presented may be expected to yield improvements in existing solvers in the relatively near future, say five years, while the more long range perspectives will be discussed in Section 5. Although reference will be given to research elsewhere, the emphasis will be on the work in the Chalmers/FLOWTECH group. Four areas will be covered: grid generation, free surface boundary conditions, turbulence modelling and propeller blade flows.

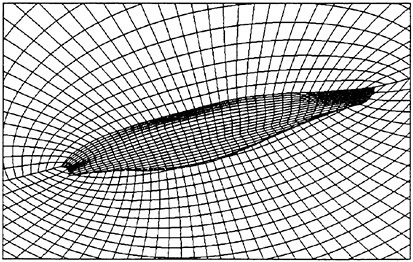

4.1 Grid generation

The ship hull is normally a smooth surface and the flow domain surrounding the hull may rather easily be transformed into a rectangular box, in which the computations are performed. Ship flows are therefore good candidates for single block structured grids, and so far the vast majority of ship flow methods employ grids of this kind. In the 1990 and 1994 workshops (8), (9) all methods used single block structured grids. There are, however, several reasons for introducing more advanced gridding. Although the hull itself is smooth, it always has appendages of different kinds. These are normally neglected, but for more advanced calculations the rudder, possible shafts and shaft brackets, bilge keels, fins, etc. have to be taken into account. A single block grid necessarily has to include singular points or lines in front of and behind the hull and this calls for special treatment in the solver. Further, a large number of grid points are normally wasted in regions where they are not needed in structured single block grids and, as pointed out above, it is difficult to obtain a high grid quality close to the ends of the hull.

For these reasons there is a growing interest in developing methods based on less restrictive gridding techniques. Little interest has however, been shown in completely unstructured grids, common in structural mechanics. Such techniques offer great flexibility, but impose more work on the solver, which has to take care of the connectivity information and has to deal with large sparse matrices. It is also more complicated to develop higher order schemes and multi-grid convergence acceleration techniques. Completely unstructured grids are also unsuitable for boundary layers at high Reynolds numbers, where extremely large gradients are experienced in the direction normal to the surface. These disadvantages are often offset by the advantage in flexibility for general purpose CFD applications, where unstructured grids may be an alternative, but in hydrodynamics this does not seem to be the case and only a few calculations with unstructured grids have been reported, see Hino (31) and a recent paper by Yang and Loehner (32).

Instead, the recent interest among hydrodynamicists has been directed towards multi-block methods,

where the structure is maintained within each block. Not surprisingly, this development started in submarine hydrodynamics, where appendages play an important part. Standard multi-block techniques for submarines are reported by Sung et al (33), McDonald and Whitfield (34) and Bull (35). Other applications are presented by Cowles and Martinelli (36) and Beddhu et al (37). The traditional multiblock techniques offer more flexibility than single block grids, but they are still restricted due to the need for matching at the common boundaries of adjacent blocks. A more modern approach is to let the grids overlap without any restrictions on continuity of grid lines. This technique, known in the United States as the Chimera technique, has become a useful tool in many engineering branches, see the 1st–4th Symposia on Overset Composite Grid & Solution Technology. (The 4th one to be held at the Army Research Laboratory, Aberdeen, Maryland, USA 23–25 September 1998). Recent applications of overlapping grids in hydrodynamics include Weems et al (38), Lin et al (39) and Masuko (40).

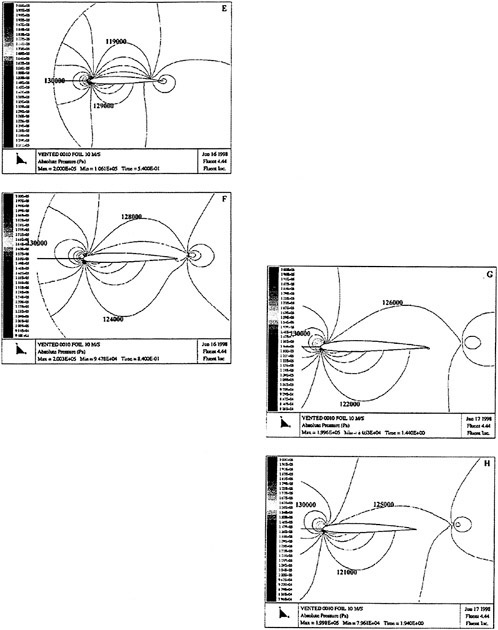

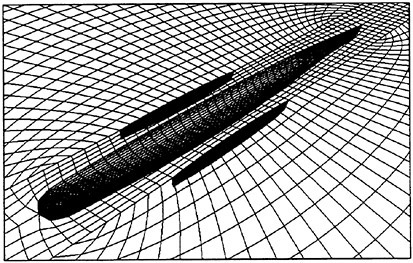

In the Chalmers/FLOWTECH group a new 3-D overlapping grid generator CHALMESH has been developed by Dr. Anders Petersson, based on his earlier 2-D code XCOG (41). The new code has an efficient user interface and seems more robust than other grid generators of this kind. Based on overlapping surface grids, which have to be provided for general cases, overlapping volume grids are grown hyperbolically out from the surface. The body-fitted grids may be embedded in one or more background grids, which may be curvi-linear or Cartesian. Holes are automatically cut out and the necessary overlap is ensured. Interpolation weights are computed and saved for all interpolation points at the edge of each grid. To avoid mismatch, special techniques are used to handle the interpolation between the extremely thin cells close to boundaries where the no-slip condition is to be applied. CHALMESH is reported in (42), and the code is available free of charge for research purposes on the Internet under the address: http://www.na.chalmers.se/%7Eandersp/chalmesh/chalmesh.html. It is presently used at different departments at several universities in Sweden and the USA.

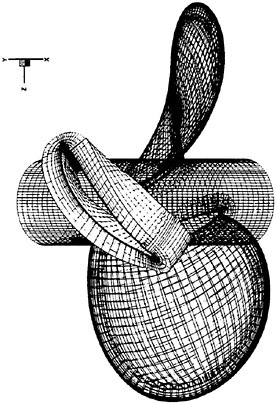

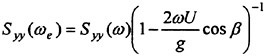

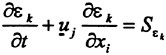

Figure 3 shows the grid generated around a three-bladed propeller. Only surface grids are shown for two of the blades, while a cut through the body-fitted grids is shown for the third blade. It is seen that there are three grids on each blade, one on each side and one wrapped around the edge. These grids are embedded in a background cylindrical grid. By arranging the grids in this way quite orthogonal grid lines may be obtained. On ship hulls typically a few grid patches are wrapped around the stern, after which a

Figure 3. The grid around a 3-bladed propeller. Body fitted volume grid shown on one blade only.

couple of rectangular grids are attached. All these are embedded into a background cylindrical grid. The rectangular grids are added to remove the line singularity of the background grid.

A new RANS method for overlapping grids has been developed within the group, mainly by Björn Regnström. Finite difference discretization is used and the discretized equations are solved implicitly for all blocks, i.e. the matrix contains equations for all points including interpolation points. To keep the discretization stencil as small as possible, central differencing is used for all terms. Alternatively, a mix of second order central and first order upwind discretization may be used for the convective terms. To stabilize the solution if central differences are used, artificial dissipation is added. The variables are collocated and Rhie-Chow interpolation is used to avoid pressure fluctuations in the SIMPLE pressure/velocity updating scheme. As will be seen below, the free surface is treated in a special way and a range of turbulence models are available. By the time of writing, laminar flow calculations have been carried out for the propeller of Figure 3, and the first turbulent results have been obtained for a ship hull. The results indicate that the overlapping algorithm works as expected, but some other fine tuning of the method is required before it can be used on a regular basis.

4.2 Free surface boundary conditions

As mentioned above, the most important result of the 1994 workshop (9) was the breakthrough of the

free surface RANS methods. No less than 10 methods featured this capability. The technique was not new, however. The Marker and Cell (MAC) method had been available for 30 years and the Volume of Fluid (VOF) method for more than 10, but they had mainly been applied to internal flow problems, such as sloshing. In ship hydrodynamics the first references are from the mid-eighties, when Miyata et al introduced their version of the MAC method called TUMMAC (43). A large number of references to subsequent developments in different groups are available and may be found in Larsson (13). They will not be repeated here. See however Miyata (44) for an overview of the impressive developments at the Tokyo University. Recent references, not in (13), include Yang and Loehner (Euler solution) (32), Beddhu et al (37) and Haussling et al (45). The latter is especially interesting, since it deals with the difficult transom stern problem.

Extensions into other areas of hydrodynamics are presented in the papers by Rhee and Stern (46), Campana et al (47) and Ohmori et al (48). While Rhee and Stern compute the wave diffraction from a fixed hull subjected to an approaching wave train, the others consider the side force and turning moment of a hull at a yaw angle.

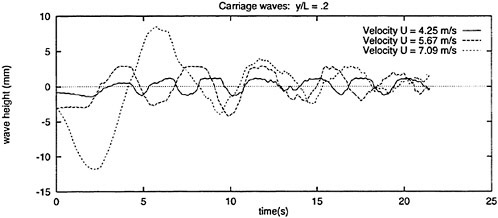

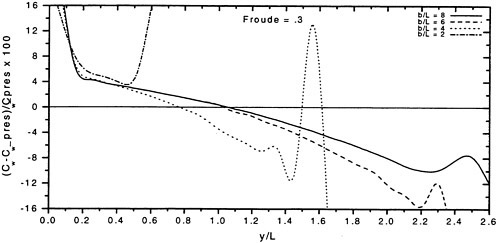

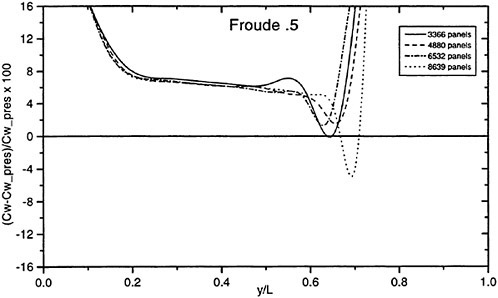

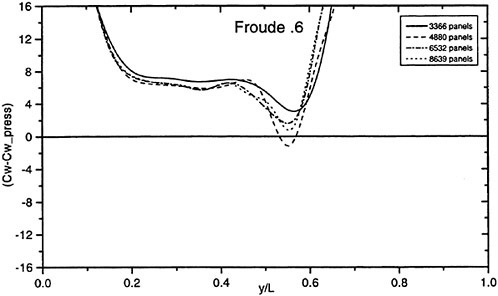

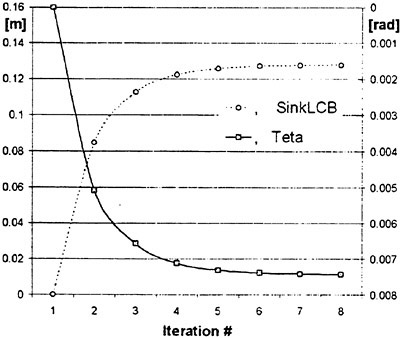

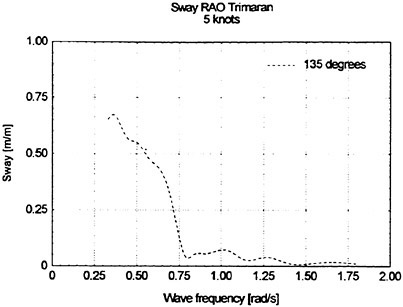

In general, predicted wave profiles along the surface of the hull agree well with measurements, while the wave height away from the hull is consistently underpredicted. This is true especially for the diverging waves, which are not well captured even at high Froude numbers (above 0.3). In the low Froude number range (below 0.2) all waves are damped out at a relatively short distance from the hull. The reason for this is obviously bad resolution. To investigate the requirements on grid resolution a Korean visiting scientist in the Chalmers/FLOWTECH group, Dr. Kang, carried out systematic grid refinement studies for the waves generated by a submerged airfoil (49). A 2-D free surface RANS code was used and great care was taken to reduce the numerical damping on the surface. It was found that approximately 50 points per wave length were needed to preserve the waves.

In a 3-D case the diverging waves have the shortest wave lengths, and as pointed out by Mori and Hinatsu (50), about five times denser grids are required in the transverse direction as compared to the longitudinal direction to really capture these waves. This means that the requirements on the number of grid points become prohibitive on today’s computers. For instance, at a Froude number of 0.15, where the fundamental wave length is about 1/7 of the hull length, approximately 106 grid points would be required on the wavy surface. Now, the dense grid could probably be concentrated in a layer relatively close to the surface, but to maintain the density in the vertical direction very near the surface the total number of points would be somewhere in the range 107–108.

Since the wave length is proportional to the square of the Froude number, the number of points on the surface would be inversely proportional to the fourth power of the Froude number, if the extension of the gridded part of the surface was kept constant. Now, the gridded part normally increases somewhat with wave length, but normally much less than linearly. Assuming that the required number of points in the vertical direction is independent of the wave length and the free surface is unchanged, the total number of points at a Froude number of 0.3 would be one order of magnitude smaller than at 0.15, i.e. in the range 106–107. No predictions presented so far have been anywhere near this number. The largest cases presented have had a total number of grid points around 106, while the number of points on the surface has been of the order of 104. This is why the Kelvin wave pattern is not obtained. It should be pointed out that panel methods seem to be able to predict very detailed wave patterns even at the lowest Froude numbers using less than 104 panels on the surface. The inability of the RANS methods to capture the waves is, of course, only a temporary problem. As will be seen below there are good prospects for increasing the number of points on the surface considerably within the not too distant future. Further, a good Kelvin wave system might not be needed for other predictions of interest, such as wave resistance, sinkage and trim, side forces and other local phenomena.

In the first free surface RANS methods of the MAC and VOF types the grid was kept fixed and the free surface tracked in the grid at every time step. This technique has been abandoned in most recent methods (a notable exception is TUMMAC), where the grid is fitted to the free surface and deformed as the waves grow with time. As pointed out in Section 2, there are two boundary conditions on the surface, the kinematic one (4) and the dynamic one. (5) represents an inviscid approximation of the latter. The exact dynamic condition expresses continuity of stresses across the surface, i.e

(17)

where the star represents values in the air.

This condition is, however rarely used. With few exceptions (Alessandrini and Delommeau (51)) the inviscid approximation is adopted, i.e. the pressure is assumed constant and set to zero. Bernoulli’s theorem cannot be used, however, so (17) may now be written

as follows

(18)

neglecting surface tension.

In most methods (18) is used as a condition for the pressure in each time step, while an unsteady version of (4) is used to update the location of the surface (and the grid) after each step. The advantage of the moving grid method is that the interface is sharp, so that grid point may be concentrated near the surface.

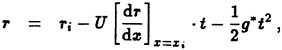

Another technique is under development in the Chalmers/FLOWTECH group, Vogt (52), (53). Like in the earlier methods, the grid is again kept fixed, and the surface tracked at every time step. The tracking is however different from the previous ones and based on the so called level set technique.

The computational domain includes both the water and part of the air above the surface. Initially the flow is at rest and a scalar “level set” function ![]() is defined in the whole domain by the distance from the flat free surface, positive downwards and negative upwards. After solving the flow equations in every time step, a differential equation for

is defined in the whole domain by the distance from the flat free surface, positive downwards and negative upwards. After solving the flow equations in every time step, a differential equation for ![]() is solved

is solved

(19)

i.e. the substantial derivative of ![]() is equal to zero. This means that every fluid particle is assigned an invariant value of

is equal to zero. This means that every fluid particle is assigned an invariant value of ![]() . The kinematic boundary condition (4) on the free surface states that the normal velocity on the surface is zero, which means that a particle once on the surface will stay there forever. Since

. The kinematic boundary condition (4) on the free surface states that the normal velocity on the surface is zero, which means that a particle once on the surface will stay there forever. Since ![]() was initially zero on the free surface, that surface will at any later time correspond to the surface

was initially zero on the free surface, that surface will at any later time correspond to the surface ![]() . It should be mentioned that a reinitialisation of the level set function is required after a few time steps, when lines of constant

. It should be mentioned that a reinitialisation of the level set function is required after a few time steps, when lines of constant ![]() may get very distorted, particularly in the air.

may get very distorted, particularly in the air.

Since the flow equations are solved in two different fluids simultaneously, physical parameters have to change at the interface. For numerical reasons a stepwise change is not possible, so a smooth variation in a thin layer at the surface is required. The necessary thickness and number of grid points of this layer, as well as other numerical parameters have been investigated by Vogt (52) and it was shown that the level set technique is an interesting alternative to the conventional moving grid methods.

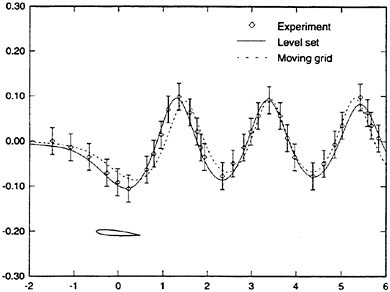

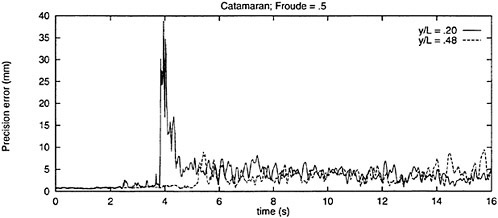

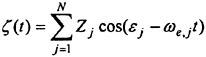

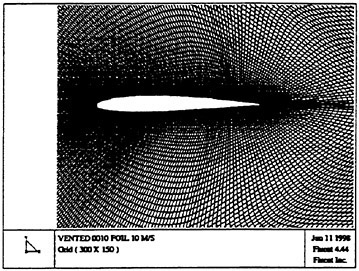

A major advantage of the level set technique is that complex wave shapes may be represented. There are no restrictions with respect to overturning waves or even changes in topology, such as wave plunging or drop formation (53). Another advantage is that updates

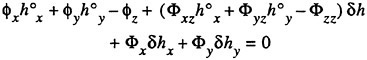

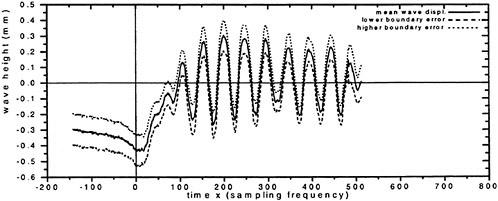

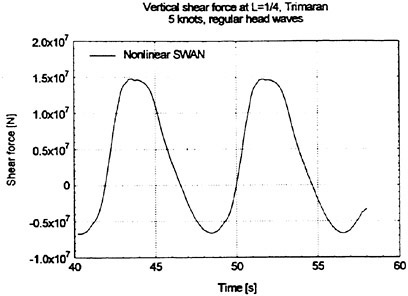

Figure 4. Comparison between level set and moving grid method. Wave from submerged wing.

of the grid and its geometrical quantities are not needed, as in the moving grid method. The technique is also robust and straightforward to implement in computer codes. In Figure 4 a comparison is made between results of the level set technique and a conventional moving grid solution for the free surface above a submerged wing. Both methods predict the wave within the experimental accuracy.

One disadvantage of the level set technique is that the flow has to be computed also in the air, where it might not be requested. The somewhat diffuse interface is another disadvantage, which increases the difficulty of concentrating grid points exactly where they are needed. The latter problem may be alleviated using the overlapping grid technique in a thin layer around the interface. Based on an extensive investigation in 2-D, Vogt (53) concluded that the level set technique is slightly more time consuming than the moving grid technique for comparable accuracy. The difference is small, however.

In conclusion, there are different free surface techniques available in RANS methods. None of them is presently capable of computing an accurate Kelvin wave pattern due to resolution problems, but this problem will be solved as the computer power increases.

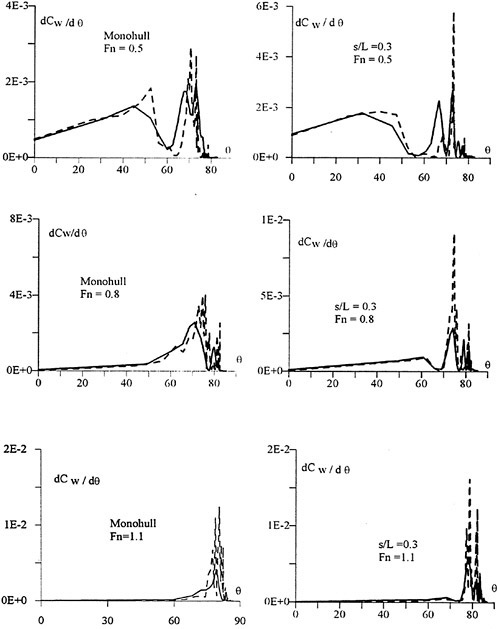

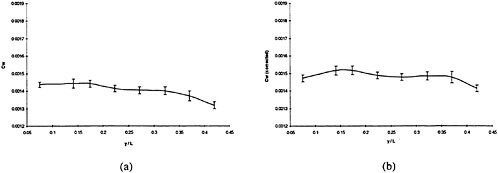

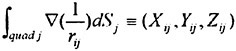

4.3 Turbulence modelling

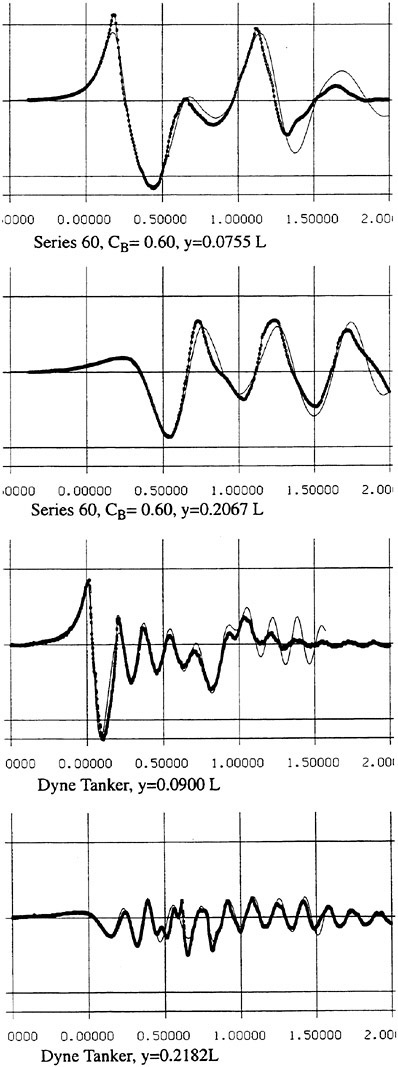

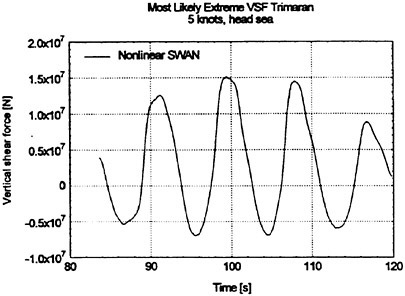

An interesting clue in the search for better stern flow prediction methods was presented by Deng et al (54) in 1993. By an ad hoc reduction of the predicted eddy viscosity in the bilge vortex a considerable improvement in the wake contours of the HSVA tanker was noted. This indicated that the major weakness of contemporary RANS methods in their ability to predict

the wake details was the inaccurate turbulence modelling. In retrospect, this is not surprising, since the only models used so far were the zero equation Baldwin-Lomax model and the two equation k-ε model, both based on the Boussinesq assumption of a scalar eddy viscosity and with no consideration of extra rates of strain, such as rotation.

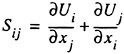

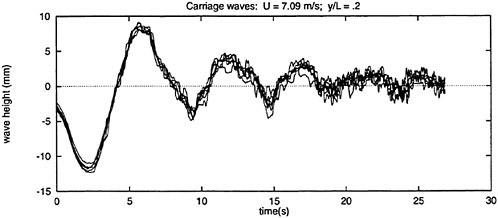

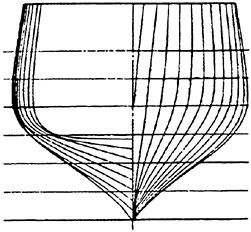

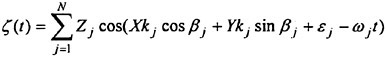

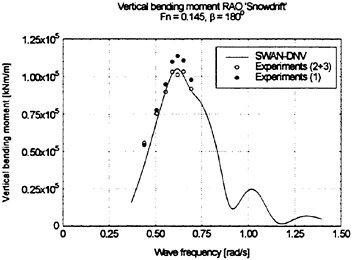

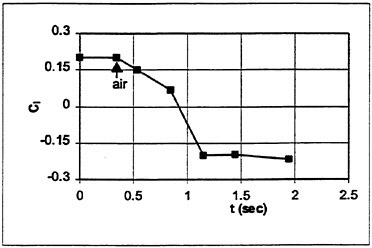

The results by Deng et al (54) inspired several groups to look into more complex turbulence models, and at the 1994 workshop (9) two methods incorporated full Reynolds stress models. Considerable improvements were noted, especially for the method by Sotiropoulos and Patel, and in a later paper (55) more results were presented, which strongly supported the use of their Reynolds stress model. One result is shown in Figure 5 where the prediction of the wake contours in the propeller plane of the HSVA hull is shown. Note the improvement relative to Figure 2!

The incorporation of a Reynolds stress model is not, however, a straightforward task, as pointed out by Deng and Vissoneau (56), since the momentum equations represent a subtle balance between terms of different origin and where pressure and shear stress gradients may be equally important. They therefore proposed a modification to the pressure/velocity algorithm, in which the turbulent stresses were included in the iterative process, and this stabilized the solution.

Figure 5. HSVA Tanker wake contours computed by a Reynolds Stress Model

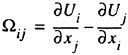

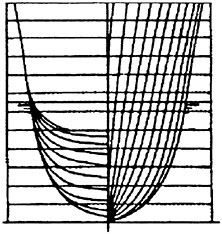

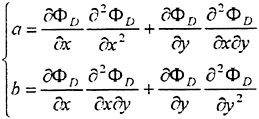

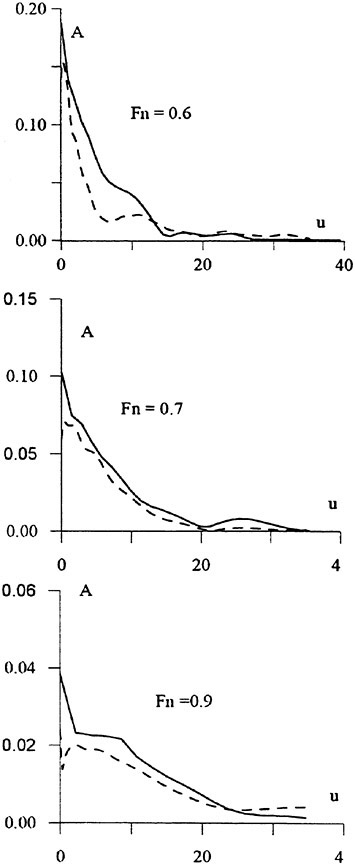

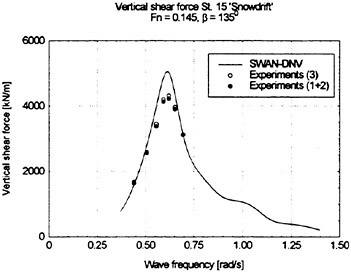

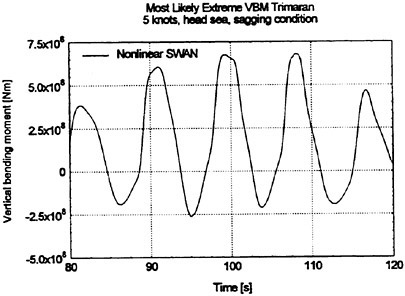

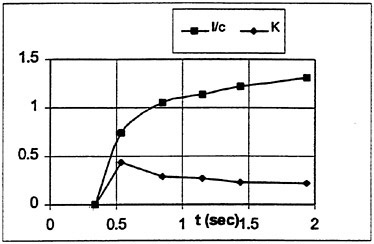

Since a Reynolds stress model includes six more transport equations as compared to the k-ε model, the computational effort increases considerably, even if the stability problem may be solved. Therefore it is of great interest to try to find simpler models with the requested capabilities. In an extensive investigation in the Chalmers/FLOWTECH group Svennberg investigates a range of turbulence models for several cases of relevance to the ship stern flow. The first report (57) includes a test of eight models ranging from the k-ε model to a full Reynolds stress model and the test case is a free vortex in a wind tunnel. Figure 6 shows the computed results at a downstream station for five of the most interesting models: the standard k-ε model (KE), the k-ω model according to Wilcox (KO), an algebraic stress model due to Gatski and Speziale with a second order constitutive relation (GS), a similar model due to Launder with a third order relation (LAU) and the Launder-Shima Reynolds stress model (RSM). Convincing results are shown for the RSM, while the KE and KO models smear out the velocity variations in both figures. A very interesting possibility is, however,

Figure 6. Velocity distribution in a free vortex. Top: Axial velocity. Bottom: Tangential velocity.

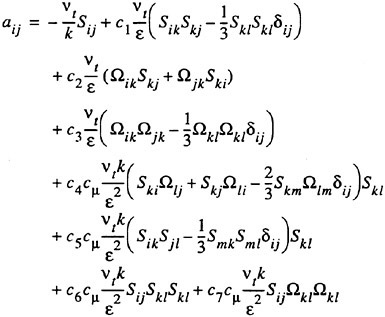

the LAU model, which is almost as accurate as the RSM and without its disadvantages. In the LAU model the Reynolds stresses are obtained from the strain and vorticity tensors

(20)

(21)

as follows

(22)

where δij is the Kronecker delta and aij is the anisotropic stress-strain relation that takes the form:

(23)

where c1–c7 are constants. There is thus a strong influence of rotation and all Reynolds stress components are computed individually.

Some results for Svennberg’s second test case, two counter rotating vortices in a flat plate boundary layer, have been presented recently in (58) and the advantage of the LAU model as compared to the KE model is confirmed. The final calculations including a full tanker hull will be completed shortly.

One more result from the first test should be mentioned. Although the RSM was the best for the predictions of Figure 6 it was in fact inferior to the KE model for a case where the vortex centre included a strong jet. This is not an interesting case for the stern flow prediction, but it may be of interest in connection with propeller modelling. Perhaps the most important conclusion from this is that the RSM is also a model with weak points, in this case the linear pressure-strain relationship, which is not suitable for jet cases, see Wilcox (59).

The search for models with the most important capabilities, but without the disadvantages of the Reynolds stress models has led to some interesting results in Japan recently. First some simple modifications of an ad hoc nature have been applied to the Baldwin-Lomax model, Tahara and Himeno (60), Kodama (61). A pressure gradient correction applied to the outer eddy viscosity has been derived based on experimental data from axisymmetric bodies. Further, the eddy viscosity is reduced based on the angle between the velocity and vorticity vectors and the vorticity is taken to be the component at right angles to the wall shear stress. The modifications have resulted in considerable improvements in the stern flow prediction for the test cases shown in the papers (24), (60), (61).

A modification of a more fundamental nature is the change of the production term in the ε-equation proposed by Okimoto et al (62). The new term, which is derived from first principles, includes the vorticity vector and could be of importance when predicting vortical flows. So far the model has only been applied to a generic case, and it has only been reported in Japanese, but its further development and testing will be of interest.

4.4 Propeller flows

During the nineties there has been a strong development in the prediction of propeller blade flows using RANS methods. This work was pioneered by Stern’s group in Iowa, which already in 1990 presented calculations for a propeller with an infinite pitch (63) and in several later papers predictions for more realistic configurations have been presented, see e.g. (64). Other investigators are Oh and Kang (65), Uto (66), Stanier (67), Sanchez-Caja (68), Abdel-Maksoud et al (69) and Mc Donald and Whitfield (34). In recent workshop on propeller CFD organized by the 22nd ITTC Propulsion Committee (5–6 April 1998 in Grenoble, France) eight different methods had been applied to the test case provided.

Most methods use structured multi-block grids, but the number of grid points vary from around 105 to more than 106. Standard turbulence models are used, either Baldwin-Lomax or some version of the k-ε model. The solvers are of different types, either finite volume or finite difference.

A surprising result of most recent calculations, in particular those presented at the workshop, is the very high accuracy in the prediction of the propeller characteristics. Over a range of advance ratios many methods predict the thrust coefficient within a few per cent of the measured one and the torque is not much worse. The result is surprising, since the presented pressure distributions are generally not in good agreement with experimental data, particularly at he inner radii, where the pressure is mostly under predicted. The

lift may still be reasonable, however, since the under prediction occurs on both sides of the blade. Further out, better correspondence with the data is obtained.

The most advanced calculations of this kind are the unsteady RANS predictions by Mc Donald and Whitfield (34) for the operating propeller behind a submarine and by Abdel-Maksoud et al (69) for the self propelled Series 60 hull. Such calculations require moving grid facilities, where the propeller grid is fixed to the blades and rotates inside the hull grid.

4.5 Full scale

The ultimate goal of ship hydrodynamics CFD is of course to predict the full scale case. If this were possible, the uncertainty in the model-ship extrapolation procedure, inevitable in a towing tank, would be avoided. Unfortunately, the application of CFD at very high Reynolds numbers is not straightforward. This is both for numerical and physical reasons. The general problem is that the ratio of the smallest to the largest scales of the flow decreases with Reynolds number. Numerically, this means that more grid points are required to obtain a given resolution and physically the nature of turbulence changes, which means that turbulence models developed at low Reynolds numbers might not be valid.

For RANS methods one important scale is the viscous length scale l+=ν/uτ, where uτ is the friction velocity defined as (τw/ρ)1/2 and τw is the wall shear stress. l+ is typically two orders of magnitude smaller, relative to the hull length, at full scale as compared to model scale. Fortunately, in a Reynolds-averaged method the scale is only important in the direction normal to the hull, where it determines the velocity distribution in the inner part of the boundary layer (neglecting surface roughness effects). To obtain sufficient resolution two orders of magnitude more grid points would thus be required, or perhaps somewhat less, if larger stretching of the grid is applied. The problem is that this gives rise to extremely elongated numerical cells near the hull surface, where the first grid point must be within y+=1. y is the distance from the surface and y+=y/l+. A typical longitudinal step size is 10−2 L, where L is the hull length, while the step size in the normal direction corresponding to y+=1 is of the order of 10−8 L. The aspect ratio of the first cell is thus 106. This causes most solvers to break down, due to bad conditioning of the system of equations. Some methods are, however, surprisingly robust. Eca and Hoekstra (70), managed to compute full scale Reynolds number cases even with the first grid point at y+=0.1. The reason for the robustness of their method, PARNASSOS, is not clear. Watson and Bull (71) carried out calculations for a series of Reynolds numbers using the commercial flow solver CFX. For the three lowest Reynolds numbers, ranging from 5×106 to 5×108 they kept the first grid point at y+=1, while the calculations at the highest Reynolds number, 109, had to be carried out with the 5×108 grid. Three interesting flat plate investigations using CFD up to very high Reynolds numbers have also been reported recently, Ishikawa (72), Dolphin (see Patel (73)) and Schweighofer (74). They will be further discussed below.

One remedy for the high aspect ratio problem is to use wall functions for representing the flow close to the surface. The first grid point may then be placed two orders of magnitude further out, which gives an aspect ratio of the first cell of the order of 104 at full scale, about the same as for methods without wall functions at model scale. This fact was utilized by Sames (75), who used the same grid at both scales, with wall functions at the high Reynolds number and without at model scale. Other full scale predictions using wall functions are those of Larsson et al (8) and Ju and Patel (76) As pointed out by Patel (73) there are good prospects for using wall functions at high Reynolds numbers, since experimental data indicate that the wall law extends to much higher values of y+ at full scale than at model scale. I fact, even the same grid might be used. However, the use of wall functions is presently abandoned by most CFD developers, since the analytical representation of the flow is not sufficiently accurate in 3-D flows with strong pressure gradients, particularly near separation.

The physical problem with high Reynolds numbers is the lack of experimental data to validate turbulence models, which have all been developed based on empirical data at moderate Reynolds numbers. Some scattered data exist for ship stern flow, but the amount of data is too small even for the validation of the mean velocities. Mostly only a small part of the propeller disk is covered. More useful are the databases obtained for the high Reynolds number flow around an axisymmetric body by Coder (77) and in the “super pipe” experiment at Princeton University, see Patel (73). Calculations for the former case were carried out by Ju and Patel (76) using wall functions and the k-ε turbulence model up to a Reynolds number of 109 and the agreement with the data was quite good at the highest Reynolds numbers. Good results at the highest Reynolds numbers were obtained also for the super pipe case using the two layer k-ε model described in Section 2 and the k-ω model by Wilcox (59). The latter model was, however, less accurate at lower Reynolds numbers. In this case the highest Reynolds number was 3× 108, based on the pipe diameter, which corresponds to an order of magnitude higher Reynolds number based on body length for a flow around a body.

As mentioned above, three different flat plate calculations at varying Reynolds numbers have been reported recently. The most comprehensive one seems to be that of Schweighofer (74). Four different turbulence models were tested in the Reynolds number range 5×106–1.3×109, namely the Cebeci-Smith and Baldwin Lomax algebraic models, Menter’s k-ω/ε shear stress transport (SST) model and Chien’s low Reynolds number k-ε model. The CFD method was the well validated FINFLO solver and careful grid dependence studies were performed. Unfortunately, the only comparison that can be made with data is for the integrated skin friction coefficient, which can be compared with generally accepted formulas, such as the ITTC—57 line. It turned out that all models but Chien’s predicted the ITTC skin friction very well at the highest Froude number. A slight under prediction of less than 1% was obtained. However, at the lowest Froude number the under prediction was about 7–8% for all models. In fact, a better correspondence over the whole Reynolds number range was obtained with the Engineering Science Database, which is closer to the Schoenherr line. Schweighofer’s results are consistent with those by Ishikawa (72) who used the Baldwin-Lomax model and found a very good correspondence with the ITTC line at the highest Reynolds number (difference less than 0.5%), while the under prediction at the lowest Reynolds number was about 9%. The third investigation, by Dolphin (see Patel (73)) is consistent with the other two in that the slope of the friction line is smaller than the ITTC line, but the computed values are somewhat higher in the whole Reynolds number range. This results in an over prediction at the highest Reynolds number by 11%. Dolphin used the Baldwin-Lomax model and the reason for his larger values cannot be found without access to the original report (an MSc thesis).

In general, the prospects for full scale RANS predictions are good. Methods which can handle the numerical problems are already available and existing turbulence models do not seem to be seriously in error at the higher Reynolds number. The strong stretching of the grids used so far is likely to reduce the numerical accuracy, but this is a temporary problem which will be alleviated as the power of computer increases. A problem not discussed is the surface roughness, which becomes more important at higher Reynolds numbers (see Patel (73)), but existing methods to include this effect should be good for estimates also at full scale.

5. Outlook

The developments described in Section 4 will lead to considerable improvements in the capability of CFD to predict ship flows both at model scale and full scale. The perspective is here relatively short, say 5 years. In the present Section the long term possibilities will be discussed. Naturally, this will be more speculative.

There is a strong link between the developments of computer capacity and CFD, and to predict future capabilities in ship flow computation some forecast must be made of the increase in computer power. As is well known the increase in processor speed has followed “Moore’s law” during the past 30 years. Moore’s law states that the speed is doubled every 18 months, or equivalently, there is a speed-up of one order of magnitude every 5 years. In a recent speech Gordon Moore himself (78) predicted this trend to continue “at least for several years”. Other sources (79) even claim an acceleration in the development rate. Further, a development towards multiple processors may be envisaged and already today the world’s fastest computers rely on massive parallelization. In December 1996, the Intel Corporation demonstrated a machine with an achieved computing speed of more than 1012 flops (1 teraflop, Tflop) using more than 7000 Pentium Pro processors. This development is predicted to accelerate and the current goal is to reach a speed of 1015 flops (1 petaflop, Pflop) before 2010, using of the order of 105–106 processors, see Bailey et al (80) or Keyes et al (79). High end computers are thus projected to increase the speed by a factor of 103 in the next 12 years and, in view of the above, a similar speed-up seems feasible also for more generally available computers, equipped with several processors.

Most CFD calculations today are run at high end workstations, which have an achieved speed of around 108 flops (100 Mflops). Good super computers are about 100 times faster. With the projected thousandfold increase in speed the super computer will be 105 times faster than today’s workstations. To make use of the increased speeds, numerical algorithms must be developed to meet the requirements on massively parallel processing, but according to Keyes et al (79) CFD methods are among the most suitable ones for this purpose. Price is another issue, but again past experience shows that the performance/price ratio increases even faster than performance itself. Neither should the increased storage requirements pose any problems (79).

What, then, can be achieved with these powerful computers? For a good multigrid method, the computer effort per time step is proportional to the number of grid points. This means that even on regular workstations the number of grid points could increase from the present level between 105 and 106 to about 108. With this increase in grid density, according to Section

4.2, there will be no problems resolving the free surface flow. Neither will there be a problem resolving the viscous full scale flow in a RANS method with the same resolution as presently at model scale. Accurate full scale RANS calculations with a free surface thus seem feasible.

Even more exciting are the prospects for less approximate solutions of the Navier-Stokes equations. Large eddy simulations (LES) should be more exact than RANS, since only the smaller eddies, which are more universal, i.e. less dependant on the boundary conditions, need to be modelled. Ultimately, even direct numerical solutions (DNS) may be feasible. In a recent paper one of the authors (Larsson (23)) estimated the computational effort required for LES and DNS solutions at model and full scale Reynolds numbers. The estimate was based on the assumption that the smallest scale of the flow, the Kolmogorov turbulence scale, should be resolved. Following Wilcox (59) and assuming that the boundary layer thickness could be set equal to half the channel height, experience from channel flow calculations could be utilized The estimate took into account the number of grid points as well as the number of time steps required, but it did not consider the lateral extension of the hull surface. Considering this, the effort for model scale LES will be 104–105 times that of a RANS solution today. For DNS the increase will be 106–107 times. LES is thus likely to be possible before 2010 on super computers. Within another decade model scale LES might be possible on workstations and DNS on super computers. At that stage the accuracy of the CFD predictions will have passed that of the towing tank.

6. Conclusions

In this review the present status of CFD in ship hydrodynamics has been assessed. Ongoing research has been reviewed and the short term benefits of the research has been evaluated. Long term developments relying on increases in computer capacity have been outlined. The main conclusions are:

-

At present, the most useful CFD results are offered by the potential flow panel methods which are used extensively for the optimization of hull shapes. Optimization of cruiser stern shapes should be avoided, however.

-

The optimization is normally based on the predicted waves and hull pressure distribution. Wave resistance coefficients may be used as well at higher speed but should not, at present, be trusted at low speeds (below Fn=0.2, say).

-

RANS methods can predict integrated quantities of the wake reasonably well, while the details cannot be obtained accurately.

-

The viscous resistance obtained by RANS methods is accurate enough for ranking purposes, provided care is exercised in the generation of the grid, particularly at the hull ends.

-

The body force approach is common for representing the propeller and many methods are capable of predicting the propeller/hull interaction.

-

Great efforts are being made to improve the grid generation and one interesting approach is the Chimera technique, which facilitates the inclusion of appendages.

-

Many free surface RANS methods are now available. The normally predict the hull wave profile quite well, but cannot predict the Kelvin wave pattern due to insufficient resolution. This problem will be removed thanks to the increase in computer power.

-

Turbulence modelling is the key issue in the prediction of the wake details. Full Reynolds stress models have shown very promising results, but some less demanding methods have been almost as accurate. Simple corrections have shown promise as well, at least for the few cases where they have been applied.

-

Several methods for predicting the flow around an operating propeller have been presented. In general, quite accurate propeller characteristics are obtained. Two methods have been applied to the propeller operating in the behind condition, with promising results.

-

Full scale RANS calculations suffer from numerical problems due to very high aspect ratio cells, but some methods are capable of handling the problem. The small viscous length scale calls for a very high resolution close to the hull and this is presently achieved by extreme stretching. This may reduce accuracy, but this is a problem to be resolved by the rapidly increasing computer power. Standard turbulence models seem to be capable of predicting flows at very high Reynolds number.

-

The rapidly increasing computer power will enable both LES and DNS solutions to be obtained at model scale within the foreseeable future. Most likely, the accuracy will then be higher than in experimental facilities.

References

(1) HESS, J.L.; SMITH, A.M.O (1962) Calculation of non-lifting potential flow about arbitrary three-dimensional bodies, Douglas Aircraft report No ES 40622

(2) DAWSON, C. (1977) A practical computer method for solving ship wave problems, 2nd Int. Conf. on Numerical Hydrodynamics, Berkeley

(3) LARSSON, L.; KIM, K.J.; ZHANG, D.H. (1989), New viscous and inviscid CFD-techniques for ship flows, 5th Int. Conf. Numerical Ship Hydrodynamics, Hiroshima

(4) JANSON, C-E. (1997), Potential flow panel methods for the calculation of free surface flows with lift, PhD Thesis, Chalmers University of Technology

(5) LARSSON, L.; BROBERG, L.; KIM, K-J.; ZHANG, D.H. (1990), A method for resistance and flow prediction in ship design, SNAME Transactions Vol. 98